Value Stream Analysis and Mapping for Project Management

(→History behind VSA/M) |

|||

| Line 10: | Line 10: | ||

==History behind VSA/M== | ==History behind VSA/M== | ||

| − | Lean theory originated at Toyota Motors Corporation. In order to understand its origins we must look back into the early 40s. By then, Toyota was trying to compete with the American automobile market by productivity means. Taiichi Ohno in 1956 traveled to the US in order to visit the automobile plants and see how could he improve its production system back in Japan. Despite what he saw on those production plants, what catches his attention is the self-service supermarkets in which he could choose exactly what he wanted and how much of it. That idea was efficient as well as timely saver for him and where to become later the fundamentals for pursuing manufacturing improvements. | + | Lean theory originated at <span class="plainlinks">[https://en.wikipedia.org/wiki/Toyota Toyota Motors Corporation]</span>. In order to understand its origins we must look back into the early 40s. By then, Toyota was trying to compete with the American automobile market by productivity means. <span class="plainlinks">[https://en.wikipedia.org/wiki/Taiichi_Ohno Taiichi Ohno]</span> in 1956 traveled to the US in order to visit the automobile plants and see how could he improve its production system back in Japan. Despite what he saw on those production plants, what catches his attention is the self-service supermarkets in which he could choose exactly what he wanted and how much of it. That idea was efficient as well as timely saver for him and where to become later the fundamentals for pursuing manufacturing improvements. |

Along the next years Ohno will develop this production system on a systematic framework based on Lean and Just-In-Time principles. | Along the next years Ohno will develop this production system on a systematic framework based on Lean and Just-In-Time principles. | ||

Toyota defined six elementary rules<ref name="WCM2"> http://world-class-manufacturing.com/Kanban/kanban.html</ref>: | Toyota defined six elementary rules<ref name="WCM2"> http://world-class-manufacturing.com/Kanban/kanban.html</ref>: | ||

Revision as of 12:55, 26 September 2016

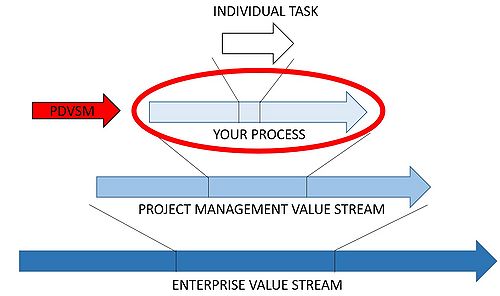

This article intends to provide a tool for Project Managers who would like to improve their own processes by applying lean concepts. In particular, throughout Value Stream Analysis and Mapping (VSA/M). VSA/M is a tool for business process improvement.[2] The tool, focuses on the development of tasks which add value to the final product, efficiently linking them together to form a continuous flow stream of value.[2] It is meant to map the project processes “as whole “, find its wastes, inefficiencies and non-value-added actions that can be erased in order to achieve a “future state”. Giving insights into the plausible “ideal future state” that it seeks to improve the overall value stream.

Since this tool has a Lean background, there will be a brief introduction regarding this matter. Then, the concept of VSA/M will be depicted between two environments, under manufacturing processes and project management processes. Followed by the set of activities which must be performed in order to improve the overall value of stream.

Contents |

History behind VSA/M

Lean theory originated at Toyota Motors Corporation. In order to understand its origins we must look back into the early 40s. By then, Toyota was trying to compete with the American automobile market by productivity means. Taiichi Ohno in 1956 traveled to the US in order to visit the automobile plants and see how could he improve its production system back in Japan. Despite what he saw on those production plants, what catches his attention is the self-service supermarkets in which he could choose exactly what he wanted and how much of it. That idea was efficient as well as timely saver for him and where to become later the fundamentals for pursuing manufacturing improvements. Along the next years Ohno will develop this production system on a systematic framework based on Lean and Just-In-Time principles. Toyota defined six elementary rules[3]:

- Never send defective products downstream to the next process

- Each process only orders what it currently needs from the upstream process

- Each process only produces the quantity ordered by the downstream process

- Maintain a level rate of production

- Use Kanban to fine-tune the rate of production

- Work to reach a stable rate of production

These advancements mainly focused on the manufacturing aspect of business would afterwards be developed to shop floor and non-shop floor activities.

These first studies where focused mainly on manufacturing processes in spite of project management. But as menctioned, the principles can still be applied either to shop floor and non-shop floor activities. And as Womack and Jones describe it, the main principles of lean for product development are[4][5]:

- Value: providing the customer with the right product, for the right price, at the right time.

- Value Stream: the set of actions that bring a product from concept to realization, order to delivery, or raw material to finished good

- Flow: seamless movement through value-creating steps.

- Pull: acting only to satisfy customer needs, rather than forcing, or pushing, a product upon the marketplace.

- Perfection: continuously and relentlessly improving the value, value stream, flow, and pull in business operations.

Two contexts, one methodology

The value stream must be analyzed and mapped thoroughly to reduce waste along processes and enable a more efficient flow. Also to move the processes towards a more rapid response for customer pull. For instance, in product development context, this means rapid response towards customer needs. Specially when it comes either to new products or permutations of the existing ones.[2]

On a manufacturing environment

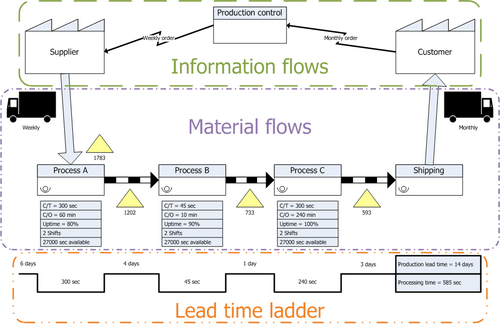

Fundamentally, the method consists on mapping the current state of the production system and apply lean techniques. In general terms, as depictured on Figure 2, the mapping of the production system is represented by three main points:

- Information flow

- Material flow

- Lead time ladder

Within the developed VSM, non-value-added tasks are identified. These activities only meant to support the value-added tasks are considered ( Type I waste ). While completely unnecessary tasks are considered ( Type II waste ) such as waiting materials in inventory.

Then a set of techniques are applied to create a future state vision where all these wastes are minimized in order to create a more efficient flow of value.[5]

On a Project Management environment

According to the product development team at MIT's Lean Aerospace Initiative[2], the value on a succesful project management is "a capability delivered at the right time, for the right price, as defined by the end user." Now, this value stream is effectively emboided on a notional designed package. Therefore, as the outcome of a value stream it can be evaluated as a stream of value, like in the manufacturing value of stream. This way fitting with other activities around the business cycle to define an overall desired future state.

In order to extrapolate the VSM under manufacturing principles to a Project Management environment, how does the flow thorough the project management processes translates into? In this case it is information. Information flows thorough the management of the project like on the manufacturing environment material does.[2] The quality of the information flow is characterized by its Form, Fit, Function and Timelines (FFFT). However, value not only comes as a function of the FFFT within the design package, it also comes as the degree the design package allows the end product to match the desires of the customer.

Since the flows are made of information instead of physical materials. As information flow thoroughout the project processes, tasks add value to the information.

In the end, as under the environment of manufacturing, Project Management processes are mapped. Then, analyzed as to pursue a desired future state.

Application

In order to build a value stream map in a coherent way, there are three main steps[1]:

- Arrange the process steps (tasks) and information flows.

- Follow the work: To uncover the true value stream, trap yourself to the product.

- Collect the information yourself: Try to walk the process, talk to participants, have them send you examples of documents or information regarding what they produce and handle.

- Exploit existing process information resources, cautiously: It is needed to understand the process personally but if someone helped collecting reliable data, use it.

- Map "in pencil": Make process maps easy, low-investment, adaptable and simple formats.

- Map the whole value stream: Have everyone work on the entire value stream and do not partition it right away. The goal is a holistic picture.

- Collect performance data on the tasks, sometimes information flows as well.

- Concentrate on what you need: If the problem is quality, look for errors and try to correlate them with their root cause.

- Exploit what you can find: Sometimes the data is not the primary purpose of the document, instead it may be usefull dates on reports as a record for cycle time.

- Make do with what you have: The data may be imperfect but if the data leads to the critical problem, it is usefull.

- Be honest: Make data reliable by putting asside possible biases.

- Dig deep (only) when you must: Only when analyzing critical problems and looking for solutions do further work collecting enough data.

- Evaluate how value is created.

- In detailed maps, specifically on lower level maps, non-value-added tasks may appear. Non-value-added activities may be hifing inside of value-added tasks, so try to add more detail to your map. Although this can lead to an unefficient way to find them, it is a good way to begin with. For deeper understanding about how to evaluate value refer to the related articles.

Some tools which are useful but were not intended for Value Stream Mapping will be described friefly[2].

- Gantt Chart[7]: A traditional method for displaying sequence, schedule and dependency between tasks.

- Process flow map[8]:Process maps to highlight waste and areas of improvement.

- Learning to see: Most proven tool for lean base VSA/M. Refer to related articles for more information.

- Design structure matrix (DSM)[9]: A well developed method for analyzing the sequences of, and information flows between, the tasks in a process.

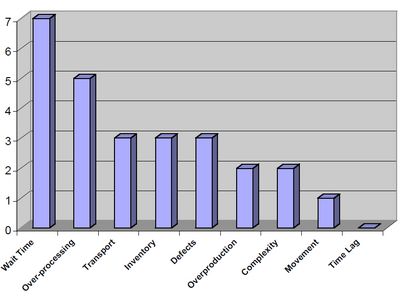

Once the current state maps is complete, it is time to proceed identifying waste. This is the part when there is a vision of " the big picture " and everything is set to improve it. Since this tool comes form manufacturing principles, a re-interpretation of the main wastes has been performed. In manufacturing environments, the flow translates into physical materials while in project management it is information flowing instead. The seven info-wastes include:

- Waiting: Late delivery of information; Delivery too early (leads to rework)

- Inventory: Lack of control; Too much in information; Complicated retrieval; Outdated, obsolete information

- Over-Processing: Unnecessary serial production; Excessive/custom formatting; Too many iterations

- Over-Production: Creation of unnecessary data and information; Information over-dissemination; Pushing, not pulling, data

- Transportation: Information incompatibility; Software incompatibility; Communications failure; Security issues

- Unnecessary Movement: Lack of direct access; “Walking” the process

- Defective Products: Haste; Lack of reviews, tests, verifications; Lack of interpretation (raw data delivered when information or knowledge needed)

The next table describes with examples each one of the seven info-wastes since it is very important to understand them in order to find them on the state map. As shown in Figure 3, from a survey carried out to 25 asking for a single example of waste in product development. The results show which ones are more likely to happen.[1]:

| Types of Information Waste | Examples | Causes |

|---|---|---|

| Waiting

Idle time due to unavailable information |

- People waiting for information |

|

| - Information waiting for people |

| |

| Inventory

Information that is unused or is “work in progress” |

- Too much information |

|

| - Multiple/redundant sources |

| |

| - Outdated/obsolete information |

| |

| - “Just-in-case” information |

| |

| Excessive Processing

Information processing beyond requirements |

- Excessive/custom formatting |

|

| - Numerous, fragmented reports |

| |

| - Unnecessary serial processing |

| |

| - Excessive approvals for information release |

| |

| Over Production

Producing, distributing more information than needed |

- Unnecessary detail and accuracy |

design |

| - Pushing, not pulling data, information |

| |

| - Over-dissemination |

participant’s needs

rather than to meet specific needs | |

| Transportation

Unnecessary movement of information between people, organizations, or systems |

- Information handled by multiple people before arriving at user |

|

| - Information hunting |

| |

| - Data re-formatting or reentry |

| |

| - Switching computers (e.g., CAD to PC) to access information |

| |

| Unnecessary Motion

Unnecessary human movement (physical or user movement between tools or system) |

- Walking to information, retrieving printed materials |

|

| - Excessive keyboard, mouse operations |

| |

| - Poor physical arrangement or organization |

| |

| Defects

Erroneous data, information, reports |

- Errors in data reporting/entries |

|

| - Errors in information provided to customers |

| |

| - Information does not make sense to user |

|

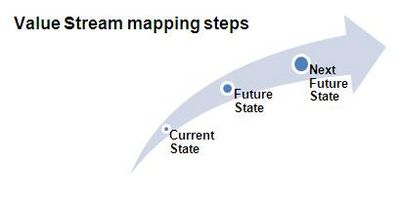

Finding a future state

After having removed as much as possible wastes. Redraw a well-documented value stream map, it is time to move towards improvement as symbolized on Figure 4. Some improvements might be seen rather visually easely while others might require some study.

The next points should help improve further on the current state:

- Minimized formatting: Reformat information only to serve the needs of tasks in a cost-effective manner.

- Visible and explicit information flows: Information hunting should be minimized as much as possible. Expectations regarding who is going to provide the information, to whom and inw hat format should be stated beforehand. Information should be easy to handle, for example physical job folders.

- Assuring availability of inromation: During the development of the project, one of the most common wastes is waiting due to lack of information. This leads to spend time trying to hunt information. Making information available is a challenge which lean solutions can help to amiliorate. Best practices include:

- Practice Information 6 sigma: Information should be stored following the six sigma principles. Information should be stored on a simple way, easy to find systematically.

- Collocate an Integrated Project Teams: Proximity greatle increases flow from an organizational or physical point of view.

- Make information visual: Walls for instance constantly updatd where information is available at a glance.

- Make information flow physically: By placing all key information pertaining a job in a folder.

- Pull, don’t push, information: Information must flow when needed.

- "Balancing the line":Using the analogy of how the physical objects flow along the line on a manufacturing environment helps to understand how information should flow. For instance, sometimes if an external approval is required to proceed and it is not forthcoming, the task will have to wait. Or where bottlenecks can mean a saturation of parts on a highly utilized machine on a line. In project management, piled up work can produce the same effect.To minimize this kind of waiting and improve the flow along the project, the following are a must:

- Eliminate bottlenecks: If there are tasks which take more time to do or have less resources available, re-allocate work load amongs the staff.

- Assure the timely availability of resources: Deadlines amongst tasks should be kept in order to create availability.

- Minimize and buffer variation: Variability should be fought for instance by making sure there are no equippement failures which lead to the delay of processes.

- Clear external constraints: External caused delays are varied but thorough techniques such as the "five why's" it is possible to find the root of the delay.

These techniques must be used as much as required in order to improve the overall value stream and meet the goals specified by the key stakeholders.

Advantages

Value Stream Mapping though, can be a tool which facilitates the transformation from a traditional manufacturing company to a Lean Enterprise. It is a planning tool to target ideal processes and roadmaps to desired improvements.[11]

Limitations

In comparison, VSA/M applied to Project Management might create some confusion for those who come from VSM in manufacturing environments. Due to the nature of information, flows are not made of physical objects and therefore it is not so visual.

Related Articles

The lessons from Toyota for product development had been captured by Fujimoto and Clark[12] and Ward and Sobek.[13][2] Follow the references for further study.

Most of the VSM work that has been acomplished is around the manufacturing context. For practical implementation of VSA/M on manufacturing operations please refer to .[14]

Understanding how to break the Product Development process down into stages:[15]

Extensive understanding about how to proceed with Evaluation of Value: [16]

Rother and Shook's Learning to See a factory floor mapping which can be extrapolated to Product Development activities:[17]

Lean Six Sigma, This book links lean and six-sigma concepts. Although it is a powerful tool for factory operations, it can be extrapolated to Project management as well.[18]

Key references

- ↑ 1.0 1.1 1.2 1.3 http://dspace.mit.edu/bitstream/handle/1721.1/81908/PDVSM_V.1_2005.pdf?sequence=1

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 http://dspace.mit.edu/bitstream/handle/1721.1/7333/Value%20Stream%20Analysis%20and%20Mapping.pdf?sequence=1

- ↑ http://world-class-manufacturing.com/Kanban/kanban.html

- ↑ http://www.lean.org/Bookstore/ProductDetails.cfm?SelectedProductId=160

- ↑ 5.0 5.1 http://web.mit.edu/esd.83/www/notebook/WomackJones.PDF

- ↑ http://www.wikiwand.com/en/Value_stream_mapping

- ↑ http://apppm.man.dtu.dk/index.php/Gantt_Charts_as_a_Tool_for_Project_Management

- ↑ https://en.wikipedia.org/wiki/Flowchart

- ↑ https://en.wikipedia.org/wiki/Design_structure_matrix

- ↑ http://www.mbaskool.com/business-concepts/operations-logistics-supply-chain-terms/7409-value-stream.html

- ↑ http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.201.6852&rep=rep1&type=pdf

- ↑ https://books.google.fr/books?id=7cCAASTW6IQC&hl=es

- ↑ https://books.google.dk/books/about/Principles_that_Shape_Product_Developmen.html?id=ZbYGtwAACAAJ&redir_esc=y

- ↑ https://www.amazon.es/Learning-See-Eliminate-Enterprise-Institute/dp/0966784308

- ↑ https://www.amazon.com/Product-Design-Development-Karl-Ulrich/dp/0070658110

- ↑ http://dspace.mit.edu/bitstream/handle/1721.1/81908/PDVSM_V.1_2005.pdf?sequence=1

- ↑ https://www.amazon.com/Learning-See-Stream-Mapping-Eliminate/dp/0966784308

- ↑ https://www.amazon.com/Lean-Six-Sigma-Combining-Production/dp/0071385215