FMEA – Failure Mode and Effects Analysis

(→FMEA Process) |

(→FMEA Process) |

||

| Line 34: | Line 34: | ||

== FMEA Process == | == FMEA Process == | ||

| + | |||

Revision as of 18:49, 9 May 2023

Contents |

Abstract

Failure Mode and Effect Analysis (FMEA) is a widely used technique for identifying and mitigating potential failures in products, systems, and processes [1]. FMEA is used in various industries, including automotive, aerospace, medical devices, and electronics, to minimize the risk of product and process failures [2]. The structured approach helps to first identify the potential failure modes, whose influence and probability of occurrence is then evaluated. This information is then further used to prioritize and implement corrective actions that reduce the risk of the failure modes occurring. The benefits of FMEA include identifying potential sources of defects in a product or process, reducing risks and costs through early defect detection and correction, improving the quality and reliability of products and processes, and assisting in decision-making and prioritization of improvement actions [3]. There are several types of FMEA, including Design FMEA, Process FMEA, and System FMEA, each of which targets specific aspects of a product or process. Design FMEA focuses on potential sources of failure in the design process, while process FMEA targets sources of failure in the production process. System FMEA examines the entire system and identifies potential failure sources that can impact the entire system [4].

This article provides a comprehensive overview of FMEA, including its origin, the different types of FMEA, the steps involved in conducting an FMEA, an example of application, and the benefits and limitations of an FMEA.

Definition and Origin

FMEA stands for "Failure Mode and Effects Analysis". The step-by-step approach is a quality management tool for analyzing and identifying possible failure modes in a system as well as their causes and effects [5]. It is used to determine the ways in which a product or process can fail, estimate the risk associated with specific causes and prioritize the actions that should be taken to reduce the risk [3]. Through the application of FMEA, project managers may detect possible issues at an early stage of product or process development and take action to evaluate, reduce, and eliminate risks. This process contributes to a functioning quality management system in which the cost of eliminating errors and the impact of an error are minimized [6].

FMEA found its beginnings when the U.S. military developed a method called „Procedures for Performing a Failure Mode, Effects and Criticality Analysis” to inspect their equipment in 1949 [7].

The term itself was created by NASA. The tool was widely used in 1963 when the first moon landing occurred. The application of FMEA contributed to NASA's success [8]. Ford introduced the quality management tool to the automotive industry in 1977. At that time Ford was driven to use FMEA after the gasoline tank of the Ford Pinto model experienced issues with light vibrations. This launched the tool's extensive use in the automotive sector. Manufacturers used various procedures and internal corporate norms at the time because there was no standard guideline [7].

The German Association of the Automobile Industry (VDA) first gathered the various standards together and established a standard that was subsequently applied in the businesses. FMEA was no longer limited to the automotive industry once the German Association for Quality (DGQ) issued a universal and industry-independent explanation of the tool in 1990. Among others, it was then used in the field of services and project management [7]. Subsequently, the standard was given a more thorough definition. In order to provide a globally consistent standard, the VDA standard and the Automobile Industry Action Group standard were aligned in 2019 [8].

Types of FMEA: Design FMEA and Process FMEA

Among other things, a distinction is made between Design and Process FMEA. While the Design FMEA (DFMEA) is used to find failures in the design of a product, the Process FMEA (PFMEA) analyzes possible errors in new or existing processes [6].

The Design FMEA or DFMEA, is applicable to the development, design, and planning of a product, particularly during the early stage or end-stage of the development of a new product. Nevertheless, DFMEA can also be used to correct already existing products. The goal of DFMEA is to uncover potential failures in the design of the individual components of a product and evaluate possible errors on the basis of development specifications which could have a negative impact on health, safety, and the environment. The System FMEA, which is a variant of the DFMEA does not examine individual components but the entire system with regard to the functional interaction of the individual parts [6].

The Process FMEA or PFMEA has the goal to uncover risks within a new or an existing process. It is used in particular for the investigation of manufacturing and assembly processes in the context of product development but also in the service and project management area. PFMEA is carried out before a new process is implemented or before changes made to existing processes take effect. Both scenarios for doing PFMEA intend to find any risks that could negatively impact the product, quality, safety, and customer satisfaction [6].

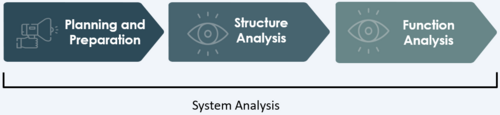

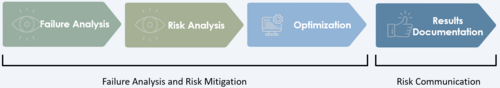

FMEA Process

There are seven steps in the process of performing an FMEA. The various steps are handled systematically and in chronological order. This framework allows multiple FMEAs to be compared due to the creation of an understandable and transparent approach [7].

The following lists and explains each of the seven steps in detail.

Planning and preparation (1)

Every FMEA starts with the planning and preparation phase. Here, it is first specifically determined which production area the FMEA will examine and what outcomes or insights are expected from the FMEA. At this step, expectations for the investigation subject are defined in terms of the desired characteristics and functions. In order to prevent future issues with specific questions that are unrelated to the intended goal, the desired level of detail for the FMEA and the expected depth should also be determined [7]. The organization of the project team that will conduct the FMEA is a key component of the planning. Depending on the type of FMEA and the subject of examination, experts from various departments should be chosen for this task to ensure a range of perspectives and approaches. Professionals from research and development, design, production, and quality assurance will often be involved. Representatives of the supplier and the customer may also be invited if processes are being looked into in which they have a key role. A firm representative who is already familiar with the FMEA approach acts as the project team's leader and leads the group through each phase and takes over the time management [6].

Structure Analysis (2)

The second step is the structure analysis. In this step, the object of investigation is divided into individual elements that can be analyzed, for which all relevant information is collected to enable a detailed analysis. The structure analysis involves the precise analysis of the structure of a product or a process [9].

The current state of the analysis can only be considered in the best possible way through the continuous exchange of information between all participants. During this exchange, the moderator has a special responsibility [6].

Function Analysis (3)

The step of the function analysis strongly contributes to the comprehensibility of the object of investigation of an FMEA [6]. First, the functions of the individual elements of the system are described. Furthermore, each function of an individual element is described in a generally valid and objective manner. In order to ensure the understanding of the object of investigation, a clear function structure is created. This can be visualized by a function tree [7]. By assigning functions in the third step, the following error analysis can be simplified, as errors can be systematically investigated [6].

Failure Analysis (4)

Subsequently, in the failure analysis, the specified individual elements are examined one after the other for errors or malfunctions. Above all, potential errors are to be recorded at this point [9][7]. In order to fully investigate all risks and to be able to successfully carry out the subsequent optimization of the product or process, the consequences and causes of the errors are also intensively determined [6][10] p. 109-111. The function tree which was created during the function analysis can be used to illustrate the associated errors and malfunctions related to the functions. This can help to provide an overview and to conclude on further error causes [9][10].

Risk Analysis (5)

During the risk analysis, the identified errors and causes are evaluated individually. This evaluation can be used to prioritize the error correction that takes place in the subsequent optimization. Serious errors can thus be prevented at first, and the available budget can be used optimally [6][11].

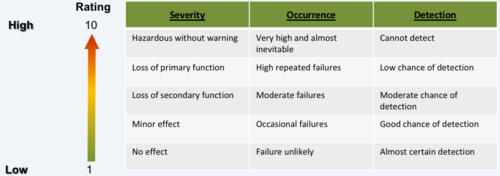

In the following, the risk priority number (RPN) is explained for the prioritization of error correction.

The RPN is the product of the three values S, O, and D, which are evaluated on a 10-point scale. Here, O (Likelihood of Occurrence) indicates the chance that the fault's underlying cause is going to occur and includes the planned preventive steps. D (Likelihood of Detection), which accounts for the planned inspection measures, expresses how likely it is that the defect will be discovered before delivery to the customer. And finally, S (Severity) discusses how the client will be affected by the consequences of the error [6][10].

When assigning points, 1 is the minimum value with which rather insignificant errors are evaluated. The value 10 is the maximum value and means that an error is the most serious. The higher the RPN for an error, the more urgently measures must be implemented [6][7]. Furthermore, a critical RPN is defined, which is used to measure the point at which errors must be eliminated without question. This critical RPN is usually in the range of 120 [11].

One way of extending the RPN is the risk matrix, in which O and D are shown in an evaluation table together with the associated risk [7]. The task priority table, which is common practice in the automotive industry, provides an additional choice. It makes a distinction between tasks with high, medium, and low priority [6].

Optimization (6)

Next, during the Optimization, solutions are developed to eliminate the identified defects. The measures may include changes in the design or production process or improved testing methods. To ensure clear accountability and effective implementation of the improvements, the planned measures are assigned to the relevant departments [6][11]. In this process, the determined RPNs or task priorities are used to prioritize. Error-preventing measures have priority. After that, error-detecting and lastly error-compensating measures should be considered [6][9]. After the measures have been implemented, another FMEA is conducted, which serves as a performance review. Here, the key figures of the RPN are determined again and the difference between the old and new RPN is used as a measure of success. The FMEA is carried out until no more potential sources of error with critical RPN, or high task priority are identified [7].

Results Documentation (7)

In the final step, the results of the FMEA are evaluated and documented. Then, depending on the type and area of the FMEA, the results are also shared with the affected stakeholders, including customers and suppliers [6]. For documentation, a worksheet can be used to capture the various steps of the FMEA. In order to be able to represent the complex structures of the FMEA, function, and error trees should also be integrated into the documentation [9].

Example of application

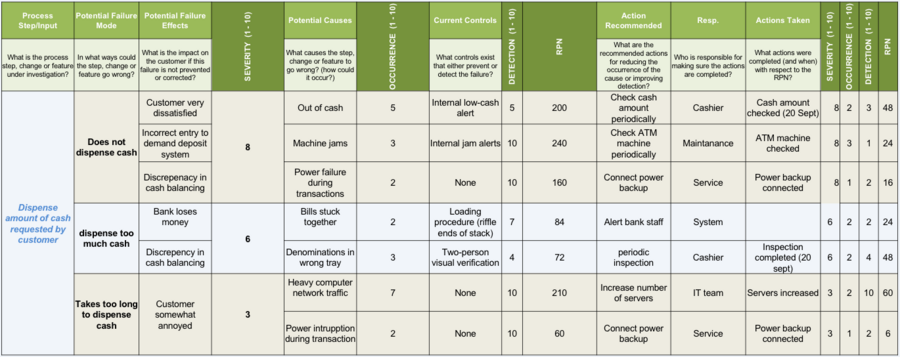

In the following, the FMEA process is illustrated and further explained using an application example.

The cash withdrawal function at an Automated Teller Machine (ATM) was selected for the application example.

In the following, only the risk analysis is considered. For this purpose, it is assumed that at the beginning of the FMEA, the object of investigation and the cross-functional project teams were determined. Furthermore, it is expected that, during a structure analysis, the individual investigation areas of the ATM were defined, and that with the help of a function analysis, the functions of these areas were figured and described in a generally valid and objective manner. Subsequently, the deficiencies of the use of an ATM were concluded by the failure analysis. In the further course, these deficiencies can be evaluated by conducting the risk analysis.

At the beginning of the risk analysis, the existing audit and prevention measures are described. The only quality assurance measures at that moment are the verification of how much cash is issued and how long the withdrawal process takes. Next, the possible errors when a customer tries to withdraw money from the ATM, the potential effects on the bank or the customer as well as the probable causes and control options are entered in the worksheet.

Finally, the RPN for the potential failure modes can be determined. For this purpose, the key figures Severity (S), Occurrence (O), and Detection (D) are evaluated on a 10-point scale. First, the Severity (S) is considered. It is measured how strong the effects of an occurring error sequence would be. The severity for the customer can be rated as medium (6) to strong (8) in case of an incorrectly raised amount of money. If a customer has to wait too long, this has a less strong severity (3). Moreover, the Occurrence (O), which corresponds to the probability with which an error cause would occur, is evaluated. The different potential causes are considered and evaluated with values from 1 to 10. 10 corresponds to an error cause that is very likely to occur. Furthermore, Detection (D), which determines the probability of detecting a defect in the product, is used for each potential failure. Here, the detection is assessed based on the currently existing controls. The higher the value given for D, the higher the probability that the error will be detected using the respective control option.

At last, by multiplying S, O, and D, the RPN can be calculated. With the help of the RPN, the priority with which a failure must be handled can be determined. It is clear that the error of no cash withdrawal is the most urgent to be corrected. Furthermore, it is possible to define the critical RPN in order to achieve even clearer results [12][13].

After finishing the risk analysis, the Optimization is performed. By doing this, the recommended actions with the responsible person and the completion date can be identified. These actions are expected to lower the Severity and the Occurrence. Moreover, further controls may improve the detection. Eventually, the values for S, O, and D and the RPN can be determined again.

In the end, when the optimizing actions are completed, the results, as well as the new values for S, O, D, and the new RPNs, can be documented [13].

Benefits and Limitations

Finally, the benefits and limitations of using FMEA are explained below.

Benefits

By applying the FMEA, it is possible not only to eliminate the effects of the errors but also to address the causes. This is achieved mainly through the clear structuring of the process and the precise documentation of the error correlations. As a result of the ability to detect errors at an early stage of product or process development, the error costs that occur can be kept as low as possible [14]. Once an FMEA has been created, it can be easily transferred to other product and process variants, as it usually has a generally valid formulated function [6]. Furthermore, competencies of different departments are used to carry out the FMEA, which enables a comprehensive view of the object of investigation. Interdepartmental work can also positively affect the relationship between employees, which can promote communication and teamwork [14]. The available budget can be used optimally by prioritizing the errors, for example with the risk priority number [6].

Limitations

However, since the FMEA consists of many individual steps with a high level of detail in order to achieve comprehensive and reliable findings, the process can also be very time-consuming. The implementation of spontaneous suggestions for improvement is therefore also difficult to execute in practice [11]. Another disadvantage is that working in interdepartmental teams can result in high personnel costs [11]. Due to the complexity and lengthiness of the process, the method can lead to resistance from stakeholders [14]. In addition, the subsequent risk assessment when assigning a value to the RPN can also be very subjective since different employees can give different ratings for the same error. Therefore, it makes sense to use standardized evaluation scales [6]. Also, employees who must critically reflect on their own work to determine errors and their causes during an FMEA might not implement this or only incompletely. Therefore, employees must be aware that they do not have to fear any negative effects on their employment position [11]. Lastly, the RPN does not show why an error is problematic. For example, the RPN does not show whether an error displeases or even harms a customer [6].

Annotated Bibliography

References

- ↑ Stamatis, D. H. (2013) Failure mode and effect analysis: FMEA from theory to execution. ASQ Quality Press.

- ↑ Annarelli, A., & Sperandini, A. (2016) FMEA: A practical guide to Failure Mode and Effects Analysis. Springer.

- ↑ 3.0 3.1 Schulze, S, & Schultmann, F. (2011) Failure Mode and Effects Analysis (FMEA) from theory to execution. John Wiley & Sons.

- ↑ Vose, D. (2008) Risk analysis: A quantitative guide. John Wiley & Sons.

- ↑ DIN EN 60812:2006-11. (2006) Analysetechniken für die Funktionsfähigkeit von Systemen—Verfahren für die Fehlzustandsart- und -auswirkungsanalyse (FMEA) (IEC 60812:2006); Deutsche Fassung EN 60812:2006. Beuth Verlag. retrieved on 13.02.2023, from https://www.beuth.de/de/norm/din-en-60812/92880886.

- ↑ 6.00 6.01 6.02 6.03 6.04 6.05 6.06 6.07 6.08 6.09 6.10 6.11 6.12 6.13 6.14 6.15 6.16 6.17 6.18 6.19 Brüggemann, H., Bremer, P. (2015) Grundlagen Qualitätsmanagement. Springer Fachmedien Wiesbaden. p.29-31, p.44-52.

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 Werdich, M. (2012) FMEA - Einführung und Moderation. Vieweg+Teubner Verlag. p.6-7, p.21, p.23-34, p.38, p.47, p.50-51, p.54–55, p.67.

- ↑ 8.0 8.1 KVP Institut GmbH. (2018) Kurzübersicht: Eine kurze Geschichte der FMEA. retrieved on 20.02.2023, from https://www.kvp.de/allgemein/kurzuebersicht-eine-kurze-geschichte-der-fmea/.

- ↑ 9.0 9.1 9.2 9.3 9.4 Hering, E., Schloske, A. (2019) Fehlermöglichkeits- und Einflussanalyse: Methode zur vorbeugenden, systematischen Qualitätsplanung unter Risikogesichtspunkten. Springer Vieweg. p.6-9, p.25.

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedJakoby - ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedSchroeder - ↑ Agile in Asia. (2021, 18. October) What is FMEA? Failure Mode and Effects Analysis Explained. retrieved on 14.02.2023, from https://www.agileinasia.com/post/what-is-fmea.

- ↑ 13.0 13.1 American Society for Quality. (2023) Learn about Quality: FAILURE MODE AND EFFECTS ANALYSIS (FMEA). retrieved on 14.02.2023, from https://asq.org/quality-resources/fmea.

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedKnorr