Lean Tools in Project Management

| (283 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ''Developed by Thomas Børgesen Bachmann'' | |

| − | |||

| − | + | The philosophy of Lean Thinking was originally applied in the automotive industry. Later it became clear that the philosophy was not only applicable in relation to the automotive industry, but it could also be used in other industries. This article covers the basic principles of Lean Thinking in relation to Project Management. The overall purpose is to give an overview of Lean Thinking. This will include a description of the background of Lean Thinking, a description of non-value activities together with tools and techniques applied in Lean Thinking. Additionally some examples will be given in how to approach Lean Tools in [https://en.wikipedia.org/wiki/Project_management Project Management]. | |

| − | The article | + | The main topics in this article are Lean Thinking and Project Management. The definitions of Lean Thinking and Project Management can be seen below: |

| + | '''[https://en.wikipedia.org/wiki/Lean_manufacturing Lean Thinking]''': Eliminate waste in order to maximize customer value with less resources.<ref>http://www.lean.org/WhatsLean/, accessed: 23-09-15</ref>. | ||

| − | + | '''[https://en.wikipedia.org/wiki/Project_management Project Management]''': Plan, organize, motivate and control the resources to achieve a specific goal of a temporary project within the specific criteria.<ref>''The Definitive Guide to Project Management''. Nokes, Sebastian. 2nd Ed.n. London (Financial Times / Prentice Hall): 2007. ISBN 978-0-273-71097-4</ref> | |

| − | == | + | == Background == |

[[File:5-Lean-Principles-278x300.jpg|200px|thumb|right|Fig 1: Visualization of the five principles of Lean ]] | [[File:5-Lean-Principles-278x300.jpg|200px|thumb|right|Fig 1: Visualization of the five principles of Lean ]] | ||

| − | Lean Thinking is the philosophy from the Japanese automotive | + | === Introduction to Lean === |

| − | The five principles | + | |

| + | Lean Thinking is the philosophy from the Japanese automotive company Toyota, and was introduced in the late 1930’s as the [https://en.wikipedia.org/wiki/Toyota_Production_System Toyota Production System] (known as TPS). Lean is basically about creating value for the customer by eliminating waste. An organization which has fully adopted the philosophy understands which activities create value for the customer and how much the customer is willing to pay for the product/service. The target in every lean project is to eliminate waste and reduce the variation in all of the processes in the value chain in order to create stability. The lean philosophy, in form of TPS, caught attention from other automotive manufacturing companies when the small Japanese automotive company Toyota became one of the leading automotive manufacturing companies in the world. In the beginning the TPS system was dedicated to the manufacturing industry, but over the past years the philosophy has been established as an overall optimization philosophy for all kind of businesses. | ||

| + | |||

| + | The Lean philosophy consists of five principles; Specify value, Integrate the value stream, Create flow by eliminating waste, Establish pull and Seek perfection (see description below and figure 1.) . | ||

| + | <ref name="TBB1">''Lean Thinking''. By James P. Womack and Daniel T. Jones: 2003. ISBN 978-0743249270</ref> | ||

{| class="wikitable" | {| class="wikitable" | ||

|+Lean Principles | |+Lean Principles | ||

|- | |- | ||

| − | !The Five Lean Principles <ref>http://leanmanufacturingtools.org/39/lean-thinking-lean-principles/ , | + | !The Five Lean Principles <ref name="TBB1"></ref> <ref>http://leanmanufacturingtools.org/39/lean-thinking-lean-principles/ , accessed: 23-09-15 </ref>. |

!Description | !Description | ||

|- | |- | ||

|1. Specify Value | |1. Specify Value | ||

| − | |Specify Value is | + | | |

| + | Specify Value is understanding that only a small fraction of the total time and effort adds value to the customer. This is mainly about identifying all the non-value activities and the activities which create value for the specific product or service. | ||

|- | |- | ||

|2. Integrate the Value Stream | |2. Integrate the Value Stream | ||

| − | |Value Stream Mapping is | + | |Value Stream Mapping is when all the activities of the product are identified from the very beginning of its lifecycle across all the processes. An overview of all the non-value activities will be visualized in a Value Stream Mapping Model. |

|- | |- | ||

|3. Create Flow by Eliminating Waste | |3. Create Flow by Eliminating Waste | ||

| − | | | + | |When The Value Stream has been mapped, it will be clear that many of the activities do not add value. In this step the non-value activities will be eliminated. Eliminating the non-value activities, will make sure that the product flows directly to the customer without any interruptions. |

|- | |- | ||

|4. Establish Pull | |4. Establish Pull | ||

| − | |This is | + | |This step is related to the concept of Just-in-time (JIT). At this point it is important to understand the demand of the customers and to create the production process in relation to their demand. The materials for the production should be available "just-in-time", so there is no need for an inventory. |

|- | |- | ||

|5. Seek Perfection | |5. Seek Perfection | ||

| − | | | + | |The principles described above have to be applied continuously in order to secure that all non-value activities become visible and eliminated. The goal is to eliminate waste completely although it is difficult to achieve. The most "Lean" organisation involve all of the employees and implement the lean mindset in all parts of the organisation. |

|} | |} | ||

| − | + | Implementing the principles of Lean Thinking in organisations should result in: <ref>http://www.leanmanufacture.net/leangoals.aspx , accessed: 23-09-15 </ref> | |

| − | * - | + | * - Quality Improvement |

| + | * - Elimination of Waste | ||

| + | * - Reduced Lead time | ||

| + | * - Reduced Total Cost | ||

| − | + | Additionally this should improve the '''customer satisfaction''' and this is the main driver of implementing Lean in any organization. | |

| − | + | === Elimination of Waste === | |

| + | Lean Thinking is used in Project Management because not only “production lines” can be “Lean” but also projects. Lean Thinking in Project Management is used to reduce the costs of the project, to make sure that project is finished within the estimated time and to make sure that the success criteria of the project is met. Lean tools can easily be applied in Project Management with the purpose of eliminating waste (known as ''Muda'' in Japanese Terms). The different types of waste are described in the table below. | ||

| − | + | '''Description of waste''': | |

| + | {| class="wikitable" | ||

| + | |+Types of waste | ||

| + | |- | ||

| + | !Waste in Lean Thinking <ref>Toyota Production System, Ohno, Taiichi, 1988, Productivity Press ISBN 978-0915299140 </ref> | ||

| + | !Waste in Lean Project Management <ref name="TBB2">http://projectmanagement.atwork-network.com/2012/03/16/lean-tools-and-techniques-for-project-management/ accessed: 23-09-2015</ref> | ||

| + | |- | ||

| + | | - '''Transportation''', every time a product is moved. Damaging of products, delays, etc. | ||

| + | | - '''Status meetings''', which are ineffective and too long to keep the participants interested. | ||

| + | |- | ||

| + | | - '''Inventory''', raw material, work-in progress or finished goods, which is costly and does not create value to the customer. | ||

| + | | - '''Too detailed plans'''. Usually the schedule changes during a project period, which makes it pointless with a too detailed plan as the plan may change many times. | ||

| + | |- | ||

| + | | - '''Waiting'''. If a process or product is not in progress. | ||

| + | | - '''Collecting inoperable data''', which will never be used. | ||

| + | |- | ||

| + | | - '''Over-processing'''. This occurs when more work is done than what is required by the customer. | ||

| + | | - '''Push sub project and meetings''', which ties up the team members and only satisfies the stakeholder but increases the duration of the project. | ||

| + | |- | ||

| + | | - '''Over-production'''. Producing more than the total demand of the product from the consumer. | ||

| + | | - '''Documentation''' which is never used. | ||

| + | |- | ||

| + | | - '''Defects'''. Creates extra cost and extra labor from the producer. | ||

| + | |- | ||

| + | | - '''Motion'''. Equipment/people moving more than required. | ||

| + | |} | ||

| − | + | The 7 different types of waste in Lean Thinking are related to the production. In Lean Project Management some similar types of waste can be found such as; Waiting, Over Processing and Defective Processes, as these are related to the planning and management of the project. | |

| − | + | As a Project Manager it is crucial to classify all processes. When all processes have been classified, the Project Manager has to identify which processes create value and which does not. Once all non-value activities have been identified, the manager must go to a detailed classification by using the table listed above. That helps to find out what kind of waste is the biggest bottleneck and at that point it is possible to make a project plan which systematically eliminates the bottlenecks/waste. | |

| − | == | + | == Lean Tools in Project Management == |

| − | The | + | This section covers The Lean Tools that can be applied in [http://apppm.man.dtu.dk/index.php/Lean_Project_Management Lean Project Management]. These tools, which are described below, help to reduce the waste and the variation of the processes. Furthermore these tools can help to identify potential improvement of processes and assist to a better understanding of the products life cycle. Not every "Lean" tool is applicable in Project Management, but some of them are amd those are listed below. <ref name="TBB5">Leading and Managing The Lean Management Process, Fliedner, Gene, 2011, Business Expert Press, New York, ISBN 978-1606492482</ref> |

| − | + | ==== Value Stream Mapping ==== | |

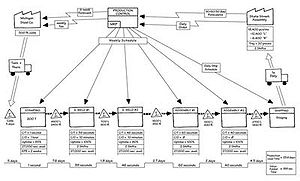

| + | [[File:VSM.jpg|300px|thumb|right|Fig 2: Detailed Map of Value Stream.]] | ||

| − | + | Visual Management in Project Management provides a lot of information quickly. Furthermore it's easier to remember information when it's presented visually. Value Stream Mapping (VSM) is a visual technique to map the current processes. VSM gives a current state view of the processes and gather information as; cycle times, inventory levels, down times, material flows and information flows. This technique can be used in different levels, such as the entire supply chain or a production area. The tool maps all the non-valued activities as well as all the valued activities. The target is to achieve a future state sceneria by using other lean tools. Figure 2 shows a very detailed plan of a Value Stream. The Map informs many different common VSM symbols, which are used to portray material and information flow. <ref name="TBB5"></ref> | |

| − | + | ==== Kaizen ==== | |

| + | While Value Stream Mapping gives an overview of the current activities, [https://en.wikipedia.org/wiki/Kaizen Kaizen Events] are useful for conducting the improvements of the activities. Kaizen events are generally a short-term project, which takes place in a period of 3 - 5 days. The objective is to improve a minor process and the scope is limited. Workers, which are closest to the current process, are key players in these projects. New strategies, techniques and equipment are not introduced in these events, but are introduced in [https://en.wikipedia.org/wiki/Kaikaku Kaikaku] Events, where the scope is larger and the more radical changes are made. <ref name="TBB5"></ref> | ||

| − | + | ==== The Gemba Walk ==== | |

| − | + | [https://en.wikipedia.org/wiki/Gemba Gemba Walk] is a powerful tool, where the Lean Manager physically visits the production floor. The manager goes to the production and walks through the entire value stream. There are a number of reasons why this is a great tool, for instance; The Lean Manager is not familiar with the process and have another view of the process. Furthermore, when the Lean Manager visits the production floor it gives a positive motivation impact on the employee and who feels valued by the attention from the manager. By using Gemba Walk avoid you PowerPoint presentations and get in more direct touch with the problems. <ref name="TBB5"></ref> | |

| − | + | ||

| + | ==== System Optimization ==== | ||

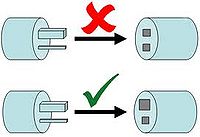

| + | [[File:PokaYoke.jpg|200px|thumb|right|Fig 3: Example of Poka Yoke.]] | ||

| + | This tool is a part of the Value Stream Mapping. Optimization is not only important on a particular workstation of a specific area, but affects the entire value stream. Therefore it is important to identify how an improvement on one workstation will affect other workstations. The goal is to create improvements without affecting other areas by integrating the change to the rest of the value stream. <ref name="TBB5"></ref> | ||

| − | + | ==== Poka-Yoke ==== | |

| + | [https://en.wikipedia.org/wiki/Poka-yoke Poka-Yoke] is a Japanese tool, which helps the workers to avoid mistakes. Poka-Yoke makes sure that a machine cannot work before the right instructions are being followed. For instance, plugging a battery into headphones. The headphones do not allow the process to begin before the battery is placed correctly. This forces the user to pay attention to the instructions and use the product in the right way. A wrong setup of the product will not make any harm to the product, but will only prevent the user from using it. Another example is shown in figure 3, where the image shows how it is only possible to plug in the power outlet in one way. <ref> http://www.lsvgroup.com/site/index.php/da/viden-om-1/vaerktojer/147-poka-yoke-1, accessed: 26-09-15</ref>. <ref name="TBB5"></ref> | ||

| − | == | + | === Summary === |

| + | The explanation and the description of the applicable Lean Tools for Project Management listed above give an idea of how to approach these tools. These can be used as analytical methods as well as planning- and problem-solving approaches. <ref name="TBB5"></ref> | ||

| − | + | The following factors in Lean Tools can be applied in Project Management: | |

| − | + | # Lean Tools give an understanding of the current processes and help to a better understanding of improvements. In order to understand this, it is required to make a current state of the processes. | |

| − | + | # Lean practices can be applied in any kind of business and project. It only depends on the creativity of the workers and the project managers creativity. | |

| − | === | + | == Consequences == |

| − | + | ||

| − | === | + | === Advantages === |

| − | + | Applying Lean Tools in Project Management provides competitive advantages. Saving space on warehousing, reducing costs, improving efficiency, saving time, responding faster to changes and eliminating waste are some of the major advantages by using the tools listed above. New production lines might be added while more space from the warehouse is available. In addition, the employees develop new skills and can respond quicker to changing demands from customers. | |

| − | + | <ref name="TBB3">http://smallbusiness.chron.com/advantages-amp-disadvantages-lean-production-46696.html accessed: 26-09-2015</ref> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | = | + | |

| − | + | ||

| − | == | + | === Limitations === |

| − | == | + | * '''Inefficiency''' |

| + | Lean can be both misused and overused. Lean can often become a goal itself, although the value of the improvement just moves the bottleneck to another process. Lean must be a trade off between the value of the improvements and the resources in the current situation. Some companies believe that Lean tools can be applied in their organization from one day to another, but the companies forget to remember that Toyota has spent more than 50 years achieving a “Lean” Production, and Toyota has still room for improvements. <ref name="TBB3"></ref> | ||

| + | |||

| + | * '''Problem with Delivering the Right Product on the Right Time (Just In Time)''' | ||

| + | [[File:Workload80.jpg|200px|thumb|right|Fig 4: Visualization of the workload balance. Source: Author's creation. ]] | ||

| + | ''"First stabilize then optimize"'' is a common proverb in Lean context. Unfortunately, some companies are optimizing and then stabilizing, which is wrong and might have major impacts on delivery times etc. For instance, if a company has uncertain delivery of raw materials, and does not have raw materials for production, then it interrupts the production flow and delayings all other processes. Therefore being aggressive with "Just in Time" might leave bottlenecks in the overall Value Stream. <ref name="TBB3"></ref> | ||

| + | |||

| + | * '''Employees Frustration''' | ||

| + | Discouraging employees by using lean methods can be a problem. The managers may seek to squeeze the economy from the production and by that discourage the employees. Continuing improvements must be a part of the workflow, but not a strain on the workers and this can be challenging in a lean environment. In a lean environment the workload of the single worker must be around 80 % every day. The last 20 % should be free of change and enhancement measures. These numbers were originally related to machine capacity but Toyota experienced that this method could be used on employees as well. Figure 4 shows how the development of the employees go, if the daily workload is not 100 %. <ref name="TBB3"></ref> | ||

| + | |||

| + | Organizations experience that implementing lean is not only about minimizing lead times and cutting cost etc.. It also involves changing company culture and convincing workers to adopt this philosophy. The companies often fail in creating a sustainable lean organization. <ref name="TBB4">http://www.leanmanufacture.net/leangoals.aspx accessed: 28-09-2015</ref> | ||

| + | |||

| + | == Additional Reading == | ||

| + | |||

| + | * Books | ||

| + | |||

| + | - ''Lean Thinking''. By James P. Womack and Daniel T. Jones. 2003. ISBN 978-0743249270 - One of the most famous books about Lean. Must read to get a detailed and overview of lean. | ||

| + | |||

| + | - ''Gemba Walk''. By James P. Womack. ISBN 978-1934109151 - Great examples from Womack. Womack gives som great examples from the real life. Particularly when he steps into the first company, and explains how he did the "Gemba Walk" and how badly the company performed (Page 48-75). This book is available at The Technical University of Denmark's' library. | ||

| + | |||

| + | * Websites | ||

| + | |||

| + | - [http://www.brighthubpm.com/methods-strategies/12663-lean-management-principles-how-to-eliminate-waste/ Elimination of Waste] - Get a fast overview of Lean Thinking in Project Management. | ||

| + | |||

| + | - [https://www.youtube.com/watch?v=RxDw0Q_gVt0 Lean Principles] - If you are not into reading, then you can find some pretty good examples on YouTube. This video might give powerful understanding of Lean. | ||

== References == | == References == | ||

<references/> | <references/> | ||

| + | |||

| + | [[Category:Project Management]][[Category:Management]][[Category:Lean Management]][[Category:Visual tools]] | ||

Latest revision as of 16:49, 18 December 2018

Developed by Thomas Børgesen Bachmann

The philosophy of Lean Thinking was originally applied in the automotive industry. Later it became clear that the philosophy was not only applicable in relation to the automotive industry, but it could also be used in other industries. This article covers the basic principles of Lean Thinking in relation to Project Management. The overall purpose is to give an overview of Lean Thinking. This will include a description of the background of Lean Thinking, a description of non-value activities together with tools and techniques applied in Lean Thinking. Additionally some examples will be given in how to approach Lean Tools in Project Management.

The main topics in this article are Lean Thinking and Project Management. The definitions of Lean Thinking and Project Management can be seen below:

Lean Thinking: Eliminate waste in order to maximize customer value with less resources.[1].

Project Management: Plan, organize, motivate and control the resources to achieve a specific goal of a temporary project within the specific criteria.[2]

Contents |

[edit] Background

[edit] Introduction to Lean

Lean Thinking is the philosophy from the Japanese automotive company Toyota, and was introduced in the late 1930’s as the Toyota Production System (known as TPS). Lean is basically about creating value for the customer by eliminating waste. An organization which has fully adopted the philosophy understands which activities create value for the customer and how much the customer is willing to pay for the product/service. The target in every lean project is to eliminate waste and reduce the variation in all of the processes in the value chain in order to create stability. The lean philosophy, in form of TPS, caught attention from other automotive manufacturing companies when the small Japanese automotive company Toyota became one of the leading automotive manufacturing companies in the world. In the beginning the TPS system was dedicated to the manufacturing industry, but over the past years the philosophy has been established as an overall optimization philosophy for all kind of businesses.

The Lean philosophy consists of five principles; Specify value, Integrate the value stream, Create flow by eliminating waste, Establish pull and Seek perfection (see description below and figure 1.) . [3]

| The Five Lean Principles [3] [4]. | Description |

|---|---|

| 1. Specify Value |

Specify Value is understanding that only a small fraction of the total time and effort adds value to the customer. This is mainly about identifying all the non-value activities and the activities which create value for the specific product or service. |

| 2. Integrate the Value Stream | Value Stream Mapping is when all the activities of the product are identified from the very beginning of its lifecycle across all the processes. An overview of all the non-value activities will be visualized in a Value Stream Mapping Model. |

| 3. Create Flow by Eliminating Waste | When The Value Stream has been mapped, it will be clear that many of the activities do not add value. In this step the non-value activities will be eliminated. Eliminating the non-value activities, will make sure that the product flows directly to the customer without any interruptions. |

| 4. Establish Pull | This step is related to the concept of Just-in-time (JIT). At this point it is important to understand the demand of the customers and to create the production process in relation to their demand. The materials for the production should be available "just-in-time", so there is no need for an inventory. |

| 5. Seek Perfection | The principles described above have to be applied continuously in order to secure that all non-value activities become visible and eliminated. The goal is to eliminate waste completely although it is difficult to achieve. The most "Lean" organisation involve all of the employees and implement the lean mindset in all parts of the organisation. |

Implementing the principles of Lean Thinking in organisations should result in: [5]

- - Quality Improvement

- - Elimination of Waste

- - Reduced Lead time

- - Reduced Total Cost

Additionally this should improve the customer satisfaction and this is the main driver of implementing Lean in any organization.

[edit] Elimination of Waste

Lean Thinking is used in Project Management because not only “production lines” can be “Lean” but also projects. Lean Thinking in Project Management is used to reduce the costs of the project, to make sure that project is finished within the estimated time and to make sure that the success criteria of the project is met. Lean tools can easily be applied in Project Management with the purpose of eliminating waste (known as Muda in Japanese Terms). The different types of waste are described in the table below.

Description of waste:

| Waste in Lean Thinking [6] | Waste in Lean Project Management [7] |

|---|---|

| - Transportation, every time a product is moved. Damaging of products, delays, etc. | - Status meetings, which are ineffective and too long to keep the participants interested. |

| - Inventory, raw material, work-in progress or finished goods, which is costly and does not create value to the customer. | - Too detailed plans. Usually the schedule changes during a project period, which makes it pointless with a too detailed plan as the plan may change many times. |

| - Waiting. If a process or product is not in progress. | - Collecting inoperable data, which will never be used. |

| - Over-processing. This occurs when more work is done than what is required by the customer. | - Push sub project and meetings, which ties up the team members and only satisfies the stakeholder but increases the duration of the project. |

| - Over-production. Producing more than the total demand of the product from the consumer. | - Documentation which is never used. |

| - Defects. Creates extra cost and extra labor from the producer. | |

| - Motion. Equipment/people moving more than required. |

The 7 different types of waste in Lean Thinking are related to the production. In Lean Project Management some similar types of waste can be found such as; Waiting, Over Processing and Defective Processes, as these are related to the planning and management of the project.

As a Project Manager it is crucial to classify all processes. When all processes have been classified, the Project Manager has to identify which processes create value and which does not. Once all non-value activities have been identified, the manager must go to a detailed classification by using the table listed above. That helps to find out what kind of waste is the biggest bottleneck and at that point it is possible to make a project plan which systematically eliminates the bottlenecks/waste.

[edit] Lean Tools in Project Management

This section covers The Lean Tools that can be applied in Lean Project Management. These tools, which are described below, help to reduce the waste and the variation of the processes. Furthermore these tools can help to identify potential improvement of processes and assist to a better understanding of the products life cycle. Not every "Lean" tool is applicable in Project Management, but some of them are amd those are listed below. [8]

[edit] Value Stream Mapping

Visual Management in Project Management provides a lot of information quickly. Furthermore it's easier to remember information when it's presented visually. Value Stream Mapping (VSM) is a visual technique to map the current processes. VSM gives a current state view of the processes and gather information as; cycle times, inventory levels, down times, material flows and information flows. This technique can be used in different levels, such as the entire supply chain or a production area. The tool maps all the non-valued activities as well as all the valued activities. The target is to achieve a future state sceneria by using other lean tools. Figure 2 shows a very detailed plan of a Value Stream. The Map informs many different common VSM symbols, which are used to portray material and information flow. [8]

[edit] Kaizen

While Value Stream Mapping gives an overview of the current activities, Kaizen Events are useful for conducting the improvements of the activities. Kaizen events are generally a short-term project, which takes place in a period of 3 - 5 days. The objective is to improve a minor process and the scope is limited. Workers, which are closest to the current process, are key players in these projects. New strategies, techniques and equipment are not introduced in these events, but are introduced in Kaikaku Events, where the scope is larger and the more radical changes are made. [8]

[edit] The Gemba Walk

Gemba Walk is a powerful tool, where the Lean Manager physically visits the production floor. The manager goes to the production and walks through the entire value stream. There are a number of reasons why this is a great tool, for instance; The Lean Manager is not familiar with the process and have another view of the process. Furthermore, when the Lean Manager visits the production floor it gives a positive motivation impact on the employee and who feels valued by the attention from the manager. By using Gemba Walk avoid you PowerPoint presentations and get in more direct touch with the problems. [8]

[edit] System Optimization

This tool is a part of the Value Stream Mapping. Optimization is not only important on a particular workstation of a specific area, but affects the entire value stream. Therefore it is important to identify how an improvement on one workstation will affect other workstations. The goal is to create improvements without affecting other areas by integrating the change to the rest of the value stream. [8]

[edit] Poka-Yoke

Poka-Yoke is a Japanese tool, which helps the workers to avoid mistakes. Poka-Yoke makes sure that a machine cannot work before the right instructions are being followed. For instance, plugging a battery into headphones. The headphones do not allow the process to begin before the battery is placed correctly. This forces the user to pay attention to the instructions and use the product in the right way. A wrong setup of the product will not make any harm to the product, but will only prevent the user from using it. Another example is shown in figure 3, where the image shows how it is only possible to plug in the power outlet in one way. [9]. [8]

[edit] Summary

The explanation and the description of the applicable Lean Tools for Project Management listed above give an idea of how to approach these tools. These can be used as analytical methods as well as planning- and problem-solving approaches. [8]

The following factors in Lean Tools can be applied in Project Management:

- Lean Tools give an understanding of the current processes and help to a better understanding of improvements. In order to understand this, it is required to make a current state of the processes.

- Lean practices can be applied in any kind of business and project. It only depends on the creativity of the workers and the project managers creativity.

[edit] Consequences

[edit] Advantages

Applying Lean Tools in Project Management provides competitive advantages. Saving space on warehousing, reducing costs, improving efficiency, saving time, responding faster to changes and eliminating waste are some of the major advantages by using the tools listed above. New production lines might be added while more space from the warehouse is available. In addition, the employees develop new skills and can respond quicker to changing demands from customers. [10]

[edit] Limitations

- Inefficiency

Lean can be both misused and overused. Lean can often become a goal itself, although the value of the improvement just moves the bottleneck to another process. Lean must be a trade off between the value of the improvements and the resources in the current situation. Some companies believe that Lean tools can be applied in their organization from one day to another, but the companies forget to remember that Toyota has spent more than 50 years achieving a “Lean” Production, and Toyota has still room for improvements. [10]

- Problem with Delivering the Right Product on the Right Time (Just In Time)

"First stabilize then optimize" is a common proverb in Lean context. Unfortunately, some companies are optimizing and then stabilizing, which is wrong and might have major impacts on delivery times etc. For instance, if a company has uncertain delivery of raw materials, and does not have raw materials for production, then it interrupts the production flow and delayings all other processes. Therefore being aggressive with "Just in Time" might leave bottlenecks in the overall Value Stream. [10]

- Employees Frustration

Discouraging employees by using lean methods can be a problem. The managers may seek to squeeze the economy from the production and by that discourage the employees. Continuing improvements must be a part of the workflow, but not a strain on the workers and this can be challenging in a lean environment. In a lean environment the workload of the single worker must be around 80 % every day. The last 20 % should be free of change and enhancement measures. These numbers were originally related to machine capacity but Toyota experienced that this method could be used on employees as well. Figure 4 shows how the development of the employees go, if the daily workload is not 100 %. [10]

Organizations experience that implementing lean is not only about minimizing lead times and cutting cost etc.. It also involves changing company culture and convincing workers to adopt this philosophy. The companies often fail in creating a sustainable lean organization. [11]

[edit] Additional Reading

- Books

- Lean Thinking. By James P. Womack and Daniel T. Jones. 2003. ISBN 978-0743249270 - One of the most famous books about Lean. Must read to get a detailed and overview of lean.

- Gemba Walk. By James P. Womack. ISBN 978-1934109151 - Great examples from Womack. Womack gives som great examples from the real life. Particularly when he steps into the first company, and explains how he did the "Gemba Walk" and how badly the company performed (Page 48-75). This book is available at The Technical University of Denmark's' library.

- Websites

- Elimination of Waste - Get a fast overview of Lean Thinking in Project Management.

- Lean Principles - If you are not into reading, then you can find some pretty good examples on YouTube. This video might give powerful understanding of Lean.

[edit] References

- ↑ http://www.lean.org/WhatsLean/, accessed: 23-09-15

- ↑ The Definitive Guide to Project Management. Nokes, Sebastian. 2nd Ed.n. London (Financial Times / Prentice Hall): 2007. ISBN 978-0-273-71097-4

- ↑ 3.0 3.1 Lean Thinking. By James P. Womack and Daniel T. Jones: 2003. ISBN 978-0743249270

- ↑ http://leanmanufacturingtools.org/39/lean-thinking-lean-principles/ , accessed: 23-09-15

- ↑ http://www.leanmanufacture.net/leangoals.aspx , accessed: 23-09-15

- ↑ Toyota Production System, Ohno, Taiichi, 1988, Productivity Press ISBN 978-0915299140

- ↑ http://projectmanagement.atwork-network.com/2012/03/16/lean-tools-and-techniques-for-project-management/ accessed: 23-09-2015

- ↑ 8.0 8.1 8.2 8.3 8.4 8.5 8.6 Leading and Managing The Lean Management Process, Fliedner, Gene, 2011, Business Expert Press, New York, ISBN 978-1606492482

- ↑ http://www.lsvgroup.com/site/index.php/da/viden-om-1/vaerktojer/147-poka-yoke-1, accessed: 26-09-15

- ↑ 10.0 10.1 10.2 10.3 http://smallbusiness.chron.com/advantages-amp-disadvantages-lean-production-46696.html accessed: 26-09-2015

- ↑ http://www.leanmanufacture.net/leangoals.aspx accessed: 28-09-2015