Theory of Constraint

| Line 85: | Line 85: | ||

[[Image:Fig2JLY.jpeg|thumb|center|upright=4|alt=DBR tool| Figure 2 Example of Drum-Buffer-Rope]] | [[Image:Fig2JLY.jpeg|thumb|center|upright=4|alt=DBR tool| Figure 2 Example of Drum-Buffer-Rope]] | ||

| − | + | ||

In above example we have a production of CT (chilling tubes). In the production of these CT tubes the constraint (bottleneck) is identified to be the chroming process. To protect the constraint a buffer is created around the CT tubes. The buffer in this example is to secure that a certain level of CT tubes is ready to be chromed. All other operations are subordinated to secure that the buffer is never idle. The drum is the constraint (chroming process) and the speed at which the constraint runs. The drum sets the beat or the pace of the process which determines the number of finished CT tubes and - in the end - determines the throughput. | In above example we have a production of CT (chilling tubes). In the production of these CT tubes the constraint (bottleneck) is identified to be the chroming process. To protect the constraint a buffer is created around the CT tubes. The buffer in this example is to secure that a certain level of CT tubes is ready to be chromed. All other operations are subordinated to secure that the buffer is never idle. The drum is the constraint (chroming process) and the speed at which the constraint runs. The drum sets the beat or the pace of the process which determines the number of finished CT tubes and - in the end - determines the throughput. | ||

Revision as of 20:22, 26 September 2015

The underlying assumption of Theory of Constraint (TOC) is that the performance of a system constraint will determine the performance of the organization. A constraint is anything that limits or prevents higher system performance relative to the goal. The constraint is the weakest link in the chain. A Five Focusing Steps methodology is used to identify an eliminate constraints of an organization as well as being a tool for continuously improvement in the organization.

Primarily we would find TOC and Constraint Management applied in manufacturing and scheduling where the speed of a constraint sets the pace of a process in a production line. However TOC is extended to apply an execution of a project as well. LIMITATIONS...

Contents |

Overview

The methodology Theory of Constraint (TOC) was introduced by E. Goldratt in the book “The Goal” in 1984 (REF5), but the roots of TOC can be traced back to the development of the software Optimized Production Technology OPT in the late 1970s (REF6, page 648).

Assumptions

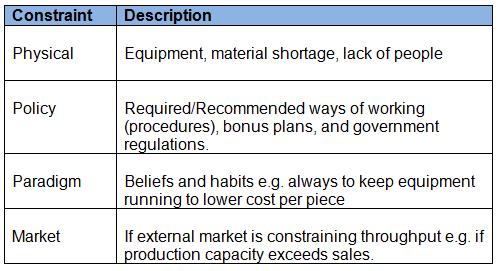

A main assumption in TOC is that the primary goal of a business is to “make more money now and in the future without violating certain necessary conditions”. (REF, p 649) To obtain this goal according to TOC an organization can be measured and controlled by three measures: Throughput, operational expense and investment (originally called inventory). Throughput, which is the most important measure according to Goldratt, measures the rate at which an organization generates money through sales. Investment is the money tied up in physical things like inventory, equipment, real estate etc.) Whereas operating expense is money spent to create output other than variable costs (capacity cost, taxes, utilities etc.) Another assumption in TOC states that every business has at least one constraint. A constraint (in manufacture often called a bottleneck) is anything that prevents an organization from making progress towards its goal of earning money. See list of constraints in below table 1

Constraints are often political.....

Two perspectives of TOC

TOC can be seen from two perspectives: the perspective of a business system and the perspective of an on going improvement process itself (REF6, p 649).

TOC as a Business System

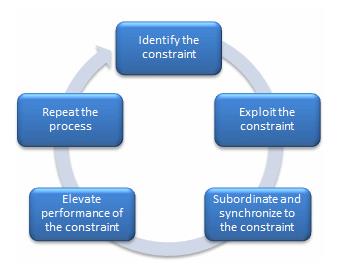

Seen from a business system viewpoint TOC emphasizes change process implemented in three levels: the mind-set of the organization, the measures that drives it and the methods employed within the organization (REF6, p. 649). From previous section we know that according to TOC in very process there is a constraint and that the total throughput can only be improved when the constraint is improved or eliminated. Accordingly, Goldratt introduced a “Five Focusing Steps” methodology to identify and eliminate constraints as well as being a tool for continuously improvement in the organization. See figure 1.

The first step of Goldratts methodology is to IDENTIFY the current constraint. The constraint is the single part of the process that limits the rate at which the goal is achieved.

In the next step EXPLOIT the constraint quick improvements to the throughput of the constraint are to be carried out by using existing resources. In short existing resources are optimized. Also it is important her to make the organization aware of the constraint and its effect on the performance of the organization.

In the step SUBORDINATE all the non-constraint activities in the process are reviewed. This is to make sure that the non-constraints are aligned with and support the needs of the identified constraint.In other words the non-constraints should avoid doing unneeded work.

In next step ELEVATE further actions shall be taken, if the constraint still exists. The aim is to eliminate the constraint from being a constraint, and actions are continued at this step until the constraint has "broken". In this step it might be considered necessary to make some investments to be able to eliminate the constraint.

Once the constraint is broken the organization move to step five REPEAT which means that this is a continuous improvement process and once a constraint is resolved the next constraint should be addressed and then the process starts at the step IDENTIFY again.

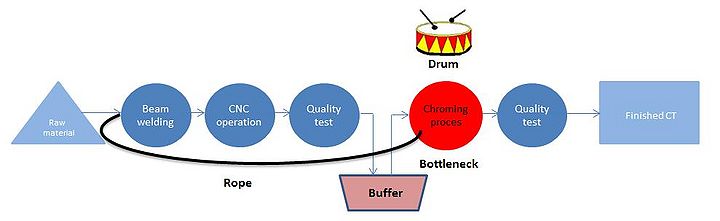

Goldratt also introduced different tools to describe / analyse the process and to develop a constraint schedule to manage buffer inventory in an organization. One of the most known is “Drum-Buffer-Rope” (DBR), which is a method of synchronizing a production to the constraint while minimizing inventory and work-in-process. Figure 2 illustrates an example of DBR.

In above example we have a production of CT (chilling tubes). In the production of these CT tubes the constraint (bottleneck) is identified to be the chroming process. To protect the constraint a buffer is created around the CT tubes. The buffer in this example is to secure that a certain level of CT tubes is ready to be chromed. All other operations are subordinated to secure that the buffer is never idle. The drum is the constraint (chroming process) and the speed at which the constraint runs. The drum sets the beat or the pace of the process which determines the number of finished CT tubes and - in the end - determines the throughput.

The rope is a signal generated by the constraint (the chroming process) indicating that some CT tubes have been consumed (made ready for chroming) and this triggers the start for new CT tubes to be processed in the process flow lying before of the constraint.

TOC as an On-going Improvement Process

If you look at TOC from the perspective of an on-going improvement process TOC suggest that an organization must answer three fundamental questions concerning change in order to accelerate its improvement process:

- What needs to be changed? (How to identify the weakest link (the constraint) in the organization?)

- What should it be changed to? (How can the organization be strengthened by developing good and practical solutions around the constraint?)

- What actions will cause the change? (How should the organization implement the solutions?)

Goldratt and his team developed a whole set of techniques known as the Thinking Process to address these questions - below two examples:

a. The Strategic Current Reality Tree Technique which identifies the root causes behind the mismatch between where the organization is today and where it wants to be at the end of the planning horizon (desired stage).

b. Evaporating Clouds is used to put focus on the root causes of the gaps identified under a. This technique can root out and resolve the conflicts behind the root cause as well as the resistance towards change in the organization.

Applications

The Five Focusing Steps methodology have mainly been applied to manufacturing and supply chain solutions as also illustrated in previous examples. But especially the Thinking Process tools have also led to TOC applications being used in the field of marketing, sales and finance

Extension of TOC for Project Management

In 1997 Goldratt extended the production application of TOC to projects. He identified the constraint of a project as “the sequence of dependent events that prevents the project from completing in a shorter interval” (REF7). Resource and activity dependencies determine the critical chain in a project, because the scheduling of these has huge impact on project cost and scope. If schedule increases with fixed deliverables scope, cost usually increases. And if scope increases with fixed cost (or resources) schedule tends to increase. Since the resource constraint is often a significant project constraint, the TOC method of project planning should consider this. The critical chain includes the resource dependencies that define the overall longest path (constraint) of the project. The method resolves all resource constraints while determining critical chain of the project. The critical path may change during the performance of a project for example if other paths experience delay. The Five Focusing Steps methodology applied on Goldratt's Critical Chain Project Management (CCPM) as the TOC extension is called is listed in table 3 below (REF7)

Table 3 Five Focusing Steps transformed info Critical Chain Project Management

Advantages and Limitations of TOC

Advantages of TOC

TOC has been compared with established operational management tools in more studies. For example as capacity scheduling in a production line TOC is an easy way to identify how many items can be produced within a certain period of time. TOC can ensure an even and efficient pace in the production taking an identified constraint into consideration.

As an improvement methodology TOC produces positive effects on flow time of a product or service through a system. TOC used in improvement processes requires limited intimate knowledge of data analysis. Only a few people in an organization need to understand the elements of the system in order to implement this method. This means that a TOC effort in this context can be localized with minimum involvement from the workforce in e.g. a manufacturing company. (REF8, p 76). As a consequence of this you could argue that especially organizations with hierarchical structure and centralized knowledge would value the TOC approach.

Think Process tools e.g. the reality trees are examined to be particular useful to address non-physical constraints such as wrong policies or inconsistent performance measures according to a study by Chaudhari and Mukhopadhyay where interactions among the supply chain members of a service industry was analysed. (REF6, p 654). This meant that.....

The Five Focusing Steps as well as the Thinking Process presents a variety of tools to approach different problems in an organization or in a project. For example to solve a relative simple product mix problem the TOC tools combined in different ways can provide a flexible and synergic approach to identify different solutions and solve a specific problem.(REF6, page 652 and 653).

Limitations of TOC

In general it is argued that TOC has borrowed research and practice especially from program and review technique (PERT) and Critical path method (CPM). FIND SOURCE

Another major obstacles to TOC (as well as Lean and Six Sigma)as an improvement methodology is that the TOC methodology address management theories as a secondary issue. TOC does not address the general theory of management or the policies of an organization (REF8). Change processes challenge existing ways of doing things in an organization, and policies and organizational values might have to be revised. TOC does not take into account that earning money is not always the only purpose of an organization.

When used as improvement process with low work force involvement, you could argue that TOC has some drawbacks. If an employee is only briefly informed and not involved in the TOC process he/she might feel less motivated (engaged). Work force involvement according to xxxxx is vital for successful implementation of TOC (REF8, p. 76).

Gupta (REF6, page 658)in his article about Constraint Management concludes that TOC has a potential to be established as a useful production management theory as it is widely applicable across the production function, however the theory of Constraint Management has not been empirically developed and tested which is required if TOC has to be accepted as a general theory in production management.

Annotated Bibliography

REF1 Bicheno, John, et (2009), The Lean Toolbox – The Essential Guide to Lean Transformation, Fourth Edition, Judge Business School, University of Cambridge, PICSIE Books; UK

REF2 Boyd, Lynn, et al (2004), Constraint Management – What is the theory?, University of Louisville, USA, International Journal of Operations & Production Management, Vol. 24 No. 4, 2004, pp350-371

REF3 Dettmer William (2000), Constraint Management, Quality America. Inc. 2000, Chapter from updated 2000 edition of The CQM Guide written by Pyzdek, Thomas originally published in 1996.

REF5

Goldratt, Eliyahu M, et al.(2014), The Goal – A Process of Ongoing Improvement, The North Rivel Pres Publishing Corporation, Fourth Revision Edition.

REF6 Gupta, M (2003), Constraint management – recent advances and practices, International Journal of Production Research, 2003 Vol. 41 no. 4 pp 647-659

REF7 Leach, Larry P. (1999), Critical Chain Project Management Improves Project Performance, Quality Systems, 1577 Del Mar Circle, Idaho USA

REF8 Nave, Dave, (2002), How to Compare Six Sigma, Lean and the Theory of Constraints – a framework for choosing what’s best for your organization, Quality Progress, March 2002.