The Critical Path Method (CPM)

(→Tool and method) |

(→Tool and method) |

||

| Line 50: | Line 50: | ||

'''Phase 1''': The construction of a sequential relationship of the individual operations in the project where each task is named and defined. | '''Phase 1''': The construction of a sequential relationship of the individual operations in the project where each task is named and defined. | ||

| − | |||

[[File:Precedence_Diagram.PNG|450px|thumb|right|'''picture 1:''' Precedence Diagram]] | [[File:Precedence_Diagram.PNG|450px|thumb|right|'''picture 1:''' Precedence Diagram]] | ||

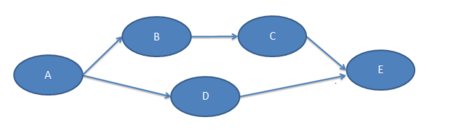

'''Phase 2''': The construction of a constructional schedule called a Precedence Diagram (Picture 1). The Precedence Diagram depicting their sequential relationship. | '''Phase 2''': The construction of a constructional schedule called a Precedence Diagram (Picture 1). The Precedence Diagram depicting their sequential relationship. | ||

| − | |||

[[File:Aktivity_Identity_box.PNG|450px|thumb|right|'''Picture 2:''' Aktivity Identity box]] | [[File:Aktivity_Identity_box.PNG|450px|thumb|right|'''Picture 2:''' Aktivity Identity box]] | ||

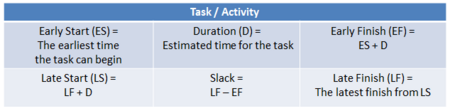

'''Phase 3''':The construction of the Activity Identity boxes (Picture 2). Each task has an Activity Identity Box which contains information regarding task name, duration, early start, early finish, late finish, late start and slack time. The completion of the Activity Identity Boxes is carried out by filling in task name and duration, furthermore performing firstly a forward pass (early start, early finish) and backward pass (late finish, late start and slack time) | '''Phase 3''':The construction of the Activity Identity boxes (Picture 2). Each task has an Activity Identity Box which contains information regarding task name, duration, early start, early finish, late finish, late start and slack time. The completion of the Activity Identity Boxes is carried out by filling in task name and duration, furthermore performing firstly a forward pass (early start, early finish) and backward pass (late finish, late start and slack time) | ||

| − | |||

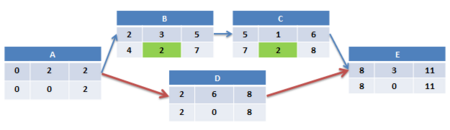

[[File:CMP_diagram.PNG|450px|thumb|right|'''Picture 3:''' CPM Diagram: | [[File:CMP_diagram.PNG|450px|thumb|right|'''Picture 3:''' CPM Diagram: | ||

Revision as of 18:32, 26 September 2015

This method article describes the Critical Path Method (CPM) also in comparison to other project management methods. This article describes how and when to use CPM methods, moreover discusses the advantages, disadvantages and applicability of the method. CPM is a step-by-step project management method for process planning. CPM was developed in 1956 by the E.I. du Pont de Nemours Company a major chemical plant construction firm in USA[1]. By focusing on tasks duration CPM identifies the minimum length of time needed to complete a project and helps define the most critical tasks that needs to be accelerate in order to complete the project within the available time. Furthermore CMP allows you to identify slack time (free resources) and can be used to monitor if the project follows the time schedule.[2] To identify the critical path through the project you can either use CPM or Program, Evaluation, Review and Technique (PERT). With available accurate task time estimate CPM is the preferred method. PERT is used in projects with inaccurate time estimates by applying three time estimates (earliest, latest, average) to create the expected time. CPM is therefore the most simplified method. CPM utilizes tasks duration as the parameter for optimization of the schedule and resource planning. In opposition to these methods based on time estimates the Critical Chain Theory utilize resources as the measured component[3]. CPM is one of the fundamental concepts in traditional project management. It can be applied for the planning, scheduling and control of construction projects[4].

Contents |

Introduction to CPM

CPM is a step-by-step method for project planning and management. It is the presentation of a project plan by a schematic diagram that depicts the sequence and interaction of all the tasks of the project[1]. The precursor of CPM was PERT (Program, Evaluation, Review and Technique) developed by the U.S. Navy and PPS (Project Planning and Scheduling). PPS focus on estimates on both time and cost for design, construction and maintenance work [1]. The main benefits of CPM for the projects managers are firstly to identify the most important tasks. By focusing on tasks duration CPM identifies the critical path and thereby the minimum length of time needed to complete a project. If any of the tasks forming the critical path take more time than their estimated durations, start or finish later than planned, then the whole project will be affected. The critical path is by the Project Management Body of Knowledge (PMBOK), an internationally recognized collection of processes and knowledge areas accepted as best practice for the project management profession, defined “the sequence of scheduled activities that determines the duration of the project.” The critical path helps define the most efficient way to schedule the project. Although many projects have only one critical path, some projects may have multiple critical paths. Secondly, CPM helps reduce timelines by identifying slack time. Slack time tells to what extent each activity in the schedule can slip (float) without delaying the project [5].

In the early stage of CPM there was not any computer programs to make the calculations and the network diagrams was made using hand drawn nodes to present the stages of a product. This was of course very time consuming compared to using newer technologies especially as a project is not a static thing but constantly changing. Today there are a number of project management software programs available that can do the calculation. Microsoft Project and Smartsheet are two different computerized tools that use CPM[5]

Tool and method

| Activity | Predecessor | Duration (weeks) |

|---|---|---|

| A | - | 2 |

| B | A | 3 |

| C | B | 1 |

| D | A | 6 |

| E | C , D | 3 |

CPM is still an incredibly important tool to project managers, even though it is almost 60 years old. It provides a visual representation of project activities and clearly presents the time required to complete tasks. Construction of a CPM can be subdivided into four phases.

Phase 1: The construction of a sequential relationship of the individual operations in the project where each task is named and defined.

Phase 2: The construction of a constructional schedule called a Precedence Diagram (Picture 1). The Precedence Diagram depicting their sequential relationship.

Phase 3:The construction of the Activity Identity boxes (Picture 2). Each task has an Activity Identity Box which contains information regarding task name, duration, early start, early finish, late finish, late start and slack time. The completion of the Activity Identity Boxes is carried out by filling in task name and duration, furthermore performing firstly a forward pass (early start, early finish) and backward pass (late finish, late start and slack time)

Phase 4:The CPM path diagram can be completed and the critical activities determining the overall project duration can be identified ( Picture 3). The critical path is identified as the path with the longest duration time e.i. the fastest time the project can be finish. In the example (Picture 3) the critical path shown with the red arrow is A, D and E because the duration time 11 weeks is longer compared to 9 weeks for A, B, C and E. Furthermore slack time for the individual activities can be calculated either thought Late Finish minus Early Finish or Late Start minus Early Start[4].

Guidance on use

The most logical and efficient way to work is on one project at the time, unfortunately this is almost never the case. Most likely people will work on the task they think is the most interesting or the task they think the management would prefer them to be working on. Working on one project at the time will result in higher quality, less stress and better teamwork.[6]

In a project with lots of tasks and dependencies it can be really hard to identify the most important tasks that, if missed, will impact the whole project. In other words, the ones you really need to worry about to make sure you meet your deadlines. CPM identifies these important tasks and can be used to evaluate whether the project stay on track or not. CPM can be made as hand-drawn diagrams but with more complicated projects it is more advantageously to use automated software programs, which are capable of handling even very complex processes [5].

CPM is one of the fundamental concepts in traditional project management. It can be applied for the planning, scheduling and control of construction projects especially by construction contractors. The critical path identified by the CPM is often used as a precursor to Gantt Charts [4].

CPM produces a planned schedule to guide the project team, and it forms the basis for tracking project schedule performance by comparing actual with planned task progress. CPM is still an incredibly important tool to project managers, even though it is almost 60 years old. It provides a visual representation of project activities and clearly presents the time required to complete tasks. Furthermore it tracks activities so the project manager does not fall behind. CPM also reduces uncertainty because of the estimated duration time and the considerations that need to be made to provide unexpected factors that may impact tasks and reduces the likelihood that an unexpected surprise will occur during the project [5].

If the project leader figures out using the CPM that he needs to shorten down the duration time or compress the project schedule then there are two way of doing it: Either Fast Tracking or Crashing. In the Fast Tracking the project leader searches for activities from the critical path that can be done parallel to each other, in order to move the project along faster. The reason to look only on tasks from the critical path is because all the other activities have slack time and having them finishing early is only going to give more slack time. While fast tracking reduces your project timeframe, it also involves risk because you are performing parallel activities that were originally planned to be performed in sequence. Crashing is the other way of compressing or shorting down a project. Here the project leader identifies the shortest possible time for which a task can be scheduled. This happens by adding more resources to completing that certain task. By speeding up the processes it might result in lower quality of work [5].

When managing a project with CPM, a challenge that might change the critical path could be resource constraint issues. Scheduling certain activities at the same time, might lead to a need of more people than there are available. A solution to this is to reschedule the activities. Resource leveling is the process of resolving these conflicts and is done by allocating resources. It might include delays from resource bottlenecks which is when a resource is not unavailable at the required time. Another result from resource leveling could be that the previously shorter path becomes the longest or most “resource critical” path. This happens when the tasks on the critical path are affected by resource constraints [5].

Moreover CPM permits comparison of alternative work programs, construction methods and equipment. CPM provides the projects manager with precise information on the effects of each variation or delay in the adopted plan and thereby indicates where to have the main focus to stay on time. Furthermore CPM allows you to identify slack time and helps you to secure that the project follows the time schedule [1].

Discussion on limitations

A challenge with the CPM is not to lose sight of the risks inherent in tasks not on the critical path. This might happen because of the extra attention the critical path requires. For example, the completion of a task not on the critical path could be delayed, this could cause that the duration time becomes long enough to change the critical path of the project. A limitation of CPM is that it highlights tasks at greatest risk for causing schedule delays, but it does not identify the source of the schedule risks. Different methods, such as the Critical Resource Path Technique identified by Aguanno (2002) calculate alternate critical paths that factor in the risks caused by dependence. on unique or constrained resources [7].

A schedule created from CPM involves a lot of fluctuation because you have to use best-guess estimates to calculate time. CPM is therefor only as powerful as the estimates entered into it. If the estimations are off or if the resources are not calculated correctly, the critical path could change and a delay will happen in worse case it may cause an entire project to fail [8].

As projects tent to be more complex having several critical paths and change of the critical paths during the project, CPM can be difficult to use and understand. The development therefor tends to develop specialized computerized methods to calculate critical path ways. An example of this is the Linear Scheduling Model [9].

The advantages of the manual method compared with using the computer method is, that it overcomes certain weaknesses which result from the assumption that each operation in the project is independent of every other operation, except for the sequential relationship shown by the network chart. Furthermore it is impractical to exert intermediate control over the calculations to recognize changes in input data or related effects between operations with the computer method. On the other hand the computer method is can calculate much faster. Especially with long duration projects where the critical path will change often it is good with fast calculations [4].

CPM often provides a better understanding than the conventional bar chart, because it illustrates relationship that controls the order of performance of the various operations. Also CPM delivers the project manager with a constructional schedule that can be used to project control and planning. Another advantage using CPM is that the knowledge of the operational flow can be used for resource allocation and equipment requirement estimates. Furthermore slack time can be used to optimize resource allocation [4].

Conclusion

CPM is one of the fundamental concepts in traditional project management. CPM utilizes tasks duration as the parameter for optimization of the schedule, resource planning and control of construction projects.

CPM is an effective and powerful method of assessing:

- The shortest time in which a project can be completed

- Task priorities

- The most critical tasks

- Resources needed to achieve a project

- Tasks which have slack time

- The sequence of activities, scheduling, and timings involved

Furthermore CPM provides a mechanism for determining all of the operations affected by a given change as well as the effect on project duration. It provides the mechanism for determine the least cost to compress project completion time. To use CPM optimal focus has be on securing accurate duration time

Additional reading

For more information on the Cynefin Framework, you might find the following sources useful

Articles

- Yamin R. & Harmelink. "Comparison of Linear Scheduling Model (LSM) and Critical Path Method (CPM)." J. Constr. Eng. Manage (2001): 127(5), 374-381. [9]

- Aguanno, Kevin . "Critical Path: An Extended Definition." MMPUBS (2002). [7]

Books

- Woodhead, James M. Antill & Ronald W. "Critical Path Methods in Construction Practice". John Wiley & Sons, Inc. (1990). [1]

- Fondahl, John W. "A non-computer approach to the critical path method for the construction". Stanford University. (1962). [4]

Links

- Verma, Eshna. "What is Critical Chain Project Management?". Simplilearn (2009): http://www.simplilearn.com/what-is-critical-chain-project-management-rar68-article [3]

- Burger, Rachel. "The Secret to the Critical Path Method in Construction". Capterra (2015): http://blog.capterra.com/construction-critical-path-method/[8]

- Dr. Larry Bennett. "The Ultimate Guide to the Critical Path Method". Smartsheet (2015): https://www.smartsheet.com/critical-path-method/[5]

Videos

- Dr. Zelbst, Pamela. "Critical Path Method and PERT explained". (2015)

- Newbold, Rob. "Critical Chain Project Management". (2011)

Bibliography

- ↑ 1.0 1.1 1.2 1.3 1.4 Woodhead, James M. Antill & Ronald W."Critical Path Methods in Construction Practice" John Wiley & Sons, Inc. (1990): 90.

- ↑ name="Sm15"

- ↑ 3.0 3.1 What is Critical Chain Project Management?, 2009

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 Fondahl, John W. "A non-computer approach to the critical path method for the construction". Stanford University. (1962).

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 The Ultimate Guide to the Critical Path Method, 2015

- ↑ 6.0 6.1 CEO Newbold, Rob. Critical Chain Project Management, 2011

- ↑ 7.0 7.1 Aguanno, Kevin. "Critical Path: An Extended Definition." MMPUBS (2002).

- ↑ 8.0 8.1 The Secret to the Critical Path Method in Constructio, 2015

- ↑ 9.0 9.1 Yamin R. & Harmelink. "Comparison of Linear Scheduling Model (LSM) and Critical Path Method (CPM)." J. Constr. Eng. Manage (2001): 127(5), 374-381.

- ↑ Dr. Zelbst, Pamela. Critical Path Method and PERT explained, 2015