Project Control

Konstantinos (Talk | contribs) |

Konstantinos (Talk | contribs) |

||

| Line 6: | Line 6: | ||

[[File:No0.jpg|thumb|left|upright=3.0|alt=A framework of Project Control]] | [[File:No0.jpg|thumb|left|upright=3.0|alt=A framework of Project Control]] | ||

| − | [[File:No7.jpg|thumb|Right|upright=3.0|alt= | + | [[File:No7.jpg|thumb|Right|upright=3.0|alt=The 5 phases of a project in respect of time and level of activity]] |

Revision as of 10:23, 2 October 2017

Abstract

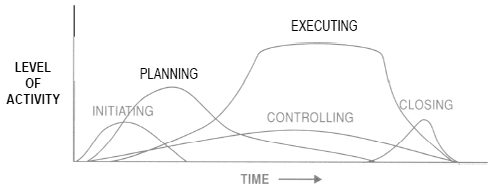

The project is a temporary one-time undertaking, that has a definable goal, interrelated and dependent activities tasks and is finite in duration. In some point, all the projects are unique, they provide a unique product, service or information. Every project operates under some constrains such as time, cost and quality. Every Project has 5 basic phases according to PMI [1]. Initiation, Planning, Execution, Monitoring and Control and Close of the Project. In this article, the Project Monitoring and Control will be examined. The goal of project control is detecting potential problems or opportunities during project execution, by measuring the deviations from the baseline schedule. The project managers will compare project status and continue to the actual plan, as resources perform the scheduled work. In addition, during Project Control, project managers may have to adjust schedules or do what is needed to keep the project on track. In case of having differences between that execution and the planning phase, this does not mean necessarily the project plan needs to be changed, however these differences should be reviewed and determined if any action is necessary. Project control is considered very important because it may determine the success of the project by the stakeholders. Project success is relevant to project cost, completion date, customer expectations, performance, quality, etc.

The Role of Project Controller

According to PMI the definition of the project management is “the application of knowledge, skills, tools and techniques to a broad range of activities in order to meet the requirements of a particular project." The process of directing and controlling a project from start to finish may be further divided into 5 basic phases:

- Conception and Initiation

- Definition & Planning

- Launch or Execution

- Monitor & Control

- Project Close

The project control, is the 4th phase “Monitor & Control”. Even if the word “control” gives the impression that the project control is only involving the 4th phase of a project, the reality Is different. The Project Control team involves from the initiation stage until the closeout of the project in order to ensure a successful control of the project. Project controllers are involvement from the initiation stage is due to the fact that is the one who will make an estimation of the overall budget as well as the delivery schedule of the project. As soon as the the planning of the project starts, the Project Controller helps with the planning of the cost and the schedule. In addition, the Project Controls team has a significant involvement throughout the entire project lifecycle. Even though Project Controller seems to be very similar to Project Manager, actually there are t differences between those two. For example one of the biggest challenges of a Project Manager is to create a harmony between the four main constrains in a project “Scope, Cost, Time, Quality”. Project controller helps the Project Manager in the management of the time and the cost of the project.

Cost Management and Cost Control

Cost management is a part of the project control and involves not only managing the budget, but also planning, and preparing for potential risks. Risks can set projects back and sometimes even require unexpected expenses. Preparation for these setbacks can save time and money. Cost management involves overall planning, co-ordination, and control and reporting of all cost-related aspects from “project initiation” to “operation and maintenance”.

The Cost Control, regardless of the size of the company is equally important. However, smaller companies tend to have tighter monetary controls, mainly due to the risk of failure. Larger companies may have the luxury to spread project losses over several projects, but the small companies may have few projects. Cost control is not only "monitoring" of costs and recording huge amount of data, but also analyzing of the data in order to take corrective action before it is too late.

The Cost Controllers may use the following methods/functions for more efficient work:

- Use cost management software for more precise and reliable estimations

- Making Monthly KPI (key performance indicators) reporting

- Ensure alignment with scheduling (current budget hours used)

- Monitoring the project progress, manpower and productivity by discipline

- Ensure alignment with scheduling (use working hours according to the plan)

- Coordinate with Contractor’s project controls team to ensure accuracy and timeliness of contractor’s project controls deliverables.

- Time Management

An accurate time estimation is essential for a successful project completion. Reasons of right time management is that the time estimates and drive the deadlines of delivery and planning of the project. If the time estimation will not be accurate enough, then will impact another people’s assessment of reliability of the company. Moreover, the time estimation many times determines the pricing of contracts, if there will be delays in the project delivery may be a financial penalty from the customer (depending on the contract).

- Some of the tactics that project controllers use for time managements are:

- Create baseline schedules

- Provide input to the project progress report

- Create schedule ‘what-if scenarios’ for strategic planning by project management

- Assist with notification of schedules delay to clients

- Create progress measurement graphs (S-Curves) to track the current status of the project

Studies have been conducted by Sabeghi et al. in order to determine the right timing of project control throughout a project. In this case an adapted version of the facility location model (FLM) was developed so the optimal timing of project control in a project life cycle can be found. In addition simulation model were conducted so the best possible disruptions in the time period between the start of the project and the first control point. The study concludes that the FLM is flexible enough to find the timing of control points using weight functions that define the important sections of any project. Moreover, the performance of this method was compared with another approaches by Raz and Erel that also utilize an analytical method to find the right timing of control points. The results showed that this model had better timing of the control points. That gives as a result that the disrupted project was completed with less delays.

How to understand when project controller is needed?

According to (Meredith and Mantel, 2006), there are three main indicators, “Performance”, “Time”, “Cost”. The primitive indicators are:

- More resources or less resources haven been used than planned

- Activities are taking long than planned

- Cost of activity (or of project to date) is higher than expected

They called primitive because they may be biased and it is not consider that progress may be overestimated or underestimated due to execution of unscheduled work done, or execution of more work of low value and less work of high value

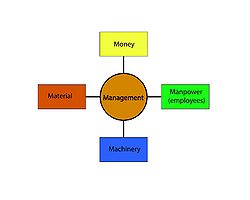

Resources and Elements of project Control

The 4M management method is a key method in this case and is the use of management engineering methods. 4M is the ISO quality management system in one of the elements. The 4 M’s stands for:

- Money

- Machinery

- Manpower

- Materials

The Manpower or “Human Resources Control” is responsible for hiring staff with needed skills as well as assign staff with specific skills to specific activities, but also to lay-off any underperforming staff. However, any move should be examined carefully before will be implemented.

The Machinery or “Physical Asset Control” is about decommissioning any underperforming equipment and instead bring in equipment with appropriate capabilities. In both of the cases any equipment decision may involve economic analysis and extra cost.

The Money or “Financial Resource Control” is about determine the amount of money that should be spent and how/where should be spent, in this case the Project Manager is assisted by Project Accountant and Project Finance Manager.

Regarding Materials new sources of superior Materials should be seek.

Desired characteristics of a project control mechanism

Project control should fulfil some desire characteristics such as:

- Flexible: it should be able to react to changes in system performance

- Cost-effective: Value of PC should exceed cost of project control

- Useful: Must really satisfy the needs of project, not the whims of the PM

- Timely: Be able to react quickly before the problem overwhelms the project

- Simple: Easy to understand and operate

- Adjustable: Capable of being adjusted to reflect changing priorities

- Documented: so that training in the future to be possible

Key Performance Indicators in Project Control

Project managers will use key performance indicators (KPIs) to determine if the project is on track. A PM will typically pick two to five of these KPIs to measure project performance:

- Project Objectives: Be aware if a project is on schedule and budget is an indication if the project will meet stakeholder objectives.

- Effort and Cost Tracking: The Project Manager will explore for the effort and cost of resources to see if the budget is on track. This type of tracking informs if a #project will meet its completion date based on current performance.

- Project Performance: This monitors changes in the project. It takes into consideration the amount and types of issues that arise and how quickly they are addressed.

These can occur from unforeseen hurdles and scope changes.

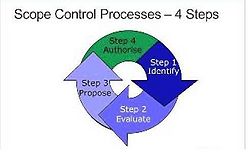

Scope Control

Scope control is a method that is used as a part of control project. The reason of implementing Scope Control process is to recognize and manage all the elements that will possible rise or lower the project scope more than the required or defined wish of the initial approved Project Scope Statement. Two are characteristics of scope control. First, the determination of the scope when changes have implemented and second the management of the changes that have been implemented. Scope Control is considered very important occurrence that is possible to change every phase of the project life cycle. This changes may come for the need in a change deliverable that may affect its functionality, but also the amount of resources and work that is demanded for the completion of the project.

- Scope Control System

Due to the fact that any scope change in a project will desire extra funds, time and resources, an agreement of all the stakeholders of the project should be prepared to discuss every possible change and impact that may occur to the project. When a final decision will be agreed for increasing or reducing the scope, the changes should be signed and documented as a matter of formal scope control. In addition, the changes should be authorized by all members of the committee.

The impact of the scope change will be recognized during the Planning Phase process and documents like Work Breakdown Structure and Project Schedule. This document will need to be re-examined and updated so they will include this time the scope change impact. The PM should communicate clearly and effectively about the scope changes, to the project team. So, the project team will be able to realize how the scope will impact their roles in the project.

- Schedule control

The Schedule control usually is managed by the PM. However, it is crucial the customer to be informed that a schedule change has or will be happened. In addition, the customer should be aware of what is being implemented to resolve the problem and the potential impact on the project performance, time line and deliverable. The schedule issues may occur from many reasons, but it must be a single and focused method for dealing with the schedule changes. When the problem is discovered, is should be investigated as soon as possible. Subsequently, a plan mast be created for correcting the problem in the shortest allowable time but also with the smaller impact. Cost consideration may be also taken into account.

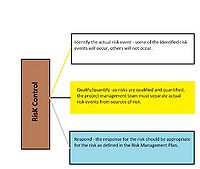

Risk Control

The execution of the Risk Management Plan is by big percentage consisted by risk Control. Risk control is an action that implemented for managing and monitoring expected and unexpected changes in a Project. It is important to understand that risk controlling is intended to be a daily, on-going process throughout the entire project lifecycle. Project team members and stakeholders should be encouraged to be aware in looking for risk symptoms, as well as for new project risks. Newly identified risks and symptoms of previously identified risks should be communicated immediately for evaluation and/or action. When changes that include risks occur the following 3 phases are implemented:

- Identification

- Qualify / Quantify

- Respond

The correct identification of risks is essential for the success of a project. An effective tool that is used for risk identification and control is the technique called “Workarounds”. According to [PMI Workarounds] the workarounds are responses to any unidentified risks that occur throughout the project execution. Workarounds are unplanned in the sense that the response was not defined in advance of the risk event occurring. When the risk event was not expected or the effect was greater that it was predicted the planned response may not be satisfactory. If this happens, it is required to repeat the response process and the risk quantification process, but also more risk response may be necessary.

Quality Control

Quality control is the application of the principles of manufacturing quality control to a project processes, including defect prevention, inspection, and reporting of quality issues. The quality control is performed by the Quality Engineering (QE) involves the control of specific project results to determine if they satisfy relevant quality standards and identifying how to exclude causes of unsatisfactory results. The quality control should be performed throughout the project. The project results include both product results like deliverables and management results like cost and schedule performance. Every project must have a QE in order to work with the PM and develop a Quality Management Plan. In addition the plan should be particularly for that project using agency quality instructions with input from the customer and other stakeholders. The project management team should have knowledge and experience in statistical quality control (sampling and probabilities) so they can help to evaluate quality control outputs. The Project management team should be aware for important things such as, tolerances and control limits as well as unusual events and common causes.

Annotated Bibliography

- Harvey Maylor ”Project management”, Fourth Edition-Financial Times Prentice Hall (2009)

This book is designed to provide to its readers an integrated view of Project Management. It explanes all the phases of a project and it uses new techniques that have been already implemented by some best-practise companies to improve their project management performance. As an example, it shows how the disciplines used by Toyota and Dr. Deming approaches can be used in any kind of project and industry. Moreover, practical case-studies and academic discussions are included in the end of each chapter.

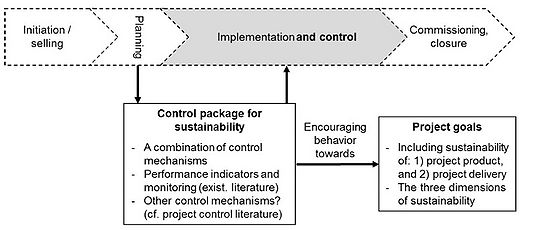

- Jesse Kivilä, Miia Martinsuo, Lauri Vuorinen “Sustainable project management through project control in infrastructure projects” International Journal of Project management 35 (2017) 1167–1183

The article of Kivilä et al. shows a qualitative study that was conducted on a large infrastructure project involving many stakeholders. The challenging thing in this study is that the project control is complemented with sustainable project governance, connecting the project to its external stakeholders and regulations.

- Narjes Sabeghi, Hamed R.Tareghian, Erik Demeulemeester, Hasan Taheri “Determining the timing of project control points using a facility location model and simulation” Computers & Operations Research 61(2015)69–80

This article is about a study for project control that has been done in unstable conditions. It states that the most important think in the control phase is the right timing so it can be costly efficient. It is used an adapted version of the facility location model (FLM) so the optimal timing can be found. Later a simulation model is used so, the possible disruptions in the time period between the beginning of the project and the first control point to be predicted.