Lead, lag and CPM

Jacob Worsøe (Talk | contribs) (→Critical Path Management) |

Jacob Worsøe (Talk | contribs) (→Critical Path Management) |

||

| Line 127: | Line 127: | ||

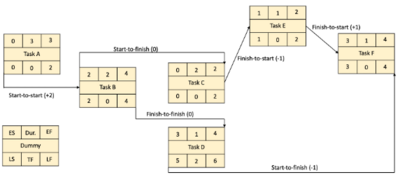

The final PDM can be seen here: | The final PDM can be seen here: | ||

| − | [[File:Precedence model with lag & lead.png|400px|thumb|center|Figure 4 | + | [[File:Precedence model with lag & lead.png|400px|thumb|center|Figure 4: Final PDM with calculated values.]] |

In this case, which is a hypothetical example, there is only float in task D. Even though there is only float in one task, it clears that task A, B, D, E, F are the critical path. This is useful for the PM, not only to consider lead and lag, but also which dependencies the project relies on. | In this case, which is a hypothetical example, there is only float in task D. Even though there is only float in one task, it clears that task A, B, D, E, F are the critical path. This is useful for the PM, not only to consider lead and lag, but also which dependencies the project relies on. | ||

Revision as of 19:28, 20 March 2022

Abstract

According to PMI a project is a temporary effort to create a value, by changing the status quo. It has an start date and an end date. In between them are some great pillars on which the project relies. One of those is the scheduling management[1]. While scheduling can be done with various tools and methods, this article will focus the use of lag & lead for scheduling. As the purpose of this article is to investigate and show how scheduling could be optimized for project efficiency, some complementary methods will be included. These methods will be Precedence Diagram Method (PDM) including Critical Path Management (CPM) to get a quantified take on possible scheduling risks that might be faced[2]. One of the goals for this article is to give practical knowledge on how to use lag, lead and CPM. As with many other calculation based tools, is it easier to grasp if examples are giving. To accommodate this has an video guide on CPM calculations in a PDM with lag and lead been made and embedded.

It should be stated, that the author of this article is aware of the fact that some other authors have chosen “lag and lead” as their topic for their contributions as well. This article tries to differentiate by focusing on the practical side, with examples and descriptions on how to conduct calculations.

Contents |

The big idea

When using lag & lead, the project activities will most often be sequenced. To get a understanding of the sequence, the precedence relations of the activities should be mapped. This could be done by the use of CPM-, Program(Project) Evaluation and Review Technique(PERT)-, and network diagrams. PERT and CPM are often referred to as PERT/CPM as they have quite some similarities[3]. Data gathering approaches for PERT and CPM are not similar however. PERT uses a more statical approach. PERT requires an optimistic-, realistic-, and a pessimistic estimate for each activity. These estimates are then used to create a weighted average and a standard deviation[3]. CPM does not require that many estimations. High accuracy of the the single estimation for a task is therefore a requirement instead[2]. CPM and PERT can be seen as iterations of the more simpler version, namely the network diagram that shows the precedence relation between actions[3]. For the purpose of this article, the precedence network will form the basis.

Research in scheduling has grown ever since its start in the late 1950’s. CPM and PERT being the main focus back then, means that they have undergone severe development. As a consequence further theories and iterations have been based on mathematics[3]. To grasp the concept of lag & lead, the computerized methods developed should be to far over the aim for this article.

Scheduling

As a first do the project manager need to realize whether the project is approached as predictive (waterfall) or adaptive[1]. This should not be confused with the development approach which is also described with these terms in PMBOK[1].

To choose the best approach, the project manager should acknowledge how much information there is to be found about the project. If the project consist of already known activities, workload and required skills the predictive would certainly be the best choice. On the other hand, would the adaptive approach be more appropriate if the tasks and workload is unknown or could change through the project. This approach is iterative and are supplying the project with beneficial insights. As scheduling with CPM and the like are vastly predictive. Therefore, the predictive approach will be examined in this article.

For the predictive approach the following steps should be considered according to PMI[1]:

- Create specific project activities based on the scope.

- Sequence the activities (find precedence relations).

- Estimate the different resources needed for each activity (i.e. time, people, physical resources).

- Allocating people to the activities.

- Adjust the above to an schedule can be agreed.

It sometimes happen that the schedule does not meet the delivery date and duration first agreed. To address the issue of delaying the project, compression methods could be applied. This could be done by crashing or fast tracking for instance. By shortening the duration of activities by adding workers or working overtime, crashing is applied directly to a specific activity, thus decreasing the duration. Another alternative would be the fast tracking method which is compressing by the use of lag & lead[1].

When using fast track, activities that normally would be sequenced will be done partially in parallel.

To use the lag & lead tool the whole schedule should be made, the tasks identified (such as resources and duration) as well as their logical relationship between them. The project management team needs an great overview of the tasks that should be done in the project. All tasks such as work packages and activities should be listed roughly[4] .

From this should the activities throughout the project be sequenced. This is done to optimize the efficiany of the project, thus exploiting the resources allocated for the project to the fullest.

Sequencing activities can be done with various methodologies according to PMI, whereas the Precedence Diagramming Method (i.e. an iteration of a Network Diagram) being one of those to develop a schedule[5].

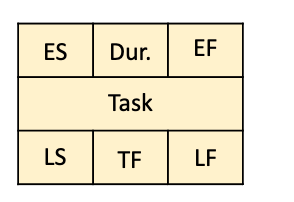

To create a fruitful diagram should the following information be included: sequence of activities, dependencies with lead and lag times, as well as the durations including float[4]. In Managing Successful Projects with PRINCE2 is it suggested to use a table like the below to get a comprehensive overview of each task in the Precedence Diagram[6]:

- ES: Earliest start

- Dur.: Duration

- EF: Earliest finish

- LS: Latest start

- Total float

- LF: Latest finish

The time unit could be a date, days or hours. The unit should be the same through the tables in a PDM.

This table introduces the term float which is the time that a task can withstand a delay. Meaning that an delay of an specified time will not affect the delivery time for of the project as a whole. Float is used to identify the critical path[6]. Usage of this in a Precedence Diagram are to be shown in the application section.

Lead is the time the work on a successor activity is initiated before the completion of the predecessor[7]. By this are two or more tasks running the same time in parallel to optimize the use of resources. Lead can be used by the project manager to loosen the Critical Path.

On the other hand is lag a more forced part as it highlights when a task has to be delayed[7].In that way it shows if resources on a unfinished task are unused.

If the project manager is aware of potential lead and lags, is it possible for her/him to develop an optimized schedule. The aim should be to ensure a Critical Path that allows the whole project to meet the required deadline.

Application

Lead

Lead can be used by the project manager to optimize the schedule by commencing a successor activity simultaneous with the running of the predecessor. The activities are thereby overlapping and gives rise to a faster delivery the project team are making the best use of allocated resources. It could be applied if one task has five workers allocated but only three are working effectively (could be due to physically constraints etc.), the two in excess could be re-allocated and already begin the successor. So, instead of having a task to start on day seven for instance, it could be initiated on day five with those re-allocated workers. The use of lead could be added in the initial planning which requires great overview and insight to specific tasks from the project manager. Lead can also be applied during replanning while the project is running.

Lag

Lag is the counterpart to lead as it is adding time between tasks. Whereas lead is actively implemented to speed-up a process, lag is more a necessity. A typical example could be drying of paint or concrete. When these are drying, workers are not able to do the subsequent task, like adding a new layer of paint. It could also be applicable in UX designing. Designers cannot implement corrections to the actual output if it is being tested, and consequently would a lag appear. The project manager should keep attention to these lags in order to avoid waste of resources. In that sense could a lag be seen as a KPI.

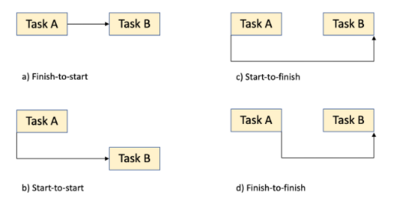

Logical relationships/dependencies

As described in The Big Idea should the logical relationships or dependencies between tasks be determined as a part of the sequencing activity. In figure 2 below can the four different dependencies be seen as described by Project Management - A Systems Approach to Planning, Scheduling, and Controlling[2].

What do they mean? It describes the relationship of the predecessor-to-successor.

Finish-to-start: The most common relationship, the finish-to-start, requires the predecessor to be finished before the successor can start. Considering the construction example again; the concrete has to dry (task A) before furniture can be placed (task B).

Start-to-finish: In this case can the successor only finish when the predecessor starts. This dependency could be used when handing over systems or functions. It could be the replacement of an old IT-system for example. The old system can be shut off(successor) once the development of the new (predecessor) is started (or maybe when it is ready to be implemented. This would require lag to be incorporated)[8].

Start-to-start: This logical relationship states that a successor cannot start before the predecessor also has started. It implies that these could be conducted in parallel. Even though stated in the relationship, it is not a requirement that they start exactly at the same time (i.e. lead or lag could be implemented one another)[9]. This dependency could be utilized for painting of buildings as an example. It consists of two tasks, basically. Setting up the scaffold(predecessor) and then do the painting(successor)[9] . Let us say that it takes six days to complete the scaffold, but the first part could be used for painting after a day. In that case could the project manager apply one day of lag to the painting task, and from there let them be done in parallel, making it a start-to-start.

Finish-to-finish: Finish-to-finish is the opposite of start-to-start and yet a bit similar as they can run in parallel. The successor cannot be completed until the predecessor are finished[5]. The example from start-to-start can be used again to explain this dependency. Again we have two tasks: painting(which is now the predecessor) and removal of scaffold(now successor). The removal of scaffold cannot be completed before the painting is finished. Lead can be applied to the removal of scaffold task, as the first parts of the building already have been painted.

The project manager should keep an eye on the use of start-to-start or finish-to-finish as the two might interfere each other[2].

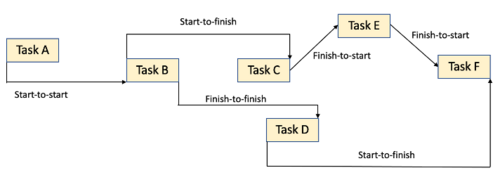

Project Schedule Diagram

According to A Guide to the Project Management Body of Knowledge (PMBOK ® Guide) – 7th Edition is a project schedule network which is also denoted as precedence network diagram (PDM) a graphical artifact. These graphical artifacts are used to visualize data and information once data have been collected and analyzed. In this case would it be the gathering of information related to each activity. Visualization of such data makes decision making easier and helps in prioritization[1]. Here it clarifies the sequence, dependencies as well as the timely resources. Lag and lead would be added on the nodes, to enlighten these properties[10]. It should be noted, that lead and lags should be added after sequencing and durations have been determined or estimated. Otherwise would lead and lag not be useful as a compressing tool.

The figure above shows a simplified version of a hypothetical PDM. A realistic project would might not have all the logical relationships. Another thing to disclaim is the relatively low number of tasks in the example. More comprehensive diagrams could be built with software such as Jira[12]. Lag and lead would be added to nodes in relation to the dependency, such as start-to-start(+1) indicating a lag of +1 (depending on time unit). Lead would be indicated as a negative number[10].

Advances by using PDM includes the overall overview of the tasks within the project and their dependencies, and the availability to find the critical path. By combining PDM as well as the described table from PRINCE2, the critical path analysis becomes easier.

Critical Path Management

As stated, is one of the benefits of using PDM, the availability of finding the critical path(s). It could also be used with PERT, but for the matter of this article is CPM sufficient.

For the critical path to be calculated, the components from the PRINCE2 table are used:

- Earliest start (is the latest of predecessor(s))[2]

- Earliest finish (earliest start + the duration of activity)[2]

- Latest start (duration subtracted from latest finish)[2]

- Latest finish (the latest start + duration)[2]

- Total Float (or slack. Calculated by: TF = LF – ES – duration)[2]

In order to calculate the earliest start and finish should a forward pass be done. Meaning that the calculations are going from the initial task to the final task. Latest start and finish are calculated by doing a backward pass (A systems approach and video). The logical relationships determines whether it is the start or finish that is being calculated first. Also, when a task has more than three nodes attached to it, values could possibly be competing. To make up for this can these two rules be used:

- For forward pass: use the largest numbers.

- For backward pass: use the smallest numbers.

This is valid for both start and finish times[11].

Should the unknown start or finish be calculated first? This is identified by the logical relationship. In a forward pass: the value from the predecessor field is added to the successor field. For instance: the relationship is start-to-finish between task B and C, the ES for B is zero, EF is two days and the durations for both are two days as well. Then would the start determine the finish, thus would EF for C equal to two. When doing the backward pass, the dependency should just be read backward as well, meaning that start-to-finish should be read as finish-to-start. See the attached video for a guide on how to calculate or figure 4 for finished calculations.

Lag and lead are a part of the CPM as well. These should be taken in consideration when doing calculations. Again does the logical relationship determine whether lag should be influence to start or finish. Or if lead should do effect on start or finish. In a forward pass should lead be subtracted and lag added to the time. It is vice versa for backward pass.

These calculations can seem a bit confusing when only described. The video below shows how to use the calculation rules as well as the PDM to find the critical path:

Guide on PDM with lag and lead (including intermediate results) and finding the critical path:

The video attached is made by the author of this wiki-article. YouTube have quite a few videos about the use of PDM to find the critical path. Some of those are including lag, but it can be hard to find guides on both lead and lag. The PDM in the video and methods are inspired by “Difficult network diagram with lag solved” on YouTube, which is part of the material used in lectures by Christian Thuesen[11].

The final PDM can be seen here:

In this case, which is a hypothetical example, there is only float in task D. Even though there is only float in one task, it clears that task A, B, D, E, F are the critical path. This is useful for the PM, not only to consider lead and lag, but also which dependencies the project relies on.

Limitations

Lag, lead and CPM are useful tools, but they are not perfect. One of the weaknesses is due to the fact that they relies a lot on the predictive approach. This means, that the estimations should be rather accurate to keep the precision of the schedule. It also requires the project manager to carefully consider where to use lag, lead and which dependencies that are present in the project. That said, the schedule as well as lead and lag could edited during the project. Edits to schedules during a project often create risks and fluctuations (A systems approach).

In this article is CPM the used model to clarify where a potential delay could be found. This method has some high requirements to accuracy for the duration estimations(A systems approach s. 416. PERT could be an alternative as it is more statically based, buy is not perfect either. In this article is only simple versions of the tools been described. As PDM and CPM have been researched in since the 50’s have they obviously developed to extend these simple forms. The backbone and the basic function are the same though (Springer, vanhueck).

A project manager should be using crashing or compressing with caution. The use of lead or in other ways doing tasks in parallel, increases risk and if failures happen would it have more consequences as more tasks are involved (a systems approach table).

When adding resources to a new task, as suggested earlier if lag is identified, the resources might need training. This requires already working resources to set aside their ongoing work. Therefore, the work pace will not just rise (a systems approach).

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 Project Management Institute, Inc. (PMI). (2021). A Guide to the Project Management Body of Knowledge (PMBOK ® Guide) – 7th Edition and The Standard for Project Management. (pp. 35, 58, 59, 188, 189 ). Project Management Institute, Inc. (PMI). Retrieved from https://app.knovel.com/hotlink/toc/id:kpSPMAGPMP/guide-project-management/guide-project-management

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 Cite: Kerzner, Harold. (2017). Project Management - A Systems Approach to Planning, Scheduling, and Controlling (12th Edition), pages from chapter 12. John Wiley & Sons. Retrieved from https://app.knovel.com/hotlink/toc/id:kpPMASAPSC/project-management-systems/project-management-systems. Last visited 20 March 2022.

- ↑ 3.0 3.1 3.2 3.3 Vanhoucke, M. (2013). Project management with dynamic scheduling: Baseline scheduling, risk analysis and project control, second edition. Project management with dynamic scheduling: Baseline scheduling, risk analysis and project control, second edition (pp. 1-318) doi:10.1007/978-3-642-40438-2 Retrieved from www.scopus.com

- ↑ 4.0 4.1 Project Schedule Baseline: Definition | Purpose | Example - Project- Management.info https://project-management.info/project-schedule-baseline/. Accessed March 20, 2022.

- ↑ 5.0 5.1 Cite: PDM - Precedence Diagramming Method [FS, FF, SS, SF] (+ Example) – Project Management.info. Link: https://project-management.info/pdm-precedence-diagramming-method/#6-example-of-precedence-diagramming%0Amethod. Accessed March 20, 2022.

- ↑ 6.0 6.1 AXELOS. Managing Successful Projects with PRINCE2 2017 Edition, The Stationery Office Ltd, 2017. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/DTUDK/detail.action?docID=4863041.

- ↑ 7.0 7.1 What Are Leads and Lags in Project Management? - Project-Management.info. https://projectmanagement.info/leads-and-lags/. Accessed March 20, 2022.

- ↑ https://www.project-management-prepcast.com/free/pmp-exam/tips/338-what-s-an-example-of-a-start-to-finish-relationship. Example of Start to finish relationship.

- ↑ 9.0 9.1 https://www.tacticalprojectmanager.com/start-to-start-dependency/).Example of start to start dependency.

- ↑ 10.0 10.1 Project Schedule Network Diagram: Definition | Uses | Example - Project-Management.info. https://project-management.info/project-schedule-network-diagram/. Accessed March 20, 2022.

- ↑ 11.0 11.1 11.2 https://www.youtube.com/watch?v=qTErIV6OqLg. This video was provided by Christian Thuesen in the Project Management Course. It shows how to find the critical path in a PDM with the table as used in the article. It was used to ensure understanding of calculations and as inspiration for an hypothetical PDM to show dependencies and calculations.

- ↑ https://www.atlassian.com/software/jira?utm_source=capterra&utm_medium=paid-review-sites&utm_campaign=P9zjira-software9xO9zppm9xV9zcapterra9xG9zallg9xL9zen9xF9zdisc9xA9ztext9xD9zalld9xU9zproject-management&utm_content=view-website&utm_source=capterra Example of PDM software tool.