Construction modularization from a lean perspective

(→T30 Hotel) |

|||

| (One intermediate revision by one user not shown) | |||

| Line 1: | Line 1: | ||

| + | ''Developed by Daniel Højgaard Hindhede'' | ||

| + | |||

| + | |||

'''Article Type 2, Case study on T30 hotel''' | '''Article Type 2, Case study on T30 hotel''' | ||

| Line 26: | Line 29: | ||

== T30 Hotel == | == T30 Hotel == | ||

| − | [[File:1.jpg |600px|thumb|right|BCB Modular construction, illustration: Jason Lee ]][[File:1111.png |600px|thumb|right|BSB Project operation flow chart[http://en.broad.com] ]] | + | [[File:1.jpg |600px|thumb|right|BCB Modular construction, illustration: Jason Lee [http://en.broad.com] ]][[File:1111.png |600px|thumb|right|BSB Project operation flow chart[http://en.broad.com] ]] |

On New Year’s Day 2012, Broad Sustainable Buildings Co. Ltd (BSB) released a time lapse video on YouTube showing how they built a 30—story hotel in just 360 hours (15 days)That video has since been viewed over 6 million times. People were astounded at the speed of this accomplishment; however Zhang Yue, Chairman & CEO of Broad Group, focuses more on the building's sustainability credentials. Tests by the China Academy of Building Research determine that T30 can withstand an earthquake of magnitude 9 on the Richter scale.[https://www.youtube.com/watch?v=-N_Q6Q-3o7M] T30 uses only 20% of the energy consumed by a traditional hotel for heating, cooling and lighting the building. Its’ internal air was found to be 20 times purer than the atmosphere outside and its’ costs between 10% and 30% less to build compared with conventional methods, using about 30% less steel and 85% less concrete. [http://www.greenindustryplatform.org/wp-content/uploads/2013/07/Broad-Group-BSB-T30-Tower-Hotel_Technical-Briefing.pdf] It was also built using less than 1% of the construction waste discarded in traditional methods and without accidents of any kind. All of the materials used in the building are free of toxic materials such as formaldehyde, lead, or asbestos and are mostly recyclable. | On New Year’s Day 2012, Broad Sustainable Buildings Co. Ltd (BSB) released a time lapse video on YouTube showing how they built a 30—story hotel in just 360 hours (15 days)That video has since been viewed over 6 million times. People were astounded at the speed of this accomplishment; however Zhang Yue, Chairman & CEO of Broad Group, focuses more on the building's sustainability credentials. Tests by the China Academy of Building Research determine that T30 can withstand an earthquake of magnitude 9 on the Richter scale.[https://www.youtube.com/watch?v=-N_Q6Q-3o7M] T30 uses only 20% of the energy consumed by a traditional hotel for heating, cooling and lighting the building. Its’ internal air was found to be 20 times purer than the atmosphere outside and its’ costs between 10% and 30% less to build compared with conventional methods, using about 30% less steel and 85% less concrete. [http://www.greenindustryplatform.org/wp-content/uploads/2013/07/Broad-Group-BSB-T30-Tower-Hotel_Technical-Briefing.pdf] It was also built using less than 1% of the construction waste discarded in traditional methods and without accidents of any kind. All of the materials used in the building are free of toxic materials such as formaldehyde, lead, or asbestos and are mostly recyclable. | ||

Latest revision as of 15:50, 18 December 2018

Developed by Daniel Højgaard Hindhede

Article Type 2, Case study on T30 hotel

Contents |

[edit] Introduction

In the building and construction sector we find some of the oldest projects known today, illustrated with the building of the pyramids in approximately 3500 BC. In spite of the sector’s long history, the project form is widely discredited for being the least developed, regarding efficiency, in the last 50 years.[1] The main focus of this article is to improve project efficiency in the construction sector. This is done by studying prefabricated modular construction methods used in a hotel project called T30, a 30 story building completed in just 15 days in Xiangyien, southern China's Hunan Province by the Broad Sustainable Building Co. ltd. (BSB) A short introduction of the Broad Group and its subsidiary Broad Sustainable Building Corporation is presented. The patented BSB modular concept is described and analysed from a lean construction point of view. Lastly, the implementation of the BSB modular concept as a lean tool for the rest of the construction sector is critically reflected on.

[edit] Broad Group

Broad Group, with a net worth of 900 million USD (2013)[3] , is a leading non-electric air conditioner and filtration systems manufacturer based in China with subsidiaries worldwide including in Australia, France, Malaysia and the United States. Corporate and Social Responsibility (CSR) has been central to Broad Group business philosophy since its foundation in 1988, with particular emphasis on environmental sustainability. The company has reaped international recognition for their business philosophy. In 2009, Broad Group was one of only ten companies to be recognized by the Bloomberg Business Week’s Greener China Business Awards, and in May, 2011, founder and chairman Zhang Yue was awarded the Champions of the Earth Award (Entrepreneurial Vision Category)[4] by the United Nations Environment Programme[5] , in recognition of Broads commitment to climate change. In 2012, the Boston Consulting Group named Broad Group one of its five “sustainability champions”[6] in developing markets, for placing resource management at the core of its business.

[edit] Broad Sustainable Building Co. Ltd.

In 2009 Broad Group expanded their portfolio to include the Broad Sustainable Building Corporation (BSB). BSB provides factory made sustainable buildings, featuring 90% prefabrication with only 10% assembly on site. Founder of BSB, Zhang Yue, explained the reason for this expansion into the construction industry as being twofold.[7]

- The 2008 earthquake in Sichuan province measuring 8 on the Richter scale killed more than 70.000 people mainly because many of the tall buildings were not earthquake resistant.

- According to BSB their tall buildings can withstand an earthquake measuring 9 on the Richter scale.

- The construction industry is the most waste heavy industry and hasn’t improved in decades.

- According to Broad’s numbers, a traditional high-rise will produce about 3,000 tons of construction waste, while a Broad building will produce only 25 tons.

Today BSB prefabricated production facilities (Broad Town) consist of 230,000 m2 of workshops with more than 4000 employees.[8] In the company’s short lifespan, they have held many records and received numerous innovation awards[9]. BCB Record breaking projects:

- In 2010 BSB constructed Ark hotel: 15 stories in just 48 hours.

- In 2011 BSB completed T-30, a 30 story hotel, in just 15 days. At a cost of less than $1000/m2 , it is considered very low cost.

- In 2015 BSB completed J57, a 57 story mixed-use building, in just 19 days.[10]

[edit] T30 Hotel

On New Year’s Day 2012, Broad Sustainable Buildings Co. Ltd (BSB) released a time lapse video on YouTube showing how they built a 30—story hotel in just 360 hours (15 days)That video has since been viewed over 6 million times. People were astounded at the speed of this accomplishment; however Zhang Yue, Chairman & CEO of Broad Group, focuses more on the building's sustainability credentials. Tests by the China Academy of Building Research determine that T30 can withstand an earthquake of magnitude 9 on the Richter scale.[11] T30 uses only 20% of the energy consumed by a traditional hotel for heating, cooling and lighting the building. Its’ internal air was found to be 20 times purer than the atmosphere outside and its’ costs between 10% and 30% less to build compared with conventional methods, using about 30% less steel and 85% less concrete. [12] It was also built using less than 1% of the construction waste discarded in traditional methods and without accidents of any kind. All of the materials used in the building are free of toxic materials such as formaldehyde, lead, or asbestos and are mostly recyclable. [13].

[edit] BSB's prefabrication technology

Unique to the BSB modular construction concept is the change in construction mode from an extensive construction process into a lean, sustainable production line. While modules are being assembled in broad town with duration of 20 days, foundation work is occurring on site at the same time with duration of 35 days. The very fast production time enable this activity to be taking off the critical path. The controlled environment in the production line also minimizes conventional on-site uncertainties like weather conditions and thereby the use of slack in the critical path. This permits earlier building occupancy and contributes to much shorter construction duration as nearly all design and engineering disciplines are part of the manufacturing process. [2]

[edit] Production

Why build in Lego if you can build with Duplo!? This is done by taking dependent WBS parts, away from the construction site and assembling them into WBS modules indoors in a closed environment production facility. The Structural parts such as slab, columns and walls are produced by automatic and semi-automatic assembly lines. Pipes and wires are pre-installed in the floor slabs in the workshops at Broad Town.

- BSB Floor slabs

Each floor slab is a standardized prefabricated concrete-filled, profiled steel module measuring 15.6 by 3.9 meters, with a depth of 45 centimeters. Fixtures like water, drainage, air-condition and electric are preinstalled directly in the floor slabs. The tops are finished with customer request flooring and bottoms are installed with system ceiling.[14]

- BSB Wall panels and columns

Exterior and interior wall panel modules are also prefabricated, including exterior cladding, insulation, sleeve piping for electric installation and interior cladding ready for assembling on site. Columns are steel constructed with a diagonal bracing for strengthening and assembled with high-strength bolts.[15]

[edit] Transportation

The modules, consisting of slab, wall panels, columns, bolts, tools, and other peripherals to connect them are transported by truck to site in pairs in line with the minutely timed construction process and lean principle just in time (JIT)

There are 2 main ways of transportation depending on component types and distance.

- Container transportation (40ft GP). All components (including 12m*2m small main boards) can be put into 40ft containers, which is suitable for marine or long-distance transport. Each container can accommodate 120 m2 of structural parts, or 90 m2 of components when exterior facade/windows are 4 included or 70m2 of components when interior walls/doors are included.[16]

- Truck transportation is used for large main slabs or assembled small main slabs. The low lorry truck must be over 9 m long and can carry loads up to 30t . It is suitable for short-and-medium distance and inland transportation and there is no need for additional assembly and hoisting onsite. But the transport size is 4m wide, which makes the components prone to be damaged in case of wind and rain. And the arrival sequence of the components must be strictly controlled.[17]

[edit] Installation

BSB installation is highly technical. Normally it is handled by cross functional teams from BSB, but other professional contractors can be trained and approved by BSB. The main contractor must be qualified and approved by relevant authorities. Installation order: structure - exterior facade/windows –interior outfitting, pipelines and wires, electromechanical equipment - commissioning - final acceptance. [18]

Standard installation period: 2 to 3 stories per day for the structure, exterior windows: 5 to 10 days, interiors: 20 days - 30 days depending on the project size.

[edit] Interview with Juliet Jiang, Senior Vice President, Broad Group

In a podcast interview with Remontech, Juliet Jiang, Senior Vice President, Broad Group, states that the production time for the entire T30 hotel was 45 days, but was considered a prototype production because the Broad Town workshops were not fully constructed and production flow was not optimal at that time. Today a similar 17.000 m2 order can be produced in 20 days at Broad Town facilities. The foundation for the structure was implemented traditionally on site with reinforced concrete. Duration for this process was 35 days which was not included in the time laps video. The reason for rapid erection time was not a publicity stunt, but to avoid rainy days[19]

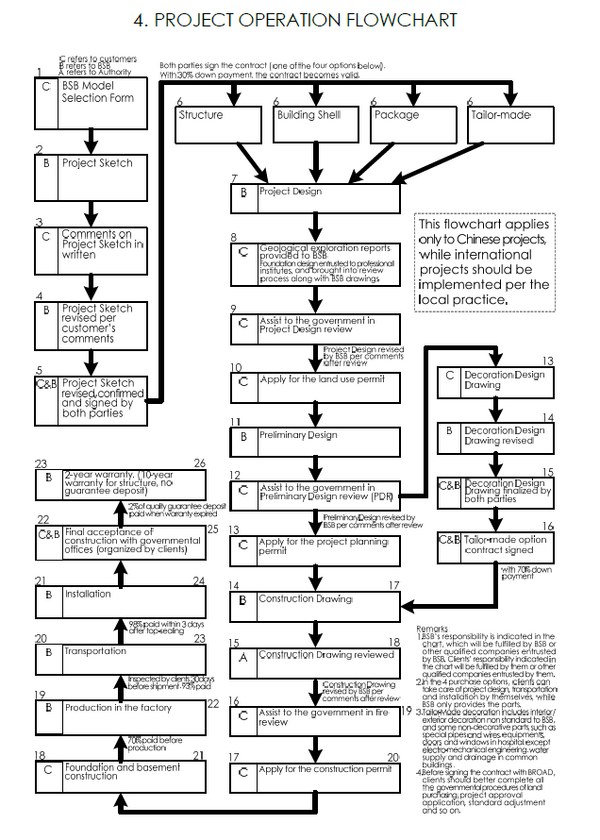

[edit] BSB Project operation flow chart

The BSB Project operation flow chart is one of 3 flow charts used in the overall construction process. This chart is rather basic and mainly addresses the customer, enabling them to grasp the entire building process, and see when and where their involvement is needed. Unfortunately, this is also the only chart available for the public.

The other two flow charts are production and installation flow charts which are combined, in lean terms, and called Last Planner. Using these charts, BCB thereby promotes conversations between on-site and production management and can take action before issues become critical. These conversations increase the chance that work flows and recognizes that personal relationships and peer pressure are critical to the process and principle of minimizing waste.

[edit] Lean Construction

Rightfully, Lean construction has been one of the most important relatively new trends in the construction sector. In recent years, the lean construction principles have been overshadowed by several tools and innovations that have become a big part of lean construction. . The success of BSB projects demonstrates that, to optimize effect, lean construction must be built on a solid foundation of the lean principles, and equally as important, lean construction needs to be implemented in a holistic approach, not just by using several lean tools to address smaller project components.

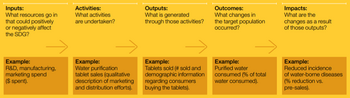

Compared to other industries such as manufacturing, lean construction is considered a relatively new concept within the construction industry . However, even in this short period of time, several innovations and practices have evolved that make up a large part of the lean construction. Some have even become so popular, that they are commonly, yet mistakenly, used as a synonym for lean construction. The most common and popular innovation is modular construction, that has been one of the most popular lean construction methods..[3] Although modular construction can be an extremely effective tool within the lean construction approach, a common misconception is in considering it the tool that will make the construction process lean merely by its sole application. The lean concept can best be described as an efficient production process; a combination of concepts such as Just in Time (JIT), Total Quality Management (TQM), supply chain management and others. The first basic principles of lean construction were presented by Lauri Koskela’s in 1992.[20] These basic principles committed to the construction flow process design and improvement to a more efficient process. They are:

- Reduce the share of non-value-adding activities (waste).

- Increase output value through systematic consideration of customer requirements.

- Reduce variability.

- Reduce cycle times.

- Simplify by minimizing the number of steps, parts and linkages.

- Increase output flexibility.

- Increase process transparency.

- Focus control on the complete process.

- Build continuous improvement into the process.

- Balance flow improvement with conversion improvement.

- Benchmarking. .[4]

[edit] Modular Construction as a Lean Tool

Since construction speed is incorporated in the lean construction concept, tools such as modular construction are vital in achieving the lean process goals of adding value and eliminating waste. Even though modular construction is considered a recent developing trend in lean construction process, modular construction has a long history of existence which can be traced back to the early 19th century where Sears, Roebuck & Co. home builders were producing home kit assemblies that presented the first mass production of modular homes.[21] Throughout the years, the prefabricated modular concept has seen many shapes and forms from prefabricated houses to container shaped stacked homes. Due to earlier inflexibilities, poor design and uniformity, the modular construction concept has not decisively taken root in the construction industry so we now see a decrease in prefabrication size despite the fact that this increases the degree of manual labor on site. Modular construction and prefabrication transforms the project form to what a construction project really is, a delivery project.[5] Modular construction is a tool that contributes to lean construction and builds on the founding principles of clean construction. Some advantages of modular construction include:[22]

- Increased speed of the overall construction process

- Less waste throughout the entire construction process

- Increase in labor productivity

- Improved work supervision

- Less susceptibility to environmental impacts, such as weather

- Smoother construction schedules

- Less material storage and handling requirements

- Increase worker safety and less risk exposure .[6]

Modular construction has become even more popular as the construction industry has become aware of its advantages. In recent years, particularly two aspects of modular construction have contributed to its popularity; its ability to reduce waste and recycle materials, and the BIM (Building Information Modeling)[23] that improves the communication aspect of lean within these modular or prefabricated constructions. Thus, modular construction is very useful in the lean construction process regarding increased productivity and reduced/elimination of waste.[24]

[edit] BCB projects analyzed from a lean perspective

The construction of the T-30 Hotel demonstrates the efficient use of the lean modular construction concepts using the right tools. The 30-storey, 17.338 m2 hotel was erected in just 15 days. Ninety percent of the building was prefabricated according to the specifications offsite with just in time deliveries. The main building structure was built in 46 hours. The building has world class soundproof and thermal insulation along with air quality monitoring for every room to overcome increasing pollution problems. The building project also had a impressive safety record with virtually no injuries reported on the project.

The Ark Hotel, another BSB project constructed before the T30, used 6 times less material and ended with extremely less waste which is about 1% compared to the building sector average of 10%. The building is considered to be 5 times more energy efficient than its’ counterparts average energy consumption. These recent BCB projects also enjoyed tremendous success using the lean principles and more advanced tools such as BIM and advanced modular and prefabrication innovations.

With the building of T30 and Ark-Hotel, BSB added the sustainability dimension to all their projects which is an integrate part of lean, since reducing energy consumption and preserving the environment is one of the ultimate longtime waste reductions. During the design phase BSB used customer requirements to add to their product value working with collaborative entities that included all the project stakeholders. By taking on a factory controlled working environment to develop most of their prefabricated sections, they reduced much of the process variability. To eliminate waste and reduce the process cycle time, they broke down every process within the construction phase. BSB also focused on the complete control process, not just the prefabricated skeleton, so that they could attain a holistic completed lean project. As a result of using a lean business model approach, BSB has demonstrated consistency regarding project quality as most of its buildings exhibit high magnitude earthquake resistance, relatively low construction and maintenance costs, environmentally friendliness and high air quality along with significantly low construction waste and amazing safety records. As a further result, using the right innovative tools of modular construction, BIM, JIT and others have been a success story in the BSB projects.

As described above, the lean approach must be adopted as a holistic system based on the solid foundation of lean principles. Therefore, like any new approach, it must receive commitment from top management to make the lean system an integral part of a company’s culture and changing the way of doing business, as one of the main concerns. Zhang Yue, Chairman & CEO of Broad Group has permeated lean values in the company culture. Fx. To become an employee of Broad, you must recite a life manual penned by Zhang, in which there are guidelines that include tips on saving energy, brushing your teeth, and having children. All prospective employees must be able, over a two-day period, to run 7.5 miles. You can eat for free at Broad Town cafeterias unless someone catches you wasting food, at which point you are not merely fined but publicly shamed. In many cases, failure of commitment from top management will result in some individual trials to implement some lean tools here and there on a need-basis. Even though the isolated use of these tools occasionally may generate success, eventually a clash will occur with the conventional ways of doing business, the end result often being major setbacks. This is why certain aspects of the construction business model have to be changed to meet the lean model concepts.

[edit] Implementation of BSB lean modularization in the construction sector

[edit] Strategic

The impressive T30 accomplishments in waste, cost, time and quality aspects are not a direct product of construction modularization but a product of a holistic implementation of lean principles and lean culture permeated through the entire Broad Organization. This raises some issues concerning the lean business model vs the conventional construction business model if T30 accomplishments should be passed on to the general construction business.

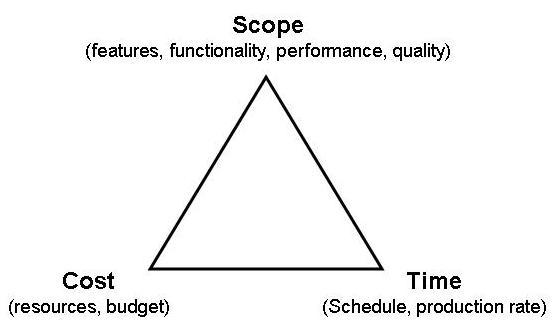

In general, the construction sector is a project oriented business with the main focus based on meeting four main goals represented in scope, budget, schedule and quality, and in addition the safety component. While still meeting these goals, a more customer oriented lean model can exceed those relative simple goals, while adding value to the customer and improving the overall process. A lean-driven business model should establish a customer focused strategy that increases/adds value to the customer while reducing waste and risk in the process. Like any other business, the main elements of the construction business are the resources, the process and the management. Lean accomplishes this largely eliminating the waste component that can be represented in the form of waiting time, motion time, over processing, transportation, storage, correction and, most importantly, underutilized resources whether it be human resources, building material or equipment..[4]

These many differences in the management approaches are why lean construction can be adopted by the construction industry in many shapes and forms, with very different outcomes. The T30 hotel form is build on a holistic lean approach and construction companies needs to implement the lean approach as a system and a way of doing business, not as a tool, in order to meet the accomplishments T30 hotel did.

[edit] Tactical

In the construction sector, a similar project to T30 is typically handled by a general or turnkey contractor, using external subcontractors and suppliers. General, or turnkey, contractors typically have one trade contract internally and no production line. BSB is thus rather unique since they essentially handle every process from production, logistics and monitoring to assembly using interdisciplinary teams. This scenario makes a holistic Lean implementation easier, as only one culture must be changed and all processes from production to installation can be trimmed internally.

The scenario is another for the turnkey contractor, where the vast majority of the craft and production is external and therefore many organizational cultures and processes that must be changed when implementing the holistic lean approach. The reason for This setup, using external subcontractors and suppliers, is used as it makes turnkey contractors’ organizations less sensitive to the construction industry’s cyclical fluctuations.

T30’s impressive achievements could offer a tactical approach to optimization in the construction industry. This could be achieved by turning the current construction project form upside down; making the supplier of a prefabricated lean modular system turnkey contractor, since all design and engineering disciplines already are part of the manufacturing process. Depending on the work load, external multidisciplinary artisan teams could be hired and schooled for assembly onsite. This would change the construction mode from an extensive construction process into a lean, sustainable production line, with a demonstrated significant improvement in waste reduction..[7]

[edit] Reflection of article process

This case study started out being a study of optimization in the construction sector with focus on prefabricated modularization as a project management tool in the building of T30. As the case study progressed, it became clear that the project accomplishments were not the sole product of a well implemented management tool, but due to the employment of the entire lean management toolbox. This changed the focus of the paper significantly. Where the original focus was on the impact of T30 modular construction methods on well-known project management tools, such as work breakdown structure, critical path method, and earned value management, the paper now concentrates primarily on lean construction principles Transformation (T), as a Flow (F), and as Value generation (V). . This is also the reason why the title of this article has changed to “Construction modularization from a lean perspective, a case study on T30 Hotel”.

[edit] Related Articles

- Modularisation: A modern process for project management

- Lean as a project management tool

- Lean construction

[edit] Annotated bibliography

- ↑ John Ryding Olsson & Mette Lindegaard Attrup 2015; Power in Projects, Programs and Portfolios 59-63 Annotation: The chapter describes the project from the first construction projects to modern IT projects. The construction industry is the oldest but least developed project form over the past 5 decades.

- ↑ The Modular Building Institute; Improving Construction Efficiency & Productivity 2010 with Modular Construction AnnotationThe National Institute of Standards and Technology (NIST)requested an committee of experts to provide advice for advancing the competitiveness and productivity of the U.S. construction industry. The committee identified five breakthroughs to improve the efficiency and productivity of the construction industry, including breakthrough number three: “Greater use of prefabrication, preassembly,modularization, and off-site fabrication techniques and processes.”

- ↑ Niels Ahrengot, Michael Leck & Thomas B. Christiansen 2014; LEAN - Implementering i danske virksomheder. Chapter 9

- ↑ 4.0 4.1 Lauri koskela 1992, Berkeley; Application of the new production philosophy to construction Annotation Lauri Koskela challenged in 1992 the construction management community to consider the inadequacies of the time, cost, quality tradeoff paradigm. Evidence from the research and observations indicated that the conceptual models of Construction Management and the tools it utilizes (work breakdown structure, critical path method, and earned value management) fail to deliver projects 'on-time, at budget, and at desired quality. Koskela argued that the mismatch between the conceptual models and observed reality underscored the lack of robustness in the existing constructs and signaled the need for a theory of production in construction. Koskela then used the ideal production system embodied in the Toyota Production System to develop a more overarching production management paradigm for project-based production systems where production is conceptualized in three complementary ways, namely, as a Transformation (T), as a Flow (F), and as Value generation (V).

- ↑ Remon Fayek Aziz & Sherif Mohamed Hafez 2013, Alexandria University; Applying lean thinking in construction and performance improvement Annotation Remon Fayek Aziz & Sherif Mohamed Hafez discusses the basic lean tools, methods, and implementation phases of lean production in construction showing the waste in construction and how it could be minimized.

- ↑ Pekka Huovila and Lauri Koskela 1997, Berkeley; Contribution of the Principles of Lean Construction to Meet the Challenges of Sustainable Development Annotation Koskela & Huovila suggests the challenges of sustainable development to be considered in the lifecycle process of buildings. Sustainable development concepts are presented featuring social, ecological, cultural and environmental facets. Kokela & Huovila establish a clear link between lean production principles and sustainability because of the flow view (eliminating waste) is crucial in production.

- ↑ Gregory A. Howell1 1999; What is lean construction? (Lean Construction Institute) Annotation" Basic introduction of Lean construction, lean production and production management