Muda, Mura and Muri

| Line 9: | Line 9: | ||

==Muda== | ==Muda== | ||

| − | Muda is the Japanese word for "waste" and relates to any activity or practice that does not in any way produce value for the customer and generate loss of resources, time and money <ref name="c">["Womack, J.(2006). From Lean Tools to Lean Management</ref> | + | Muda is the Japanese word for "waste" and relates to any activity or practice that does not in any way produce value for the customer and generate loss of resources, time and money <ref name="c">["Womack, J.(2006). From Lean Tools to Lean Management</ref>. |

| − | The | + | The Muda waste can typically be broken into two categories: |

| + | |||

| + | '''Muda Type I :''' non-value adding practices, which are considered necessary for end consumer. | ||

| + | |||

| + | '''Muda Type II : '''non-value added practices, which are considered unnecessary for end consumer. The goal for a company aiming to go lean is to eliminate the type II of waste. | ||

| + | |||

| + | |||

| + | There are, as claimed by the renowned "father of the Toyota production system", Taiichi Ohno, 7 categories of waste. A common mistake for companies is to focus only on reducing or eliminating the Muda waste, thinking that it represents and covers all types of excess waste, but simply eliminating Muda will not be of help to the company without finding the reason for the waste, which will usually correlate with the two other wasteful practices; Mura and Muri. | ||

| + | |||

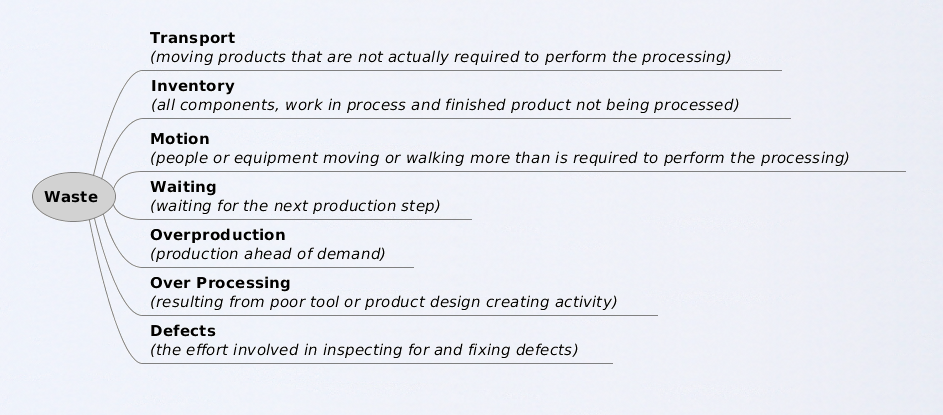

| + | '''The Seven Categories of Waste:''' | ||

- '''Transportation''' (relates to the movement of products between locations and operations. Transportation of a product does not usually add any value to the product that the customer would want to pay for. Furthermore, every time a product is moved it heightens the risk for it being delayed, lost or damaged) | - '''Transportation''' (relates to the movement of products between locations and operations. Transportation of a product does not usually add any value to the product that the customer would want to pay for. Furthermore, every time a product is moved it heightens the risk for it being delayed, lost or damaged) | ||

| Line 17: | Line 26: | ||

- '''Inventory''' (depicts the stock of finished goods, raw material and the Work in Progress (WIP) that a business obtains. However, it has not yet produced any profit, neither for the customer or the producer and therefore can be a wasteful practice) | - '''Inventory''' (depicts the stock of finished goods, raw material and the Work in Progress (WIP) that a business obtains. However, it has not yet produced any profit, neither for the customer or the producer and therefore can be a wasteful practice) | ||

| − | - '''Motion''' (details the physical activity of a machine or individual whilst comporting an action) | + | - '''Motion''' (details the physical activity of a machine or individual whilst comporting an action, could lead to overuse and strain) |

- '''Waiting''' (the operation of waiting for a worker or machine to finish, a delivery to arrive etc. Whenever a product is waiting to be worked on, valuable time and resources might be spent as a result) | - '''Waiting''' (the operation of waiting for a worker or machine to finish, a delivery to arrive etc. Whenever a product is waiting to be worked on, valuable time and resources might be spent as a result) | ||

| Line 23: | Line 32: | ||

- '''Over-processing''' (operations produced beyond what the customer call for. It also includes utilisation of resources, machines or materials that are of higher quality, more precise or costly than actually required by the customer) | - '''Over-processing''' (operations produced beyond what the customer call for. It also includes utilisation of resources, machines or materials that are of higher quality, more precise or costly than actually required by the customer) | ||

| − | - '''Over-production''' (happens when a company is producing higher number of products than what is needed from their customers at that given time. For example producing large batches of products will be risky as consumer needs may change over the period in which a batch will last. Overproduction is considered the most serious of the Muda waste types as it often lead or generates the other types. As for instance overproduction will lead to more inventory for the company | + | - '''Over-production''' (happens when a company is producing higher number of products than what is needed from their customers at that given time. For example producing large batches of products will be risky as consumer needs may change over the period in which a batch will last. Overproduction is considered the most serious of the Muda waste types as it often lead or generates the other types. As for instance overproduction will lead to more inventory for the company <ref name="d"> [''http://www.consulting-xp.com/blog/?p=546''] ''Le BLOG XP Consulting (2015)''</ref>. |

- '''Defects and Rework''' (this category refers to the product rejection and altering needs within the business operations. When a defect transpires, added costs occurs as the good will need rework, and production might need rescheduling, which also leads to additional labour costs. ) | - '''Defects and Rework''' (this category refers to the product rejection and altering needs within the business operations. When a defect transpires, added costs occurs as the good will need rework, and production might need rescheduling, which also leads to additional labour costs. ) | ||

An eight category is sometimes also added, and was defined by Womack et al. (2003) as producing goods that do not meet customer needs or requirements. <ref name="e"> ''Womack, James P., Jones, Daniel., (2003), Lean Thinking, Free Press''</ref>) Some also make use of a category | An eight category is sometimes also added, and was defined by Womack et al. (2003) as producing goods that do not meet customer needs or requirements. <ref name="e"> ''Womack, James P., Jones, Daniel., (2003), Lean Thinking, Free Press''</ref>) Some also make use of a category | ||

| − | disclosing the loss of human potential to create value whilst simultaneously producing waste <ref name="f"> [''http://agileknowhow.com/2016/07/14/getting-rid-3-ms-agile-tackles-problem-muda-mura-muri/''] ''Mysliwiec, P (2016)''</ref>. Geoffrey Mika (1999) also supplemented the theory with three additional forms of waste that has achieved global acknowledgement. Firstly, | + | disclosing the loss of human potential to create value whilst simultaneously producing waste <ref name="f"> [''http://agileknowhow.com/2016/07/14/getting-rid-3-ms-agile-tackles-problem-muda-mura-muri/''] ''Mysliwiec, P (2016)''</ref>. Geoffrey Mika (1999) also supplemented the theory with three additional forms of waste that has achieved global acknowledgement. Firstly, a waste related to working with the incorrect metrics or the lack thereof. Followingly, he presents a waste linked to not making use of a complete worker by not granting them permission to share ideas or suggestions and take part in the Participative Management, and lastly the waste linked to incorrect use of computers, not utilising the proper software, having the right training facilitated and time spent playing games, online socialising and web surfing. <ref name="g"> ''Mika, Geoffrey L. (1999) Kaizen Event Implementation Manual''</ref>) |

| − | Many of the other theories that link to the waste types divide between the identification of non-value-adding work and | + | Many of the other theories that link to the waste types divide between the identification of non-value-adding work and wasted work. Explaining that it is crucial to identify the expectations being the reason for the current work process and to challenge them when needed. <ref name="h"> [''https://www.graphicproducts.com/articles/toyota-production-system/ ''Graphiproducts.com''</ref>. |

<ref name="i"> ''Toyota Production System, Ohno, Taiichi, 1988, Productivity Press''</ref> [[File:Different kinds of waste in lean manufacturing.png]] | <ref name="i"> ''Toyota Production System, Ohno, Taiichi, 1988, Productivity Press''</ref> [[File:Different kinds of waste in lean manufacturing.png]] | ||

| Line 45: | Line 54: | ||

==Application== | ==Application== | ||

The three M's in lean manufacturing, Muda, Mura and Muri are often analogous and to eliminate one often means that the others is eliminated simultaneously. By applying various tools such as Kanban, Just in time (JIT) etc. it can strengthen the production stream and assist to reduce Mura, the waste of unevenness. Kanban is a well renowned scheduling system utilised in lean manufacturing, also developed by Taiichi Ohno and is an effective tool to highlight problem areas, measuring lead time throughout the full process stages. The aim with Kanban is to create an upper limit to the "Work in Process" inventory, trying to avert overloading of the manufacturing system <ref name="l"> ''Shingō, S., A Study of the Toyota Production System from an Industrial Engineering Viewpoint. Productivity Press. p. 228 (1989)''</ref>. Just in Time (JIT) is also a methodology developed as part of the Toyota Production System, and it aims to reduce flow times within production systems and the response times from suppliers and customers. Other manufacturing companies have also tried to develop their own similar methods, for instance has IBM created a continuous-flow manufacturing concept while Motorola has generated the short-cycle manufacturing (SCM) method.<ref name="z"> ''Goddard, Walter E. 1986. Just-in-Time: Surviving by Breaking Tradition. Essex Junction, Vt." Oliver Wight Ltd.''</ref> | The three M's in lean manufacturing, Muda, Mura and Muri are often analogous and to eliminate one often means that the others is eliminated simultaneously. By applying various tools such as Kanban, Just in time (JIT) etc. it can strengthen the production stream and assist to reduce Mura, the waste of unevenness. Kanban is a well renowned scheduling system utilised in lean manufacturing, also developed by Taiichi Ohno and is an effective tool to highlight problem areas, measuring lead time throughout the full process stages. The aim with Kanban is to create an upper limit to the "Work in Process" inventory, trying to avert overloading of the manufacturing system <ref name="l"> ''Shingō, S., A Study of the Toyota Production System from an Industrial Engineering Viewpoint. Productivity Press. p. 228 (1989)''</ref>. Just in Time (JIT) is also a methodology developed as part of the Toyota Production System, and it aims to reduce flow times within production systems and the response times from suppliers and customers. Other manufacturing companies have also tried to develop their own similar methods, for instance has IBM created a continuous-flow manufacturing concept while Motorola has generated the short-cycle manufacturing (SCM) method.<ref name="z"> ''Goddard, Walter E. 1986. Just-in-Time: Surviving by Breaking Tradition. Essex Junction, Vt." Oliver Wight Ltd.''</ref> | ||

| − | |||

Companies including Toyota, Harley Davidson and Dell utilise the JIT philosophy. For example Dell is therefore able to offer remarkably shorter lead times to their customers by making their suppliers carry inventory instead of doing it themselves, whilst also demanding short lead time on receiving components enabling Dell to quickly assembly products and deliver to end customer <ref name="m"> [''http://www.brighthubpm.com/methods-strategies/71540-real-life-examples-of-successful-jit-systems/''] ''Wilson, J (2015)''</ref>.Moreover, the Trusted Platform Value (TPV) and the 5S methodology are frameworks that can be applied to eliminate the waste of overburden, Muri. | Companies including Toyota, Harley Davidson and Dell utilise the JIT philosophy. For example Dell is therefore able to offer remarkably shorter lead times to their customers by making their suppliers carry inventory instead of doing it themselves, whilst also demanding short lead time on receiving components enabling Dell to quickly assembly products and deliver to end customer <ref name="m"> [''http://www.brighthubpm.com/methods-strategies/71540-real-life-examples-of-successful-jit-systems/''] ''Wilson, J (2015)''</ref>.Moreover, the Trusted Platform Value (TPV) and the 5S methodology are frameworks that can be applied to eliminate the waste of overburden, Muri. | ||

Revision as of 15:43, 2 October 2017

Contents |

Introduction

Muda, Mura and Muri is a methodological concept originally developed by the car manufacturing company Toyota, and is often referred to as the 3 M's of waste in lean manufacturing. Lean manufacturing or lean production refers to a methodical approach to eliminate wastes in a manufacturing company without reducing productivity. The three M's collectively describe the practices companies can eliminate in order to reduce the non-value adding utilisation of resources. The concept aims not for companies to work better but to get rid off practices that does not add any type of benefit[1].

The three waste types, consisting of Muda, Mura and Muri can typically be found in both manufacturing and office processes and is applicable in lean project management and project based production processes. As various projects are often challenged with multiple and diverse obstacles, reducing the 3 M's (Muda, Mura and Muri) may be a helpful aid when trying to reduce project failure. The concept can be utilised and applied in the planning and execution stages to improve the performance of a project.

Lean project management is the adoption of lean concepts put into a project management circumstance, with a primary aim for a project to deliver more value with less waste. This is essentially done with removal of bottlenecks during the production process, which can then expedite growth and boost productivity. The lean management principles are mostly derived from the Toyota Production System (TPS) and their idea of lean from 1990, and automaker company Toyota has been renowned for the way it grew from a small company to a global brand making use of the lean practices [2]. Toyota's belief is that the main practice of lean is not the tools but the reduction of the three waste types to uncover issues systematically, and then rather use the tools where the ideal can not be achieved. The primary goal of the elimination of Muda, Mura and Muri is to integrate light-weight processes and frameworks that can be applied and utilised with limited need for documentation and added efforts.

Muda

Muda is the Japanese word for "waste" and relates to any activity or practice that does not in any way produce value for the customer and generate loss of resources, time and money [3].

The Muda waste can typically be broken into two categories:

Muda Type I : non-value adding practices, which are considered necessary for end consumer.

Muda Type II : non-value added practices, which are considered unnecessary for end consumer. The goal for a company aiming to go lean is to eliminate the type II of waste.

There are, as claimed by the renowned "father of the Toyota production system", Taiichi Ohno, 7 categories of waste. A common mistake for companies is to focus only on reducing or eliminating the Muda waste, thinking that it represents and covers all types of excess waste, but simply eliminating Muda will not be of help to the company without finding the reason for the waste, which will usually correlate with the two other wasteful practices; Mura and Muri.

The Seven Categories of Waste:

- Transportation (relates to the movement of products between locations and operations. Transportation of a product does not usually add any value to the product that the customer would want to pay for. Furthermore, every time a product is moved it heightens the risk for it being delayed, lost or damaged)

- Inventory (depicts the stock of finished goods, raw material and the Work in Progress (WIP) that a business obtains. However, it has not yet produced any profit, neither for the customer or the producer and therefore can be a wasteful practice)

- Motion (details the physical activity of a machine or individual whilst comporting an action, could lead to overuse and strain)

- Waiting (the operation of waiting for a worker or machine to finish, a delivery to arrive etc. Whenever a product is waiting to be worked on, valuable time and resources might be spent as a result)

- Over-processing (operations produced beyond what the customer call for. It also includes utilisation of resources, machines or materials that are of higher quality, more precise or costly than actually required by the customer)

- Over-production (happens when a company is producing higher number of products than what is needed from their customers at that given time. For example producing large batches of products will be risky as consumer needs may change over the period in which a batch will last. Overproduction is considered the most serious of the Muda waste types as it often lead or generates the other types. As for instance overproduction will lead to more inventory for the company [4].

- Defects and Rework (this category refers to the product rejection and altering needs within the business operations. When a defect transpires, added costs occurs as the good will need rework, and production might need rescheduling, which also leads to additional labour costs. )

An eight category is sometimes also added, and was defined by Womack et al. (2003) as producing goods that do not meet customer needs or requirements. [5]) Some also make use of a category disclosing the loss of human potential to create value whilst simultaneously producing waste [6]. Geoffrey Mika (1999) also supplemented the theory with three additional forms of waste that has achieved global acknowledgement. Firstly, a waste related to working with the incorrect metrics or the lack thereof. Followingly, he presents a waste linked to not making use of a complete worker by not granting them permission to share ideas or suggestions and take part in the Participative Management, and lastly the waste linked to incorrect use of computers, not utilising the proper software, having the right training facilitated and time spent playing games, online socialising and web surfing. [7])

Many of the other theories that link to the waste types divide between the identification of non-value-adding work and wasted work. Explaining that it is crucial to identify the expectations being the reason for the current work process and to challenge them when needed. [8].

Mura

Mura presents the wastes of unevenness or irregularity and often occurs in linkage with inconsistency in customer demand, cycle times variation and an uneven work pace. It is most often used in relation to material flow, but can also be seen throughout a company's operations and day-to-day activities. The waste of unevenness is usually what creates many forms of the 7 categories of Muda. The Mura waste can often be eliminated by creating and encouraging openness in the supply chain, and is referred to as "levelling" and is often perceived as a counter measure to Mura [10].

The Mura waste would for example appear in a long-winded implementation project of a new IT system. In the initiation process, work is usually slow and planning, documentation and preparation tasks take longer than expected. After a while, time pressure is increased and work pace escalates, however, the anticipated date of completion is drawing near and the team works overtime to try to finish their tasks in time for the due. Suddenly, defects are discovered. Now the team needs to work even harder to attempt to correct the issues, but there is not enough time. This waterfall example illustrates how the waste of unevenness results in additional Muda wastes and affects the company. Resources and finances are needed to complete the project in time, the client is displeased and worried for the new finish date, the team is overworked and unmotivated.

Muri

Depicts the waste of overburden by causing unnecessary stress and strain to employees or equipment. Some strain is to be expected within a workplace but within set and safe regulations [11]. Muri can transpire as a result of lack of training, poorly developed workplaces, lack of maintenance, limited focus on safety and non-successful measures of performance. Muri is usually a result of the unevenness waste, Mura, but it also often commences from various organisational matters, for example procedural and structural bottlenecks.

Application

The three M's in lean manufacturing, Muda, Mura and Muri are often analogous and to eliminate one often means that the others is eliminated simultaneously. By applying various tools such as Kanban, Just in time (JIT) etc. it can strengthen the production stream and assist to reduce Mura, the waste of unevenness. Kanban is a well renowned scheduling system utilised in lean manufacturing, also developed by Taiichi Ohno and is an effective tool to highlight problem areas, measuring lead time throughout the full process stages. The aim with Kanban is to create an upper limit to the "Work in Process" inventory, trying to avert overloading of the manufacturing system [12]. Just in Time (JIT) is also a methodology developed as part of the Toyota Production System, and it aims to reduce flow times within production systems and the response times from suppliers and customers. Other manufacturing companies have also tried to develop their own similar methods, for instance has IBM created a continuous-flow manufacturing concept while Motorola has generated the short-cycle manufacturing (SCM) method.[13]

Companies including Toyota, Harley Davidson and Dell utilise the JIT philosophy. For example Dell is therefore able to offer remarkably shorter lead times to their customers by making their suppliers carry inventory instead of doing it themselves, whilst also demanding short lead time on receiving components enabling Dell to quickly assembly products and deliver to end customer [14].Moreover, the Trusted Platform Value (TPV) and the 5S methodology are frameworks that can be applied to eliminate the waste of overburden, Muri.

One crucial factor to the elimination of the 3 waste types is that the companies also implement a continuous improvement mindset, in order to continue to reduce waste and focus on improving workplace safety, customer satisfaction, product performance and productivity[15]

There is no ultimate approach or order on how to reduce the 3 M's, however The Danish Lean Forum has published a recommended elimination process:

1. Reduce Muda To be able to overcome the three wastes, Mura should be reduced to create more surplus for the Lean practices. By trying to identify the Muda wastes it is also likely that the two other M's will more easily appear. However, it can be argued that Muda is often discovered after the process is operating and then attended to reactively. It is management's responsibility to inspect and explore the Muda waste during the project processes and also ensuring reduction of other more rooted causes by examining the linkages to the Mura and Muri waste types. The Muda and Mura wastes should continuously be linked back to the Muri waste and planning stage also for the next upcoming project [16]

2. Reduce Mura To reduce the unevenness waste, companies and organisations should aim for a healthy and strong alignment of activities and processes, as this will decrease delay and day-to-day waste time. this could for instance be done through Just-in-time systems, which are based on limited inventory, aiming to maximise productivity by reducing storage overhead. Multinational consumer goods manufacturing company Procter & Gamble (P&G) is for example avoiding market risk by cutting down stock through cooperating with wholesale companies including Walmart and building stock response systems to the supplier companies [17]. The global clothing retail company, Zara, has taken on a fast-production approach to always meet the newest trends and customer wants and needs. The company does not make use of mass production practices, but produces new products within five weeks with their local partners in Spain, enabling shorter lead times, lower stocks and transportation time and costs [18]

3. Reduce Muri Muri should be discussed and focused on as part of the planning and preparation process of a project. Consistently reducing the Muri waste should be done through competence management and weekly planning meetings. By ensuring follow-up meetings on the planning the process could also be more heavily linked to Kaizen, referring to the continuous improvement approach. Making use of self-organizing teams is also a useful way to ensure reduced burden to employees on project level, as the employees knows best how to coordinate and regulate their work in order to amend and improve it.

Aiming for standardised work is also a possible method, setting pre-decided task time, repeatable process steps and work flows. By making use of the standardised work method organisations have previously proven, not only to reduce Muri but also increase employee morale, quality and productivity and reduce the overall costs [19]

Aims and Strategy

The aims of the Muda, Mura and Muri methodology and the lean manufacturing practice differs based on the various authors, where some claim that the primary aim is focused on expanding the profit for the company and increasing efficiency and productivity. Others state that the most important factor of the reduction of wastes is based on the value it will offer the customers. Apart from the differing opinions, most authors state that they believe the application of lean practices and reduction of the Muda, Mura and Muri wastes have some common goals: [20], [21], [22]

- Curtail time spent Decreasing the time that is spent on finishing a task is one of the most effective means to reduce waste and decrease costs.

- Improve the overall quality Understanding the consumers demands and needs and meeting their requirements is vital to obtain competitive advantage in the ever-changing market, therefore the overall quality of the products a company offers is crucial.

- Decrease total costs Limiting the company's offers to only entail products that satisfy customer demands is important in order to reduce overproduction and keep low inventory costs.

- Eliminate wasteful activities reducing non-value adding activities and practices is an aim as this will naturally lead to more freed resources, time and space.

Advantages

Reducing the three M wastes can enable the company to focus on "smart work" and not "hard work". This may facilitate a more inspired and invested work environment where the employees are more involved and have higher concern for the success of their respective project and the company as a whole. Furthermore, as elimination of the 3 M's requires clear strategic plans for the future of the company, the employees and managers will have a more clear-cut and defined understanding of the company's prospects.

As reduction of the Muri waste focuses on eliminating overburden, the methodology promotes increased work place safety, hopefully resulting in fewer accidents and mishaps. This will also increase employee satisfaction and boost productivity.

Elimination of the three wastes requires continuous work and consideration, which may enable the company to keep focused and the employees productive and on track. Furthermore, by curtailing the communication void between management and employees, chances are high that project involvement and productivity will rise.

Limitations and Challenges

“If you are going to do Toyota Production System, you must do it all the way. You also need to change the way you think. You need to change how you look at things.”—Taiichi Ohno. As stated by the creator of the Toyota Production System, eliminating the 3M's requires a thorough transformation. This is therefore incredibly demanding and especially for a medium or large-scale organisation, as you will need to innovate and change the entire mindset of the business. Teams are usually able to change direction and mentality in a much more rapid order, and is therefore more capable of implementing the Toyota Production System approach more immediately, eliminating the Muda, Mura and Muri waste much quicker. A possible method for larger organisations to achieve less waste and elimination of the 3M's is therefore to begin with focusing on reducing the 3M's within the teams and their respective projects. Doing this may also lead to shape the practices of the whole of the organisation.

Many of the companies that have tried to apply the lean philosophy and eliminate the three waste types have been able to adhere to the strict methodology. Some of the main limitations with the Muda, Mura and Muri methodology include:

Supplier management: When aiming to cut non-value adding practices, companies will usually become more dependent on cooperating with reliable and professional suppliers. This can be problematic as there may be an increased pressure on ensuring and maintaining satisfying relationships with supplier, also as the situation of the supplier may have greater influence on the company as a result. For instance, for a lean manufacturing project to work suppliers must agree to produce components in smaller batches and also deliver frequently to assembly plants. If suppliers do not agree to do this the company will hold more inventory, increase the carrying costs and reduce capability to enhance their quality and productivity via shorter production runs and better process sequences [23].

Dependency: Reducing the three M wastes will put more responsibility and dependency on suppliers, management and employees. Not only is it difficult to inspire all individuals within the company to follow the change towards the lean philosophy, but it may also prove challenging to ensure that everyone involved keeps following the new practice to and stay united. If some does not follow the methodology there will appear a weak link, hence productivity will decrease. [24].

Morale: It may take long for results to appear after reducing the waste types, during this process company and employee morale may weaken. Also, if the implementation of the 3M's methodology happens during a project, that respective project may suffer. It is vital that managers stay consistent in this procedure to ensure a steady and dependable environment during the application of the Muda, Mura and Muri methodology.

Key references:

Ohno, Taiichi (1988), Toyota Production System: Beyond Large-Scale Production, Cambridge, MA: Productivity Press, ISBN 0915299143: A book where the inventor of the Toyota Production System and its methodologies describes how car manufacturing company Toyota applied lean practices to their operations and how lean principles can be applied to improve any type of production practice. The book is a useful tool for anyone who aims to improve efficiency and effectiveness through reduction of wasteful and non-value adding practices

Liker, J., 2004, The Toyota Way, 14 management principles from the world greatest manufacturer New York: Mc-Graw Hill In his book, Liker describes 14 various management principles which he believes a company should adopt. Liker divides these management principles by making use of the 4P model: Philosophy, People & Partners, Process and Problem Solving. The author describes how the Toyota Production System and its practices is heavily linked to culture, and what companies should do in order to succeed with their application of lean practices.

Roos, Daniel, Ph.D.; Womack, James P., Ph.D.; Jones, Daniel T.: The Machine That Changed the World : The Story of Lean Production, Harper Perennial (November 1991) A book describing the reason for Toyota's success linked and related to car manufacturing companies General Motors and Ford. The book also describes the differences between craft, lean and mass production and why lean is the most optimal method for companies wanting to increase efficiency and value for the customer.

References

- ↑ Emiliani, Bob; Stec, David; Grasso, Lawrence; Stodder, James (2007). Better thinking, better results: case study and analysis of an enterprise-wide lean transformation (2nd ed.). Kensington, Conn: Center for Lean Business Management.

- ↑ [https://leanforum.wordpress.com/2015/08/20/lean-muda-mura-muri/] Liker, J (2004)

- ↑ ["Womack, J.(2006). From Lean Tools to Lean Management

- ↑ [http://www.consulting-xp.com/blog/?p=546] Le BLOG XP Consulting (2015)

- ↑ Womack, James P., Jones, Daniel., (2003), Lean Thinking, Free Press

- ↑ [http://agileknowhow.com/2016/07/14/getting-rid-3-ms-agile-tackles-problem-muda-mura-muri/] Mysliwiec, P (2016)

- ↑ Mika, Geoffrey L. (1999) Kaizen Event Implementation Manual

- ↑ [https://www.graphicproducts.com/articles/toyota-production-system/ Graphiproducts.com

- ↑ Toyota Production System, Ohno, Taiichi, 1988, Productivity Press

- ↑ [http://leanmanufacturingtools.org/71/muda-mura-and-muri-lean-manufacturing-wastes/ Lean Manufacturing Tools

- ↑ [http://missiontps.blogspot.dk/p/3ms.html] Kumar, M (2013)

- ↑ Shingō, S., A Study of the Toyota Production System from an Industrial Engineering Viewpoint. Productivity Press. p. 228 (1989)

- ↑ Goddard, Walter E. 1986. Just-in-Time: Surviving by Breaking Tradition. Essex Junction, Vt." Oliver Wight Ltd.

- ↑ [http://www.brighthubpm.com/methods-strategies/71540-real-life-examples-of-successful-jit-systems/] Wilson, J (2015)

- ↑ Akinlawon, Akin O. "Thinking of Lean Manufacturing Systems". SAE International (2017)

- ↑ [https://www.lean.org/lexicon/muda-mura-muri] Lean Enterprise Institute (2015)

- ↑ ["Shining examples". Special report: Logistics: The Economist. June 15, 2006

- ↑ [https://theleadershipnetwork.com/article/lean-manufacturing/zara-lean-fashion-retail] Robinson, N (2015)

- ↑ [https://bobsleanlearning.wordpress.com/2010/01/14/muda/] Hobbard, B (2010)

- ↑ [Womack, J.P. & Jones, D.T., 2003. Lean Thinking: Banish Waste and Create Wealth in Your Corporation, New York: Free Press.

- ↑ [Dennis, P., 2002. Lean Production Simplified: A Plain Language Guide to the World's Most Powerful Production System, New York: Productivity Press.

- ↑ [Bicheno, J., 2004. The new lean toolbox: towards fast, flexible flow, Buckingham: PICSIE Books.,

- ↑ [http://sloanreview.mit.edu/article/the-limits-of-lean/] Cusumano, M (1994)

- ↑ [https://www.linkedin.com/pulse/advantages-disadvantages-lean-project-delivery-khan] Khan, M (2016)