Six Sigma and PMBOK

| Line 123: | Line 123: | ||

All management is concerned with these, of course, but project management brings a unique focus shaped by the goals, resources and schedule of each project. | All management is concerned with these, of course, but project management brings a unique focus shaped by the goals, resources and schedule of each project. | ||

| + | |||

| + | |||

| + | ==Six Sigma== | ||

| + | |||

| + | Six Sigma is a set of practices originally developed by Motorola to systematically improve processes by eliminating defects. A defect is defined as nonconformity of a product or service to your specifications. Six Sigma is also defined as a management strategy to promote change in organizations, making it reaches improvements in projects, processes, products and services for customer satisfaction. Basically it is a method that provides organizations tools to improve the capability of their business processes. This increase in performance and decrease in process variation lead to defect reduction and improvement in profits, employee morale, and quality of products or services. (http://asq.org/learn-about-quality/six-sigma/overview/overview.html) | ||

| + | Unlike other forms of management of productive or administrative proceedings Six Sigma's priority is to obtain results in a planned and clear way seeking better quality and also financial gains. | ||

| + | |||

| + | The methods applied to Six Sigma are not unique to it, but are common business practices originally developed in other methods and attached to existing tools in the quality movement. Some of the most common sets of tools of Six Sigma are borrowed both from statistical process, as from project management. The Six Sigma approach uses statistical analysis to measure and improve the performance of production in organizations. | ||

| + | |||

| + | Six Sigma projects follow two methodologies inspired by the Plan-Do-Check-Act cycle of Walter A. Shewhart (widely broadcast by W. Edwards Deming, the post-war Japan). These methodologies, composed of five phases each, are called by the acronyms DMAIC and DMADV. | ||

| + | |||

| + | *DMAIC is used for projects focused on improving existing business processes. | ||

| + | *DMADV is used for projects focused on creating new designs of products and processes. | ||

| + | |||

| + | |||

| + | ===DMAIC=== | ||

| + | |||

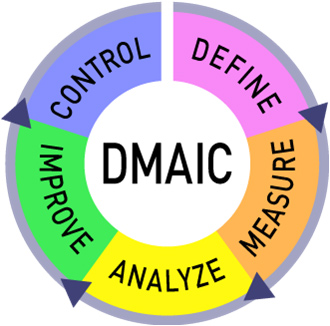

| + | DMAIC is a data-driven quality strategy used to improve processes. It is an integral part of a Six Sigma initiative, but in general can be implemented as a standalone quality improvement procedure or as part of other process improvement initiatives such as lean.[[File:Six_Sigma_DMAIC.jpeg]] | ||

| + | |||

| + | The five phases that make up the process: | ||

| + | |||

| + | *Define the problem, improvement activity, opportunity for improvement, the project goals, and customer (internal and external) requirements. | ||

| + | *Measure process performance. | ||

| + | *Analyze the process to determine root causes of variation, poor performance (defects). | ||

| + | *Improve process performance by addressing and eliminating the root causes. | ||

| + | *Control the improved process and future process performance. | ||

| + | |||

| + | |||

| + | ===DMADV=== | ||

| + | |||

| + | DMADV is used when you want to set up/design a whole new process, that should be meeting the desired level of performance from the beginning. DMADV may also be used when there is a need to redesign an existing product or process, rather than constantly correcting the process. The soul of DMADV is in understanding the customer’s requirements | ||

| + | |||

| + | *Define the project goals and customer (internal and external) deliverables | ||

| + | *Measure and determine customer needs and specifications | ||

| + | *Analyze the process options to meet the customer needs | ||

| + | *Design (detailed) the process to meet the customer needs | ||

| + | *Verify the design performance and ability to meet customer needs | ||

Revision as of 21:56, 28 September 2015

Contents |

Overview

One of the most challenging issues of today's business leaders is to not only know how to gain competitive advantage, but rather how to maintain it.

Today, in addition to the concern about profit margins, cost reduction and expenses, revenue growth, market penetration, productivity, customer satisfaction, employees and shareholders; preservation of the brand and quality assurance and leadership, yet you need to combine these variables with an attention to social responsibility, ethics and environmental preservation.

All this has led organizations to employ various types of methodologies that ensure agility in the implementation of its corporate strategy and its effective applicability.

Most of the time strategies have been implemented under pressure such as regulatory agencies, comply with national or international standards, establish the use of outsourced teams, respect the environment, better results, change in the market, changes in customer behavior, increased competitiveness and search for innovation among others.

What tools can allow organizations an assurance that the implementing a determined strategy would achieve the desired results within a established management pre-set cycle? How to ensure that the strategy to be adopted will reach and integrate the current organization's value chain?

Through this challenge, organizations find themselves searching for new methodologies for ensuring the implementation of their strategies either through Quality Programs, Management by Guidelines, Process Management, Balanced Score Card (methodology created by Norton and Kaplan that allows mapping of the strategic objectives), Integrated Management Systems, Project Management and Six Sigma among others.

Regardless of the decision taken, it will always depend on the implementation, coordination and acceptance by the leadership. Can Six Sigma Program and Project Management contribute effectively to ensure an efficient strategic? Can these two methodologies work together?

Project

A project is a temporary endeavor undertaken to create a product, service or result. Its temporary nature indicates a beginning and an end defined. The ending is achieved when the objectives have been achieved or when they conclude that these objectives will not or cannot be achieved and the project is terminated.

Each project creates a product, service or result. Although elements repetitive may be present in some project deliverables, this repetition does not change fundamental uniqueness of the project work. For example, office buildings are built with the same or similar materials or by the same team, but each is unique - with different designs, circumstances, suppliers, etc.

An ongoing work effort is generally a repetitive process because it follows the existing procedures of an organization. On the other hand, due to the unique nature of projects, there may be uncertainty how the products, services, or results created by project. The tasks may be new to the project team, which requires planning more dedicated than other routine work. In addition, projects are undertaken in all organizational levels. A project may involve a single person, a single or multiple organizational units.

Methods

Project management

Project management is the application of knowledge, skills, tools, and techniques to project activities to meet the project requirements.

It has always been practiced informally, but began to emerge as a distinct profession in the mid-20th century. PMI’s A Guide to the Project Management Body of Knowledge (PMBOK® Guide) identifies its recurring elements:

Project management processes fall into five groups:

- Initiating Process Group. Are the processes performed to define a new project or a new phase of an existing project by obtaining authorization to start the project or phase;

- Group planning processes. The processes performed to define the project scope, refine the objectives and develop the course of action necessary to achieve the purposes for which the project was created;

- Group of running processes. The processes performed to execute the work defined in the project management plan to satisfy the specifications thereof;

- Group monitoring and control processes. The processes required to track, review and regular progress and project performance, identify any areas in which changes are needed in the plan and initiate the corresponding changes;

- Closing Process Group. The processes performed to finalize all activities of all groups of processes to formally close the project or phase.

The PMBOK Guide is a set of practices in project management organized by the PMI institute and is considered the foundation of knowledge about project management. It provides guidelines for managing individual projects and defines project management related concepts. It also describes the project management life cycle and its related processes, as well as the project life cycle.

It also is process-based, meaning it describes work as being accomplished by processes. Processes overlap and interact throughout a project or its various phases. Processes are described in terms of:

- Inputs (documents, plans, designs, etc.)

- Tools and Techniques (mechanisms applied to inputs)

- Outputs (documents, plans, designs, etc.)

Project management knowledge is arranged on ten areas:

Integration

Manage the other knowledge areas, coordinate and control possible changes. It produces the following documents: Opening Term Performance Data Work, Change Requests, Work Performance Reports and Registration of Changes.

Scope

Defines the coverage, the verification and the control level. The scope management has processes that address:

Planning the project management; Collecting Requirements; Defining the scope; Creating the Work Breakdown Structure (WBS); Validate the scope; Controlling the scope.

Time

Planning and managing the schedule, defining activities, sequencing activities, estimating resources activities and the duration of activities, developing and controlling the schedule. It produces the following documents: List of activities, activity attributes, list of milestones, project schedule network diagrams, resource requirements of the activities, resource breakdown structure, estimated duration of activities, project schedule, schedule data, project calendar and schedule forecast.

Cost

Plan costs, estimate costs, determine budget and control costs. Produces the following documents: Estimates of the costs of activities, bases the estimates, financial resource requirements of the project and anticipated costs.

Quality

Deal with quality management plan, perform quality assurance and quality control. It produces the following documents: Quality Metrics, quality checklists and quality control measurements.

Procurement

Management of purchases, perform acquisitions, manage acquisitions and close acquisitions. It produces the following documents: Specification of the work of procurement, procurement documents, criteria for selecting resources and proposals of suppliers and agreements.

Human resources

Planning and managing human resources, mobilizing staff, developing the staff and managing the project team. Produces the following document: Project staff assignments.

Communications

Communications management plan, manage communications, communications distribution and control communications.

Risk management

Management of risks, identifying risks, conducting a qualitative risk assessment, performing quantitative risk analysis, planning responses to the risks and controlling risks. Produces the following document: Risk registers.

Stakeholder management

Identify stakeholders, plan the stakeholder management, manage stakeholder engagement and control stakeholder engagement. It produces the following documents: Stakeholder register and registration issues. Stakeholders should be involved throughout the entire project life cycle, and their expectations and needs taken into account.

The relationship between these factors is such that if any of them change, at least one other factor is likely to be affected. For example, if the schedule is reduced, probably the budget needs to be changed to include additional features in order to realize the same amount of work in less time.

If you cannot increase the budget, scope or quality may be reduced to deliver a product in less time with the same budget. The project stakeholders may have differing ideas as to which factors are the most important, creating an even greater challenge.

Changing the project requirements may create additional risks. The project team should be able to assess the situation and balance the demands in order to deliver a successful project.

Because of the potential for change, the project management plan is iterative and goes through progressive elaboration throughout the project life cycle. Progressive elaboration involves continuously improving and detailing a plan as more detailed and specific information and more accurate estimates become available. That is, as the project evolves, the management team can manage a higher level of detail.

All management is concerned with these, of course, but project management brings a unique focus shaped by the goals, resources and schedule of each project.

Six Sigma

Six Sigma is a set of practices originally developed by Motorola to systematically improve processes by eliminating defects. A defect is defined as nonconformity of a product or service to your specifications. Six Sigma is also defined as a management strategy to promote change in organizations, making it reaches improvements in projects, processes, products and services for customer satisfaction. Basically it is a method that provides organizations tools to improve the capability of their business processes. This increase in performance and decrease in process variation lead to defect reduction and improvement in profits, employee morale, and quality of products or services. (http://asq.org/learn-about-quality/six-sigma/overview/overview.html) Unlike other forms of management of productive or administrative proceedings Six Sigma's priority is to obtain results in a planned and clear way seeking better quality and also financial gains.

The methods applied to Six Sigma are not unique to it, but are common business practices originally developed in other methods and attached to existing tools in the quality movement. Some of the most common sets of tools of Six Sigma are borrowed both from statistical process, as from project management. The Six Sigma approach uses statistical analysis to measure and improve the performance of production in organizations.

Six Sigma projects follow two methodologies inspired by the Plan-Do-Check-Act cycle of Walter A. Shewhart (widely broadcast by W. Edwards Deming, the post-war Japan). These methodologies, composed of five phases each, are called by the acronyms DMAIC and DMADV.

- DMAIC is used for projects focused on improving existing business processes.

- DMADV is used for projects focused on creating new designs of products and processes.

DMAIC

DMAIC is a data-driven quality strategy used to improve processes. It is an integral part of a Six Sigma initiative, but in general can be implemented as a standalone quality improvement procedure or as part of other process improvement initiatives such as lean.

The five phases that make up the process:

- Define the problem, improvement activity, opportunity for improvement, the project goals, and customer (internal and external) requirements.

- Measure process performance.

- Analyze the process to determine root causes of variation, poor performance (defects).

- Improve process performance by addressing and eliminating the root causes.

- Control the improved process and future process performance.

DMADV

DMADV is used when you want to set up/design a whole new process, that should be meeting the desired level of performance from the beginning. DMADV may also be used when there is a need to redesign an existing product or process, rather than constantly correcting the process. The soul of DMADV is in understanding the customer’s requirements

- Define the project goals and customer (internal and external) deliverables

- Measure and determine customer needs and specifications

- Analyze the process options to meet the customer needs

- Design (detailed) the process to meet the customer needs

- Verify the design performance and ability to meet customer needs

Considerations

Integrating Six Sigma techniques with the project management methodologies is the way to go for companies focusing on continuous improvement.

The DMAIC methodology in Six Sigma (Define, Measure, Analyze, Improve, Control) provides a structured approach to solving business issues. The tools used in Six Sigma are meant to identify the root causes for process defects so that the company can provide to the customers consistent quality products on time and at low cost. The project management tools and techniques emphasis the project attributes such as development, control, completion etc.

Though the Six Sigma methodology is effective when it comes to troubleshooting or for improving the current processes in existence using the DMAIC method, there are some issues to be considered. If Six Sigma alone is used for project management then controlling the project processes can be difficult. This is because the DMAIC approach is for controlling process improvements and not for controlling the project management process.

Combing the process control facet of project management with the troubleshooting factor of Six Sigma would ensure that the organization can create a process troubleshooting system that is consistent, controlled and most importantly predictable. One can integrate these two very strong methods at the beginning of the project life cycle itself while planning. Utilizing the Six Sigma techniques for problem definition would reduce the chance for errors in assessment.

The Six Sigma tools for problem measurement can be utilized in the validation phase in the project management. Incorporating budgeting, scheduling and resource management into the life cycle will ensure that the management is in a better position to make informed decisions. Utilizing these Six Sigma tools throughout all the phases of the project would incorporate effective troubleshooting and efficient processes into the project management methodology. The project management in turn would help in monitoring and tracking the project progress, thus adding to the control element to the project.

Hence as companies are striving to improve their processes, while reducing costs and bringing to the market newer products which add to the profit, the integration of Six Sigma with project management is inevitable. This integration would help in cost reduction, enhancing process efficiency, rapid implementation and faster product development cycles

Conclusion

Six Sigma can complement and extends PMBOK Project Management Process, but does not replace it. Both disciplines help each other and make important contributions to successful business outcomes.