FMEA

(→General introduction to Risk Management) |

(→Theory and purpose) |

||

| Line 31: | Line 31: | ||

==== Theory and purpose ==== | ==== Theory and purpose ==== | ||

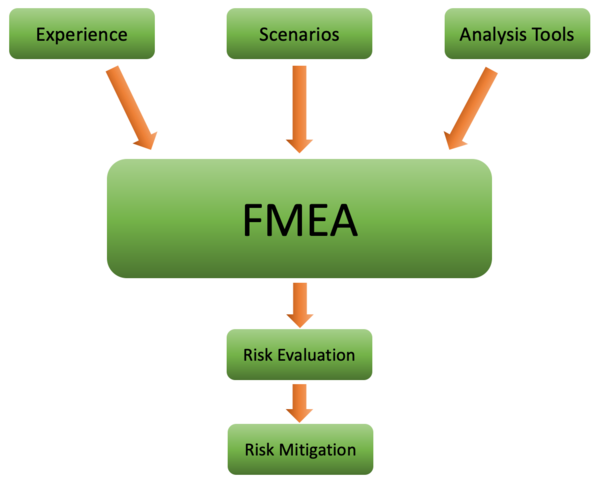

The main theory behind Failure Mode and Effect Analysis (FMEA) is that preventing a problem is preferred over dealing with its consequences. The FMEA tool is a systematic approach to identifying potential failure modes in a system, product, process or strategy and evaluating the potential effects. The purpose of FMEA is to proactively identify and mitigate risks before they occur in order to improve the quality, reliability, safety and strategy. The FMEA process involves breaking down the system, product, process or strategy into smaller components, thoroughly analyzing each component to identify potential failure modes, their effects, and their probability of occurring. The results are then used to prioritize failure modes based on their risk profile and to develop mitigation strategies for further use. More so, the tool is particularly useful in high risk industries where failures have serious consequences such as aerospace, automotive, and the medical industry, but can be applied in most industries. | The main theory behind Failure Mode and Effect Analysis (FMEA) is that preventing a problem is preferred over dealing with its consequences. The FMEA tool is a systematic approach to identifying potential failure modes in a system, product, process or strategy and evaluating the potential effects. The purpose of FMEA is to proactively identify and mitigate risks before they occur in order to improve the quality, reliability, safety and strategy. The FMEA process involves breaking down the system, product, process or strategy into smaller components, thoroughly analyzing each component to identify potential failure modes, their effects, and their probability of occurring. The results are then used to prioritize failure modes based on their risk profile and to develop mitigation strategies for further use. More so, the tool is particularly useful in high risk industries where failures have serious consequences such as aerospace, automotive, and the medical industry, but can be applied in most industries. | ||

| − | Overall, the Failure Mode and Effect Analysis is a powerful tool for risk management and process improvement, allowing organizations and risk managers to proactively manage risks and improving performances. By identifying and addressing potential failure modes before they occur, organizations can reduce downtime, improve product quality, enhance safety and reliability, and strengthen the the strategy. | + | Overall, the Failure Mode and Effect Analysis is a powerful tool for risk management and process improvement, allowing organizations and risk managers to proactively manage risks and improving performances. By identifying and addressing potential failure modes before they occur, organizations can reduce downtime, improve product quality, enhance safety and reliability, and strengthen the the strategy.<ref name=GeneralFMEA> </ref>. |

==== When to Apply FMEA==== | ==== When to Apply FMEA==== | ||

Revision as of 17:34, 9 May 2023

The Failure Mode and Effect Analysis.

A tool used for analyzing how potential events can occur doe to failure within the company or project team. The elements analyzed with use of the FMEA tool, can be separated in a matrix and consists of failure events, how they can occur, why they occur and how the failure can be avoided. The different scenarios then get graded with regard to impact-fulness and chance of occurrence, the multiplied score is the used to rank each risk failure event according to their importunateness. The reason for the FMEA tool to have influence on the project management, is because the tool is strictly guiding the PM and his/her team to what topics to focus on in order to get a successful project result. The following report will include:

New:

The Failure Mode and Effect Analysis (FMEA) is a powerful tool used for analyzing potential failure events within a company or project team. It involves breaking down the system, product, or process into smaller components and analyzing each component to identify potential failure modes, their effects, and the likelihood of occurrence. This information is then organized in a matrix, which allows for a systematic evaluation of failure scenarios based on their impactfulness and likelihood of occurrence. By multiplying the scores for impactfulness and likelihood of occurrence, risks can be ranked according to their importunateness.

The FMEA tool is particularly useful in project management, as it guides project managers and their teams on which topics to focus on in order to achieve successful project outcomes. By proactively identifying potential risks and developing mitigation strategies, organizations can reduce downtime, improve product quality, and enhance safety and reliability. This report will provide a detailed overview of the FMEA tool, including its history, purpose, implementation, limitations, and strengths, as well as a real-life example of its application.

Contents |

General introduction to Risk Management

Risk management is the general term for managing unforeseen threats and opportunities. This includes identifying and analyzing risks as well as reacting or preparing appropriately to the identified potential scenarios of a project, program and portfolio. Furthermore, risk management can be applied on a verity of levels and scenarios, but the purpose remains to be a focus on minimizing, eliminating or taking advantage of unknown situations. Managing risk are to some extend essential as a proper risk management strategy can ensure a more optimal resource allocation as well as lowering the effects from an identified situation occurring all of which will improve a company's performance. However, to master risk management, the organization has to structure their approach depending on the particular stage of the project, program, portfolio and importantly use tools and methods of which align with a scope defined by the organization. [1] An example would be if a company is about to end a construction project. As the risk management is less uncertain, a tool like the Post Project Review (PPR) [2] would become attractive to use as it focuses on structuring the experience within the risk management of the project, for future projects exceed the previous performance with regard to the risks. In other words, the PPR tool is useful to a risk manager who has existing data of an ended project to apply to similar future projects. Another scenario within risk management, and perhaps the most common scenario, is regarding the risk management of a new strategy, project, system or product. A scenario where the existing organization has limited knowledge of what risks to asses and how to asses them. An example could be a scenario regarding a new investment project within a new portfolio area, where the investment project has limited similarities to the existing projects within the portfolio. To mitigate risks in such scenario properly, another type of risk management tool is to be applied like the FMEA risk assessment tool. [3]

Introduction to the FMEA tool

In a world where failure makings are assessed to be increasingly important with growing expectations from customers, clients, managers, investors and organizations, the importance of projects initialized on precise estimations and assessments becomes the backbone of business. [1] In this world, the risk assessments methodologies make the main arguments for how the outcome of a project, system or strategy may be derived. Investing in a project without assessing the potential risks would be similar to walking out of the front door barefooted not knowing if it's going to rain, snow or be 45 degrees celcius. It is possible, but the outcome could be very unpleasant. This makes for the use of risk assessments and the Failure Mode and Effect Analysis (FMEA) methodology.

Invented to systematically test and analyze different ways in which a system can fail and with what following consequences that might occur. The tool was originally developed for military purpose in the 1950s but has become a more recognized failure mode assessment tool within the healthcare, public and private industry. The FMEA tool is a datadriven brainstorm where to potential failures are listed and the consequences of the failures ranked for a clear overview of which elements to perform damage control or potentially change entirely. This makes a project manager or team able to improve their initial risk assessments. [3] Furthermore, being a technique first used more than 50 years ago it has been continuously improved and is now recognized as a key element of many quality management systems and general project, program and portfolio management scenarios. [4]

Theory and purpose

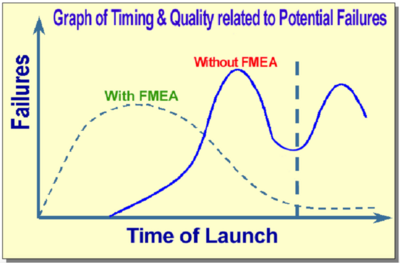

The main theory behind Failure Mode and Effect Analysis (FMEA) is that preventing a problem is preferred over dealing with its consequences. The FMEA tool is a systematic approach to identifying potential failure modes in a system, product, process or strategy and evaluating the potential effects. The purpose of FMEA is to proactively identify and mitigate risks before they occur in order to improve the quality, reliability, safety and strategy. The FMEA process involves breaking down the system, product, process or strategy into smaller components, thoroughly analyzing each component to identify potential failure modes, their effects, and their probability of occurring. The results are then used to prioritize failure modes based on their risk profile and to develop mitigation strategies for further use. More so, the tool is particularly useful in high risk industries where failures have serious consequences such as aerospace, automotive, and the medical industry, but can be applied in most industries. Overall, the Failure Mode and Effect Analysis is a powerful tool for risk management and process improvement, allowing organizations and risk managers to proactively manage risks and improving performances. By identifying and addressing potential failure modes before they occur, organizations can reduce downtime, improve product quality, enhance safety and reliability, and strengthen the the strategy.[5].

When to Apply FMEA

Being a general qualitative risk management tool, the applications can vary widely. However, the tool is applicable for, quantitative risk management, qualitative risk management and a combination, depending on the particular scenario. In general there are four areas of which the FMEA tool is relevant to apply.[7]

- Product development

- Process development

- Service development

- Strategic management

With the four typical areas of deployment, it's further important to understand why a manager might want to apply the FMEA. The main reasoning for applying the tool in three initial areas is due to the development. As the FMEA tool is well sorted for uncertainty of failure modes for projects not initiated yet, all of which focusing on being preventive of failures occurring due to uncertainty. More so, as all development phases are in a mobile and agile stage compared to in use phases, the result from the FMEA can help the development teams to mitigate elements of the product, process or service in order to meet a better result when their final work is put into affect. The last element is the strategic management, the FMEA is applicable within this area in a more continuous way. Meaning the the FMEA tool can be used for strategic choices as the tool complies information to help the manager identify which areas of the strategy mitigate and if the existing strategy should be changed, updated or discontinued all together, based on scenario assessments.[7] An example could be a project manager looking into new projects to invest in. The PM should then gather the most experienced team within the project team and maybe even some prominent stakeholders, in order to get as many failure modes as possible. Then the PM could prioritise due to different sets of focuses on the project result. For instance, if a particular stakeholder has highly important needs from what the project delivers, then the potential failure modes affecting those needs would become relevant to encounter. [5] Alternatively looking into an existing project, then the Project Manager could use the FMEA as an evaluation tool for current as well as previous incidents. The important difference here is that the tool would now be used with a focus on solutions to the failure modes rather than a pinpointing of which failure modes to mitigate.

The FMEA tool and how it works

The FMEA tool is matrix based tool structuring information gathered and scenario created from a team within the organization. The purpose of this is to create as much intel and experience as possible from within the organization to use in the FMEA context. The tool in itself consists of a matrix with seven predefined columns off which the risk manager can insert information based on what was gathered and calculate the Risk Priority Number (RPN). It is important to note that a FMEA matrix can easily be modified, but in general the matrix would consist of seven columns. [4]

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Establish service journey | Possible failures | Consequence of failures | Impact (1-10) | List potential causes | Likeliness (1-10) | RPN (Impact x Likeliness) |

| Elements of assessment | Potential failures connected to the stage |

The consequences from each failure |

How much the failure impacts the organization or project |

The reason(s) behind the failure |

The probability of the failure occurring |

The Risk Priority Number Indicating what to prioritize |

Each stage in the FMEA has an individual role in establishing an overview of the potential failures or risks that the organization could encounter. The first stage is establishing the scope of which the assessments is based on. This would preferably be a listed timeline if looking at a continuous events, an example could be a service journey or it could be a list of failure-mode-scenarios or other elements in a project that are not time-dependent to each other. An example could be a construction project YAYAYAYAYAYDYA. Following is an example of a scenario with a flight journey, with the listed sequential stages:

Flight journey:

- Greed customer in the airport

- Receive luggage and print tickets

- Ensure that the customer knows of where and when the plane leaves

- Retrieve the ticket at the gate

- Seat the customer on the plane

- Serve food and beverages while in flight

- Ensure that the plane lands safely

- Retrieve the luggage to the customer.

All the listed stages are only to be listed in the first column (Establishing service journey). After identifying all stages of the journey, the second step in in using the FMEA tool is to describe the potential failure mode for each state meaning to gather as much quantitative or qualitative data, depending on the particular failure mode, in order to thoroughly asses the potential failure modes. The second column (Possible failures) is then used to list all potential failures connected to each stage in the flight journey. This part requires a team member(s) with great knowledge or experience to ensure the correct failures to be listed. The third column (Consequence of failures) requires an analysis of each possible failure listed and what outcome that could potentially occur if such a failure was to happen. This process can be time-consuming and implicates precise estimations to ensure all consequences are listed with regard to the project scope. The fourth column (Impact) is a column used to notate how impactful the consequences are to the organization or project based on a scale from 1 - 10 where 10 is the highest impact. It is important that this stage is performed in a transparent manner and without implicating too much subjective biases. This stage is well affected by the knowledge within the risk management team and the quality of the output depends on how objective the team can perform this scoring. The fifth column (List potential causes) requires a back-tracing problem finding analysis, an example could be the use of a Fishbone Diagram[8] or 5 Why's[9] root cause problem seeking tool. SKRIV AT DET HANDLER OM AT FINDE PROBLEMET both of which have the purpose of identifying what the potential causes of what the failure mode could be. The sixth stage (Indicate likeliness) is used to indicate the probability of the failure happening on a scale from 1 - 10 where 10 is the highest probability of the failure taking place in comparison to the rest of the identified failures. The estimation of this stage is best supported by data of previous scenarios to ensure an objective scoring, but for some scenarios without any historical information to how often the failure could take place, a subjective guesstimate based on the skillsets and knowledge within the risk management team can be the only solution.

The last stage (RPN) is a multiplication of the Impact scores and the Likeliness scores to create a Risk Priority Number for the risk manager to prioritize which failure modes to focus on for mitigation actions.[3]

An example of how a full FMEA matrix is performed can be followed bellow. More so, the table can (by the authors permission) be copied and used for any risk management scenario requiring a failure mode and effect assessment.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|

| Establish service journey | Possible failures | Consequence of failures | Impact (1-10) | List potential causes | Likeliness (1-10) | RPN |

| #1 Greed customer in the airport. |

Missing the costumer and the customer not checking them in. |

The customer won't make the flight at all |

1 | - Lack of service education. - Lack of signs and guidance towards the counter. |

2 | 2 |

| #2 Receive luggage and print tickets. |

Not receiving all luggage or printing the wrong ticket(s). |

The customer is not able to go trough security. Delayed flight departure or the customer missing the flight and becoming unsatisfied |

5 | - Lack of service education. - Bad position to identify all luggage at the counter. |

4 | 20 |

| #3 Ensure that the customer knows of where and when the plane leaves. |

Not informing the customer correctly about the flight information. |

Leaving the customer confused and unable to find the correct gate in time of departure. Delayed departure. |

4 | - Lack of service education. - Stressed situation. |

3 | 12 |

| #4 Retrieve the ticket at the gate. | Missing a customer at the gate counter. | Risk of boarding the wrong customer resulting in a delayed flight departure |

7 | - Stressed situation. - Bad gate structure. - Not identifying. a confused passenger or a passenger with bad intentions. |

2 | 14 |

| #5 Seat the customer on the plane. | Seating the passenger in a wrong seat. | Risk of passengers having to sit on the same seat and needing to discuss which seat to be replaced at. Delaying the departure. |

2 | - Miss-communication from flight attendants. - Over-booked plane. |

8 | 16 |

| #6 Serve food and beverages while in flight. |

Missing a passenger and their chance to get serviced in flight. |

Missing opportunity of earning money or leaving passenger unsatisfied. |

2 | - Communication among flight attendants. - Bad service practice. |

9 | 18 |

| #7 Ensure that the plane lands safely. |

A rough landing or crashing the plane. | Unsatisfied customers or having to deal with big financial consequences due to expenses connected to a flight crash. |

10 | - Missed maintenance. - Un-experienced officers. - Bad pilot practice. |

1 | 10 |

| #8 Retrieve the luggage to the customer. |

Missing the luggage on the way to the luggage pick-up-area. |

Unsatisfied customer and potentially having to compensate financially for the lost luggage. |

7 | - Bad practice from on-ground staff. |

5 | 35 |

This example shows how the FMEA tool is visually structured. The output from this example consists of a clear structure and failure mode ranking for the risk manager to attend. It shows how step #8 in this customer journey is the most important element to attend, being the overall most likely and impactful risk within the service journey. Furthermore, the FMEA result shows how the Ensure that the plane lands safely #7 mode has a low priority from a risk management perspective even though it has the absolute highest impact. All of the gathered information is now to be assessed and implemented into the product, process, systems development, the risk management strategy or in some occasions business strategies.[10]

Important notes and limitations of the tool

Before using the FMEA matrix, it is important for the project manager to clearly understand if their project is a system, product or process. To get the most beneficial output from the tool, it is often important to apply it as early as possible in a project, this could be in the initialization of the risk assessments of a project or particular part of the project. This means that what ever result made from the assessment can potentially help avoiding a potential failure, before it happens. The reasoning is based on how the method is interpreted as it is a ranking tool for potential risk taking place. Furthermore, the tool being predictive of what to manage in time, the risk management should consider if the tool can benefit their project as it has no means to decrease risk or any general control of existing risks. More so, the FMEA is not a "stand-alone" risk management tool as it relies on individual analysis tools in order to compile the output. [4]

The FMEA has some clear limitations. Firstly, when using the tool, the output is very much defined by the quality of the input. To get the absolute best from the FMEA, the project manager needs to gather a lot of information, data and unbiased experience. However, if the quality of the output is not as important as the result of the ranking, then the FMEA might still be a genuinely good tool for a project manager to manage potential risks. This is due to the reasoning behind the tool being a structuring or ranking tool. Another limitation to the tool is due to the structure of the information. More so, the FMEA tool is limited in creating interconnections between each failure mode, resulting in a missed opportunity for identifying how the modes effect each other, ******leaving the risk manager with a more two-dimensional assessment, where the actual relation is three-dimensional******. Another important aspect is the financial aspect of adapting the tool. As the data and information for the FMEA matrix can consist of financially heavy assessments or data gatherings, the risk manager needs to understand whether the tool delivers a cost effective result when considering the risk elements and how they would affect the organization or project in regard to the expenses associated with performing the risk assessment. Lastly and the biggest limitation regarding the FMEA tool is the time associated with performing a failure mode and effect assessment. As a fully conducted FMEA should consist of all possible failure modes in order to get conclusive risk assessment. The list of failure modes can be infinitely long and the resources to ensure proper analysis's equally long leaving a all important knowledge of which modes to include.[4]

Advantages and disadvantages

Advantages:

- Proactive approach: FMEA allows organizations to proactively identify potential failure modes and their effects, and develop strategies to mitigate them before they occur. This can help to reduce downtime, improve product quality, and enhance safety and reliability.

- Cost-effective: FMEA can help organizations to identify and prioritize areas for improvement and optimize resource allocation, which can ultimately lead to cost savings.

- Versatile: FMEA can be applied in a variety of industries and contexts, from manufacturing to healthcare to software development. It is a flexible and customizable tool that can be tailored to meet the specific needs and requirements of different applications.

Disadvantages:

- Time-consuming: FMEA can be a time-consuming process, especially when applied to complex systems or processes. It requires significant effort and resources to gather data, identify potential failure modes, and develop mitigation strategies.

- Subjectivity: FMEA relies on the expertise and judgment of the individuals involved in the analysis, which can introduce a degree of subjectivity into the process. Different people may have different opinions about the likelihood and severity of potential failure modes and their effects, which can lead to inconsistencies in the analysis.

- Limited scope: FMEA is primarily focused on identifying and mitigating potential failure modes and their effects. It may not be effective in addressing other types of risks, such as strategic or financial risks, which may require different tools and approaches.

Theory and purpose

How what goes in and what comes out? how should a project, program, portfolio manager use it?

The FMEA tool is considered a part of a risk assessment. The tool is considered a "what could happen" or "What would happen" situation assessment tool and is useful after gathering an overview of risks from I.e. a risk matrix assessment or similar tools. [3] The purpose of the tool is to avoid biased decisions based on limited analysis of dept or assumptions based assessments. The methodology consists of assessing each and every element of identified risks fully from the initial defined risks and trough to the absolute end of potential secondary impacts. This helps to create a more accurate assessment of the impact in particular the impact of a potential risk occurring with regard to the side effects and rebound effects depending on the particular usage. Furthermore, the tool does not exceed in assessing the probability of an instance occurring as this is out side the scope of the tool. This can however be assessed with a simulation approach, depending of the event of topic.

New:

The main theory behind Failure Mode and Effects Analysis (FMEA) is that it is better to prevent a problem than to deal with its consequences. FMEA is a systematic approach to identifying potential failure modes in a system, product, or process, and evaluating their potential effects. The purpose of FMEA is to proactively identify and mitigate risks before they occur, in order to improve quality, reliability, and safety.

The FMEA process involves breaking down the system, product, or process into smaller components, and then analyzing each component to identify potential failure modes, their effects, and the likelihood of occurrence. The results are then used to prioritize risks and develop mitigation strategies. FMEA is particularly useful in industries where failure can have serious consequences, such as aerospace, automotive, and medical device manufacturing.

Overall, FMEA is a powerful tool for risk management and process improvement, allowing organizations to take a proactive approach to managing risk and improving performance. By identifying and addressing potential failure modes before they occur, organizations can reduce downtime, improve product quality, and enhance safety and reliability.

Annotated Bibliography

3 key references.

References

- ↑ 1.0 1.1 Project Management Institute, Inc. The Standard of Risk Management in Portfolios, Programs and Projects, Year 2019

- ↑ Project Management Procedures, High Voltage Power Network Construction By Keith Harker, Published by The Institution of Engineering and Technology, London, United Kingdom, Year 2018

- ↑ 3.0 3.1 3.2 3.3 Innovation Portal: FMEA tool and how it works , http://www.innovation-portal.info/wp-content/uploads/FMEA.pdf/ , By Joe Tidd and John Bessant, October 21st, Year 2014

- ↑ 4.0 4.1 4.2 4.3 Applying FMEA in risk management, Risk Management Using Failure Mode And Effect Analysis, By D.H. Stamatis, Year 2019

- ↑ 5.0 5.1

- ↑ Information about standards, Using FMEA to Manage Risk Under IATF 16949, [1], Last visited: 9/5-2023

- ↑ 7.0 7.1 How to effectively use FMEA, Effective FMEAs: Achieving safe, reliable, and economical products and processes using failure mode and effects analysis Vol.1, By John Wiley & Sons, Year 2012

- ↑ Introduction the root cause analysis tool Fishbone diagram, Fishbone diagram for technological analysis and foresight, By Mario Coccia, Year 2020

- ↑ Introduction to the problem identification method 5 Why's, The Five Why's Technique, By ASB, Year 2009

- ↑ A project management guide, THE STANDARD FOR PROJECT MANAGEMENT and A GUIDE TO THE PROJECT MANAGEMENT BODY OF KNOWLEDGE, (PMBOK guide), 7th edition, Year 2021

- ↑ Visualization of theoretical interpretation, Created by the Author