The Critical Path Method (CPM)

| Line 2: | Line 2: | ||

This method article describes the Critical Path Method (CPM) also in comparison to other project management methods. This article describes how and when to use CPM methods, moreover discusses the advantages, disadvantages and applicability of the method. CPM is a step-by-step project management method for process planning. CPM was developed in 1956 by the E.I. du Pont de Nemours Company a major chemical plant construction firm in USA<ref name="Woodhead"/>. By focusing on tasks duration CPM identifies the minimum length of time needed to complete a project and helps define the most critical tasks that needs to be accelerate in order to complete the project within the available time. Furthermore CMP allows you to identify slack time (free resources) and can be used to monitor if the project follows the time schedule.<ref> name="Sm15"</ref> | This method article describes the Critical Path Method (CPM) also in comparison to other project management methods. This article describes how and when to use CPM methods, moreover discusses the advantages, disadvantages and applicability of the method. CPM is a step-by-step project management method for process planning. CPM was developed in 1956 by the E.I. du Pont de Nemours Company a major chemical plant construction firm in USA<ref name="Woodhead"/>. By focusing on tasks duration CPM identifies the minimum length of time needed to complete a project and helps define the most critical tasks that needs to be accelerate in order to complete the project within the available time. Furthermore CMP allows you to identify slack time (free resources) and can be used to monitor if the project follows the time schedule.<ref> name="Sm15"</ref> | ||

To identify the critical path through the project you can either use CPM or [[Program, Evaluation, Review and Technique (PERT)]]. With available accurate task time estimate CPM is the preferred method. PERT is used in projects with inaccurate time estimates by applying three time estimates (earliest, latest, average) to create the expected time. CPM is therefore the most simplified method. CPM utilizes tasks duration as the parameter for optimization of the schedule and resource planning. In opposition to these methods based on time estimates the [[Critical Chain Theory]] utilize resources as the measured component<ref name="Ver09"/>. | To identify the critical path through the project you can either use CPM or [[Program, Evaluation, Review and Technique (PERT)]]. With available accurate task time estimate CPM is the preferred method. PERT is used in projects with inaccurate time estimates by applying three time estimates (earliest, latest, average) to create the expected time. CPM is therefore the most simplified method. CPM utilizes tasks duration as the parameter for optimization of the schedule and resource planning. In opposition to these methods based on time estimates the [[Critical Chain Theory]] utilize resources as the measured component<ref name="Ver09"/>. | ||

| − | CPM is one of the fundamental concepts in traditional project management. It can be applied for the planning, scheduling and control of construction projects. | + | CPM is one of the fundamental concepts in traditional project management. It can be applied for the planning, scheduling and control of construction projects<ref name="Fon62"/>. |

==Introduction to CPM== | ==Introduction to CPM== | ||

| − | CPM is a step-by-step method for project planning and management. It is the presentation of a project plan by a schematic diagram that depicts the sequence and interaction of all the tasks of the project. The precursor of CPM was PERT (Program, Evaluation, Review and Technique) developed by the U.S. Navy and [[PPS (Project Planning and Scheduling)]]. PPS focus on estimates on both time and cost for design, construction and maintenance work. | + | CPM is a step-by-step method for project planning and management. It is the presentation of a project plan by a schematic diagram that depicts the sequence and interaction of all the tasks of the project<ref name="Woodhead"/>. The precursor of CPM was PERT (Program, Evaluation, Review and Technique) developed by the U.S. Navy and [[PPS (Project Planning and Scheduling)]]. PPS focus on estimates on both time and cost for design, construction and maintenance work <ref name="Woodhead"/>. |

The main benefits of CPM for the projects managers are firstly to identify the most important tasks. By focusing on tasks duration CPM identifies the critical path and thereby the minimum length of time needed to complete a project. If any of the tasks forming the critical path take more time than their estimated durations, start or finish later than planned, then the whole project will be affected. The critical path is by the [[Project Management Body of Knowledge (PMBOK)]], an internationally recognized collection of processes and knowledge areas accepted as best practice for the project management profession, defined “the sequence of scheduled activities that determines the duration of the project.” The critical path helps define the most efficient way to schedule the project. Although many projects have only one critical path, some projects may have multiple critical paths. | The main benefits of CPM for the projects managers are firstly to identify the most important tasks. By focusing on tasks duration CPM identifies the critical path and thereby the minimum length of time needed to complete a project. If any of the tasks forming the critical path take more time than their estimated durations, start or finish later than planned, then the whole project will be affected. The critical path is by the [[Project Management Body of Knowledge (PMBOK)]], an internationally recognized collection of processes and knowledge areas accepted as best practice for the project management profession, defined “the sequence of scheduled activities that determines the duration of the project.” The critical path helps define the most efficient way to schedule the project. Although many projects have only one critical path, some projects may have multiple critical paths. | ||

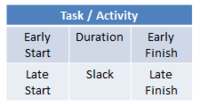

Secondly, CPM helps reduce timelines by identifying slack time. Slack time tells to what extent each activity in the schedule can slip (float) without delaying the project <ref name="Sm15"/>. | Secondly, CPM helps reduce timelines by identifying slack time. Slack time tells to what extent each activity in the schedule can slip (float) without delaying the project <ref name="Sm15"/>. | ||

Revision as of 11:56, 22 September 2015

This method article describes the Critical Path Method (CPM) also in comparison to other project management methods. This article describes how and when to use CPM methods, moreover discusses the advantages, disadvantages and applicability of the method. CPM is a step-by-step project management method for process planning. CPM was developed in 1956 by the E.I. du Pont de Nemours Company a major chemical plant construction firm in USA[1]. By focusing on tasks duration CPM identifies the minimum length of time needed to complete a project and helps define the most critical tasks that needs to be accelerate in order to complete the project within the available time. Furthermore CMP allows you to identify slack time (free resources) and can be used to monitor if the project follows the time schedule.[2] To identify the critical path through the project you can either use CPM or Program, Evaluation, Review and Technique (PERT). With available accurate task time estimate CPM is the preferred method. PERT is used in projects with inaccurate time estimates by applying three time estimates (earliest, latest, average) to create the expected time. CPM is therefore the most simplified method. CPM utilizes tasks duration as the parameter for optimization of the schedule and resource planning. In opposition to these methods based on time estimates the Critical Chain Theory utilize resources as the measured component[3]. CPM is one of the fundamental concepts in traditional project management. It can be applied for the planning, scheduling and control of construction projects[4].

Introduction to CPM

CPM is a step-by-step method for project planning and management. It is the presentation of a project plan by a schematic diagram that depicts the sequence and interaction of all the tasks of the project[1]. The precursor of CPM was PERT (Program, Evaluation, Review and Technique) developed by the U.S. Navy and PPS (Project Planning and Scheduling). PPS focus on estimates on both time and cost for design, construction and maintenance work [1]. The main benefits of CPM for the projects managers are firstly to identify the most important tasks. By focusing on tasks duration CPM identifies the critical path and thereby the minimum length of time needed to complete a project. If any of the tasks forming the critical path take more time than their estimated durations, start or finish later than planned, then the whole project will be affected. The critical path is by the Project Management Body of Knowledge (PMBOK), an internationally recognized collection of processes and knowledge areas accepted as best practice for the project management profession, defined “the sequence of scheduled activities that determines the duration of the project.” The critical path helps define the most efficient way to schedule the project. Although many projects have only one critical path, some projects may have multiple critical paths. Secondly, CPM helps reduce timelines by identifying slack time. Slack time tells to what extent each activity in the schedule can slip (float) without delaying the project [5].

In the early stage of CPM there was not any computer programs to make the calculations and the network diagrams was made using hand drawn nodes to present the stages of a product. This was of course very time consuming compared to using newer technologies especially as a project is not a static thing but constantly changing. Today there are a number of project management software programs available that can do the calculation. Microsoft Project and Smartsheet are two different computerized tools that use CPM[5]

Tool and method

Construction of a CPM can be subdivided into two phases. Phase 1: The construction of a sequential relationship of the individual operations in the project where each task is named and defined. Phase 2: A constructional schedule (flowchart) including estimated time duration for all tasks and showing sequential relationship. The CPM path diagram can now be completed and the critical activities determine the overall project duration can be identified. Furthermore slack time can be calculatedCite error: Closing </ref> missing for <ref> tag.

CPM is one of the fundamental concepts in traditional project management. It can be applied for the planning, scheduling and control of construction projects especially by construction contractors. The critical path identified by the CPM is often used as a precursor to Gantt Charts Cite error: Closing </ref> missing for <ref> tag

- Aguanno, Kevin . "Critical Path: An Extended Definition." MMPUBS (2002). [6]

Books

- Woodhead, James M. Antill & Ronald W. "Critical Path Methods in Construction Practice". John Wiley & Sons, Inc. (1990). [1]

- Fondahl, John W. "A non-computer approach to the critical path method for the construction". Stanford University. (1962). [4]

Links

- Verma, Eshna. "What is Critical Chain Project Management?". Simplilearn (2009): http://www.simplilearn.com/what-is-critical-chain-project-management-rar68-article [3]

- Burger, Rachel. "The Secret to the Critical Path Method in Construction". Capterra (2015): http://blog.capterra.com/construction-critical-path-method/[7]

- Dr. Larry Bennett. "The Ultimate Guide to the Critical Path Method". Smartsheet (2015): https://www.smartsheet.com/critical-path-method [5]

Videos

- Dr. Zelbst, Pamela. "Critical Path Method and PERT explained". (2015)

- Newbold, Rob. "Critical Chain Project Management". (2011)

Bibliography

- ↑ 1.0 1.1 1.2 1.3 Woodhead, James M. Antill & Ronald W."Critical Path Methods in Construction Practice" John Wiley & Sons, Inc. (1990): 90.

- ↑ name="Sm15"

- ↑ 3.0 3.1 What is Critical Chain Project Management?, 2009

- ↑ 4.0 4.1 Fondahl, John W. "A non-computer approach to the critical path method for the construction". Stanford University. (1962).

- ↑ 5.0 5.1 5.2 The Ultimate Guide to the Critical Path Method, 2015

- ↑ Aguanno, Kevin. "Critical Path: An Extended Definition." MMPUBS (2002).

- ↑ The Secret to the Critical Path Method in Constructio, 2015

- ↑ Dr. Zelbst, Pamela. Critical Path Method and PERT explained, 2015

- ↑ CEO Rob Newbold. Critical Chain Project Management, 2011