Fault Tree Analysis in Projects

(→Boolean algebra) |

(→Boolean algebra) |

||

| Line 63: | Line 63: | ||

:<math>Q=(A+B+C)+(D\bullet E)+F</math> | :<math>Q=(A+B+C)+(D\bullet E)+F</math> | ||

| − | If the probabilities of the base events are known, it is then possible to calculate the probability for the top event, ''Q'', to occur. Based on the equation from Boolean algebra, it is possible to find the different paths that can occur in the fault tree for the top event to occur. These different paths are referred to as '''cut sets'''.<ref> | + | If the probabilities of the base events are known, it is then possible to calculate the probability for the top event, ''Q'', to occur. Based on the equation from Boolean algebra, it is possible to find the different paths that can occur in the fault tree for the top event to occur. These different paths are referred to as '''cut sets'''.<ref>''http://www.weibull.com/hotwire/issue63/relbasics63.htm'' ''weibull.com - Reliability Engineering Resource Website''</ref> For instance if base event ''A'' occurs, then the top event will be triggered. The same goes for base events ''B'', ''C'', and ''F''. However failure on base event ''D'' does not trigger the top event due to the AND gate, therefore a possible cut set with base event ''D'' would be ''DE'' as it requires base event ''E'' to occur as well. It is especially interesting in the case of a fault tree analysis to look at '''minimal cut sets''', which are defined as the minimal amount of combinations of the base events that can cause the failure of the top event.<ref>''http://www.weibull.com/hotwire/issue63/relbasics63.htm'' ''weibull.com - Reliability Engineering Resource Website''</ref> |

==Application== | ==Application== | ||

Revision as of 15:50, 16 September 2016

Fault tree analysis (FTA) is defined by the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) as a "technique for identifying and analysing factors that can contribute to a specified undesired event".[citation]

FTA has its wide range of application in many fields of engineering such as systems engineering, reliability engineering, and safety engineering. It also serves as an applicable tool for identifying the causes of undesired events in projects.[citation] Undesired events in projects can for instance be exceeding the budget, time delays, lack of team synergy, or any other events that have a negative effect on the project. This is referred to as the top event.

The purpose of FTA is to give both a qualitative and quantitative analysis of the factors that can trigger the undesired top event. A qualitative analysis shows via a graphical representation of a tree the top event that is to be analysed, along with the pathway of all the intermediate and basic events that leads up to the top event. A quantitative analysis shows the probability of a top event being triggered by the input probabilities of the basic events that leads up to the undesired event. The quantitative analysis is calculated through Boolean algebra.[citation]

Contents |

History

Methodology

FTA is based on the analysis of a top event. This is an event that is believed to be of great importance to the project or an event which has not been given enough attention. A top event needs to be defined as a failure, as it is an undesired event that is to be avoided. Examples of such events can be the delayal of the project if time is considered a constraint. Other projects may be funded by a tight budget where it is crucial to stay within the budget's limits, therefore a top event could be failure to meet the expected budget. Only one top event can be chosen for each fault tree, however it is often recommended to develop several fault trees[citation] each with their different top events if the project is of a large scale or if several top events are of great importance, such as the safety in a powerplant.

Once a top event has been chosen, the causal factors for said event needs to be identified. Figure 1 is a representation of a basic fault tree with "Exceeded budget limits" as the top event. Beneath it all the causal factors located, that may trigger the top event. The graphical illustration of the fault tree consists of symbols with the intended purpose of clarifying the different relations between the different causal factors.

Symbols

Boolean algebra

Boolean algebra can be used for a quantitative analysis of a fault tree. By using Boolean algebra, it is possible to calculate the probability of different events, as well as the top event to occur. Figure 2 is the same fault tree as the previous fault tree in Figure 1, and all of the base events have been assigned a letter to identify them, with the assumption that the events governmental regulations and penalties are also base events. The top event is furthermore assigned the letter Q. For the quantitative analysis only the base events are of interest because they are the lowest causal factors, therefore the intermediate causal factors are of no importance to the analysis and are left blank.

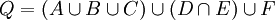

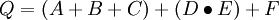

OR gates denote a sum because the base events do not depend on each other while AND gates denote a product because the base events depend on each other. The algebraic representation of the fault tree thus becomes:

Which can be rewritten as:

If the probabilities of the base events are known, it is then possible to calculate the probability for the top event, Q, to occur. Based on the equation from Boolean algebra, it is possible to find the different paths that can occur in the fault tree for the top event to occur. These different paths are referred to as cut sets.[1] For instance if base event A occurs, then the top event will be triggered. The same goes for base events B, C, and F. However failure on base event D does not trigger the top event due to the AND gate, therefore a possible cut set with base event D would be DE as it requires base event E to occur as well. It is especially interesting in the case of a fault tree analysis to look at minimal cut sets, which are defined as the minimal amount of combinations of the base events that can cause the failure of the top event.[2]

Application

minimal cut sets

Example

Strengths and weaknesses

Limitations

See also

Further reading

Annotated bibliography

- ↑ http://www.weibull.com/hotwire/issue63/relbasics63.htm weibull.com - Reliability Engineering Resource Website

- ↑ http://www.weibull.com/hotwire/issue63/relbasics63.htm weibull.com - Reliability Engineering Resource Website