Kanban framework

From DTU ProjectLab

(Difference between revisions)

| Line 2: | Line 2: | ||

Kanban can be referred to as either a method within process improvement or a visual method in Just-in-Time and Lean manufacturing, following article will be focusing on its uses in process improvement. | Kanban can be referred to as either a method within process improvement or a visual method in Just-in-Time and Lean manufacturing, following article will be focusing on its uses in process improvement. | ||

| − | The Kanban methodology originates from Japan and is therefore a Japanese word that can be translated to “signboard”. Kanban is a framework that is used in teams that is following the agile methodology, which has gained popularity throughout the software development industry, since the adaption by David Anderson back in 2010. To practice Kanban, it is essential to acquire a lean thinking mindset, which focuses on the improvement of processes and elimination of waste, called Muda in Japanese | + | The Kanban methodology originates from Japan and is therefore a Japanese word that can be translated to “signboard”. Kanban is a framework that is used in teams that is following the agile methodology, which has gained popularity throughout the software development industry, since the adaption by David Anderson back in 2010. To practice Kanban, it is essential to acquire a lean thinking mindset, which focuses on the improvement of processes and elimination of waste, called Muda in Japanese [[<ref {{cite book |last1=Bloggs |first1=Joe |author-link1=Joe Bloggs |last2=Bloggs |first2=Fred |author-link2=Fred Bloggs |date=1974 |title=Book of Bloggs}}</ref>]]. To understand more about Lean visit following link Lean in Project Management. When teams want to implement lean and a lean mindset, Kanban can work as a beneficial method to bring exactly this to the team. |

| + | |||

| + | name=Learning Agile> Learning Agile. (2015). Kanban, Flow and Constantly Improving. [https://getnave.com/blog/what-is-the-kanban-method/ | ||

| + | |||

| + | {{cite book |last1=Bloggs |first1=Joe |author-link1=Joe Bloggs |last2=Bloggs |first2=Fred |author-link2=Fred Bloggs |date=1974 |title=Book of Bloggs}} | ||

“The Kanban Method introduces a complex adaptive system that is intended to catalyze a Lean outcome within an organization. Complex adaptive systems have initial conditions and simple rules that are required in order to seed complex, adaptive, emergent behavior.” – David Anderson | “The Kanban Method introduces a complex adaptive system that is intended to catalyze a Lean outcome within an organization. Complex adaptive systems have initial conditions and simple rules that are required in order to seed complex, adaptive, emergent behavior.” – David Anderson | ||

Revision as of 11:19, 11 February 2022

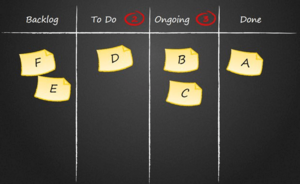

Figure 1: Example of a simple Kanban board [1]

Kanban can be referred to as either a method within process improvement or a visual method in Just-in-Time and Lean manufacturing, following article will be focusing on its uses in process improvement. The Kanban methodology originates from Japan and is therefore a Japanese word that can be translated to “signboard”. Kanban is a framework that is used in teams that is following the agile methodology, which has gained popularity throughout the software development industry, since the adaption by David Anderson back in 2010. To practice Kanban, it is essential to acquire a lean thinking mindset, which focuses on the improvement of processes and elimination of waste, called Muda in Japanese [[[2]

Cite error:

<ref> tags exist, but no <references/> tag was found