Concurrent Engineering

Helenasoes (Talk | contribs) (→Big idea) |

Helenasoes (Talk | contribs) (→What is Concurrent Engineering?) |

||

| Line 11: | Line 11: | ||

Concurrent engineering (CE) is neither a technique nor a tool. It is a manner of thinking that calls for a wide range of techniques and methods. The execution of a project's processes simultaneously with the participation of both upstream and downstream functions over the course of the project's life-cycle is the very essence of concurrent engineering <ref name="stjepandic"> Stjepandić J., et al. (eds) (2015) Concurrent engineering in the 21st Century: foundations, developments and challenges. Switzerland: Springer International Publishing.</ref>. | Concurrent engineering (CE) is neither a technique nor a tool. It is a manner of thinking that calls for a wide range of techniques and methods. The execution of a project's processes simultaneously with the participation of both upstream and downstream functions over the course of the project's life-cycle is the very essence of concurrent engineering <ref name="stjepandic"> Stjepandić J., et al. (eds) (2015) Concurrent engineering in the 21st Century: foundations, developments and challenges. Switzerland: Springer International Publishing.</ref>. | ||

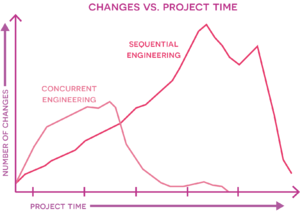

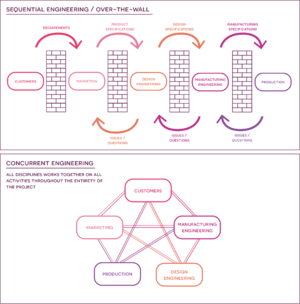

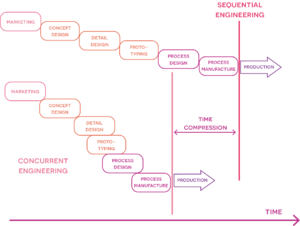

| − | The approach aims to decrease the number of larger iterations further down in the process, where the impact is much greater, by encountering and solving them as they appear in the earlier phases of the project (figure 1) [[File:Changes v project time.png|thumb| | + | The approach aims to decrease the number of larger iterations further down in the process, where the impact is much greater, by encountering and solving them as they appear in the earlier phases of the project (figure 1) [[File:Changes v project time.png|thumb|300px|Changes vs. project time]]. This is made possible by the concurrent nature of the approach, in which integrated, multifunctional teams collaborate and work together simultaneously to address multiple project-related issues at the same time. As the control and responsibility is shared amongst the departments across the project’s phases, and because their activities overlap, they are able to identify potential problems as they appear and are able to address them faster<ref name="swink">Swink, M.L. (1998). “A tutorial on implementing concurrent engineering in new product development programs,” in Journal of Operations Management, 16(1), pp. 103-116. Available at: https://doi.org/10.1016/S0272-6963(97)00018-1.'</ref>. This is opposite to the traditional sequential engineering (SE) approach, where each activity is handled by one functional organization at a time (marketing, design, manufacturing etc.) and then thrown “over-the-wall” to the next organization (figure 2) [[File:OverTheWall.png|thumb|300px|SE (Over-the-wall) & CE]] without communication. The problem with this approach is that it might be in the very late stages of the process that a problem is identified, because of the lack of communication between organizations, which will result in the activity/product being sent back over-the-wall to fix the issues <ref name="bhuiyan"> Bhuiyan, N. et al. (2006). “Implementing Concurrent Engineering” in Research-Technology Management, 49(1), pp. 38-43. Available at: https://doi.org/10.1080/08956308.2006.11657357</ref> resulting in a prolonged process time and increased costs. By working concurrently the overall project duration is greatly reduced, as there is constant collaboration and iterations between the teams in the process, ensuring that larger and time-consuming issues will not occur in the final stages, when changes can be both costly and time-consuming. The reduction in time for CE compared to the sequential approach can be seen in figure 3 [[File:Time reduction.png|thumb|300px|Project time reduction]]. And the benefits of the implementation of CE in a project setting can also be deduced from the figure, as it results in an increased productivity and an overall lower cost of the project due to the reduction in duration<ref name="swink"/>. Which also means that the time-to-market for the potential product or service is also decreased, providing the company with a competitive advantage on the market compared to their competitors. |

== Application/Implementation == | == Application/Implementation == | ||

Revision as of 19:55, 11 February 2023

Contents |

Abstract

The implementation of concurrent engineering in a project management framework will be explained holistically in this article. As concurrent engineering in its nature is highly dependent on the successful collaboration between the project’s organizational parties, this article will look into the following three aspects: the people participating in the project, the project process itself, and the technology and/or tools required to achieve these. The article will focus on how to make the concurrent engineering approach successful by addressing topics like the value of knowledge sharing, the necessity of interdisciplinary teams, effective project planning and what tools are required to achieve these aspects. Finally, the approach's advantages and disadvantages are discussed, and lastly they are paired with the preceding sequential engineering approach to address the situations in which one approach is better to apply than the other.

Big idea

Context

Concurrent engineering (CE) emerged in the 1980s as a result of the need for a more integrated method of operation to keep up with growing competition in the market, respond to a shorter product life-cycle, and meet shifting market and customer demands[1]. Concurrent engineering was thought to be a potential answer to the issues faced by businesses at the time, in order to help them create cheaper goods that could be supplied faster and have higher functionality [2]. Concurrent engineering functioned as a direct response and opposite to the previous traditional "over the wall", sequential engineering (SE) approach, with the overall goals of higher productivity and lower costs by shorter development time and shorter time-to-market.

“Concurrent Engineering is a systematic approach to the integrated, concurrent design of products and their related processes, including manufacturing and support. This approach is intended to cause the developers from the outset to consider all elements of the product life cycle from conception to disposal, including quality, cost, schedule, and user requirements.” - Winner, R.J et al. (1988) [3]

What is Concurrent Engineering?

Concurrent engineering (CE) is neither a technique nor a tool. It is a manner of thinking that calls for a wide range of techniques and methods. The execution of a project's processes simultaneously with the participation of both upstream and downstream functions over the course of the project's life-cycle is the very essence of concurrent engineering [4].

The approach aims to decrease the number of larger iterations further down in the process, where the impact is much greater, by encountering and solving them as they appear in the earlier phases of the project (figure 1) . This is made possible by the concurrent nature of the approach, in which integrated, multifunctional teams collaborate and work together simultaneously to address multiple project-related issues at the same time. As the control and responsibility is shared amongst the departments across the project’s phases, and because their activities overlap, they are able to identify potential problems as they appear and are able to address them faster[5]. This is opposite to the traditional sequential engineering (SE) approach, where each activity is handled by one functional organization at a time (marketing, design, manufacturing etc.) and then thrown “over-the-wall” to the next organization (figure 2) without communication. The problem with this approach is that it might be in the very late stages of the process that a problem is identified, because of the lack of communication between organizations, which will result in the activity/product being sent back over-the-wall to fix the issues [6] resulting in a prolonged process time and increased costs. By working concurrently the overall project duration is greatly reduced, as there is constant collaboration and iterations between the teams in the process, ensuring that larger and time-consuming issues will not occur in the final stages, when changes can be both costly and time-consuming. The reduction in time for CE compared to the sequential approach can be seen in figure 3 . And the benefits of the implementation of CE in a project setting can also be deduced from the figure, as it results in an increased productivity and an overall lower cost of the project due to the reduction in duration[5]. Which also means that the time-to-market for the potential product or service is also decreased, providing the company with a competitive advantage on the market compared to their competitors.Application/Implementation

The concurrent character of the approach makes CE essentially a socio-technical concept[4]. As previously stated, it calls for close coordination and communication across the project's many phases and disciplines. Since effective stakeholder communication, their willingness and ability to collaborate, and the support of tools and communication technologies are crucial components to support and sustain a CE project management strategy, the primary requirements for a successful concurrent engineering project are also related to these elements. These elements can collectively be classified as a company's organizational system, which is a holistic framework in which individuals carry out processes with the aid of tools (methods, tools, or technologies) in order to achieve specific objectives within the organization and/or project environment [7]. To better address the essential elements of the framework and what is needed when attempting to implement the concurrent engineering framework in a project management scenario, the following sections will explain these three aspects: People, Process, and Technology/Tools.

Process

Some key aspects for CE is to have a well-defined process with clear ownership and defined goals. That includes:

- Considering and planning overlapping of activities

- Ensuring that ownership of the process occurs

- Defined, clear and quantitative goals

Overlapping activities

The first step in implementing CE is to define the process and the corresponding schedule of activities and the decision on how to manage the process with the required overlapping activities, needs to be evaluated. This includes how and when the activities should be overlapping in order for the project to be completed most effectively, efficiently and where all risks are considered early in the process. Overlapping activities have shown to reduce development time, when there is high level of communication and cross-disciplinary teamwork present, but there is also evidence of it not being beneficial for all project governance[6]. This can happen if there are two or more overlapping activities, where changes in the upstream activities mean large changes are required in the downstream activities that have already been completed as a result of the overlapping. For this reason it is important to consider which activities are overlapping and that the downstream impact is considered prior to planning overlap, in order to reduce the amount of activities having to be redone.

Ownership and defined scope

For the CE process, a process owner needs to be appointed as a lack of ownership means a lack of project discipline. There needs to be a person in charge that the team can consult when facing a problem. The process owner's main purpose is to oversee that the CE process is utilized properly and updated when changes are made. A process owner has responsibility for the entire process as well as the sub-processes related to it, and by having a process owner, it ensures better responsiveness to imminent changes and better learning for future process improvements[6]. But in order for the process owner to succeed in implementing CE there needs to be stated clear and measurable goals for the project to work towards. The scope needs to be clearly defined in order for the project team to know what the common goal is, so they all have a shared foundation when working concurrently on the project, as this ensures fewer misunderstandings throughout the project.

People

In order to achieve a successful CE implementation a few aspects have to be considered. They all relate to the collaboration between the people within the project and functions as prerequisites that must be achieved or thought of before embarking on a transition or implementation of a CE approach for a project:

- Staffing and creating an effective CE team

- The need for multidisciplinarity

- The role of the project manager in a CE setting

Concurrent Engineering Teams (CE team + tutorial)

For a CE team to be successful, some requirements are put into place in order for the project to have the best possible starting point. These requirements state that an effective team should have no more than 10 members, and that all members must choose - by their own volition - to be on the project and be driven by their intrinsic motivation to stay engaged throughout the entire project

Multidisciplinary teams (Trygg + thesis)

Project manager (tutorial + CE teams)

Technology/Tools

Need for communication and collaboration makes new technologies a necessity to allow for information sharing

Implementation approach

When is it applicable? How to implement? When to implement?

Benefits & Limitations

Benefits:

Shorter time-to-market - compared to SE

Possible to make changes/alterations early on - focus on solving the issues in their early stages/as they appear in the beginning, so they will not have such a high impact later on

minimized risks of loss (time and knowledge between departments/tasks)

Limitations:

Need for close collaborations between departments

Maybe do a table to compare CE and SE? - Benefits and limitations

Concurrent vs. sequential engineering When to choose one or the other?

CE: no need for a defined output (only scope) in the beginning - SE: need for at defined goal/output

Bibliography

Concurrent Engineering in the 21st Century: Foundations, Developments and Challenges

The newest advancements and industry-best practices for the guiding principles of the framework are covered in-depth in this book's presentation of concurrent engineering. It delves deeply into CE procedures and practices, as well as practical applications and experiences. The book offers a thorough overview of CE from many different viewpoints and industries since it is a compilation of research by numerous professors and scholars.

References

- ↑ Trygg, L. (1993). “Concurrent Engineering practices in selected Swedish companies: a movement or an activity of the few?” in Journal of Product Innovation Management, 10(5), pp. 403–415. Available at: https://doi.org/10.1016/0737-6782(93)90098-B

- ↑ Clark, K.B. & Fujimoto, T. (1991). Product development performance: strategy, organization, and management in the world auto industry. Harvard Business School Press, Boston

- ↑ Winner, R.J. et al. (1988). The role of concurrent engineering in weapons system acquisition. IDA R-338. USA: Institute for Defense Analyses.

- ↑ 4.0 4.1 Stjepandić J., et al. (eds) (2015) Concurrent engineering in the 21st Century: foundations, developments and challenges. Switzerland: Springer International Publishing.

- ↑ 5.0 5.1 Swink, M.L. (1998). “A tutorial on implementing concurrent engineering in new product development programs,” in Journal of Operations Management, 16(1), pp. 103-116. Available at: https://doi.org/10.1016/S0272-6963(97)00018-1.'

- ↑ 6.0 6.1 6.2 Bhuiyan, N. et al. (2006). “Implementing Concurrent Engineering” in Research-Technology Management, 49(1), pp. 38-43. Available at: https://doi.org/10.1080/08956308.2006.11657357

- ↑ Boer, H & Krabbendam, JJ (1993). Inleiding organisatiekunde (Introduction to organisational science). University of Twente, Enschede, The Netherlands.