Lean Design Management

| Line 156: | Line 156: | ||

The case showed a very positive implementation of Lean Design, where the value definition led to specific changes in the project. The project, based on the evaluations, was very successful and ended within time and budget. The study notes that there are certain communication and psychological barriers at the workshop that challenges the process. <ref name="Emmit"> | The case showed a very positive implementation of Lean Design, where the value definition led to specific changes in the project. The project, based on the evaluations, was very successful and ended within time and budget. The study notes that there are certain communication and psychological barriers at the workshop that challenges the process. <ref name="Emmit"> | ||

| + | </ref> | ||

= References = | = References = | ||

<references /> | <references /> | ||

Revision as of 18:11, 26 September 2016

Lean Design Management focuses on the Project Purpose. The project purpose deals with "why" the project is being undertaken, and the project purpose should therefore define the outcome of the project. [1] Lean design management works to define the the values of the project, and through collaboration incorporate these values into the project.

Lean design management provides a set of specific management tools for the design phase, mainly focused on construction projects. The philosophy behind Lean Design management is derived from Lean Construction, that focuses on two main values: Minimizing waste, and creating work flow. Lean Design however has a broader focus, with the emphasis on translating values and visions to a concrete project, securing maximum value for clients and providing a realistic and constructable solution for contractors. [2]

Lean Design management uses workshops as a basis for the cooperation, both for the value creation and the value delivery. The number and types of workshops can change with the project it is applied to, but this article presents 7 different types of workshops:

• Cooperation

• Vision

• Realism

• Critics

• Design phase

• Constructability

• Execution.

Contents |

Background

Lean Design utilizes some the ideas from Lean Construction in the design process. Lean construction originates from the Toyota production line, where Toyota developed the Toyota Production System (TPS), a production system to optimize the car-production line at Toyota. The main values of Lean Production are to minimize waste and maximize value.

The developer of Lean production, Shingo S. defined waste as anything that did not create value for the customer/client, thus optimizing the production by making it Lean.The minimization of waste and maximization of value are also the underlying values for Lean Construction, where the tools from Toyota are used to optimize the processes that make up the “production” in construction.

[3]

In Lean design these values are also present, with the addition of the value definition. The value definition is established through a series of workshops gathering different sets of stakeholders in workshops, where they collaborate to establish a common set of project values, and with collaboration with all stakeholders, transform these values into a concrete buildable project, that will provide most value for the client within the budget.

Theory

The term Lean in relation to production(and later construction) originates from from the book: “The machine that changed the world” by Womack, Jonés and Roos. This book presented the Japanese way of producing cars, and how it differed from the American and European way. This book started a Lean wave through production, and soon thereafter “Application of the New Production Plilosophy to Construction” by Lauri Koskela introduced Lean to Construction.

From the litterature, the core values of both Lean Production and construction are:

• Determine the value chain that creates value for the client

• Optimize this Value Chain

• Keep the product moving – Storage is waste.

• Use Pull-logistics

• Aim for continuous improvement

These values were implemented into the Toyota Production system (TPS). The focus of TPS is not only to have the know-how to produce products, but also have the know-why. The production is oriented towards creating value, and this is the goal of the production. All that does not work for this goal is then defined as waste, as described by Shigeo Schingo. In Lean Construction this perspective on waste is also present. Lean Construction takes some of the philosophy from the TPS to the construction industry, and implies a production perspective. In this perspective, Lean Construction provides a range of different tools to minimize waste and create value with a focus on flow in the processes. These tools include the successful Last Planner system.

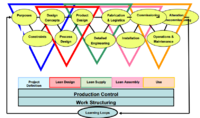

With the successful implementation of Lean in construction, Lean was also applied to the design phase, creating the whole Lean Project Delivery system, as seen on the figure. In the figure, all the phases of a project from the definition to use are showed. Lean design Management as described in this article works with the: Project definition and Lean Design. After these phases, the construction begins, and Lean Construction can be applied.

Where Lean Construction in the construction phase creates value from a set of predefined constraints (drawings, models, material etc.), Lean design focuses on the definition of value and how to improve the client value. To create the best possible end value for the users, the client value must be optimized, regardless of the construction phase.

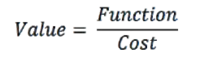

To optimize the client value in a project, firstly the client must identify what values are in the end product, the project purpose. This is not easy to define, as the value changes with perspective, time and a range of other parameters.Different definitions of value exist in litterature, as described in (Thyssen et al, 2008). One of the simplest definitions is seen in figure. This definion underlines the importance of the project purpose. The function of an ended project can be defined as the degree of which the project fulfills the project purpose, and this divided by cost returns the value.

The definition of project value

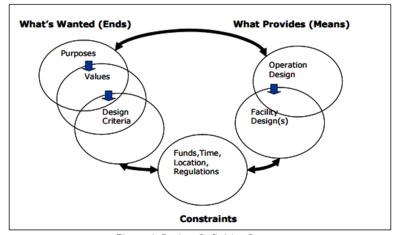

To maximize the value of a project, firstly the values have to be defined. Lean design management approaches the value definition through collaboration between the stakeholders and the client. The approach can be formulated through an analogi: [4] If you go to a realtor and ask for an apartment in a popular part of town, you have set up a constraint that the realtor can follow, and easily provide an answer to. But what if the price is too costly? – If the client instead engages in a discussion with the realtor, the client can explain the purpose(Ends) that needs be fulfilled – 2 bedrooms, near water etc. This enables the realtor, as an expert, to find the best suited apartment for the client, that maximizes the value for the client purpose.

The same implies for a construction project. For the AEC (Architects, Engineers and Contractors) to develop the best project to suit the clients purpose(ends), the AEC needs to first understand the purpose. This will enable the AEC to construct a project suited with the expertise of the three fields to maximize the value.

G. Ballard describes this as the project definition process, which consists of three parts, which are seen in the figureThe Ends: why is the project being constructed, and what is the purpose.

The Means: How is this project constructed. From the Ends, the AEC outlines how to deliver a project to maximize client value

The Constraints: Funds, times location. The frame that the given project must fall under, and the frame in which to optimize value.

To optimize the Ends, the AEC and client needs to evaluate the means and constrains against the Ends throughout the project definition a design phase. This can ideally be done through a workshopmodel, with several project, value and partnering workshops in the early phase of a project.

These workshops are divided into two types: Value creation and value delivery. [5]

In the Value Creation, the project values are created – This is also called value management (Emmit, 2016). In this phase, the goal is to: “discuss, explore, challenge disagree and eventually agree on commonly shared project values”. The values decided upon are then written down by the team in priority,

After the value creation, the value delivery phase begins – This is also described as value engineering, where values are defined into a specific project and the project is delivered. The value engineering is carried out to optimize the product against the given values, with minimum waste, which is in line with the core values of Lean.

The workshops works as a forum to help understanding the different perspectives the stakeholders have on the given values, and discuss how different solutions will fulfill these values. The workshops works as “value generators” – and later “value drivers”.

To ensure the effect of the Lean design, it is suggested that a process facilitator is pointed out. The role of the process facilitator is to engage discussion, identify potential issues between the stakeholders and ensure that these are resolved through discussion. It is important that the process facilitator remains objective through the whole process, ideally the process facilitator is external to the project.

If the participants in the workshops have a negative attitude, this is resolved by the process facilitator, with discussion. If the problems persist, and the participant is unwilling to engage in the discussions, they must be asked to leave the process and be replaced by others.

These workshops, and a suggested implementation method is described in the Implementation chapter

Implementation of Lean Design Management

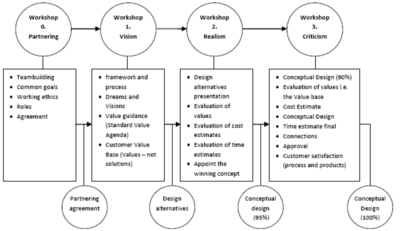

The implementation of Lean Design can vary in different forms, but the forms all imply workshops as a tool for the collaboration process. Emmit et al, 2005 created the creative workshop model, as seen on the figure. The creative workshop model consists of 4 workshops: Partnering, Vision, Realism and Criticism. These workshops focus on the value creation, and ends with a conceptual design. This method was tried by Thyssen and Emmit between 2005 and 2007 in a construction project, and the results of are presented in the chapter: Industry implementation and results

The implementation of Lean design presented In this article follows a 7-workshop approach, developed by Lean Construction-DK. This approach is similar to the approach by Thyssen and Emmit, but adds workshops beyond the project definition phase, to ensure that the client value set in the workshops follows into the design and construction phase.

The different workshops run from the very beginning of the project, to the end of the design process, with varying stakeholders present. The workshops provided here are just examples of a Lean Design process, as the complexity and size of different projects might require different worhshop setups.

In the very early phase of a project, the client has to step forward and define a set of demands and values, that has to be put into the finished project. As the client might not always have a strong organization with building experience, it is important to invite engineers and contractors in, and develop the project together.

Vital to all workshops is, that the people collaborating will be the people later directly involved in the project. If the contractor participates in the early workshops with a manager, and this manager is not assigned to the project later, the assigned manager will not have the same insight in the client and engineer values, and the workshop gains will be lost.

Workshop zero: Cooperation

The goal of this workshop is to establish a collaboration contract between the client, the engineers and the contractor. This workshop is not project oriented, but serves to create a foundation for the collaboration in the project. The cooperation contract is typically a partnering contract.

Who: Client, Engineers, Contractors, (end users).

When: As early as possible

Workshop 1: Vision

Workshop one focuses on product values. In this workshop, the end users and client defines and conveys their desired values, visions, needs and dreams to the architect, engineers and contractors. This gives an understanding of exactly which vision the whole project is working towards for all stakeholders in the process. In this process the budget is not yet discussed, and the emphasis is on the needs and values, and not what the client can afford.

Who: Client, End users, Engineers, contractors. '

When: Early in the process. Before any project sketches/propositions.

Workshop 2: Realism

In this workshop, the vision from the previous workshop in concretized. The vision and dream is evaluated against the budget and framework. The goal of this workshop is to maintain the values from the vision, and create the best realistic project within budget. As the dreams and wishes are not always realistic, it is important in this stage to prioritize wishes, and establish how the budget is distributed. It is important to continuously discuss and provide alternative solutions, in order to secure the best project. After the second workshop a project proposal is devoped by the engineers

Who: Client, engineers and end users, but the contractor can also provide important criticism on the buildability.

When: Before the engineering design begins.

Workshop 3: Criticism

In this workshop the project proposal is evaluated, and the necessary decisions to narrow the project down to a workable project for the engineers are taken. It is vital that the decisions taken by the client are done as a discussion with the engineers, in order to secure the best solutions. In the end of the workshop, the project proposal and all decisions are weighted against the vision from workshop 1, and it is evaluated if the priorities of the project are aligned with the vision, if this have not changed in the mean time.

Who: Client and engineers

When: Before the design phase enters a high detail phase

Workshop 4: Design Phase

This workshop the focus changes from defining and prioritizing, to planning the design phase. Planning the design phase involves mapping interfaces, and process planning the different phases and tasks. In this workshop it is also determined how to “pull” the contractor experience for the design phase, to secure a buildable project.

Who: Engineers, Client and contractor.

When: In the beginning of the detailed design phase

Workshop 5: Buildability

This workshop focuses on discussing the design solutions. The contractor has gone through the design solutions, and evaluated if the solutions are buildable. The contractor has brought alternative solutions, and through a discussion with the engineers, the best solution for the project is chosen.

Who: The engineers and the contractor.

When: During the detailed design phase, before the final project.

Workshop 6: Execution

Just before the beginning of construction, the engineers go through the designed project with the contractor. This can be combined with the contractors process planning, to step by step go through the phases of the project.

Who: The contractors and the engineers.

When: Just before construction begins.

Industry implementation and results

As Lean Design management is a relatively new management concept, it has yet to widely implemented in the construction sector. However, several experiments has been carried out in Denmark, and some contractors have implemented Lean Design with their own alterations. This chapter will present the findings of 2 experiments with Lean Design.

Cite error: Invalid <ref> tag;

refs with no content must have a name

Gefionparken

The first experiment presented is Gefionparken, where Lean Design was implemented in the Design phase. The project Gefionparken consists of 90 dwellings, with the Frederikssund Municipality as a client. The design phase was monitored by an external partner from SBI, and the implementation was evaluated through questionnaires, which the participants filled out after every workshop/meeting, followed by an end evaluation.

The focus in this experiment was only on the delivery of value and optimization, and not the definition of value. The client asked not to be involved in the process at all, and only wanted to see the finished design project. The Lean design implemented excluded the three first workshops described in implementation chapter, but the initiation workshop was included. It was remarked the workshop created a solid foundation for the successful collaboration.

The conclusions from the project showed exceptional teamwork throughout the design phase. In all disagreements the situations were handled professionally. Especially a worklist tool was underlined as good tool for the design. The project was evaluated against a defined set of criteria in the questionnaires on a scale of 1-10, where 10 is set as an optimal project. The results from the project showed that the project was evaluated very close to an optimal project and almost all parameters, especially on the “mutual professional respect” and “the participants motivation”.

Throughout the project there were only few negative reactions in the questionnaires, but these were not further described in the paper. [6]

Case Study

A case study with Lean Design is presented by Thyssen et. Al, which also took place in Denmark. The case study is a construction project with 42 apartments, covering an area of 3600 m2. The project was set in the Copenhagen area, with a board of residents combined with Copenhagen municipality as client. The end users were set to be elderly people in need of care and families with a disabled child. The whole process was observed, and results were recorded through non participant observation. The process with Lean Design was evaluated through questionnaires, where the process was evaluated on a scale from 1-10 against a defined set of criteria.

In this case, Lean design was tried with value definition phase and the value delivery phase. The end users were included in workshops, where the older users and families with disabled children presented their needs and wished for the apartments, resulting in larger bathroom anf bedroom spaces and improved ventilation system, which was done within budget. There were further wishes from the end users for improvement which could not be fulfilled within the budget, but the design allowed for adaptability for those wishes, so they could be fulfilled in the future.

The project results scored very high in the evaluation, with a 9.0 average with a variance of 0,85. This score indicates great satisfaction with the process. It was remarked that the client had been very enthusiastic about the project, and was able/willing to make decisions with the other stakeholders at the workshops.

Criticism about the process was also recorded in the project. It was noted that there were several complaints about the amount of time set for the workshops. The Architects were not happy with making changes throughout the workshop, and the stakeholders seemed focused on discussing solutions rather than value.

The case showed a very positive implementation of Lean Design, where the value definition led to specific changes in the project. The project, based on the evaluations, was very successful and ended within time and budget. The study notes that there are certain communication and psychological barriers at the workshop that challenges the process. [7]

References

- ↑ Geraldi et al (2016) :” How to DO projects. DTU

- ↑ 'Bertelsen et al. (2010) :” Guide til bedre projekter med Lean Construction. Lean Construction-Dk

- ↑ Bertelsen et al. (2012) :” Håndbog I Trimmet Byggeri. Foreningen for Lean Construction-DK

- ↑ 'Ballard, Glenn (2008) :” The Lean Project Delivery System: An Update. The Lean Construction Journal

- ↑ Emmit, Stephen (2010) : Managing Interdisciplinary projects. Taylor and Francis

- ↑ Larsen et al (2005) : Evaluering af forsøg med trimmet projektering og trimmet byggeri. Statens byggeforskningsinstitut

- ↑