Earned Value Management (EVM) in construction projects

Thorgeir11 (Talk | contribs) |

Thorgeir11 (Talk | contribs) |

||

| Line 292: | Line 292: | ||

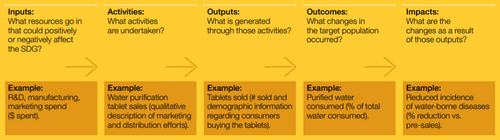

[[File:2.png|500px|thumb|right|'''Figure 1:''' Tasks.]] | [[File:2.png|500px|thumb|right|'''Figure 1:''' Tasks.]] | ||

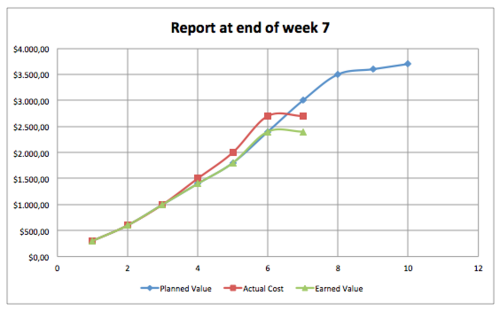

| − | [[File:3a.png|500px|thumb|right|'''Figure 2:''' | + | [[File:3a.png|500px|thumb|right|'''Figure 2:''' Report at week 7.]] |

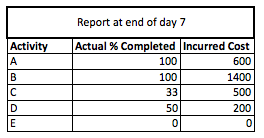

His report at the end of week 7 can be seen in table A. | His report at the end of week 7 can be seen in table A. | ||

| Line 314: | Line 314: | ||

| 100% | | 100% | ||

| 50% | | 50% | ||

| + | |||

| + | |} | ||

| + | |||

| + | {| class="wikitable" style="text-align:left;" | ||

| + | |+ style="caption-side:bottom; "|'''Table A:''' Task completion at week 7. | ||

| + | |- style="vertical-align:top;" | ||

| + | ! Report at end of week 7 | ||

| + | |- | ||

| + | |- style="vertical-align:top;" | ||

| + | |''' Activity ''' | ||

| + | |''' Actual % completed ''' | ||

| + | |''' Incurred cost ''' | ||

| + | |||

| + | |- | ||

| + | |- style="vertical-align:top;" | ||

| + | | '''A''' | ||

| + | |100 | ||

| + | |600 | ||

| + | |||

| + | |- | ||

| + | |- style="vertical-align:top;" | ||

| + | | '''B''' | ||

| + | |100 | ||

| + | |1400 | ||

| + | |||

| + | |- | ||

| + | |- style="vertical-align:top;" | ||

| + | | '''C''' | ||

| + | |33 | ||

| + | |500 | ||

| + | |||

| + | |- | ||

| + | |- style="vertical-align:top;" | ||

| + | | '''D''' | ||

| + | |50 | ||

| + | |200 | ||

| + | |||

| + | |- | ||

| + | |- style="vertical-align:top;" | ||

| + | | '''E''' | ||

| + | | | ||

| + | | | ||

|} | |} | ||

Revision as of 12:45, 24 September 2016

Earned Value Management(EVM) is a well-known technique used in Project Managment to control the cost and time performance of a project and is also used to predict the final project cost and duration. [1]

Contents |

History

The Us federal government introduced Earned Value management(EVM) in 1967 as a part of the cost/schedule control systems criteria (C/SCSC) to understand the financial aspects of programs and to be used in acquisition programs of large degree in an attempt to generate a consistent method based on best practices. Earned Value management and methods that vary from EVM to a small degree have been used under handful of names, including earned value project management, earned value analysis, earned value method, cost/schedule summary reporting, Earned Value Management Systems(EVMSC), and the current 32 guidlines in the EIA-748 Standard for Earned Value Management Systems(EVMS) [2]

Concept overview

Earned Value management is a systematic process that is used to measure the performance of a project at different times throughout the life cycle of a project. EVM is useful to help project managers or people in general that are responsible for a project to determine whether a project is on schedule, or if the project is over or under budget. EVM can also be used to compare the actual work that has been performed to the work that was estimated and planned for the project at a certain time during the project, EVM can also be used to forecast projected performance. EVM is a technique that can be applied, to at least some degree, to the management of projects in any industry and using any contracting approach. [1]

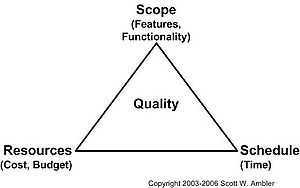

EVM measures project progress and performance by the integrated management of three fundamental elements of project management, cost, schedule and scope which make up the Project Management Triangle as can be seen in figure 1.

In most cases in practice, the progress of an project is evaluated by comparing it against earned value indices and estimates against historically values, past projects or according to numerous criteria

To sum up the objectives of Earned Value Management:

- To relate time phased budgets to exact contract task or/and statement of work.

- To provide the necessary basis to capture the work progress assessment against the pre-planed baseline plan

- To relate schedule, technical and cost performance

- To provide the necessary timely, valid and auditable information so it can be used for the proactive project management analysis and the corresponding action

- To provide the managers with a practical level of summarization to able effective decision making

Implementation of the method

Steps to EVM

In this sector there will be an simplification of the steps that need to be taken in EVM, this is done since each of the step is quite comprehensive and each and every one could be an article on its own.

step 1-5 is before the project starts

Step 1. Building the foundation for the project - this step is about deconstructing the project Statement of Work(SOW) into more discrete, measurable components to develop the Work Breakdown Structure(WBS) and the tasks/activities that are essential to execute the work.

Step 2. Determine the resources and effort required to execute the work. This is an estimation, and it can provide useful for the company to use previous projects that have been similar to make the estimations.

Step 3. Make up a Resource leaded schedule of the time that it is expected to take executing the work.

Step 4. Define a methodology to measure activity/task completion that suits the project (EV methods).

Step 5. This steps is about pricing the resources and efforts that are expected to be used during the project, this is done to make a project budget (Budgeted Cost of Work Scheduled or Planned value).

step 6-10 is after the project has begun

Step 6. Now the project has begun and in this step the actual cost(AC) of work performed by period is collected against the WBS below the level required for reporting.

Step 7. Using which ever methodology created in step 4, calculation are made to determine the completion percentage of an activity/task

Step 8. In this step Earned Value(EV) or Budgeted Cost of work is calculated. That is achieved by multiplying the completion percentage of the task/activity against the total budget for that task/activity

Step 9. In this step Schedule Variance(SV) is calculated. that is achieved by subtracting the Planned value from the Earned value(EV)

Step 10. Calculate the Cost Performance Index, which is often referred to as the cost efficiency of a project in order to calculate the Estimate at completion(EAC) which is the new projected estimated total cost at project completion given the information at time calculated.

Terminology

Key Parameters

The first three parameters are considered the three dimensions of earned value: Planned Value, Earned Value and Actual Cost. Both Planned Value and Actual Cost dimensions will apply to nearly all construction projects. The only dimension that is sometimes unknown is Earned Value in construction, especially on lump-sum or fixed price jobs. [4]

| Parameter | Description |

|---|---|

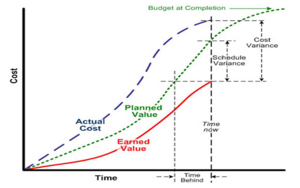

| Planned Value (PV) | Is a budget baseline that has been established for a project/work package/activity. It is a function of cost and time as can be seen in figure 2. PV baseline can be used to view the value to be earned at a certain time/phase in the project. PV is frequently referred to as the S curve simply because of the shape of the curve. |

| Actual Cost (AC) | Is the cumulative actual cost that has been spent on a project/work package/activity. |

| Earned value (EV) | is the cumulative value that has been earned for the work completed at a certain point in time.

Formula: Earned value(EV)=total budget for activity*completed proportion |

| Budget at completion (BAC) | BAC is the final point and the highest value of the cumulative Planned value curve. BAC represents the total budget for the project/work package/activity.

|

Measuring project performance

The following variances and indices are used in EVM to measure the performance of a project at any given time.

| Earned Value Variances | Description | Formula | Result |

|---|---|---|---|

| Cost Variance (CV) | The difference between the amount budgeted and the amount that was actually spent on the work performed. CV shows whether and by how much amount the project is over or under pre-approved budget. | = Earned Value (EV) - Actual Cost (AC) | > 0 means under budget

< 0 means over budget |

| Schedule Variance (SV) | The difference between the amount budgeted and the amount that was planned for the project. SV is a good indicator to show if and by how much your work is behind or ahead of pre-approved schedule. | = Earned Value (EV) - Planned Value (PV) | > 0 means ahead of schedule

< 0 means behind schedule |

| Earned Value Indices | Description | Formula | Result |

|---|---|---|---|

| Cost Performance Index (CPI) | The ratio of approved budget for work performed(EV) to what was actually spent on the work(AC). CPI reflect the relative value of the work that has been completed to the amount paid for the task. CPI is often reffered to as the Cost efficiency of a project.

Additional note According to Fleming and Koppelman CPI is one of the two most useful EVM metrics, the reason for that is according to a study of 155 actual contracts showed that at the 20% point of project completion , the final projected results from CPI would only change by +/- 10%. This proves that CPI is an excellent to accurately determine requirements for final performance, in order to meet financial goals. [5] |

= EV/AC | > 1 means better progress for the money spent

< 1 means less progress for the money spent |

| Schedule Performance Index (SPI) | The ratio of approved budget for work performed to the actual approved budget for work performed(EV) to what was budgeted for the project(PV). SPI is useful since it reviels if the project is behind or ahead of schedule. | = EV/PV | > 1 means more work performed than had been scheduled

< 1 means less work performed than had been scheduled |

| Project Percent Complete | Percent of project work complete at a given time.

Remember BAC = Budget at Completion |

= (EV/BAC) * 100 | |

| To Complete Performance Index (TCPI) | The cost performance index required to complete the project on the predetermined budget or the required future cost efficiency that is needed to achieve the target Budget at completion(BAC). | =(BAC-EV)/(BAC-AC) |

Forecasting measures

To make a forecast of the future state of an project an simplified assumption is made: the cost performance(CPI) and the Schedule Performance(SPI) are assumed to be a representative indicator for the actual future performance of the project.

| Earned Value Forecast | Description | Formula |

|---|---|---|

| Estimate at completion (EAC) | The estimated total cost at project completion. The formula for EAC is based on the assumption that the current performance gives a fair indication of future performance | = BAC/CPI |

| Variance at completion (VAC) | The estimated variance between actual total cost(EAC) and planned total cost(BAC) at project completion. | = BAC-EAC

|

EVM Graph

The parameters above can be seen in a visual representation in figure 2. It can be useful to have the numbers translated into something visual for a more simple understanding of the status of the ongoing project. Most of the necessary information can be found in the graph and visually it can be seen in the figure that:

- the Actual Cost(AC) of the project is above the predetermined Planned Value(PV) that had been established.

- The Earned Value(EV) of work completed is lower than the Planned Value

- By comparing the gaps between the Actual Cost and Earned value the Cost Variance of the project can be found. According to this figure the project is above the pre-approved budget

- By comparing the gaps between the Planned Value and Earned value the Schedule Variance of the project can be found. According to this figure the project is behind schedule

Example

In this section there will be an short simplified example of EVM in a project that has five tasks A,B,C,D,E. Figure 1. Step 1 For each of the tasks the duration has been estimated, the cost of each task per week and finally the total cost of each task. These cost are called Planned value(PV) in EVM. In more detailed examples and projects a Statement of Work(SOW) can be very useful if used in the right ways.

| Task | Predecessor | Duration(Weeks) | Cost/Week | Total Cost |

|---|---|---|---|---|

| A | 2 | 300 | 600 | |

| B | A | 3 | 400 | 1200 |

| C | B | 3 | 400 | 1200 |

| D | B | 2 | 200 | 400 |

| E | D | 3 | 100 | 300 |

| 3700 |

To keep track of the status of each of the projects a Gantt Chart has proven to be very useful since it provides much needed clarity, helps with coordination and last but not least time management, helping teams understand the overall impact of project delays which is an vital part of the EVM method. In this Gantt chart there can be seen the planned schedule and the actual performance of the project up until week 7 when the project manager decided to take a closer look at the progression of the project.

His report at the end of week 7 can be seen in table A. Using the data from that table to fill up the Gantt Chart. According to the report and from the Gantt Chart it can be concluded that task C and D are behind schedule.

| Task | Planned completion | Actual completion |

|---|---|---|

| C | 66% | 33% |

| D | 100% | 50% |

| Report at end of week 7 | ||

|---|---|---|

| Activity | Actual % completed | Incurred cost |

| A | 100 | 600 |

| B | 100 | 1400 |

| C | 33 | 500 |

| D | 50 | 200 |

| E |

Now it is time from the project manager to analyze the situation and take a closer look at the Earned Value Variances(, Earned Value Indices and Earned Value Forecast

The project manager made some calculations which can be seen in table 3.

| Task | Schedule Variance (SV) | Cost Variance(CV) | Schedule Performance Index(SPI) | Cost Performance Index(CPI) |

|---|---|---|---|---|

| A | Exactly on schedule | Exactly On budget | Exact amount of work performed that has been scheduled | Exact amount of progress for the money spent |

| B | Exactly on schedule | Over budget | Exact amount of work performed that has been scheduled | Less progress for the money spent |

| C | Behind on schedule | Over budget | 50% of work performed that has been scheduled | Less progress for the money spent |

| D | Behind on schedule | Exactly on budget | 50% of work performed that has been scheduled | Exact amount of progress for the money spent |

| E | - | - | - | - |

Advantages

The use of EVM to make progress payments on construction projects.

When undergoing a project there is often a risk that the owner of the project is going to overpay their suppliers for the work they completed. This is due to the fact that Cost-type arrangements have inherent risk for the sake of the owners focusing on the expense paid and forgetting to closely monitor the actual work done for the money spent. One way of mitigating this risk is to accurately measure the value of work completed, compare that against the original budget authorized for the completed work, and only pay for actual work completed. There are two broad contractual environments in the building industry, Cost type and fixed price

Cost type

Cost type is often used in construction projects to cover the initial design work and both the first and final design. In project that are high risk, f.x. nuclear energy construction the cost type contract is sometimes used for all of the phases of the project.

Cost reimbursable type arrangement works in the following manner: the supplier will be refunded each month for the actual cost(AC) during the project, which is subjected to the terms of their agreement, meaning that all costs (excluding fee) are submitted by the supplier/contractor to the owner, who pays the bill. Because of this arrangements there can be a substantial difference between the physical work done and the dollars being spent on the project. Quentin W. Fleming and Joel M. Koppelman provide four recommendations to reduce the risk for cost type contracts

1. Project owners should order the supplier/constructor to provide a "schedule of values" which is time-phased, and the sum of all items will be listed up to the total contract value. This time-phased schedule provides the owner a valuable and simple form of "planned value(PV)" which can be used to measure the performance of the project through its life cycle

2. At the end of each month, when the supplier/contractor provide their invoice that reflect the Actual cost(AC) incurred, order the contractor to update their schedule of values, which is the Earned value(EV) of the project. This gives the owner a tool to monitor the earned value against the planned value and the earned value minus the actual cost to get the cost variance of the project

3. It can be useful to monitor the performance of both the cumulative Cost Performance index(CPI) and the Schedule Performance Index(SPI) to compare the results of one project to all other projects with similar circumstances in the company.

4. Forecast the likely final cost at regular intervals with the Estimate at completion (EAC) method to ensure that the project is on budget, and if it is not make the necessary adjustment to stay on track

Fixed price

In most Fixed price contracts suppliers/contractors are given progress payments based on the amount of work completed, along with the authorized budget for the completed work. This method is highly useful with the Earned Value Management method. Effective method to establish an earned value baseline could be to require the supplier/contractor to make a critical path method(CPM) , with the necessary resources integrated into the CPM model, and the sum of these resources must sum to 100% of the contract value. Actual costs(AC) related to the earned value are oft missing in the fixed price work. If there is no AC then we lack the ability to make up the Cost performance index(CPI), which is one of the most important indicator in the EVM method. Suppliers/contractors who accept a fixed price job are likely to be reluctant to disclose how much profit they are making on the job, actual cost to earned value. The profit that the contractor is set to make should not be concern to the project owner, it's only when the contractor starts to incur a loss, especially a large loss that the project owner could get concerned. This is due to the fact that a loss increased the likelihood that the supplier is unable to complete the job. To mitigate the risk to the owners Quentin W. Fleming and Joel M. Koppelman provide two recommendations

1. Condition all fixed price suppliers to hand over their anticipated costs that have incurred, to match with their planned value(PV) projections contained with either previously mentioned time-phased schedule of values, or their CPM resource loaded model. These costs incurred forecasts usually resemble the "S" shaped curve . Unless there are justifying reasons there forecast should resamble the "S" curve, else the projections may be "front-loaded", or the project owner might be paying for work that has not been completed

2. To minimize the financial risk of the project, there could be a good thing to condition the supplier to have their chief financial officer(CFO) to validate each month that they have not exceeded their planned value of cost incurred. On the other hand if the supplier has exceeded their planned value , require them to reveal the amount of their actual cost incurred, so it is possible to compare it to the earned value and be able to quickly determine how much loss the contractor has suffered.

10 Benefits of EVM

Davis S. Christensen enlisted the 10 benefits of EVM in the article The costs and benefits of the earned value management process

1. It is a single management control system that providing reliable data

- Even though the criteria does not require an external report, managing with one system while reporting from another one is not effective neither efficient. The concept of the criteria encourages companies to use their own internal management control system, given that the these systems meet the management standards that are described by the criteria.

2. Integration of schedule, work and cost using WBS

- One requirement of the criteria is that all the authorized work and the related resources are well defined and integrated using a project-oriented work breakdown schedule(WBS)

3. Database of criteria-compliant projects useful for comparative analysis

- Due to the consistent reporting of criteria-compliant projects for over 30 years, there is a database useful for comparative analysis. Analysts have used this information in the database to create important insights for managers and relative people.

4. Cumulative Cost performance Index(CPI), early warning signal

- CPI has been shown to stabilize to within +/- 10% by the 20 percent completion part for most defense acquisition contracts. In most cases the cumulative CPI only worsens. This along with other indicators suggest that cot management must take place early to be effective.

5. Schedule Performance Index, early warning signal(SPI)

- SPI is useful to identifying schedule problems, notably when used with Critical Path information. Schedule problems are frequently resolved by increased spending, an adverse SPI is also foretelling of later cost problems. The criteria suggests that all work should be scheduled and traceable from the master program level down to the detailed levels.

6. Cost Performance Index(CPI), predictor for final cost of a project

- CPI is also useful to determine a fair lower limit for the estimated final cost of a project. A lower band can provide to be useful for planning and control purposes. The criteria recommends regular evaluation of the estimate.

7. Index-based method to predict final cost of a project

- There are evidence that show when the SPI and CPI are combined to estimate a reliable upper bound to the Estimate at Completion(EAC). When combined with the CPI based lower bound, then a "most likely" range of EAC is determined. If the contractor's EAC is outside this calculate range, then there may be a problem with the estimation of the contractor.

8. To-Complete performance index to assess the forecasted final cost

- TCPI is useful to evaluate the reasonableness of the contractor's EAC or other financial goals. TCPI is the ratio of remaining work to the remaining budget. This can help managers to evaluate the reasonableness of critical financial goals within the project, e.g. completing the remaining work within the predefined budget.

9. Periodic Cost Performance Index as a benchmark

- While cumulative performance indices are effective for predicting trends at summarly levels in the Work Breakdown Schedule, CPI's at regular intervals are useful for cost performance trends at the more detailed levels of the WBS

10. Management by expectation principle can result in reduced information overload

- By leading the managment attention to only the most urgent problems, the chance of information overload can be reduced.

Limitations

There are several limitations when it comes to applying earned value management... Here below is a compilation of limitations from different perspectives

Is the plan correct

EVM was never meant to be a stand-alone tool. But rather, it should be applied with other schedules and reports to understand where your project time line and budget stands. Moreover, if the initial plan is inaccurate, then the tracking of the project will never match the plan. This becomes wearying task since then it becomes necessary not only to adjust the planned project, but also the actual plan needs to be adjusted.

Convoying the information Understanding of the Earned value management is often beyond most of the stakeholders. Formulas and terminology are unfamiliar to those who are not using the application daily. That is way it is necessary to convoy the information to stakeholders and team members in the most straight forward manner. This can be achieved by using charts e.g. the S-shaped curve and not going into to much detail regarding exact formulas.

Mismatched opinions and quality control If a project team is used to Earned Value Management there can often occur debates on the best mathematical formulas that should be used in the tracking of the projects process, also there could be different view on what to track.

http://www.brighthubpm.com/monitoring-projects/10056-how-earned-value-management-is-limited/

Annotated Bibliography

Kwak, Y. H., & Anbari, F. T. (2012). History, practices, and future of earned value management in government: Perspectives from NASA. Project Management Journal, 43(1) [2] This article goes over the historical background of earned value management, from the origin of the concept and how it has evolved over time. This article describes shortly why to use EVM and the main attributes of the methodology behind it.

Strategic Consulting Solutions inc. (2012). 10 Steps to Understanding Earned Value Management [3] This article provides a useful simplified 10 steps to understand and use earned value management. This article is useful to demonstrate how earned value management works without over complicating it with highly technical terms

Earned Value Management. (n.d.) [4] This page gives a great overview of the calculations behind earned value management. The page covers the variances of earned value: Cost variance(CV) and schedule variances(SV), provides the formula for these variances along with what the results of these equations would suggest about the progress of the project. Earned value indices are also covered in the same manner, formula and interpretation of the result. Formulas used for the forecasting process of earned value management. Finally the page displays a graph of earned value metrics as a function of cost and time. Actual cost, planned value and earned value are plotted using data from the project.

http://edward-designer.com/web/pmp-earned-value-questions-explanined/ </ref>

Fleming, Q. W., & Koppelman, J. M. (2002). Using earned value management. Cost Engineering (Morgantown, West Virginia), 44(9), 32–36. [7] Fleming and koppelman,

http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.196.3738&rep=rep1&type=pdf

S. Christensen, D. (2011). THE COSTS AND BENEFITS OF THE EARNED VALUE MANAGEMENT PROCESS. doi:10.1.1.196.3738

References

- ↑ 1.0 1.1 1.2 1.3

- ↑ 2.0 2.1 Kwak, Y. H., & Anbari, F. T. (2012). History, practices, and future of earned value management in government: Perspectives from NASA. Project Management Journal, 43(1), 77–90. doi:10.1002/pmj.20272

- ↑ 3.0 3.1 Strategic Consulting Solutions inc. (2012). 10 Steps to Understanding Earned Value Management

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 Earned Value Management. (n.d.). Retrieved September 16, 2016, from http://www.chambers.com.au/glossary/earned_value_management.php

- ↑ 5.0 5.1 Fleming, Quentin and Joel Koppelman. The Two Most Useful Earned Value Metrics: The CPI And The TCPI. 1st ed. Primavera systems, inc, 2008. Web. 14 Sept. 2016.

- ↑ 6.0 6.1 E. (2015, February 20). Earned value analysis worked example. Retrieved September 23, 2016, from https://www.youtube.com/watch?v=z7b3SYQuqJM

- ↑ 7.0 7.1 Fleming, Q. W., & Koppelman, J. M. (2002). Using earned value management. Cost Engineering (Morgantown, West Virginia), 44(9), 32–36.

- ↑ 8.0 8.1 S. Christensen, D. (2011). THE COSTS AND BENEFITS OF THE EARNED VALUE MANAGEMENT PROCESS. doi:10.1.1.196.3738

Further reading

THE USE OF EARNED VALUE ANALYSIS (EVA) IN THE COST MANAGEMENT OF CONSTRUCTION PROJECTS

CRITICAL ANALYSIS ON EARNED VALUE MANAGEMENT (EVM) TECHNIQUE IN BUILDING CONSTRUCTION

file:///C:/Users/Lib1/Downloads/Candido%20et%20al.%20%202014%20-%20Critical%20Analysis%20on%20Earned%20Value%20Management%20(EVM)%20Technique%20in%20Building%20Construction%20.pdf

The two most useful earned value metrics: the CPI and the TCPI

http://tem-sw.com/library/Fleming-Koppelman-EVM-paper.pdf