Line Balancing - Yamazumi Chart Method

| (13 intermediate revisions by one user not shown) | |||

| Line 8: | Line 8: | ||

A project manager should use this tool to both manage, execute and control the project schedule, as early/late start/finish dates of projects/activities are easily identifiable from the otputs. Other resource levelling, smoothing, crashing and fast tracking techniques can be applied if necessary, ensuring the timely completion of a project or the delivery of products. | A project manager should use this tool to both manage, execute and control the project schedule, as early/late start/finish dates of projects/activities are easily identifiable from the otputs. Other resource levelling, smoothing, crashing and fast tracking techniques can be applied if necessary, ensuring the timely completion of a project or the delivery of products. | ||

| + | |||

| + | ==Benefits== | ||

| + | |||

| + | The Yamazumi chart provides a time management mechanism to rebalance a project when supply and demand changes quickly. | ||

| + | |||

| + | The chart provides a simple visual indication of project activities that are: | ||

| + | |||

| + | -Overloaded | ||

| + | |||

| + | -Underutilized | ||

| + | |||

| + | because of delays, wastage or blockages. | ||

==Methodology== | ==Methodology== | ||

| − | + | ===Step 1: Create activity list=== | |

A list of all sub-activities that are required in order to complete the project are listed in sequential order. Sub-activities can be grouped and named according to their stage in the project or process. | A list of all sub-activities that are required in order to complete the project are listed in sequential order. Sub-activities can be grouped and named according to their stage in the project or process. | ||

| Line 20: | Line 32: | ||

|+ Example sub-activity list | |+ Example sub-activity list | ||

! Activity sequence | ! Activity sequence | ||

| − | ! Sub- | + | ! style="border: 1px solid black; padding: 5px; background: #ffdead;" | Sub-Activity |

|- | |- | ||

! 1 | ! 1 | ||

| − | | | + | | Warm pressing machine |

|- | |- | ||

! 2 | ! 2 | ||

| − | | | + | | Setup next pressings |

|- | |- | ||

! 3 | ! 3 | ||

| − | | | + | | Align nuts |

| + | |- | ||

| + | ! 4 | ||

| + | | Align studs | ||

| + | |- | ||

| + | ! 5 | ||

| + | | Load plate | ||

|} | |} | ||

| − | + | ===Step 2: Classification=== | |

All sub-activities are labelled as: | All sub-activities are labelled as: | ||

| − | - Value added | + | - Value added (VA) |

| − | - Non-Value added | + | - Non-Value added (NVA) |

| − | - Waste | + | - Waste (W) |

| − | Each label helps to clearly identify which sub-activities add value to the project | + | Each label helps to clearly identify which sub-activities add value to the project and must be completed for project success. Sub-activities that are labelled as NVA or W should be minimised or eliminated from project processes where possible. |

{| class="wikitable" | {| class="wikitable" | ||

|+ Examples of sub-activities and their classifications | |+ Examples of sub-activities and their classifications | ||

| − | ! | + | ! style="border: 1px solid black; padding: 5px; background: #efefef;" | Activity Sequence |

| − | ! | + | ! style="border: 1px solid black; padding: 5px; background: #ffdead;" | Sub-Activity |

| + | ! style="border: 1px solid black; padding: 5px; background: #ffdead;" | Classification | ||

|- | |- | ||

| − | ! | + | ! 1 |

| − | | | + | | Warm pressing machine |

| + | | style="border: 1px solid black; padding: 5px; background: #ff0000;" | Waste | ||

|- | |- | ||

| − | ! Non-value added | + | ! 2 |

| − | + | | Setup next pressings | |

| + | | style="border: 1px solid black; padding: 5px; background: #ffff00;" | Non-value added | ||

|- | |- | ||

| − | ! | + | ! 3 |

| − | | | + | | Align nuts |

| + | | style="border: 1px solid black; padding: 5px; background: #ffff00;" | Non-value added | ||

| + | |- | ||

| + | ! 4 | ||

| + | | Align studs | ||

| + | | style="border: 1px solid black; padding: 5px; background: #ffff00;" | Non-value added | ||

| + | |- | ||

| + | ! 5 | ||

| + | | Load plate | ||

| + | | style="border: 1px solid black; padding: 5px; background: #00ff00;" | Value added | ||

|} | |} | ||

| − | + | ===Step 3: Takt Time (Time)=== | |

Takt time (or 'Cycle demand time') is defined as the rate of demand for a particular project or process and is calculated by dividing the total amount of available work time by the number of deliverables required by a customer. Takt time can also be described as the business running speed, where running faster can mean greater inventory and profits, and running slower can mean falling below customer demands. | Takt time (or 'Cycle demand time') is defined as the rate of demand for a particular project or process and is calculated by dividing the total amount of available work time by the number of deliverables required by a customer. Takt time can also be described as the business running speed, where running faster can mean greater inventory and profits, and running slower can mean falling below customer demands. | ||

| Line 74: | Line 104: | ||

Furthermore, if sub-activities do not have the same speed, then each Takt time for each activity will have to be calculated separately, as one sub-activity may make more or less parts than the other sub-activity. | Furthermore, if sub-activities do not have the same speed, then each Takt time for each activity will have to be calculated separately, as one sub-activity may make more or less parts than the other sub-activity. | ||

| + | |||

| + | Lets make a simple example. We have one manufacturing system that produces two part types, A and B. We have a flexible manufacturing system whose capacity we can adjust by adding or removing workers in the system. | ||

| + | |||

| + | We want to find out how many workers we need to add to the line next week. Hence, your period of interest is next week. We estimate that the customer orders 4.000 products next week, and we have a 5 day workweek with one shift of 7.5 work hours each. This gives us a total available work time of 37.5 hours or 135.000 seconds. | ||

| + | |||

| + | \displaystyle Customer \; Takt \; Next \; Week= \frac{135.000s}{4.000 pcs}=33.75\frac{s}{pcs} | ||

| + | |||

| + | If for example our workers need 60 seconds to produce one part in average (including machine problems and defects), then we would need at least 1.7 workers to fulfill the customer demand. | ||

| + | |||

| + | ===Step 4: Allocate durations to each sub-activity=== | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |+ Examples of sub-activities, their durations and their classifications | ||

| + | ! style="border: 1px solid black; padding: 5px; background: #efefef;" | Activity Sequence | ||

| + | ! style="border: 1px solid black; padding: 5px; background: #ffdead;" | Sub-Activity | ||

| + | ! style="border: 1px solid black; padding: 5px; background: #ffdead;" | Duration (minutes) | ||

| + | ! style="border: 1px solid black; padding: 5px; background: #ffdead;" | Classification | ||

| + | |- | ||

| + | ! 1 | ||

| + | | Warm pressing machine | ||

| + | | 10 | ||

| + | | style="border: 1px solid black; padding: 5px; background: #ff0000;" | Waste | ||

| + | |- | ||

| + | ! 2 | ||

| + | | Setup next pressings | ||

| + | |5 | ||

| + | | style="border: 1px solid black; padding: 5px; background: #ffff00;" | Non-value added | ||

| + | |- | ||

| + | ! 3 | ||

| + | | Align nuts | ||

| + | |2 | ||

| + | | style="border: 1px solid black; padding: 5px; background: #ffff00;" | Non-value added | ||

| + | |- | ||

| + | ! 4 | ||

| + | | Align studs | ||

| + | |2 | ||

| + | | style="border: 1px solid black; padding: 5px; background: #ffff00;" | Non-value added | ||

| + | |- | ||

| + | ! 5 | ||

| + | | Load plate | ||

| + | |10 | ||

| + | | style="border: 1px solid black; padding: 5px; background: #00ff00;" | Value added | ||

| + | |} | ||

| + | |||

| + | ===Step 5: Generate Yamazumi Chart=== | ||

| + | |||

| + | [[File:Draft Yamazumi Chart.jpg|frame|center|alt=A draft chart.|An example of a Yamazumi chart'.]] | ||

==Uses== | ==Uses== | ||

| Line 91: | Line 168: | ||

| C | | C | ||

|} | |} | ||

| − | ==Example== | + | ==Industry Example== |

Latest revision as of 15:11, 19 February 2018

Contents |

[edit] Overview

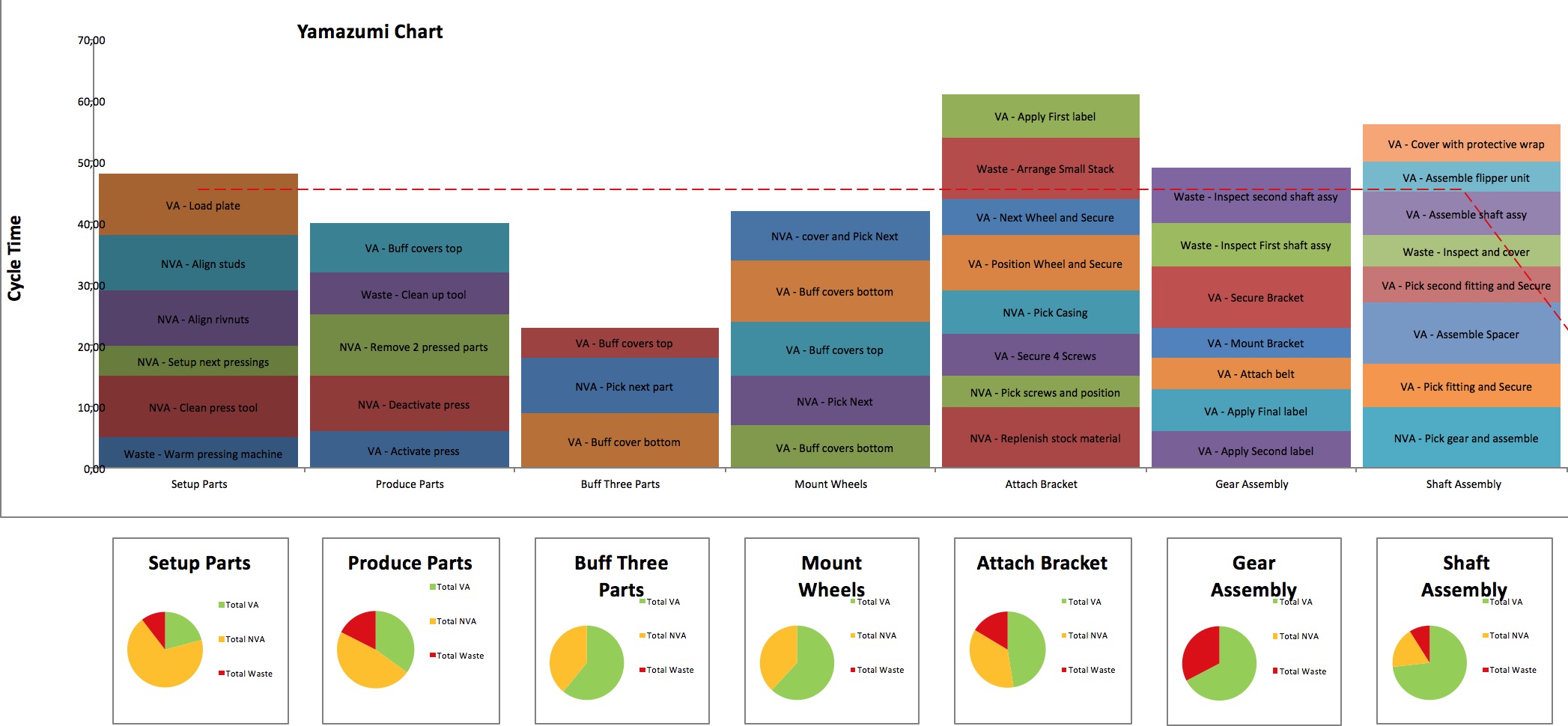

Line balancing (LB) is a resource optimisation strategy that aims to optimise and/or shorten the project schedule duration model based on the supply and demand of project resources. The LB technique is classified under Control Schedule (CS), which monitors activities and implements both corrective and preventative actions to minimise deviation and risks to scheduled plans.

The LB strategy involves assessing project scopes, decomposing project deliverables into smaller manageable parts, creating activity lists, highlighting activities that are delayed/constrained/overburdened or free/waiting and rebalances, reallocates or adds extra resources to smooth out the project schedule. The Yamazumi Chart (YC) is an analytical tool and technique that is used to visualise this time management strategy.

The YC requires activities to be properly defined and sequenced, and their resources and durations to be accurately estimated. This method enables project managers to appropriately adjust a schedule management plan as it manages the supply and demand resources across multiple activities. Project managers are also able to identify risks and perform quantitiative risk analyses from the YC output data at it will identify procsses that not value-adding, non-critical or waste. Once the YC is established, it can easily be updated with new data and can then then be used to optimise the project continuously or at multiple points during the project life.

A project manager should use this tool to both manage, execute and control the project schedule, as early/late start/finish dates of projects/activities are easily identifiable from the otputs. Other resource levelling, smoothing, crashing and fast tracking techniques can be applied if necessary, ensuring the timely completion of a project or the delivery of products.

[edit] Benefits

The Yamazumi chart provides a time management mechanism to rebalance a project when supply and demand changes quickly.

The chart provides a simple visual indication of project activities that are:

-Overloaded

-Underutilized

because of delays, wastage or blockages.

[edit] Methodology

[edit] Step 1: Create activity list

A list of all sub-activities that are required in order to complete the project are listed in sequential order. Sub-activities can be grouped and named according to their stage in the project or process.

This step helps managers to clearly see how each activity or process compares to the others, which take the longest and which may require extra resources.

| Activity sequence | Sub-Activity |

|---|---|

| 1 | Warm pressing machine |

| 2 | Setup next pressings |

| 3 | Align nuts |

| 4 | Align studs |

| 5 | Load plate |

[edit] Step 2: Classification

All sub-activities are labelled as:

- Value added (VA)

- Non-Value added (NVA)

- Waste (W)

Each label helps to clearly identify which sub-activities add value to the project and must be completed for project success. Sub-activities that are labelled as NVA or W should be minimised or eliminated from project processes where possible.

| Activity Sequence | Sub-Activity | Classification |

|---|---|---|

| 1 | Warm pressing machine | Waste |

| 2 | Setup next pressings | Non-value added |

| 3 | Align nuts | Non-value added |

| 4 | Align studs | Non-value added |

| 5 | Load plate | Value added |

[edit] Step 3: Takt Time (Time)

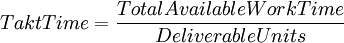

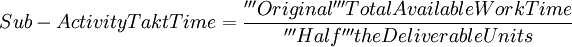

Takt time (or 'Cycle demand time') is defined as the rate of demand for a particular project or process and is calculated by dividing the total amount of available work time by the number of deliverables required by a customer. Takt time can also be described as the business running speed, where running faster can mean greater inventory and profits, and running slower can mean falling below customer demands.

Expressed as a formula:

The Takt Time formula, whilst very simple, can easily be misunderstood or applied inappropriately and can have disastrous effects on the time management of a project. When parallel sub-activities are contributing to higher level dependent activities, the Takt Time changes. For example when two sub-activities are contributing to a single activity, the final activity retains the original customer Takt Time, however the two sub-activities have double the Takt Time.

Expressed as a formula:

Furthermore, if sub-activities do not have the same speed, then each Takt time for each activity will have to be calculated separately, as one sub-activity may make more or less parts than the other sub-activity.

Lets make a simple example. We have one manufacturing system that produces two part types, A and B. We have a flexible manufacturing system whose capacity we can adjust by adding or removing workers in the system.

We want to find out how many workers we need to add to the line next week. Hence, your period of interest is next week. We estimate that the customer orders 4.000 products next week, and we have a 5 day workweek with one shift of 7.5 work hours each. This gives us a total available work time of 37.5 hours or 135.000 seconds.

\displaystyle Customer \; Takt \; Next \; Week= \frac{135.000s}{4.000 pcs}=33.75\frac{s}{pcs}

If for example our workers need 60 seconds to produce one part in average (including machine problems and defects), then we would need at least 1.7 workers to fulfill the customer demand.

[edit] Step 4: Allocate durations to each sub-activity

| Activity Sequence | Sub-Activity | Duration (minutes) | Classification |

|---|---|---|---|

| 1 | Warm pressing machine | 10 | Waste |

| 2 | Setup next pressings | 5 | Non-value added |

| 3 | Align nuts | 2 | Non-value added |

| 4 | Align studs | 2 | Non-value added |

| 5 | Load plate | 10 | Value added |

[edit] Step 5: Generate Yamazumi Chart

[edit] Uses

| Industry | Benefits |

|---|---|

| Value Added | A |

| Manufacturing | Optimising Repetitive Production Processes |

| Dentistry | C |

[edit] Industry Example

[edit] Downloadable Template

[edit] Referénces

Project Management: A guide to the Project Management Body of Knowledge (PMBOK guide), Section 6: Project Time Management; 6.2.2 Define Activities: Tools and Techniques; 6.2.2.1 Decomposition; 6.2.3.1 Activity List; 6.6 Develop Schedule; 6.7 Control Schedule; 6.6.2.4 Resource Optimization Techniques; 6.6.2.7 Schedule Compression

IMPROVEMENT OF OVERALL EFFICIENCY OF PRODUCTION LINE BY USING LINE BALANCING [1]

Lean Manufacturing Implementation Using Value Stream Mapping: A Case study of Pumps Manufacturing Company [2]

Optimization Assembly Process base on Motion Time Study in Manufacturing Industry: Study Case and Implementation [3]

Ohno, Taiichi. The Toyota Production System: Beyond Large-Scale Production. Portland, Oregon: Productivity Press, 1988.

Backup idea:

Edward De Bono's 6 Thinking Hats