Kanban: a project management framework

Guilleroigp (Talk | contribs) (→Origin of Kanban) |

Guilleroigp (Talk | contribs) (→Origin of Kanban) |

||

| Line 7: | Line 7: | ||

=== Origin of Kanban === | === Origin of Kanban === | ||

Kanban agile methodology has its origin in the [[Wikipedia:Toyota Production System| Toyota Production System (TPS)''']]. It was first implemented in the fifties by Taichii Ohno, an industrial engineer working for the company. <ref name="Dos"> Ohno, T.: Toyota Production System. Beyond Large-Scale Production. Productivity Press, Portland (1988) </ref> After the second world war, the Japanese automotive industry was stucked in the context of a strong United States within this industry. Due to this situation, Kiichiro Toyoda, the CEO of Toyota set out to put an end to this situation focusing on the efficiency of Japanese market. The target was to match the efficiency of the American market and represented a great challenge, as the US market was ten times more efficient than the Japanese. The company centered its efforts towards innovation and the efficiency of its industrial processes, moving towards a [[Wikipedia: Lean thinking| JIT (just-in-time)''']] manufacturing system. During this change of direction, [[Wikipedia:Taiichi Ohno| Taiichi Ohno''']], an industrial engineer working for the company, developed a new work methodology inspired by the ´´grocery store model´´ that he observed in the American supermarkets chain [[Wikipedia:Piggly Wiggly| Piggly Wiggly''']]. The concept of this model is that the stores stock need to be maintained in a sufficient level so that the customer’s demand is met looking for keeping the lowest stock level possible. Thus, Taiichi Ohno decided to introduce a visual demand tracking system in the factory consisting of cards that were attached to finished goods, and once a good was sold, the card returned to the production line. <ref name="Tres"> Kanban tool, History of Kanban, last visited 3rd of March 2020, https://kanbantool.com/es/guia-kanban/historia-de-kanban </ref> This way, the production lines worked once a stablished number of cards returned the production line, and the idea of it was to: | Kanban agile methodology has its origin in the [[Wikipedia:Toyota Production System| Toyota Production System (TPS)''']]. It was first implemented in the fifties by Taichii Ohno, an industrial engineer working for the company. <ref name="Dos"> Ohno, T.: Toyota Production System. Beyond Large-Scale Production. Productivity Press, Portland (1988) </ref> After the second world war, the Japanese automotive industry was stucked in the context of a strong United States within this industry. Due to this situation, Kiichiro Toyoda, the CEO of Toyota set out to put an end to this situation focusing on the efficiency of Japanese market. The target was to match the efficiency of the American market and represented a great challenge, as the US market was ten times more efficient than the Japanese. The company centered its efforts towards innovation and the efficiency of its industrial processes, moving towards a [[Wikipedia: Lean thinking| JIT (just-in-time)''']] manufacturing system. During this change of direction, [[Wikipedia:Taiichi Ohno| Taiichi Ohno''']], an industrial engineer working for the company, developed a new work methodology inspired by the ´´grocery store model´´ that he observed in the American supermarkets chain [[Wikipedia:Piggly Wiggly| Piggly Wiggly''']]. The concept of this model is that the stores stock need to be maintained in a sufficient level so that the customer’s demand is met looking for keeping the lowest stock level possible. Thus, Taiichi Ohno decided to introduce a visual demand tracking system in the factory consisting of cards that were attached to finished goods, and once a good was sold, the card returned to the production line. <ref name="Tres"> Kanban tool, History of Kanban, last visited 3rd of March 2020, https://kanbantool.com/es/guia-kanban/historia-de-kanban </ref> This way, the production lines worked once a stablished number of cards returned the production line, and the idea of it was to: | ||

| − | |||

* <span style="color: cadetblue">'''''Minimize inventory'''''</span> levels and production cycle time. | * <span style="color: cadetblue">'''''Minimize inventory'''''</span> levels and production cycle time. | ||

Revision as of 13:05, 25 March 2022

Over the last decades important new approaches have appeared in operations planning and control of production systems.[1] Kanban (看板, meaning ‘signboard’ in Japanese)[2] is a visual system whose first purpose was to gain control in processes and make their workflow more manageable. The efficiency of daily activities within industrial processes represent a challenge for every production company. In fact, this tool is not only applicable to production processes, but also to every project management taking place in almost every business function (operations, marketing, recruitment, business expansion, among others).

The target of Kanban is achieved by the implementation of certain activities or practices that, if well implemented, will gradually help improving the workflow in a project. Its improvement implies not only a reduction of lead time and a better organization of the activities, but also a reduction of waste, a more value-added approach for the customer and a better predictability for future scenarios. These benefits are crucial in today's market, characterized for experimenting changes and competitiveness in a fast-paced environment.

Contents |

Big idea

Origin of Kanban

Kanban agile methodology has its origin in the Toyota Production System (TPS). It was first implemented in the fifties by Taichii Ohno, an industrial engineer working for the company. [3] After the second world war, the Japanese automotive industry was stucked in the context of a strong United States within this industry. Due to this situation, Kiichiro Toyoda, the CEO of Toyota set out to put an end to this situation focusing on the efficiency of Japanese market. The target was to match the efficiency of the American market and represented a great challenge, as the US market was ten times more efficient than the Japanese. The company centered its efforts towards innovation and the efficiency of its industrial processes, moving towards a JIT (just-in-time) manufacturing system. During this change of direction, Taiichi Ohno, an industrial engineer working for the company, developed a new work methodology inspired by the ´´grocery store model´´ that he observed in the American supermarkets chain Piggly Wiggly. The concept of this model is that the stores stock need to be maintained in a sufficient level so that the customer’s demand is met looking for keeping the lowest stock level possible. Thus, Taiichi Ohno decided to introduce a visual demand tracking system in the factory consisting of cards that were attached to finished goods, and once a good was sold, the card returned to the production line. [4] This way, the production lines worked once a stablished number of cards returned the production line, and the idea of it was to:

- Minimize inventory levels and production cycle time.

- Increase the speed of information exchange.

- Improve productivity.

The Kanban method

The main target of the Kanban methodology is to make workflow more visual. Through the design of a Kanban board, processes can be more clear and a more efficient scenario could be achieved by the reduction of the work in progress (WIP). Thanks to a better and more transparent visualization of the processes, problems could be better identified, highlighting which points of the process are not working efficiently.

The Kanban basic elements to run the methodology are a board divided into columns and cards. Every column of the board represents a stage in the timeline of the project. On the other hand, cards represent a work item.

The representation of the methodology could be either physical or digital. The physical representation is done by drawing the board on paper or in a blackboard and using stickers as cards. The more advanced options are digital, such as software systems that include a Kanban virtual solution.

Kanban Board

A Kanban board allows displaying the entire process in one unique system, offering a more manageable workflow. This board is usually divided into three columns which represent the stage of every task: “To do”, “In progress” and “Complete”. However, depending on the project that is being done, the name of the columns can be adapted. In the case of a software project, for example, the board could be divided into different columns that represent every phase that tasks go through such as backlog, analyze, review, build, integrate and test and the acceptance final stage. An example of a simple Kanban board is shown in Figure 1. The idea of the backlog column is to include some ideas that different team members can have. This way, in the case the team has an overview of the different ideas that could also be worked, helping the commitment of the participants. Also, the different lanes can be subdivided in two columns, differentiating between "in progress" and "Done" stages. This helps making more visual those in which exact moment tasks are. [5]

It is also possible and a good practice to creating a Kanban board to settle a work in progress (WIP) limit. It can be done by stating a maximum number of tasks that can be be at the same time in a column. If this maximum number is achieved, everyone in the project team should notice, so the information is shared and thus focus on making the cards move forward. By doing this, bottlenecks can be avoided and the flow optimization is maximized.[5]

When there are new work tasks to do in the project, cards representing these new tasks are added in the “To do” column, in the left hand side of the board. During the progress of the tasks, cards start moving from the left to the right hand side of the board until the “Done” stage, which determines the completion of a task. There are usually some rules settled by the project manager to determine when a task is completed, and every team member participating in the project is aware of them, so the system can be updated regularly.

In project management it is really important to have a proper idea about how the performance is being in order to correct mistakes, make improvements and meet the capacity of it in terms of money and time. This management is done by the measurement of some key analytical metrics and indicators. A better explanation about the most relevant metrics and measurement outcomes are further developed in the ‘Performance measure’ section.[6] Kanban boards are characterized for being simple , as the organization of work in such a structured way allows a smooth and simple navigation[5]:

- It makes visual the workflow, helping to identify the work in progress.

- It is accessible, as every project participant has access to it.

- It is current, as the workflow progress is shown in a daily basis.

- It is standardized, so everyone can follow the same efficient workflow.

Kanban Cards

Cards are the elements in a Kanban system that represent the different tasks to be done within the project. The cards include all the information needed to describe the task properly. The information included would be determined by the purpose of the task. In the case that the Kanban is used in a production line, some specifications about quantities and lead times should be included, for example. In the case of a project, the cards would include the following information[5]:

- Task name: a head name which defines the task is needed for better identifying the task. It should be concise and provide relevant information.

- ID : it could help identify, differentiate and classify better the different tasks.

- Description of the work: it is necessary to include a proper description of the task. A good communication leads to a correct development of the task.

- Date: different dates can be included, such as the delivery date to state the work deadline in the case there is, or a target time to accomplish a task.

- Responsible: there is one or two of the team members that is the main responsible of the task, so including his name in the card would help better know who is doing what and who to ask in case there is anything to solve or to talk about.

- Team members involved: the list of the rest of all participants in the task are also included with the same purpose.

An example of how this card would look like is shown in Figure 2.

The purpose of describing the work to do through cards are many, and the outcomes of using them can be listed in three main points: Focus in important and relevant information about the different tasks Bring better and more efficient results from every task: they help creating a sense of ownership and clear guidelines and targets to meet. Improve efficiency: due to the establishment of a deadline, it is possible top have a better track of tasks.

Referencia foto cards: https://www.interlakemecalux.com/blog/kanban-system

Kanban Principles: implementation (ADD VIDEO IMPLEMENTATION OR PHOTO)

The Kanban methodology could be summarized into different principles which represent the basic practices to go through in the development of the Kanban tool to make its implementation successful [7]

- Visualize the current workflow: it is crucial to make the processes visual and accessible so that everyone involved in the project development understands how the work is performed.

- Limit Work in progress (WIP): by reducing the workers’ workload, they can better focus in the work to be done without feeling overloaded. This way, lead times could be reduced, and the workflow can result in a more continuous one.

- Measurement and management of workflow: not only is it important to understand the workflow, but also to understand how successful the performance is currently being. There are some different statistics and graphics that can be useful for monitoring the Kanban process. One of those is the Cumulative Flow Diagram (CFD), which is further developed. [8]

- Service level agreement (SLA) and policies: to guarantee a good service level resultant from a project, minimum standards are stablished. This standards policies involve, for example, the assignment of tasks to the different project members or the momentum a task can be transferred to the next stage. These standards are stablished by the expectations of members involved in the project or affected by its outcomes.

- Models to identify improvement opportunities: project teams should work together and make an effort to analyze the current process and examine continuously what can be improved. This can be done by the application of models such as the Theory of Constraints or Value Stream mapping (VSM), for instance [9].

Project measurement

One of the main reasons for implementing Kanban in project management is to have a better tracking of the workflow. From this tool it is also possible to extract some metrics which could help project managers to better analyze the team’s performance. This can be done using a Cumulative Flow Diagram (CFD). This tool shows an overview that represents how the work is flowing through the Kanban System. [10]

This graphical representation represents the time in the ‘x’ axis and the number of cards in the ‘y’ axis. There are some differently colored bars growing upwards, and each of them represents a column of the Kanban board being used in the project (backlog, to do…). An example is shown in Figure 3. Thanks to this representation, the project manager could analyze some metrics: work in progress (WIP), lead time, cycle time and throughput.

Kanban: an Agile methodology

Agile in Project Management

AÑADIR FOTO BIEN

Over the last decades, project management has been changing from a more linear approach to an environment in which agile is dominating. This linear approach was followed through the waterfall methodology, where deadlines and objectives of every project are based on fixed estimations or assumptions, so companies drive their projects missing the changing environment that surrounds it. This waterfall methodology that companies use are proven to be inefficient in changing environments, as projects are supposed to follow clear steps which are not designed to be re-thinked or re-designed, so it can be very costly and time. [3]

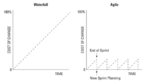

Agile, on the other hand, consists of an approach that help teams to achieve more efficient and effective practices in the which require flexibility in uncertain environments and where changes are fast. This could be done by the application of a set of different agile methodologies. These methodologies have an iterative approach, which means that they involve an evolutionary development, so that during its application steps are repeated in a cyclic way. [3] The main differences regarding the opportunity to make a change and its costs between both the traditional approach and the disruptive agile one are represented in Figure 1.

Regarding project management, the application of agile can be addressed to different areas, such as software development, processes improvement or project management in general. It was first used in the IT industry, where companies found in agile a great solution to solve the traditional problems found in software development processes. There is a mindset around the concept of agile consisting of a good flow of information between the stakeholders involved in order to bring more value to the customer while making progressive and meaningful steps. [4]

What is Scrum?

Another agile methodology that is also commonly used for managing projects is Scrum. This project management framework is more commonly used for product developments, and it favors teams to work and collaborate together better. It is also used for project management, In this methodology there is usually a product owner who is directing the tool application from the beginning. The Scrum Papers:, Nut, Bolts, and Origins of an Agile Framework, Scrum, Inc. Jeff Sutherland, Version 1.1 – 2 Apr 2012

Project backlog: The manager has to collect all the different requirements from the different stakeholders involved, such as the customers. Through the collection of all these features, a list of the different work to do is listed and can be prioritized.

Sprints: there are periods in which the members involved in the things to do. The team has to be committed to determine which is the work to do in order to bring a solution. The different works defined from the requirements are given a specific time framework to be done. Every time period is known as ‘sprint’, and in it a scrum board, similar to the one used in Kanban, is used to help tracking the progress of the tasks.

Meetings: gathering the whole team involved in the project is one of the key practices in Scrum. A sprint-planning meeting is done to prepare it, then an everyday 15-minute meeting in order to make a project follow up. In these daily meetings, all the team member participating state what they did the day before and they review the day plan.

Sprint review: after every sprint, a review about the performance is done. The good practices and also the bad results are shared from a product perspective.

Sprint retrospective: the sprint retrospective consists on focusing on the process review, with the objective of solving issues or perform better in future scenarios.

Scrumban: an hybrid of Scrum and Kanban

Scrum can be used together with the application of Kanban, under a technique known as Scrumban. It consists of a methodology to manage projects, combining the best characteristics of both Scrum and Kanban, with the target of getting better and faster results. It can be used in the management of every kind of project, even in big size projects of different kind: software development, product development, etc.

These are different practices that Scrumban is taking from both Scrum and Kanban:

Scrum Ken Schwaber, Jeff Sutherland, ‚The scrum guide‘

- Process iterations in continuous intervals, with a review and a retrospective by the end of every sprint. - Work is prioritized depending on how complex the task. - There is a general team agreement to define when a work is considered to be finished.

Kanban

- The team works with defined tasks to do. Thus, there is a backlog of tasks from where team members can get a next to-do step. - There is a limit in the number of tasks to do at a time (WIP limit) - Generally, tasks are represented by cards which move forward through different pre-defined phases represented in a board.

There are some exclusive features from Scrumban not seen either in Kanban or Scrum https://www.agilealliance.org/scrumban/:

- There are no hierarchies. Every team is managed independently, without the existence of a clear leader. - Projects do not necessarily need to have a finish deadline. Sprints usually last two weeks, letting teams reviewing and repeating the process.

The main benefit of using Scrumban is that it allows managing long-term projects in a really flexible way. It is a tool that can help managing better projects which do not have a clear deadline, so that a continuous workflow can be implemented. https://asana.com/es/resources/scrumban

It can also be positive to use this tool when Scrum is being too rigid for a team working in a project. It is usually seen in New Technollogy-Based firms (NTBFs), whose managers can benefit from the benefits of the flexibility this agile tool provides in uncertain and changing environments. Sońta-Drączkowska, E., & Mrożewski, M. (2019). Exploring the Role of Project Management in Product Development of New Technology-Based Firms. Project Management Journal, 875697281985193. doi:10.1177/8756972819851939

Scrum vs. Kanban

Both Scrum and Kanban methodologies have in common the target of bringing continuous improvement to every project. Both are agile methodologies, and hence they help getting some outcomes that are part of the Agile concept. They both have the listed similarities: https://kanbantool.com/kanban-vs-scrum They allow limiting WIP Based on a pull system instead of a push one Centered in organizing teams A better communication through a visual and efficient flow of the information

However, there are some differences between both of them, which are stated in the following table:

| Scrum | Kanban |

| Main thing in the development: sprints |

Main thing in the development: tasks |

| Based on an iterative process |

No iterations |

| Roles such as the Scrum Master, Product Owner or the development team |

Not focused in assigning roles, but the main role would be the Project Manager |

| Improvements delivered after sprint |

Continuous improvement |

| Scrum board resetted after a Sprint |

Kanban board is permanent |

| Work items must fit into a sprint |

Items do not break down, no clear time limitations |

| Daily meetings are mandatory |

Daily meetings optional |

| Changes permitted after every sprint |

Continuous changes permitted |

It is clearly seen that both Scrum and Kanban could help delivering positive outcomes, however, depending on the project that has to be managed it would be more interesting to use one or the other. It could also be that any of them is clearly fitting the project needs and thus Scrumban can play an important role. [12].

Benefits and shortcomings of Kanban

The application of Kanban helps projects to be driven down in terms of costs and help teams become more efficient through the transformation of workflows into more efficient and visual direction. Nonentheless, there are also some some disadvantages that could come up by the election of this project management framework [13].

Benefits

- ´´´Great visibility of the flow: recognition of workflow thanks to the Kanban board and its cards, which represent an informational hub centre. Team members can get an update of the status of the project at any time.

- ´´´Efficiency improvement: a better visualization of the workflow leads to an easier identification of bottlenecks and shortcomings in the projects. These could be thus eliminated or avoided and help outlining the efficiency and this way reduce the delivery time.

- Increase productivity: as a result of an efficiency improvement, the productivity is increased. This is because Kanban helps shortening the cycle times by the limitation of the WIP.

- Collaboration and team focus: the idea of focusing on a task avoiding switching continuously helps optimizing the overall time invested. It is done in a collaborative environment, as the organization and priorisation of tasks help increasing commitment and the feeling of membership to the project.

- Better predictability: thanks to the reliable metrics obtained, a more accurate analytical approach for future scenarios can be done from historical data such as the throughput.

https://kanbanize.com/kanban-resources/getting-started/what-is-kanban https://getnave.com/blog/kanban-benefits/ https://kanbanzone.com/2019/benefits-of-kanban-for-project-management/

Shortcomings

Many of the disadvantages of Kanban can appear because of a bad management of the tool. These bad practices include https://iwconnect.com/agile-methodologies-scrum-vs-kanban-advantages-disadvantages/:

- Obsolete Kanban board: it will lead to problems for developing the project.

- Complexity: sometimes, the team running the Kanban make it too complicated to manage it properly.

- Lack of timing: the lack of clear timeframes could become a clear disadvantage.

- Dependence: Kanban cannot represent an extreme reliable method in a project when talking about the quality outputs obtained. It is a tool used for monitoring.

Brechner. Eric (2015). Agile Project Management with Kanban (Developer Best Practices) . 2016 49th Hawaii International Conference on System Sciences

https://wisdomplexus.com/blogs/pros-cons-kanban/

References

- ↑ R.J. Boucherie, X. Chao and M. Miyazawa (2001), "Arrival first queueing networks with applications in kanban production systems".

- ↑ Kanban tool, History of Kanban, last visited 3rd of March 2022, https://kanbantool.com/es/guia-kanban/historia-de-kanban

- ↑ 3.0 3.1 3.2 Ohno, T.: Toyota Production System. Beyond Large-Scale Production. Productivity Press, Portland (1988)

- ↑ 4.0 4.1 Kanban tool, History of Kanban, last visited 3rd of March 2020, https://kanbantool.com/es/guia-kanban/historia-de-kanban

- ↑ 5.0 5.1 5.2 5.3 Atalassian Agile Coach. Last accessed 3rd March 2022, https://www.atlassian.com/es/agile/kanban/boards.

- ↑ Sonya Siderova, (2018). Last accessed 2nd March 2022, https://getnave.com/blog/kanban-metrics/#:~:text=The%20two%20Kanban%20metrics%20that,are%20connected%20by%20Little's%20Law.

- ↑ Andrew T. Pham and David K. Pham., “Business-Driven IT-Wide Agile (Scrum) and Kanban (Lean) Implementation”, 2013

- ↑ Kanbanzone. Last accessed 5th March. https://kanbanzone.com/resources/kanban/

- ↑ P. Santos, A. Caetano, B. D. Souza, G. Travassos, “On the benefits and challenges of using Kanban in software engineering: a structured synthesis study”, 2018

- ↑ Atalassian Agile Coach. Power Cumulative Diagram. Last accessed 3rd March 2022, https://kanbanzone.com/2019/power-of-cumulative-flow-diagram/

- ↑ Andrew T. Pham and David K. Pham., “Business-Driven IT-Wide Agile (Scrum) and Kanban (Lean) Implementation”, 2013

- ↑ 12.0 12.1 Popova O., “Adaptation of flexible project management models based on Scrum and Kanban technologies”, 2019

- ↑ P. Santos, A. Caetano, B. D. Souza, G. Travassos, “On the benefits and challenges of using Kanban in software engineering: a structured synthesis study”, 2018