Critical Path Method in Construction Industry

Adam.pekala (Talk | contribs) (→Resource-Dependent Critical Path Method) |

|||

| (2 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| + | ''Developed by Adam Dominik Pekala'' | ||

| + | |||

| + | |||

'''Critical Path Method (CPM)''' is a project management method created in 1958 in American company DuPont to improve internal production processes. Since then the method is widely used in industries such as construction, aerospace, defense, engineering, research and many more. However, this article focuses on its use in civil engineering industry and construction. The method is suitable for all kind of construction projects that require many independent activities to be completed. | '''Critical Path Method (CPM)''' is a project management method created in 1958 in American company DuPont to improve internal production processes. Since then the method is widely used in industries such as construction, aerospace, defense, engineering, research and many more. However, this article focuses on its use in civil engineering industry and construction. The method is suitable for all kind of construction projects that require many independent activities to be completed. | ||

| Line 170: | Line 173: | ||

== Resource-Dependent Critical Path Method == | == Resource-Dependent Critical Path Method == | ||

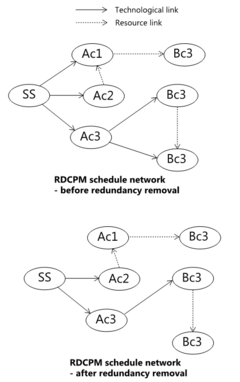

| − | [[File:CPM Figure10a.PNG| | + | [[File:CPM Figure10a.PNG|240px|right|thumb|<center>Figure 5: RDCPM - Redundancy ''(source: own construction based on <ref name=RDCPM/>)</center>'']]Since as mentioned in Linear Resource Based CPM chapter it is impossible to identify corrects slacks and critical path which is resource based using regular CPM method, further studies were undertaken and 4-step resource dependent critical path method was created (RDCPM). This method, however, was constrained by assumption of maximum resources being available during the whole duration of a project. A new method was created and called Enhanced RDCPM<ref name=RDCPM>[https://www.jstage.jst.go.jp/article/jscejcei/69/2/69_I_110/_article]''”Enhanced Resource-Dependent Critical Path Method for Identifying Resource Dependencies in Variable Resource Constrained Project” Journal of Japan Society of Civil Engineers, Ser. F3 (Civil Engineering Informatics) Vol. 69 (2013) No. 2 p. I110-I120''</ref> - taking from the traditional CPM and Resource Constrained Scheduling. It is divided in 6 steps which are as follows: |

# Performing CPM – standard analysis is performed with forward and backward pass to calculate ES, EF, LS, LF and floats for each of the activities. | # Performing CPM – standard analysis is performed with forward and backward pass to calculate ES, EF, LS, LF and floats for each of the activities. | ||

# Inserting Dummy Activities – if the project has varying resources during its execution it might be impossible to identify resource dependencies for activities. It is inserted in-between the periods where the availability of the resources varies – classic RCS can be easily used. Moreover dummy activities might help to establish resource links between activities so that the schedule is easily updateable. | # Inserting Dummy Activities – if the project has varying resources during its execution it might be impossible to identify resource dependencies for activities. It is inserted in-between the periods where the availability of the resources varies – classic RCS can be easily used. Moreover dummy activities might help to establish resource links between activities so that the schedule is easily updateable. | ||

Latest revision as of 15:34, 18 December 2018

Developed by Adam Dominik Pekala

Critical Path Method (CPM) is a project management method created in 1958 in American company DuPont to improve internal production processes. Since then the method is widely used in industries such as construction, aerospace, defense, engineering, research and many more. However, this article focuses on its use in civil engineering industry and construction. The method is suitable for all kind of construction projects that require many independent activities to be completed.

Critical path is a sequence of activities that lead to the shortest possible completion of the project. These activities are called critical activities and every delay in each of these activities will result in delay of the whole project. This article depicts ways of using the method to analyze projects as sets of several groups of activities to reduce the bottleneck points and finish the project on time and within the budget. Methodology of creation of the basic CPM direct acyclic graph (DAG) is presented in a way of short step-by-step tutorial.

Construction projects, although very complicated, are similar or even identical in a way of having similar unit activities and resources. Scheduling in linear construction projects require use of aforementioned resources from one activity to another in such a way, that continuity and logic between network activities is sustained. In the article the procedure for CPM-based scheduling in linear construction projects is described and explained. Moreover, Resource Dependent Critical Path Method (RDCPM) is presented based on Hong Kong Polytechnic University practical method based on the additional dimension of time added to the dimension of time. As a summary, advantages and disadvantages of the method are described as well as limitations to the use of CP-Method. At the end of the article annotated bibliography with reference links and follow-up material is provided.

Contents |

[edit] Big idea

[edit] Short history

While the method itself had been created in 1958, its induction to construction industry happened awhile later. There are always two stages recognized while implementing a new method: first stage, when there has been an initial interest aroused in the industry and second, while the overall effects on the industry are known. It took as long as in 1968 when the method was known well enough to consider it to be in its second stage – mainly due to time-consuming characteristic of construction projects.[1] Nevertheless, the method was adapted to specifics of civil and construction projects’ characteristic and was successfully used in the industry ever since.

[edit] Evolution

What helped CPM to be more and more popular was that it is of great utility while managing bigger projects – the method was immediately implemented to projects of value higher than £100’000[1](value from 1968, approx. £2’000’000 nowadays). The method itself has not changed much in terms of its methodology. Algorithms of calculation of critical path remain the same. What changed significantly is the use of the computers in its implementation to the projects. Back when the method was created hand calculations were common almost for all of the projects, at least for tender stages. Project managers mentioned from 50 up to 600 activities[1] as a range for hand calculations using CPM. Nowadays various types of software is used i.a. Primavera[2], MS Project[3] or various spreadsheets.

[edit] Software and CPM spreadsheets

As mentioned above, computerization has affected all of the industries and it has also changed the way CPM was used. Below there is most popular software presented.

[edit] Microsoft Project

It is one of the most commonly used computer programs to manage projects. According to Malaysian case it was used in approximately 80% of cases.[4] Link to the producent website can be found here. As it can be difficult to start without any addtional assistance a tutorial prepared by Illinois Institute of Technology which can be accessed here. It provides with good basis and thoroughly explained example which can be very useful for further work with bigger projects

[edit] Primavera Scheduling P6

Second most popular piece of computer software on the market. Claimed to be intuitive in use and suitable for greatest projects is a competitive alternative for MS Project. More information can be found here. The webpage offers overlook at various online trainings and provides with interesting free training videos about the use of Primavera P6 and CPM method itself.

[edit] Excel spreadsheets

They are cheaper alternative to aforementioned licensed, proffesional software. For smaller projects they might be as effective as their big brother MS Project and big sister Primavera P6. Spreadsheets have usually the algorithms of CPM implemented inside and they are intuitive for inexperienced user. Some producers are saying that "If you can copy and paste, enter data into cells, and follow a few simple guidelines, you can do a critical path analysis with almost no learning curve."[5] Some examples of easy-to-use spreadsheets are presented here

[edit] General methodology

The Critical Path Method indicates sequence of activities that determine the earliest possible completion for analyzed project. The resulting sequence (or sequences – there might be more than one) is called the critical path. All of its activities are called critical activities and any delay in those will cause a delay for the project or phase in general. A guide to create the critical path is as follows:

- Identify the activities – a thorough check and investigation on every activity present in the project or stage should be made - project scope and details are helpful. Every activity should be described with estimated (but precise) duration.

- Activity sequence establishment – it is the most important step to create working and correct critical path. For this to be done correctly three questions should be answered for every activity:

- which tasks should take place before this task

- which tasks should be completed at the same time

- which tasks should happen immediately after this task

- Network diagram creation – it should be prepared based on the prepared sequence

- Activity completion time estimation - this value should be estimated based on the experience or resource catalogues. Since CPM is a deterministic model it does not take into account variation in the completion time - an exact number has to be put in.

- Identification of critical path – based on parameters such as Earliest Start Time, Earliest Finish Time, Latest Finish Time, Latest Start Time (to be explained in following chapter)

- Live updating of critical path diagram – all of the changes that are happening to the project should be implemented into the diagram and method for them to be accurate during whole project time

[edit] Graph creation method

[edit] Terminology and suggested layout

For CPM a natural representation of the critical path is a Directed Acyclic Graph[6]. This is a type of graph that is created by collection of vertices and direct edges in a way that there is no loop (no way to start at one activity and after following a sequence loop back to the same activity).

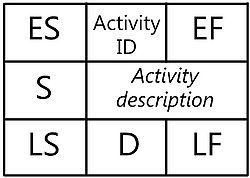

Graphs for CPM are specific type of PERT graphs. However, in CPM the time of a single activity are identical and there is no distinguishing between optimistic, pessimistic and most likely time. For creating a network there are many types of activity boxes sugested, one of which is presented on the right.

On the figure:

- ID - Activity number

- ES - Earliest possible start

- EF - Earliest possible finish

- LS - Latest possible start

- LF - Latest possible finish

- D - Duration

- S - Slack

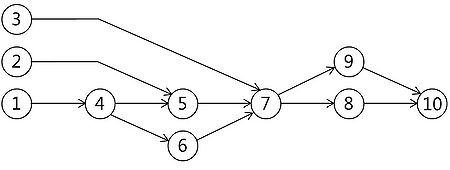

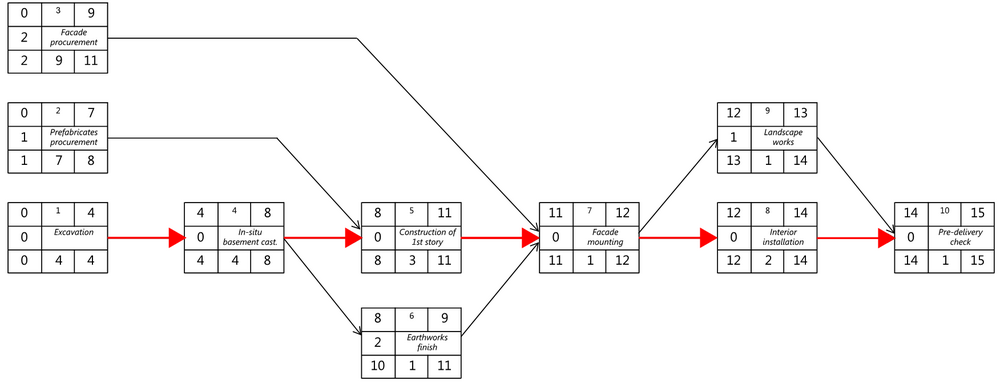

[edit] Example of CPM graph creation

Based on a simplified one story building and reduced to basic number of activities a CPM method with CPM graph creation will be presented. First of all, following the methodology there is a need to point out all of the activities that are identyfied in the project and estimate their duration. In the example activity list from the table below will be used. Then, by analyzing inter-activity dependencies, a dependecy graph is drawn. As a rule of thumb the graph starts on the left side with starting activities (independent activity that happens in t=0) and finishes with last activity that is the last activity (followed usually by activities from the critical path).

| ID/Number | Name/Description | Estimated duration |

| 1 | Excavation | 4 |

| 2 | Prefabricates procurement | 7 |

| 3 | Facade procurement | 9 |

| 4 | In-situ basement casting | 4 |

| 5 | Construction of 1st story | 3 |

| 6 | Finishing earthwork | 1 |

| 7 | Facade mounting | 1 |

| 8 | Interior instalation | 2 |

| 9 | Landscape works | 3 |

| 10 | Pre-delivery check | 1 |

There are two main steps to be performed based on the activities' duration provided in activity table - forward pass calculation and backwards pass calculation.

[edit] Forward pass calculation

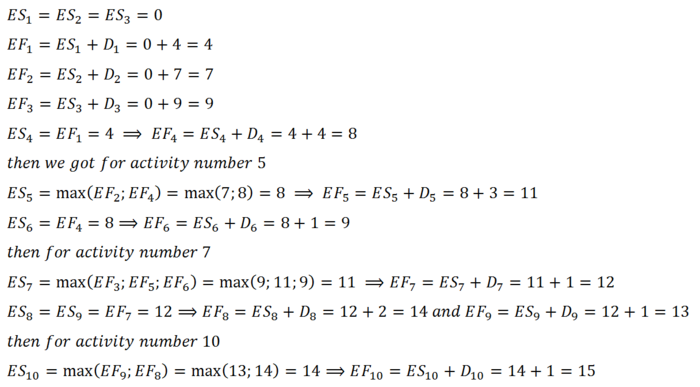

As in the dependency tree there are three starting activities - all of them are granted Early Start time equal to zero. Based on the dependency graph and durations we calculate earliest finish time of those by adding duration to start time of analysed activity. Earliest start time of analysed activity is the highest value of earliest finish of preceding activities. Calculations to obtain ES and EF times are performed as follows:

Based on the duration of single activity total project time has been derived and is equal to 15 weeks.

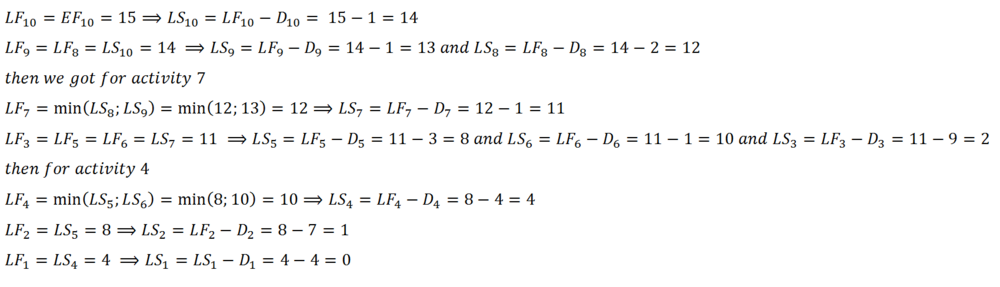

[edit] Backward pass calculation

Given the ES and EF times total duration of the project is obtained. This value is the latest finish for last activity. Afterwards, latest start values are calculated by substracting duration from latest finish value. For preceding activities latest finish is the minimum value of latest start of depedent activities. In our example LF and LS times are derived as presented below:

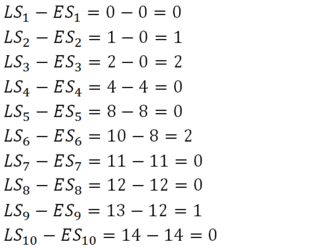

[edit] Slack calculation

Based on values of ES and LS the possible slack is calculated. Slack is a delay time that will not cause any delay for the whole project. Calculations of slack are based on LF and EF times and are the difference between those two. There is no slack on a critical path.

[edit] CPM Graph

Based on all of the information above a CPM graph is sketched. To create the graph all of the results from calculations presented above are put into boxes presented in suggested layout. These boxes are then placed according to the dependency graph. All of the activities with no slack are called critical activities and the sequence of those is called critical path - marked red on the graph.

[edit] Resource based CPM scheduling in linear projects in constrction

[edit] Intoduction and differences

Construction projects, although made as "one-off" and completely different from each other are very similar in a way of repeating processes within one project. Multi-storey buildings, highways being built stage by stage or even gas pipelines. All of them have linear, repetitive characteristics and they require special approach in scheduling. Critical Path Method provides the scheduler with slack/free float time, times of earliest start or finish but it assumes unlimited resources. Scheduling of a construction projects has to be made while keeping in mind not only continouos use of resources but also the logic between activities at the same time. The most useful and most convenient method to do so is Line of Balance or Linear Scheduling Method. Created in early 1940s and developed in 1952 and 1960 by US Navy with the idea of evaluating production lines - processes with lots of repetitions and using series of workstations. It took as long as to 2004 while The National Agency of the United Kingdom implemented it for repetitive housing units[7]. The methodology and rules for Linear Critical Path Calculations are almost the same as for regular CPM. However, here calculations are based on activities divided in different stages. Combination of those will produce logical network with availability of resources and continuity of its usage.

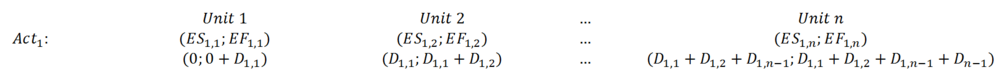

[edit] Forward pass calculations

Foward pass calculations are driven the same logic as for regular CPM. However, the calculations are divided for different activities and substages of the activities. The linear method assumes that as soon as one stage is finishd, the second stage should follow immediately. Below there are First Activity calculations presented in division for n-stages.

More of the calculation steps and thorough methodology including lags and delays can be followed in the technical paper of Journal of the South African Institution of Civil Engineering[7].

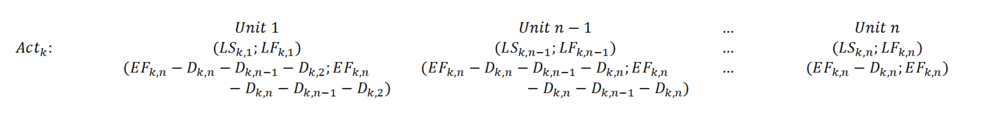

[edit] Backward pass calculations

The backward pass in linear scheduling goes from the last stage in last activity and follows the same logic as for regular CPM. Below there are k-th activity calculations presented in division for n-stages.

More of the calculation steps and thorough methodology including lags and delays can be followed in the technical paper of Journal of the South African Institution of Civil Engineering[7].

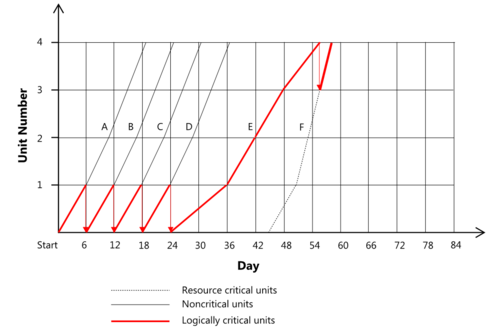

[edit] Linear schedule example

Known from CPM, activities with no float time are considered critical. However, contrary to linear scheduling, CPM cannot maintain resource continuity as it focuses basically on satisfying logical dependecies and might be adjusted afterwards by resource availability criteria. Linear projects require continuous usage of resources what leads to two types of criticalities - logic criticalities (defined by CPM) and resource criticalities. If any of the activities is resource critical according to linear scheduling, it will be delayed and cause the whole project to delay. On this basis some of the non-critical CPM activities might become critical in linear schedules.

A way of showing the dependencies is by drawing differently sloped lines on graphs. This procedure for linear-CPM graph is completely user-based and does not follow any strict algorithm. Here the scheduler defines the critical activities (both logically and resource dependent) and places them on the graph based on calculated previously values of Early/Late Start and Finish times.

Based on the sample graph with 6 activities divided into 4 stages each there are following criticalities:

- A1, B1, C1, D1, E1-E4 and F4 are logically critical due to inter-actvity dependencies

- F1-F3 were scheduled as resource dependent to provide resource continuity. If any of these activities is delayed, F4 (critical path) will be delayed

- remaining activities are non-critical. If they are delayed they will disturb resource continuity, not the delivery time.

[edit] Resource-Dependent Critical Path Method

- Performing CPM – standard analysis is performed with forward and backward pass to calculate ES, EF, LS, LF and floats for each of the activities.

- Inserting Dummy Activities – if the project has varying resources during its execution it might be impossible to identify resource dependencies for activities. It is inserted in-between the periods where the availability of the resources varies – classic RCS can be easily used. Moreover dummy activities might help to establish resource links between activities so that the schedule is easily updateable.

- RCS forward pass calculation – based on previously performed steps RCS forward calculation is performed to set the maximum available resources and omit resources that are overloaded. More information about the process can be found in here[8]

- RCS backward pass calculation – RCS backward pass is performed to establish resource constrained LSj and LFj based only on original CPM ES and EF.

- Resource Dependency identification – Authors of the enhanced RDCPM indicate two different dependencies that exist in the projects.

- Strict Resource Precedence Relation – relation in which a delay in finish time pre-occurring activity results in delay in finish time of following activity

- Flexible Resource Precedence Relation – relation in which a delay in finish time of pre-occurring activity results in delay of start time only, in following activity

- Removal of redundant precedence relations – all of the redundant activities can be safely removed from the schedule. If an activity is preceded by two inter-dependent activities, one of the links can be safely removed. Example of link removal is presented in Figure 5.

[edit] Method advantages

Critical Path Method is very simple but complete project management tool. It is intuitive and easy to learn and can be performed quickly and successfully, even without use of computer software (good for quick estimations on site in site office). Its first and possibly the greatest advantage is that it provides with completion time for each and every activity, stage or project.

Moreover, it provides the user with logical discipline based on activities' dependencies and, what is more, offers a visual representation of the project activities. This might be a big advantage compared for example to bar charts where all dependencies tend to be blurry. It is crucial in the industry - knowing the dependencies has been mentioned a great advantage even in 1968 – more than 90% of contractors claimed it useful[1]

CPM results in one or more critical paths - those enable project manager to track critical activities – and in result to spot activities that should be of particular attention due to possible delay-causing. It helps keeping project on schedule and predicts where the delays might come from.

[edit] Use limitations

First and foremost the limitation of CPM is that the duration of each activity is fixed. Contrary to PERT, where three different times are assigned to an activity[9], CPM methodology takes for granted that the activity duration can be very accurately estimated and does not allow for any extensions.

Secondly, a big limitation of basic CPM is time-based focus. CPM can plan the project based on activities duration and provide with correct time-based critical activities. However, it does not take into account resources and resource-based critical activities. If the last prove to be different than the first, the project might be delayed and it might happen unexpectedly. It should be kept in mind that apart from some techniques described above CPM itself does not account for resource-based dependencies but accounts for unlimited resources necessitating further adjustments.[7] Considering resources, regular CPM does not enable the user to calculate correct resource-based time floats. In that case either CPM and resource analysis should be performed or Enhanced RDCPM should be implemented.

Some projects are repetitive with circular references between some activities. That kind of project cannot be managed by CPM as it is not suitable for cyclic activities - each activity has only one defined ES, EF, LS and LF. CPM graphs are clear and present dependencies. However, many construction managers prefer to use bar charts on site as they enable to track time clearer and in more efficient way.

Next limitation depends on size of the project. Large ones are characterized by thousands of activities. This will mean that there are dozens of dependecies and figuring them out might take a long time. Here it is very useful to use a planning software or spreadsheet to make creating CPM easier.

Last but not least, CPM is not good for dynamic tracking of the process. A change in one activity means that the whole diagram must be recalculated. While it is hardly a problem when the planning was computer based, it might cause some difficulties if one need a quick estimate and is away from the PC or file.

[edit] Conclusions

Critical Path Method has gone a long way since it was created and right now various types and evolutions are in use. Judging by opinions and survey results in construction industry it was a kind of breakthrough for planers, schedulers and project managers. Its flexibility and possibility of application in almost every construction project makes it an almost complete tool for sequencing analysis. If the CPM is performed correctly it will give the project manager all of the critical activities and, if updated on a regular basis, will prevent or at least warn about a delay.

CPM is a simple tool to analyze complex projects. Its abilities have been spotted back in 1960s and nowadays its use can be even easier with lots of software out there on the market to support calculations and scheduling.

It is important to choose appropriate version/evolution of a method to suit the project being analyzed best – it will result in high accuracy in project planning and minimize unexpected during procurement – and therefore can be a guarantee of a smooth procurement.

[edit] Bibliography and further links

- ↑ 1.0 1.1 1.2 1.3 [1]“Critical path analysis and the civil engineering industry, D.H.Wade, ICE Proceedings, Volume 39, Issue 2, 01 February 1968 , pages 289 –303”

- ↑ [2] Primavera P6 Scheduling - producent and distributor website

- ↑ [3] MS Project - producent website

- ↑ [4]"The Usage of Critical Path Method Software in Malaysian Construction" Suhaidi Elias, Noriah Ismail, The International Journal of Knowledge, Culture and Change Management - Volume 11, Issue 5, 2012 ISSN 1447-9524

- ↑ [5] Vertex 42 Spreadsheets - easy to use CPM/PERT spreadsheet in free and licensed version

- ↑ [6] Directed Acyclic Graph - Wikipedia Page (accessed on 21-09-2015)

- ↑ 7.0 7.1 7.2 7.3 7.4 [7] “A procedure for critical path method-based scheduling in linear construction projects” On-line version ISSN 2309-8775, Journal of the South African Institution of Civil Engineering

- ↑ 8.0 8.1 8.2 [8]”Enhanced Resource-Dependent Critical Path Method for Identifying Resource Dependencies in Variable Resource Constrained Project” Journal of Japan Society of Civil Engineers, Ser. F3 (Civil Engineering Informatics) Vol. 69 (2013) No. 2 p. I110-I120

- ↑ PERT Program evaluation and review technique (PERT) - DTU MAN Wiki (accessed on 27-09-2015)

[edit] Description

- “Critical path analysis and the civil engineering industry, D.H.Wade, ICE Proceedings, Volume 39, Issue 2, 01 February 1968 , pages 289 –303” - Critical path analysis and the civil engineering industry is an old article that treats about first impressions and first applications of the method few years after the method was created. Interesting content is based on feedback from contractors and consultants from civil engineering industry. Total number of around 180 interviewees were given a questionnaire treating use of CPM in the industry and ongoing projects. Advantages and disadvantages are presented as well as comparison to other method used in the industry at the same time. Even though the article seems to be outdated it still provides crucial data and valid information from practitioners of CPM.

- “A procedure for critical path method-based scheduling in linear construction projects” On-line version ISSN 2309-8775, Journal of the South African Institution of Civil Engineering- the article treats about procedures and adaptation of the method to linear civil engineering projects. Since a lot of the projects are repetitive in some way a evolution of CPM is needed to provide for accurate scheduling. The article presents thorough explanation of CPM in linear projects explaining step-by-step calculations as well as provides reader with an example. It is easy to read and understand and was a crucial source in writing parts treating about linear CPM in this article.

- "Enhanced Resource-Dependent Critical Path Method for Identifying Resource Dependencies in Variable Resource Constrained Project” Journal of Japan Society of Civil Engineers, Ser. F3 (Civil Engineering Informatics) Vol. 69 (2013) No. 2 p. I110-I120 - this article presents the evolution of CPM on form of resource based scheduling. Written in reader-friendly manner, it provides with step-by-step explanation of calculation method, providing with graphical examples for each of the calculation step process. Moreover, it treats about project management software and RDCPM contribution to those types of programs.

[edit] Follow-up reading material

- "The Usage of Critical Path Method Software in Malaysian Construction" Suhaidi Elias, Noriah Ismail, The International Journal of Knowledge, Culture and Change Management - Volume 11, Issue 5, 2012 ISSN 1447-9524 The article is a kind of a case study based on Malaysian Construction Industry. Again, survey among ca. 110 contractors was distributed and the use of the software was analysed. Article mentions CPM-based software as a advantage for the project managers to increase performance of the projects. Questions and answers about type of software, increase of efficency or frequence of software usage are presented which gives an overlook on Malaysian industry. The study seems reliable given reasonable number of interviewees and the article might be a good follow-up after reading the article above.

- "Resource-Activity Critical-Path Method for Construction Planning" Ming Lu, Heng Li The article gives an overlook on existing methods as well as provides with Resource Dependent CPM approach. Algorithm of RACPM and its development is presented. It is a great follow-up material for deeper understanding of Resource-Activity Dependent planning in construction industry. Ideal source for people interested in resource-activity integration presented in the article above.