The Kaizen Method in Project Management

(→Limitations) |

(→Kaizen-Teian) |

||

| (145 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| − | == | + | == Introduction == |

| + | [[File:Kaizen-1.png|frame| <ref name=“PICTURE”>https://wellimaginethat.com.au/kaizen-art-continual-improvement/</ref>]] | ||

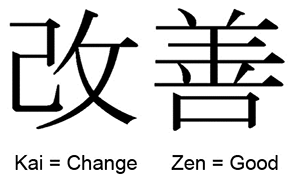

| + | ''Kaizen'' (改善, かいぜん), the Sino-Japanese word or ''Continuous Improvement'' (CI) is a strategy where employees at all levels of a company work together proactively to achieve regular, incremental improvements to the manufacturing process. In a sense, it combines the collective talents within a company to create a powerful engine for improvement. | ||

| + | It has a dual nature, as an action plan, where events are organized focusing on improving specific areas within a company, and as a philosophy, where all employees are actively engaged in suggesting and implementing improvements to the company. | ||

| + | <ref name="LEANPRODUCTION">https://www.leanproduction.com/kaizen/#:~:text=Kaizen%20(Continuous%20Improvement)%20is%20a,a%20powerful%20engine%20for%20improvement.</ref> | ||

| + | Kaizen is easy to understand, not hard to implement, and because of the broad concept behind the word: “change for the good,” there are many ways you can apply Kaizen in an organization. <ref name="KARTA">https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology</ref> | ||

| − | Kaizen | + | == History == |

| − | + | Although Masaaki Imai is considered the father of Kaizen, founding the Kaizen Institute Consulting Group (KICG) and publicing his book "Kaizen: Japanese spirit of improvement" both in 1986<ref name="WIKI">https://en.wikipedia.org/wiki/Masaaki_Imai</ref>, kaizen has its origins during World War II. When the United States entered the war, a group of Americans led by W. Edwards Deming, an engineer and statistician, set out to convert car factories into tank factories, quickly and with minimal resources. To achieve their lofty goal, Deming and his colleagues asked the workers to find small ways to improve their processes and quickly found out that small changes led to significant, measurable, and innovative results. | |

| + | After World War II, Deming traveled to Japan to help with manufacturing, as Japan was trying to rebuild. The Japanese took to heart the Deming principles. Businessman and industrial engineer Taiichi Ohno was the first Japanese business figure to translate Deming quality control principles into incredible, world-leading results. He called it the Toyota Production System (TPS). TPS, also known as “just-in-time” manufacturing, a system for reducing waste and maximizing efficiencies through continuous improvement. | ||

| + | Kaizen is also identified as a significant example of a Lean business strategy. Taiichi Ohno used Kaizen in the Toyota factory to improve the quality of the vehicles. Initially, in companies like Ford or GM, the cars were assembled and sold without proper quality controls in place. Once the customers drove the cars and found problems, they would come back to the company to fix the issues. Deming principles changed that process so that every part is checked in the assembly line; if any problem is found, the assembly is stopped, and the issue is fixed then and there.<ref name="KARTA">https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology</ref> | ||

| − | + | == Kaizen-Teian == | |

| − | 1 | + | ''Teian'' is often translated simply as "suggestion" by American companies, whereas in Japan it means "proposal"<ref name="TEIAN 1">Kaizen teian 1. English, Developing systems for continuous improvement through employee suggestions/ edited by the Japan Human Relations Association; foreword by Peter B. Grazier, 1991</ref> |

| − | + | . Together with kaizen, they describe a philosophy which dictates that small, incremental changes, routinely applied and sustained over a long period of time, result in significant benefits for a business<ref name="VOCOLI">https://www.vocoli.com/blog/september-2013/what-is-kaizen-teian/</ref>. | |

| − | + | There are two directions in kaizen teian activity, which are: | |

| + | *ideas for increasing sales | ||

| + | *ideas for keeping costs down<ref name="TEIAN 1">Kaizen teian 1. English, Developing systems for continuous improvement through employee suggestions/ edited by the Japan Human Relations Association; foreword by Peter B. Grazier, 1991</ref> | ||

| + | Continuous improvement proposals linked to '''increased sales''' include ideas for improving service , product image, product selection, display methods, quality of goods, and similar innovations. These improvement ideas arise most commonly in the areas of marketing, sales and service. As a company matures, proposals of this type gain importance. On the other hand, it is virtually improssible to measure the direct effect of such innovations on improved sales, because sales results are influenced by many complex factors.<ref name="TEIAN 1">Kaizen teian 1. English, Developing systems for continuous improvement through employee suggestions/ edited by the Japan Human Relations Association; foreword by Peter B. Grazier, 1991</ref> | ||

| − | + | '''Keeping costs down''' is achievable by working more efficiently, while eliminating low quality, overwork, waste and inconsistency and by constantly bringing forward creative proposals that help reduce costs as much as possible. Most of the kazen teian improvements designed to improve production at the workplace fall into this category. More often than not, these innovations result from things that workers notice in their workplace, so the effect of such improvement can usually be measured easily. It is more difficult to measure intangible factors such as the boost to worker morale that results from creative improvements in the workplace or place of production.<ref name="TEIAN 1">Kaizen teian 1. English, Developing systems for continuous improvement through employee suggestions/ edited by the Japan Human Relations Association; foreword by Peter B. Grazier, 1991</ref> | |

| − | + | ||

| + | == Process == | ||

| + | The typical kaizen-teian process can be broken down in 3 phases: | ||

| + | *Phase 1:Planning and Preparation | ||

| + | The first challenge is to identify an area for improvement. This requires understanding the business and uncovering an area where significant bottlenecks or delays occur. Employee involvement is key as they more clearly understand areas of conflict or "mess" within the organization. Throughout the process, continuously involve workers from the targeted administrative or production area to uncover issues and supplement the team with outside perspectives. | ||

| + | A factory looking to increase production speed and wonders where their workers are losing time or money. Workers could explain that drill bits used in production break bi-weekly and time is lost replacing the broken equipment. From here, the company can investigate causes and solutions while exploring alternatives. Toyota famously adopted a kaizen philosophy and developed a practice of asking “Why” five times to uncover the root cause of a problem. | ||

| + | *Phase 2: Implementation | ||

| + | Before being implemented, participants must work to develop a clear understanding of the current state to establish a clear and consistent understanding of goals. This is where Toyota’s “5 Whys” are beneficial. Ask the right questions, then assess areas of improvement and make changes. | ||

| + | After asking the “5 Whys,” our hypothetical factory discovered that the cause of their drill bit destruction is due to the poor quality of current bits. This may lead them to implement a solution by researching and replacing drill bits with a stronger, more durable version. | ||

| + | *Phase 3:Follow-up | ||

| + | Follow up serves as way of testing hypothetical solutions and monitoring their success. Using metrics routinely tracks new performance, measuring gains, to ensure that improvements are sustained, and not just temporary. Organizations are able to achieve continuous improvement in targeted activities and processes while learning from these new developments. | ||

| + | For the example given above, this means monitoring the lifespan of the replacement drill bits. By tracking changes in productivity, time, and money saved, focus can be redirected towards continuing alternative improvements on the factory floor.<ref name="VOCOLI">https://www.vocoli.com/blog/september-2013/what-is-kaizen-teian/</ref>. | ||

| − | == | + | == Plan-Do-Check-Act == |

| − | ''' | + | The ''Plan-do-check-act cycle'' also known as PDCA is a four-step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for Continuous Improvement(CI). The PDCA cycle is considered a project planning tool. The PDCA Cycle steps are: |

| − | + | #Plan: Recognize an opportunity and plan a change. | |

| − | + | #Do: Test the change. Carry out a small-scale study. | |

| − | + | #Check: Review the test, analyze the results, and identify what you’ve learned. | |

| − | + | #Act: Take action based on what you learned in the study step. If the change did not work, go through the cycle again with a different plan. If you were successful, incorporate what you learned from the test into wider changes. Use what you learned to plan new improvements, beginning the cycle again.<ref name="ASQ">https://asq.org/quality-resources/pdca-cycle</ref> | |

| − | + | ||

| − | ''' | + | == Application of PDCA == |

| − | + | As an example, The Pearl River, NY School District, a 2001 recipient of the Malcolm Baldrige National Quality Award, used the PDCA cycle as a model for defining most of their work processes, from the boardroom to the classroom. The PDCA model was the basic structure for the district’s: | |

| − | + | *Overall strategic planning | |

| − | + | *Needs analysis | |

| − | + | *Curriculum design and delivery | |

| + | *Staff goal-setting and evaluation | ||

| + | *Provision of student services and support services | ||

| + | *Classroom instruction | ||

| + | [[File:ppit-pdsa-example.gif|frame|left|Figure 1: Plan-do-check-act example]] | ||

| + | |||

| + | '''Plan''' | ||

| + | The A+ Approach begins with a "plan" step, which the school district calls "analyze." In this step, students’ needs are analyzed by examining a range of data available in Pearl River’s electronic data "warehouse." The data reviewed includes everything from grades to performance on standardized tests. Data can be analyzed for individual students or stratified by grade, gender, or any other subgroup. Because PDCA does not specify how to analyze data, a separate data analysis process (Figure 3) is used here as well as in other processes throughout the organization. | ||

| + | [[File:ppit-pearl-river-process.gif|frame|left|Figure 2: Pearl River Analysis Process]] | ||

| + | |||

| + | '''Do''' | ||

| + | The A+ Approach continues with two "do" steps: | ||

| + | #The "align" step asks what the national and state standards require and how they will be assessed. Teaching staff also plans curricula by looking at what is taught at earlier and later grade levels and in other disciplines to ensure a clear continuity of instruction throughout the student’s schooling. Teachers develop individual goals to improve their instruction where the "analyze" step showed any gaps. | ||

| + | #The "act" step is where instruction is provided, following the curriculum and teaching goals. Within set parameters, teachers vary the delivery of instruction based on each student’s learning rates and styles. | ||

| + | |||

| + | '''Check''' | ||

| + | Formal and informal assessments take place continually, from daily teacher assessments to six-week progress reports to annual standardized tests. Teachers also can access comparative data on the electronic database to identify trends. High-need students are monitored by a special child study team. | ||

| + | Throughout the school year, if assessments show students are not learning as expected, mid-course corrections are made (such as re-instruction, changing teaching methods, and more direct teacher mentoring). Assessment data become input for the next step in the cycle. | ||

| + | |||

| + | '''Act''' | ||

| + | In this example, the "act" step is "standardization." When goals are met, the curriculum design and teaching methods are considered standardized. Teachers share best practices in formal and informal settings. Results from this cycle become input for the "analyze" phase of the next A+ Approach cycle. | ||

| + | <ref name="ASQ">https://asq.org/quality-resources/pdca-cycle</ref> | ||

| + | |||

| + | == Advantages == | ||

| + | |||

| + | Some of the advantages of implementing Kaizen in an organization are: | ||

| + | *Utilization of Resources – Kaizen focuses on improving products through the utilization of existing resources to achieve incremental and continuous improvement. Kaizen is centered around making small changes instead of relying on massive changes or investments to gain improvements. | ||

| + | *Increased Efficiency – Central to Kaizen methodology is the importance of providing a well-planned work area, eliminating unnecessary waste such as movement or in operations, and imparting proper training for all employees. | ||

| + | *Employee Satisfaction – Kaizen is about creating an atmosphere of teamwork and change, where new ideas are encouraged. Team members are asked to examine the processes and make suggestions for improvement.<ref name="KARTA">https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology</ref> | ||

== Limitations == | == Limitations == | ||

| − | |||

| − | |||

| − | |||

| − | + | Despite the many benefits of Kaizen, there are some limitations business managers need to be aware of before deciding to implement it. This is because implementing kaizen is tantamount to altering current management systems. As soon as kaizen is implemented in an organisation, it is very difficult to return to old management systems. Hence, kaizen might be easier to implement in businesses without already established management systems. | |

| − | + | ||

| − | + | *One of the greatest kaizen disadvantages is that people are always reluctant to change. Therefore, when businesses want to implement kaizen, they have to put up with a certain resistance. Employees might not be ready to accept a different system from what they have been used to. On the other hand, management might be reluctant to implement kaizen because they feel it is expensive. | |

| − | + | *In addition, when implementing kaizen, could be very difficult for some organisations to change their current approach to work. Hence, if a business is not prepared for change when implementing kaizen, it could lead to friction. | |

| + | *Another kaizen disadvantage is the method of training. The kaizen methodology requires training staff and management to understand and adopt the kaizen philosophy. This might require altering the usual process of work. | ||

| + | *Employees might be excited at first to implement changes. However, their excitement could wear away when the changes become difficult to adapt to. As such, they may resort to old practices and stick to ‘business as usual’.<ref name=“Draminu”>https://draminu.com/kaizen-advantages-and-disadvantages/</ref> | ||

| + | |||

| + | == References == | ||

| + | <references/> | ||

Latest revision as of 13:56, 27 March 2022

Contents |

[edit] Introduction

Kaizen (改善, かいぜん), the Sino-Japanese word or Continuous Improvement (CI) is a strategy where employees at all levels of a company work together proactively to achieve regular, incremental improvements to the manufacturing process. In a sense, it combines the collective talents within a company to create a powerful engine for improvement. It has a dual nature, as an action plan, where events are organized focusing on improving specific areas within a company, and as a philosophy, where all employees are actively engaged in suggesting and implementing improvements to the company. [2] Kaizen is easy to understand, not hard to implement, and because of the broad concept behind the word: “change for the good,” there are many ways you can apply Kaizen in an organization. [3]

[edit] History

Although Masaaki Imai is considered the father of Kaizen, founding the Kaizen Institute Consulting Group (KICG) and publicing his book "Kaizen: Japanese spirit of improvement" both in 1986[4], kaizen has its origins during World War II. When the United States entered the war, a group of Americans led by W. Edwards Deming, an engineer and statistician, set out to convert car factories into tank factories, quickly and with minimal resources. To achieve their lofty goal, Deming and his colleagues asked the workers to find small ways to improve their processes and quickly found out that small changes led to significant, measurable, and innovative results. After World War II, Deming traveled to Japan to help with manufacturing, as Japan was trying to rebuild. The Japanese took to heart the Deming principles. Businessman and industrial engineer Taiichi Ohno was the first Japanese business figure to translate Deming quality control principles into incredible, world-leading results. He called it the Toyota Production System (TPS). TPS, also known as “just-in-time” manufacturing, a system for reducing waste and maximizing efficiencies through continuous improvement. Kaizen is also identified as a significant example of a Lean business strategy. Taiichi Ohno used Kaizen in the Toyota factory to improve the quality of the vehicles. Initially, in companies like Ford or GM, the cars were assembled and sold without proper quality controls in place. Once the customers drove the cars and found problems, they would come back to the company to fix the issues. Deming principles changed that process so that every part is checked in the assembly line; if any problem is found, the assembly is stopped, and the issue is fixed then and there.[3]

[edit] Kaizen-Teian

Teian is often translated simply as "suggestion" by American companies, whereas in Japan it means "proposal"[5] . Together with kaizen, they describe a philosophy which dictates that small, incremental changes, routinely applied and sustained over a long period of time, result in significant benefits for a business[6]. There are two directions in kaizen teian activity, which are:

- ideas for increasing sales

- ideas for keeping costs down[5]

Continuous improvement proposals linked to increased sales include ideas for improving service , product image, product selection, display methods, quality of goods, and similar innovations. These improvement ideas arise most commonly in the areas of marketing, sales and service. As a company matures, proposals of this type gain importance. On the other hand, it is virtually improssible to measure the direct effect of such innovations on improved sales, because sales results are influenced by many complex factors.[5]

Keeping costs down is achievable by working more efficiently, while eliminating low quality, overwork, waste and inconsistency and by constantly bringing forward creative proposals that help reduce costs as much as possible. Most of the kazen teian improvements designed to improve production at the workplace fall into this category. More often than not, these innovations result from things that workers notice in their workplace, so the effect of such improvement can usually be measured easily. It is more difficult to measure intangible factors such as the boost to worker morale that results from creative improvements in the workplace or place of production.[5]

[edit] Process

The typical kaizen-teian process can be broken down in 3 phases:

- Phase 1:Planning and Preparation

The first challenge is to identify an area for improvement. This requires understanding the business and uncovering an area where significant bottlenecks or delays occur. Employee involvement is key as they more clearly understand areas of conflict or "mess" within the organization. Throughout the process, continuously involve workers from the targeted administrative or production area to uncover issues and supplement the team with outside perspectives. A factory looking to increase production speed and wonders where their workers are losing time or money. Workers could explain that drill bits used in production break bi-weekly and time is lost replacing the broken equipment. From here, the company can investigate causes and solutions while exploring alternatives. Toyota famously adopted a kaizen philosophy and developed a practice of asking “Why” five times to uncover the root cause of a problem.

- Phase 2: Implementation

Before being implemented, participants must work to develop a clear understanding of the current state to establish a clear and consistent understanding of goals. This is where Toyota’s “5 Whys” are beneficial. Ask the right questions, then assess areas of improvement and make changes. After asking the “5 Whys,” our hypothetical factory discovered that the cause of their drill bit destruction is due to the poor quality of current bits. This may lead them to implement a solution by researching and replacing drill bits with a stronger, more durable version.

- Phase 3:Follow-up

Follow up serves as way of testing hypothetical solutions and monitoring their success. Using metrics routinely tracks new performance, measuring gains, to ensure that improvements are sustained, and not just temporary. Organizations are able to achieve continuous improvement in targeted activities and processes while learning from these new developments. For the example given above, this means monitoring the lifespan of the replacement drill bits. By tracking changes in productivity, time, and money saved, focus can be redirected towards continuing alternative improvements on the factory floor.[6].

[edit] Plan-Do-Check-Act

The Plan-do-check-act cycle also known as PDCA is a four-step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for Continuous Improvement(CI). The PDCA cycle is considered a project planning tool. The PDCA Cycle steps are:

- Plan: Recognize an opportunity and plan a change.

- Do: Test the change. Carry out a small-scale study.

- Check: Review the test, analyze the results, and identify what you’ve learned.

- Act: Take action based on what you learned in the study step. If the change did not work, go through the cycle again with a different plan. If you were successful, incorporate what you learned from the test into wider changes. Use what you learned to plan new improvements, beginning the cycle again.[7]

[edit] Application of PDCA

As an example, The Pearl River, NY School District, a 2001 recipient of the Malcolm Baldrige National Quality Award, used the PDCA cycle as a model for defining most of their work processes, from the boardroom to the classroom. The PDCA model was the basic structure for the district’s:

- Overall strategic planning

- Needs analysis

- Curriculum design and delivery

- Staff goal-setting and evaluation

- Provision of student services and support services

- Classroom instruction

Plan The A+ Approach begins with a "plan" step, which the school district calls "analyze." In this step, students’ needs are analyzed by examining a range of data available in Pearl River’s electronic data "warehouse." The data reviewed includes everything from grades to performance on standardized tests. Data can be analyzed for individual students or stratified by grade, gender, or any other subgroup. Because PDCA does not specify how to analyze data, a separate data analysis process (Figure 3) is used here as well as in other processes throughout the organization.

Do The A+ Approach continues with two "do" steps:

- The "align" step asks what the national and state standards require and how they will be assessed. Teaching staff also plans curricula by looking at what is taught at earlier and later grade levels and in other disciplines to ensure a clear continuity of instruction throughout the student’s schooling. Teachers develop individual goals to improve their instruction where the "analyze" step showed any gaps.

- The "act" step is where instruction is provided, following the curriculum and teaching goals. Within set parameters, teachers vary the delivery of instruction based on each student’s learning rates and styles.

Check Formal and informal assessments take place continually, from daily teacher assessments to six-week progress reports to annual standardized tests. Teachers also can access comparative data on the electronic database to identify trends. High-need students are monitored by a special child study team. Throughout the school year, if assessments show students are not learning as expected, mid-course corrections are made (such as re-instruction, changing teaching methods, and more direct teacher mentoring). Assessment data become input for the next step in the cycle.

Act In this example, the "act" step is "standardization." When goals are met, the curriculum design and teaching methods are considered standardized. Teachers share best practices in formal and informal settings. Results from this cycle become input for the "analyze" phase of the next A+ Approach cycle. [7]

[edit] Advantages

Some of the advantages of implementing Kaizen in an organization are:

- Utilization of Resources – Kaizen focuses on improving products through the utilization of existing resources to achieve incremental and continuous improvement. Kaizen is centered around making small changes instead of relying on massive changes or investments to gain improvements.

- Increased Efficiency – Central to Kaizen methodology is the importance of providing a well-planned work area, eliminating unnecessary waste such as movement or in operations, and imparting proper training for all employees.

- Employee Satisfaction – Kaizen is about creating an atmosphere of teamwork and change, where new ideas are encouraged. Team members are asked to examine the processes and make suggestions for improvement.[3]

[edit] Limitations

Despite the many benefits of Kaizen, there are some limitations business managers need to be aware of before deciding to implement it. This is because implementing kaizen is tantamount to altering current management systems. As soon as kaizen is implemented in an organisation, it is very difficult to return to old management systems. Hence, kaizen might be easier to implement in businesses without already established management systems.

- One of the greatest kaizen disadvantages is that people are always reluctant to change. Therefore, when businesses want to implement kaizen, they have to put up with a certain resistance. Employees might not be ready to accept a different system from what they have been used to. On the other hand, management might be reluctant to implement kaizen because they feel it is expensive.

- In addition, when implementing kaizen, could be very difficult for some organisations to change their current approach to work. Hence, if a business is not prepared for change when implementing kaizen, it could lead to friction.

- Another kaizen disadvantage is the method of training. The kaizen methodology requires training staff and management to understand and adopt the kaizen philosophy. This might require altering the usual process of work.

- Employees might be excited at first to implement changes. However, their excitement could wear away when the changes become difficult to adapt to. As such, they may resort to old practices and stick to ‘business as usual’.[8]

[edit] References

- ↑ https://wellimaginethat.com.au/kaizen-art-continual-improvement/

- ↑ https://www.leanproduction.com/kaizen/#:~:text=Kaizen%20(Continuous%20Improvement)%20is%20a,a%20powerful%20engine%20for%20improvement.

- ↑ 3.0 3.1 3.2 https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology

- ↑ https://en.wikipedia.org/wiki/Masaaki_Imai

- ↑ 5.0 5.1 5.2 5.3 Kaizen teian 1. English, Developing systems for continuous improvement through employee suggestions/ edited by the Japan Human Relations Association; foreword by Peter B. Grazier, 1991

- ↑ 6.0 6.1 https://www.vocoli.com/blog/september-2013/what-is-kaizen-teian/

- ↑ 7.0 7.1 https://asq.org/quality-resources/pdca-cycle

- ↑ https://draminu.com/kaizen-advantages-and-disadvantages/