PDCA cycle

(→Presentation of the method) |

|||

| Line 16: | Line 16: | ||

''Developed by Eric Vincent Vong'' | ''Developed by Eric Vincent Vong'' | ||

| + | |||

| + | |||

| + | == History of the PDCA cycle == | ||

| + | |||

| + | === Shewhart cycle === | ||

| + | |||

| + | The foundations of the PDCA method begin with the development of the Shewhart cycle by Walter A. Shewhart in 1939. This cycle consists of three main phases, which are: | ||

| + | #The Specification phase | ||

| + | #The Production phase | ||

| + | #The Inspection phase | ||

| + | |||

| + | |||

| + | Shewhart wrote about his cycle: | ||

| + | <blockquote>''"It may be helpful to think of the three steps in the mass production process as steps in the scientific method. In this sense, specification, production, and inspection correspond respectively to making a hypothesis, carrying out an experiment, and testing the hypothesis. The three steps constitute a dynamic scientific process of acquiring knowledge."'' '''''Walter A. Shewhart'''''</blockquote> | ||

| + | |||

| + | |||

| + | === Deeming wheel === | ||

| + | |||

| + | In 1950, after being influenced by the work of Shewhart, W. Edwards Deming presented in front of the Japanese Union of Scientists and Engineers his method about the continuous improvement of products. This method, which will know a lot of success inside Japanese companies and will later be called the Deming wheel, is a cycle made up of four main phases: | ||

| + | #The Design phase | ||

| + | #The Produce phase | ||

| + | #The Sell phase | ||

| + | #The Redesign phase | ||

| + | |||

| + | |||

| + | === PDCA cycle === | ||

| + | |||

| + | In 1951, the Japanese executives recast the Deming Wheel into a more versatile tool that can be used for the continuous improvement of any processes or products, creating then a more genetic tool. It is the birth of the PDCA cycle as it is known nowadays, with its four main phases: | ||

| + | #The Plan phase, which can be assimilated to the Design phase. | ||

| + | #The Do phase, which can be assimilated to the Produce phase. | ||

| + | #The Check phase, which can be assimilated to the Sell phase. | ||

| + | #The Act phase, which can be assimilated to the Redesign phase. | ||

Revision as of 18:20, 11 February 2023

"It [The PDCA cycle] is a flow diagram for learning and for improvement of a product or of a process." [1] W. Edwards Deming

The PDCA (Plan-Do-Check-Act) cycle, also known as the Deming cycle or the Shewhart cycle, is a project management method used to continuously improve the quality of a process or a product. This cycle is based on the four following phases: Plan, Do, Check, and Act.[2]

- In the Plan phase, the problem to tackle is identified, and an action plan is set up.

- In the Do phase, the plan is put into action by the project team.

- In the Check phase, the differences between the results and the expectations are evaluated.

- In the Act phase, corrective actions are taken in order to improve the evaluated situation.

By breaking down a complex problem into these four phases, the organization obtains a clear overview of the situation and is forced to systematically identify areas of improvement, take actions about it, compare the results and the expectations, and make the necessary adjustments.

The PDCA cycle is an iterative method, which means that at the end of the fourth phase, it is recommended to implement again the method on the new situation to continue the improvement of the product or the process. This iterative approach results in an increase of efficiency and effectiveness inside the organization.

Developed by Eric Vincent Vong

Contents |

History of the PDCA cycle

Shewhart cycle

The foundations of the PDCA method begin with the development of the Shewhart cycle by Walter A. Shewhart in 1939. This cycle consists of three main phases, which are:

- The Specification phase

- The Production phase

- The Inspection phase

Shewhart wrote about his cycle:

"It may be helpful to think of the three steps in the mass production process as steps in the scientific method. In this sense, specification, production, and inspection correspond respectively to making a hypothesis, carrying out an experiment, and testing the hypothesis. The three steps constitute a dynamic scientific process of acquiring knowledge." Walter A. Shewhart

Deeming wheel

In 1950, after being influenced by the work of Shewhart, W. Edwards Deming presented in front of the Japanese Union of Scientists and Engineers his method about the continuous improvement of products. This method, which will know a lot of success inside Japanese companies and will later be called the Deming wheel, is a cycle made up of four main phases:

- The Design phase

- The Produce phase

- The Sell phase

- The Redesign phase

PDCA cycle

In 1951, the Japanese executives recast the Deming Wheel into a more versatile tool that can be used for the continuous improvement of any processes or products, creating then a more genetic tool. It is the birth of the PDCA cycle as it is known nowadays, with its four main phases:

- The Plan phase, which can be assimilated to the Design phase.

- The Do phase, which can be assimilated to the Produce phase.

- The Check phase, which can be assimilated to the Sell phase.

- The Act phase, which can be assimilated to the Redesign phase.

Presentation of the method

The PDCA cycle is a continuous improvement method that is commonly used in various organizations, such as in manufacturing industries or healthcare industries. It provides them a structured approach on how to deal with their problems or on how to handle possible improvements. The PDCA method has four phases, each leading to the other, and aims to establish a virtuous circle about continuous improvement culture inside the company. [3]

Plan

The first phase of this method is the Plan phase, which is one of the most important parts in project management. Indeed, that phase is very crucial because it is the moment where the foundations of the project are set, by clearly defining the problem and the objectives to reach. Consequently, the Plan phase is usually carried out in three stages, which are the following:

- Firstly, identify the problem to solve or a potential improvement that can be addressed, by using for example different project management tools and techniques, such as the method of the five W’s or brainstorming meeting sessions for example.

- Secondly, understand the causes of the problem or point out the improvement actions that can be taken to increase the overall efficiency and effectiveness of a process or a product, by using for instance the fishbone diagram.

- Thirdly, look for solutions and develop an action plan, based on the problems identification made in stage 2 and on the objectives defined in stage 1. Here, it is important to consider the feasibility and the impact of each solution, and to emphasize the most relevant ones. Finally, the action plan must contain clear milestones and responsibilities, by using a Gantt chart and a responsibility assignment matrix for example.

Do

The second phase of this method is the Do phase, in which the action plan is implemented in the field. This implementation may involve the creation of a prototype, the realization of tests or the writing of software codes. In this phase, each subteam inside the project team works on its side, according to the action plan.

One point to mention and to be very careful about is that even if each subteam works on its side, it is essential to have clear communication and collaboration between the different people involved in the project, by having regular meeting sessions. Indeed, because some tasks can be impacted by another ones, it is important to be aware of the progression of each task related to the project. Moreover, these meetings help the project team to avoid the tunnel effect, which is when a person or a team only focus on its own tasks.

Check

The third phase of this method is the Check phase, in which the project team makes sure that the solutions that have been implemented to tackle the problem or to improve an existing process are effective and efficient enough. For that, a comparison between the previous situation, the current results after implementing the solutions and the expected outcomes must be carried out, by using for example specific tools such as the key performance indicators or customer satisfaction surveys.

The goal of the Check phase is to highlight any gaps between the actual results and the expected outcomes in order to use this information in the next phase, in which corrective actions can be taken to continue the improvement of the process or the product. Furthermore, in a world where the climate change and the corporate social responsibility became fundamental issues, it is important to also consider the sustainability of the solution in comparison with the sustainable development goals of the United Nations.

Act

The final phase of this method is the Act phase, in which the project team takes the necessary actions to improve the results obtained in the Do phase, based on the analysis made in the Check phase. This part is usually realized in two stages, which are the following:

- Firstly, the project teams try to minimize the gaps that have been identified in the Check phase by taking corrective actions in order to improve the overall quality of the process or product. The objective of this part is to get as close as possible to the expected outcomes planned in the Plan phase, after having a first experience in the field.

- Secondly, the project team draws conclusions of the whole four phases and uses the knowledge accumulated throughout the process to begin a new iteration of the PDCA cycle, to try to reach an even better final solution. Each experience with the PDCA cycle should be documented so that each organization has their own best practices when implementing the PDCA method and avoids to always fall in the same traps.

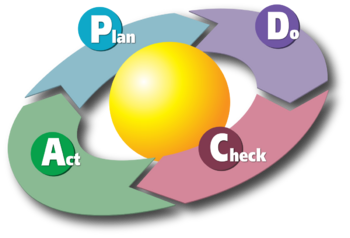

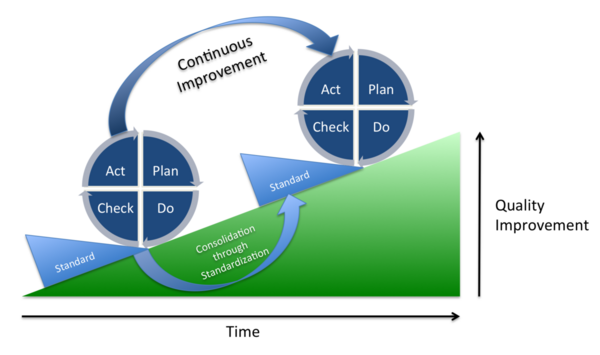

Visual representation

To keep in mind all the important aspects of the PDCA cycle, it is possible to represent this method as a circular flow diagram, with each phase of the PDCA cycle represented by a section of the circle. The circle form reinforces the idea of the continuous improvement and suggests that this virtuous cycle never ends. Thus, each iteration of the method leads towards a better situation, a better quality of the product of the process than the previous one.

Moreover, another visualization of the PDCA method is to represent it as a wheel on a slope, with the aim to reach the top. After each rotation, a block is placed behind the wheel to prevent it from rolling down the slope. This representation indicates that the progress made should be maintained and that each improvement must be built on top of that, symbolizing the capitalization of the knowledge.

To conclude, the different visual representations of the PDCA cycle are very important to convey the key elements of the method quickly and easily to all employees of the organization, regardless of their position in the company.

Examples

Toyota

Toyota is a Japanese automobile company, well known for its efficiency and its quality control. The PDCA method has been and is still a key point of their success, especially in its production process. Indeed, this company uses the PDCA method to make sure to always meet the highest quality standards, by optimizing their process and by capitalizing on their knowledge.

The PDCA method used by Toyota to improve their production process can be described as following [4]:

- In the Plan phase, the company defines the production goals and sets up an action plan to achieve them. This action plan emphasizes details about the production processes, by answering the five W’s (What, When, Who, Where, and Why).

- In the Do phase, the company puts into action the plan defined previously to produce vehicles. During that stage, different kind of data is collected, for instance speed or quality of the production, so that it can be analyzed in the next phase.

- In the Check phase, the company compares the initial plan and its expected goals with what really happened during the production in order to evaluate the differences. By analyzing the data previously collected, Toyota is able to highlight areas that can be improved.

- In the Act phase, the company takes action to improve its production processes based on what was found in the Check phase. Toyota, for example, implemented new tools and new processes to improve their production process.

The PDCA method is part of Toyota’s culture, as underlined by Adriaan van Wyk, former production leader of Toyota South Africa Motors, in which he worked from 2003 to 2008:

"PDCA is so deeply ingrained in Toyota’s fabric that it was not taught explicitly. I had to become part of the culture and live it before I could make it my own.” [5] Adriaan van Wyk

Ningbo Women and Children’s Hospital

In 2019, the Department of Obstetrics and Gynecology at the Ningbo Women and Children’s Hospital in China decided to apply the PDCA method to reduce the time between the decision to conduct a cesarean section and the delivery of the newborn during emergency cases. This time is called DDI, which stands for “Decision to Delivery Interval”. By shortening this time, it would improve the chance of survival of the mother and the newborn.

The PDCA method used in this hospital can be described as following [6]:

- In the Plan phase, that took place in 2019, the hospital identified that the average DDI time was equal to 14.40 minutes. By analyzing their process, three main causes impacting an increase of the DDI time have been pointed out:

- A defective process

- A lack of first-aid experience

- A poor cooperation between the departments

- In the Do phase, the hospital tackled each of these causes by implementing improvement measures:

- Establish a specific team to deal with these emergencies and standardize the working processes.

- Implement regular theoretical and practical trainings.

- Involve multiple departments when conducting emergency drills.

- In the Check phase, the hospital evaluated the progress monthly, by creating a summary about the improvements measured over time.

- In the Act phase, the hospital refined their processes, which leads to a successful reduction of their average DDI time, from 14.40 minutes in 2019 to 12.18 minutes in 2020.

Variation of the method

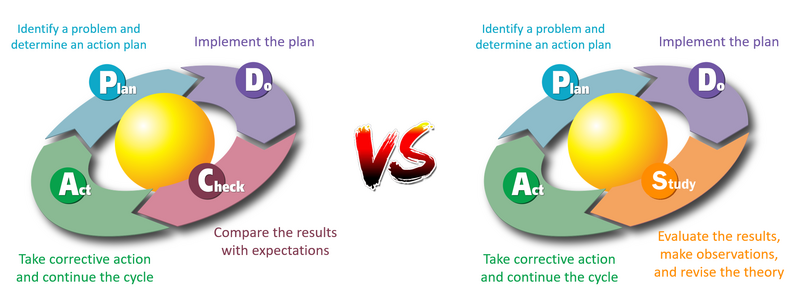

PDSA

In the 1980s, Deming introduced an alternative of the PDCA cycle, called PDSA cycle, which stands for Plan-Do-Study-Act. The main change is that the Check phase, in which the project team is supposed to compare and evaluate the differences between the results and the expected outcomes, is replaced by the Study phase, in which the project team is supposed to evaluate the results of the plan and make observations. Apart from that, the three other phases of the PDSA cycle are the same as the PDCA cycle. [1].

Consequently, the PDCA cycle seems to be more focused on continuous improvement through a more structured approach whereas the PDSA cycle seems to be more focused on testing and implementing changes quickly, and on revising the theory if necessary.

OPDCA

More recently, some scholars decided to add an Observe phase at the beginning of the PDCA cycle, changing it into the OPDCA cycle. This change was made to emphasize the importance of the observation of the current situation before creating any action plan [7]. However, most people tend to always use this method as the PDCA cycle and not as the OPDCA cycle because they include the observation part inside the Plan phase.

DMAIC (from the Six Sigma)

The DMAIC cycle is a method widely used in the Six Sigma method and aims to improve a business process. DMAIC stands for Define-Measure-Analyze-Improve-Control and is highly inspired from the PDCA cycle.

The five phases can be described as following [8]:

- Define: Define the problem or the opportunity for improvement

- Measure: Quantify the current perform of the process thanks to data collection

- Analyze: Analyze the data previously collected to identify the roots of the problems, which can negatively impact the performance of the process

- Improve: Take actions to address the roots of the problems

- Control: Implement a control plan to sustain the improvements made during the Improve phase.

Pros and cons

Pros

Here is a non-exhaustive list of the advantages of the PDCA cycle [9]:

- It is a versatile method because it can be used to improve any products or processes, but it can also be implemented to improve change management or resource management.

- It helps the organizations to have a continuous improvement by encouraging them to systematically evaluate and improve their processes and systems.

- It creates a sense of ownership inside the company for all the employees because their points of view and insights matter to use the PDCA cycle.

- It is an easy tool to understand with a simple visual representation.

Cons

Here is a non-exhaustive list of the disadvantages of the PDCA cycle [9]:

- It needs a lot of commitment from the employees because it is a tool which must be continuously used to have continuous improvements of the processes and systems.

- It requires a lot of time to implement the method because each possible improvement is broken down into four different phases, which can be time-consuming (for example, create a thorough action plan)

- It can be rejected by some employees of the company because they do not want to spend too much time on this method, which can lead to a speed reduction of its implementation.

References

- ↑ 1.0 1.1 W. Edwards Deming, "The New Economics for Industry, Government, Education", 1993

- ↑ Nancy R. Tague, "The quality toolbox, Second Edition", 2005

- ↑ Rémi Bachelet, "L’essentiel des outils d’organisation de projet", Ecole Centrale de Lille, 2019

- ↑ Jeffrey Liker, "The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer", 2004

- ↑ Adriaan van Wyk, "PDCA - Make a 400 year old principle the foundation of your success", LinkedIn article, 2019

- ↑ Ming-Na Lu, Bai-Lei Zhang, Qiao-Hong Dai, Xian-Hu Fu, "Application of the Plan-Do-Check-Act Cycle in Shortening the Decision to Delivery Interval Time", Risk Management and Healthcare Policy, 2022

- ↑ Foresight University, "Shewhart-Deming’s Learning and Quality Cycle"

- ↑ Michael L. Gorge, "Lean Six Sigma: Combining Six Sigma Quality with Lean Production Speed", 2002

- ↑ 9.0 9.1 Tobias Lauenroth, "PDCA cycle - Structuring goal achievement", 2022