Critical Path Method in Construction Industry

Adam.pekala (Talk | contribs) (→Critical path based scheduling in constrction) |

Adam.pekala (Talk | contribs) (→Critical path based scheduling in linear projects in constrction) |

||

| Line 121: | Line 121: | ||

== Critical path based scheduling in linear projects in constrction == | == Critical path based scheduling in linear projects in constrction == | ||

Construction projects, although made as "one-off" and completely different from each other are very similar in a way of repeating processes within one project. Multi-storey buildings, highways being built stage by stage or even gas pipelines. All of them have linear, repetitive characteristics and they require special approach in scheduling. Critical Path Method provides the scheduler with slack/free float time, times of earliest start or finish but it assumes unlimited resources. Scheduling of a construction projects has to be made while keeping in mind not only continouos use of resources but also the logic between activities at the same time. | Construction projects, although made as "one-off" and completely different from each other are very similar in a way of repeating processes within one project. Multi-storey buildings, highways being built stage by stage or even gas pipelines. All of them have linear, repetitive characteristics and they require special approach in scheduling. Critical Path Method provides the scheduler with slack/free float time, times of earliest start or finish but it assumes unlimited resources. Scheduling of a construction projects has to be made while keeping in mind not only continouos use of resources but also the logic between activities at the same time. | ||

| + | The most useful and most convenient method to do so is Line of Balance or Linear Scheduling Method. Created in early 1940s and developed in 1952 and 1960 by US Navy with the idea of evaluating production lines - processes with lots of repetitions and using series of workstations. It took as long as to 2004 while The National Agency of the United Kingdom implemented it for repetitive housing units. | ||

== Resource-Activity Critical Path Method == | == Resource-Activity Critical Path Method == | ||

Revision as of 21:58, 21 September 2015

Critical Path Method (CPM) is a project management method created in 1958 in American company DuPont to improve internal production processes. Since then the method is widely used in industries such as construction, aerospace, defense, engineering, research and many more. However, this article focuses on its use in civil engineering industry and construction. The method is suitable for all kind of construction projects that require many independent activities to be completed.

Critical path is a sequence of activities that lead to the shortest possible completion of the project. These activities are called critical activities and every delay in each of these activities will result in delay of the whole project. This article depicts ways of using the method to analyze projects as a several groups of activities to reduce the bottleneck points and finish the project on time and within the budget. Methodology of creation of the basic CPM direct acyclic graph (DAG) is presented in a way of short step-by-step tutorial.

Construction projects, although very complicated are similar or even identical in a way of having similar unit activities and resources. Scheduling in linear construction projects require use of aforementioned resources from one activity to another in such a way, that continuity and logic between network activities is sustained. In the article the procedure for CPM-based scheduling in linear construction projects is described and explained. Moreover, Resource Activity Critical Path Method (RACPM) is presented based on Hong Kong Polytechnic University practical method based on the additional dimension of time added to the dimension of time. As a summary, advantages and disadvantages of the method are described as well as limitations to the use of CP-method. At the end of the article annotated bibliography with reference links is provided.

Contents |

Big idea

Short history

While the method itself has been created in 1958 its induction to construction industry happened awhile later. There are always two stages recognized while implementing the method: first stage, when there has been an initial interest aroused in the industry and second, while the overall effects on the industry are known. It took as long as in 1968 when the method was known well enough to consider it to be in its second stage – mainly due to time-consuming characteristic of construction projects.[1] Nevertheless, the method was adapted to specifics of civil and construction projects’ characteristic and was successfully used in the industry ever since.

Evolution

What helped CPM to be more and more popular was that it was of great utility while managing bigger projects – the method was immediately implemented to projects of value higher than £100’000[1] (value from 1968, approx. £2’000’000 nowadays). The method itself has not changed much in terms of its methodology. Algorithms of calculation of critical path remain the same. What changed significantly is the use of the computers in its implementation to the projects. Back when the method was created hand calculations were common almost for all of the projects, at least for tender stages. Project managers mentioned from 50 up to 600 activities as a range for hand calculations using CPM. Nowadays various types of software is used i.a. Primavera[2], MS Project[3] or various spreadsheets.

General methodology

The Critical Path Method indicates sequence of activities that determine the earliest possible completion for analyzed project. The resulting sequence (or sequences – there might be more than one) is called the critical path. All of the activities are called critical activities and any delay in those will cause a delay for the project or phase in general. A guide to create the critical path is as follows:

- Identify the activities – a thorough check and investigation on every activity present in the project or stage should be made - project scope and details are helpful. Every activity should be described with duration.

- Activity sequence establishment – it is the most important step to create working and correct critical path. For this to be done correctly three questions should be answered:

- which tasks should take place before this task

- which tasks should be completed at the same time

- which tasks should happen immediately after this task

- Network diagram – it should be prepared based on the prepared sequence

- Activity completion time estimation - this value should be estimated based on the experience or resource catalogues. Since CPM is a deterministic model it does not take into account variation in the completion time - an exact number has to be put in.

- Identification of critical path – based on parameters such as Earliest Start Time, Earliest Finish Time, Latest Finish Time, Latest Start Time (to be explained in following chapter)

- Live updating of critical path diagram – all of the changes happening to the project should be implemented for the diagram and method to be accurate during whole project time

Graph creation method

Terminology and suggested layout

For CPM a natural representation of the critical path is a Directed Acyclic Graph[4]. This is a type of graph that is created by collection of vertices and direct edges in a way that there is no loop (no way to start at one activity and after following a sequence loop back to the same activity).

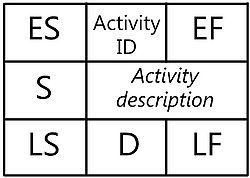

Graphs for CPM are specific type of PERT[5] graphs. However, in CPM the time of a single activity are identical and there is no distinguishing between optimistic, pessimistic and most likely time. For creating a network there are many types of activity boxes sugested, one of which is presented below.

Where:

- ID - Activity number

- ES - Earliest possible start

- EF - Earliest possible finish

- LS - Latest possible start

- LF - Latest possible finish

- D - Duration

- S - Slack

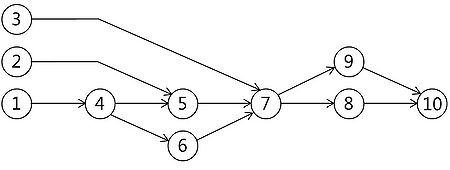

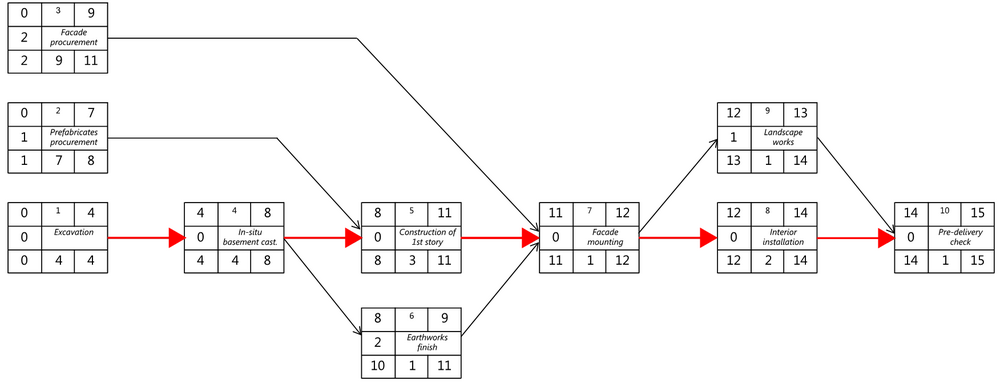

Example of CPM graph creation

Based on a simplified one story building and reduced to basic number of activities a CPM method with CPM graph creation will be presented.

| ID/Number | Name/Description | Estimated duration |

| 1 | Excavation | 4 |

| 2 | Prefabricates procurement | 7 |

| 3 | Facade procurement | 9 |

| 4 | In-situ basement casting | 4 |

| 5 | Construction of 1st story | 3 |

| 6 | Finishing earthwork | 1 |

| 7 | Facade mounting | 1 |

| 8 | Interior instalation | 2 |

| 9 | Landscape works | 3 |

| 10 | Pre-delivery check | 1 |

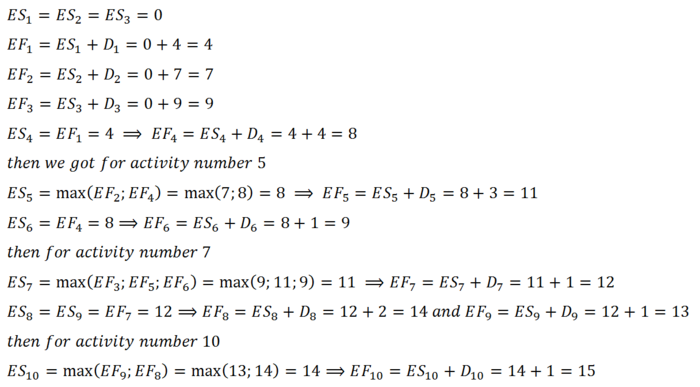

There are two main steps to be performed based on the activities' duration provided in activity table - forward pass calculation and backwards pass calculation.

Forward pass calculation

As in the dependency tree there are three starting activities - all of them are granted starting time equal to zero. Then calculations to obtain ES and EF times are performed as follows:

Based on the duration of single activity total project time has been derived and is equal to 15 weeks.

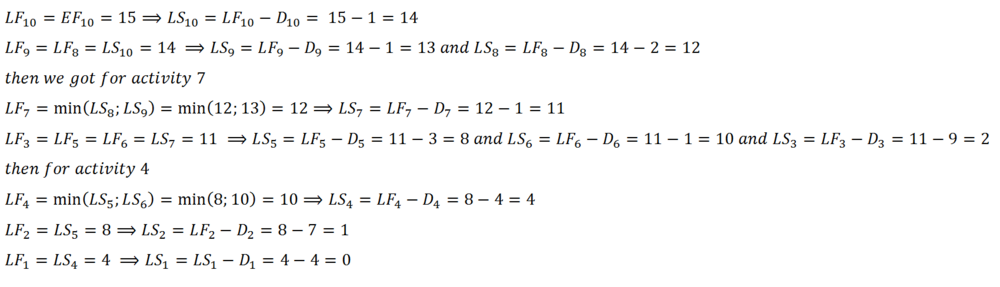

Backward pass calculation

Based on the total project time and single activity duration LF and LS times are derived. Calculations should follow method presented below:

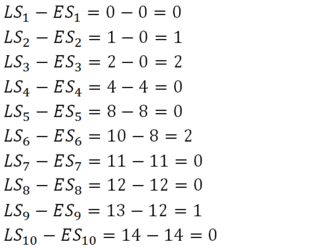

Slack calculation

Based on values of ES and LS the possible slack is calculated. Slack is a delay time that will not cause any delay for the whole project. There is no slack on a critical path.

CPM Graph

Based on all of the information above a CPM graph is sketched. All of the activities with no slack are called critical activities and the sequence of those is called critical path - marked red on the graph.

Critical path based scheduling in linear projects in constrction

Construction projects, although made as "one-off" and completely different from each other are very similar in a way of repeating processes within one project. Multi-storey buildings, highways being built stage by stage or even gas pipelines. All of them have linear, repetitive characteristics and they require special approach in scheduling. Critical Path Method provides the scheduler with slack/free float time, times of earliest start or finish but it assumes unlimited resources. Scheduling of a construction projects has to be made while keeping in mind not only continouos use of resources but also the logic between activities at the same time. The most useful and most convenient method to do so is Line of Balance or Linear Scheduling Method. Created in early 1940s and developed in 1952 and 1960 by US Navy with the idea of evaluating production lines - processes with lots of repetitions and using series of workstations. It took as long as to 2004 while The National Agency of the United Kingdom implemented it for repetitive housing units.

Resource-Activity Critical Path Method

Use Limitations

Advantages and disadvantages

Conclusions

Bibliography and further links

- ↑ 1.0 1.1 [1] “Critical path analysis and the civil engineering industry, D.H.Wade, ICE Proceedings, Volume 39, Issue 2, 01 February 1968 , pages 289 –303”

- ↑ [2] Primavera P6 Scheduling

- ↑ [3] MS Project

- ↑ [4] Directed Acyclic Graph

- ↑ [5] Program Evaluation and Review Technique

Sample Code snips

This is a list

- List1

- List2

- List2

This is a picture

This is big, italian and underlined * You can choose to work on one of two types of articles: *

Here's some links

Articles Fall Term 2015 User's Guide Configuration settings list MediaWiki FAQ MediaWiki release mailing list Help Content

Aaanndd some references