Lean in building and construction industry

m (→Tools improving the transformation, flow and value) |

m (→Early involvement of contractors and suppliers) |

||

| Line 112: | Line 112: | ||

Integrated contractual agreements is a way of achieving integrated project delivery. This type of contract align different project parties, and has become a popular solution. | Integrated contractual agreements is a way of achieving integrated project delivery. This type of contract align different project parties, and has become a popular solution. | ||

| − | |||

== Limitations of Lean Construction == | == Limitations of Lean Construction == | ||

Revision as of 23:52, 28 September 2015

Managing projects on time and within budget, is one of the biggest challenges in the construction industry today. As projects evolve the complexity increases, and uncertainties sets a break on the growth in the industry. As a consequence to this there has been a lower efficiency improvement over time compared with other industries. Managing waste, such as delays and miscommunication, is one of the biggest improvement areas. A way to comprehend where this waste emerge from and how to reduce it, some companies opened their eyes to lean project management. Lean project management is a production management-based approach aimed to make planning more effective and slim production. This is achieved through having a focus on eliminating unnecessary waste in the value chain. It is based on proper use of resources through good planning, good communication and good structure. This way of thinking originated in 1948 from automotive industry and Hajime Ohba, former General Manager of Toyota Supplier Support Center.[1]

Lean project management has since 1948 further evolved in order to adapt the variation of the construction industry. This is because of the difference between the production industry and the project-based construction industry. In the early 1990 lean project management expanded into lean construction. Lean construction as a tool focuses on good planning and transparency throughout the entire course of the project. This can help minimize uncertainty, which, in the chain of events, can further lead to risk mitigation.

Lean Project Management

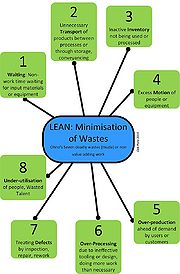

The main focus within Lean Project Management is to always search for unnecessary use of resources in a production or a service chain. Activities that do not increase the value of the product for the customer, is considered as waste, or "Muda", and should be removed. The term "Muda" origins from Japan, and is a key concept in the Toyota Production System and Lean thinking. [2] It is essential for a project to be cost effective and have no redundancy when it comes to products, personnel and the like. The main task of the management in a company that works with Lean is to eliminate this waste. Toyota chose to classify these unnecessary wasting activities into seven different activities[3]. However, in recent years, an eighth activity have been added. It is called misuse of resources, or under-utilisation. [4]

MUDA:

- Waiting

At a construction site, it is considered as waste when people are forced to wait for the preceding activity to end before one can start on their task.

- Transportation

Examples of poor planning of transport may be that the vehicle is not fully utilized. This leads to more trips, or that there are transported too much and must return to the pickup location with materials that are redundant.

- Inventory/stock

Storing unfinished products and parts, or finished products waiting to be shipped out to customers, cost the company the rent for storage space. On the other side, poor inventory planning and not having product available, can lead to work being postponed. "Just in Time" is a tool for better planning of inventory, which is discussed in section 6.2.

- Motion

This is the movement when working in a workplace. It is natural to move around a bit, but there are some unnecessary movement, leading to waste of resources. This may for example be that the worker have to collect tools needed to perform a job on the other side of the construction site.

- Over production

The demand is a factor that is difficult to predict. Therefore, it is also difficult to know how much to produce, and it often occurs over production. Everything produced but not used, is wastes.

- Over-processing

The work performed on a product or service that are not directly create value for the customer is called over processing. This type of waste is difficult to measure because it is more difficult to control.

- Defects

Errors and omissions can easily occur and this can cause delay. Therefore, it is important to have procedures and systems for how to treat it and how to minimize the resulting impacts.

- Under-utilisation

Unused and improper use of expertise is an example of misuse of resources. It does not help to have competent workers on a project if you do not use them for what they are best at.

When you have implemented these aspects into the companies way of thinking, the company is using Lean. Furthermore, there are two important principles one must follow in order to call a change for a product of Lean. First is "continuous improvement". This means that after Lean is "introduced", the company must continue to look for improvements. There are no correct operation. Second, "respect for people". It is essential that there is room for making mistakes within an company. That allows employees to present real numbers and discuss any error, rather than amplify reports and forecasting of sales[5]

Lean Project Management versus Lean Construction

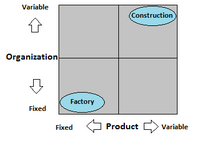

Lean will generally be put in the context of automobile production and as such it can be difficult to be seen as a value-added process in the construction industry. To better understand the difference between using lean within manufacturing compared with using lean within a construction project, one needs to understand what differentiates the two. First, a normal Lean production has solid products made in series. On a construction site there will be created a "unique" product for each project. Secondly, another significant difference is location; a factory will be located at the same place all the time. While a construction project is anticipated to take place at several different locations.

Furthermore, there are other components in the construction industry one must take into account. The construction industry consists of different disciplines. In addition to contractors there are electricians, carpenters, bricklayers, etc. The flow of the different projects is entirely dependent on the planning and interaction between the various actors such as builders, building managers and consultants. Another aspect is that there are different contracts, as well as different contributors, at the project which creates a unique setting.

Indeed this just illustrates a few of the differences between the two. Nevertheless, when taken into account it clearly indicates that there is a need for a new comprehensive shift in the industry.

What is Lean Construction?

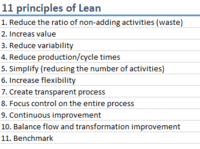

In short terms, Lean Construction is a production management based approach to project delivery. The concept involves using techniques adapted to the construction industry to improve the flow of value through better use of resources. The origins can be traced back to the early 1990. Professor Lauri Koskela published in 1992 the dissertation “Application of the new production philosophy to construction”, where he summarized his perception of Lean theory into 11 principles (see figure 3)[6]. With these principles he formed the foundation of the application of the theory to construction industry. He discussed in his dissertation the difference between the traditional conceptual basis of construction, looking at construction as driven by activity in contrast to the new concept, construction driven by flow. His conclusion was that the management of construction driven by activities deteriorate flows, with a focus on only the activity and not the whole project as a series of activities. The consequences is that there is developed waste, and therefore a shift in the industry was needed, to a more flow-based management. Lean Construction was evolved, and in 1993, the term was implemented by the International Group for Lean Construction in the construction, architecture and engineering industry.

To create an ideal production system for project-based production, Koskela developed a system where production is conceptualized in three complementary ways: as a Transformation, as a Flow and as Value.

- Transformation is the production of inputs into output. This is based on achieved by resources, workers, machines, etc. and measured in cost.

- Flow is progress in activities that are smooth and uninterrupted. This is measured in time.

- Value defining what creates value for the customer. Everything else is Muda. This is measuret in quality.

Additionally, the projects must be seen as a dynamic and unpredictable system, and as a social system. By putting the projects into a system it is easier to understand the activities and create customized tools for improvement.

The first step of Lean Construction is to understand the "push and pull" of a production system. [7] The effect of both dependence and variations on activities and supply chains is essential for a successful project. By detecting and eliminating all unnecessary activities and expenses, and identify where there is potential for improvement, there will be a better flow in the processes. This will give an identification of objectives and a better production control. There are some given precondition for better flow in construction project, this is discussed in section 4. Later on in the article there will be discussed some tools for better flow. See section 6.

Another aspect to give the project a better flow, is involving the contractors and suppliers on a early stage. This is a key differentiator for good planning. By specifying targets, schedules and realistic expectations in communities will be able to create a more cooperative environment and more transparency. This will be discussed in section about "Early involvement of contractors and suppliers".

Because of the diversity in this industry, there is no single way of managing Lean Construction. There are many aspects one have to be aware of, and as Lean is a way of thinking, it must be implemented throughout the whole company. Rybkowski et al. (2013) defines Lean as a “path of continuous learning”. [8] As a consequence, one of the biggest pitfalls of introducing Lean, is an inconsistent leadership. Today, the management principles behind the construction industry is often characterized by bad control and unfavorable design, which eventually can lead to waste and value lost. [9] The construction site itself is characterized by complex and chaotic systems. Particularly challenging is the flow of material and information, creating latency and misconceptions. [10]

Seven preconditions for flow in a construction project

The concept of the seven flows is essential in order to better understand and improve the flow. It is a series of pre-conditions that need to be aligned in order for an activity to begin. A fault in any of these seven flows may result in delay or "Making-do" waste, a waste that occurs when an activity has started without the necessary flows or inputs.

To simplify, the terms "healthy" and "unhealthy" activity are used, to distinguish between value-added - and non-value-added work. A "healthy" activity takes place when the seven conditions are met.

The seven preconditions [11]

1. The preceding activity ended. The preceding activity must be completely finished and completed in an orderly manner before the next activity can begin. additionally. Full completion means that the workers have cleaned up after themselves and any tool or material has not been left in the workplace. The activities that take place are often interdependent, and therefore the next activity cannot start before the preceding is complete. Earthworks has to finish before they can lay the concrete base. Here it is important to be aware of the projects critical path. The critical path is the "longest sequence of activities in a project plan which must be completed on time for the project to complete on due date. An activity on the critical path cannot be started until its predecessor activity is complete; if it is delayed for a day, the entire project will be delayed for a day." [12]

2. The material is ready for use. Materials in this context means a raw material that is about to be processed. For example, concrete mass, wood, steel, cables, or whatever material for the intended purpose must be ready to use when the activity starts.

3. Aids. Aids are tools that are essential for getting the job done. Examples include; cranes, machinery, scaffolding etc. The tools must be present and in working order when the activity will be conducted.

4. Workers. The workers have to be allocated to the right task at the right time. If this is not done properly there may occur waiting time, and the project may be delayed. Other issues are that the workers may be committed elsewhere, sick or in any way prevented from working. Furthermore, in certain cases there might only be a limited number of workers with the specific skills needed.

5. Information. To give out the right information to the right person at the right time is fundamental in this industry. An example is that all building projects are dependent on accurate and correct drawings. A drawing that is not correctly updated can lead to rework and major delays. It does not help to construct a roof identical to the drawing if this does not fit the building anymore.

6. The area. It is also important to have space to perform the job. A bricklayer for example, cannot lay tiles on a floor surface that is at the same time being used by an electrician to add heating.

7. External preconditions. There might be necessary permits, specific weather requirements and other external environmental factors affecting progress. For example, by the demolition of a building or blasting inside a mountain near a residential area, there has to be a notification in advance.

Designing a production system, which meets these preconditions, is only possible through the collaboration of all project participants and clear responsibilities (Owner, A/E, contractors, Facility Managers, End-user) at early stages of the project.

Tools improving the transformation, flow and value

Last planner system

"Last planner system" is a planning system which aims at production flow. It focus on collaboration and participation, throughout a rolling weekly schedule. Involvement of the participants has shown a feeling of ownership of the project and plans. When planning a phase of a project, all participants are gathered in the process, to ensure that all the expertise that is needed is included. Last planner system give schedule/plan predictability for the stakeholders throughout controlled activities; timeline for when the activities should be done, expected resource consumption and prerequisites for implementation of the activity. [13]

When a task is completed, the last planner responsible declares the completion to his superiors. To declare it completed, the task has to be complete to an appropriate standard, and the tools used is cleared. The finished task is reported in the weekly meetings, and the next activity can start, based on trust that the job is done properly. To keep the weekly meetings brief and with participation, it is held with simple paper forms. There can be used Post-it notes, paper, pencil, eraser and photocopier.

There are 4 different steps of LPS:

1) It starts with a master plan or a phase schedule at a project level. The stakeholders are involved early at this stage. The work strategies are defined and milestones are set.

2) Look ahead plan. This plan links the master and the phase schedule, and it ensures that the work is made ready. It breaks down the tasks, identifying and removing constraints and designing operations. Because of the uncertainty with a long timeline, this plan is restricted to 5-6 weeks. Longer timeline would result in unreliable and meaningless planning.

3) Weekly work plan: represents a reliable weekly work plan.

4) Measurement of “Percent of Planned completed”, PPC. This measures the effectiveness and not productivity.

Due to the complex sequence of events, there are establish short planning horizons and percentage planned-complete measurements (PPC). The weekly plan is based on reliable promises between the participants, and learning based upon analysis of PPC and reasons for variance. The PPC and the variations are summarized, and the reasons for delays is registered in a “Pareto chart”. This to make it easier to identify where there is most likely to yield the most results. To better understand and take advantage of the information from this chart there are used tools as 5 Why analysis and cause-effect diagrams.

Just In Time

Just-in-time (JIT) is a principle developed in the 1950s, where the goal to produce a product to meet a precise need for a specific time and reduce or eliminate inventory.[14] The principle origin from the the car manufacturer Toyota, in order to reduce inventory as a waste factor. Just-in-time will therefore say to deliver what is needed at the right time and place for each stage of the production process. As a result of this, the company do not need to build up inventory in anticipation of a future demand, which will reduce unnecessary storage costs and create customized flow of goods.

Other examples of waste as JIT has influence on is unnecessary movement, unnecessary equipment and overproduction. This leads to a faster flow of materials, increased productivity, lower capital and management costs, higher quality and greater flexibility and speed. The challenge with this principle is that it requires a completely new and fundamental way of thinking with a good planning for it to function optimally.

Building Information Modeling (BIM)

A more modern and technical approach to controlling the flow is by using advance modeling techniques such as BIM. With the right use this can improve a company's efficiency through visual project clarification and reduction of misunderstandings, mistakes and re-work when it comes to the drawings and documentation.

There are BIM for each of the different disciplines (building, structural, electrical, plumbing, pipes, etc.), and one can combine these models to a multidisciplinary BIM. This provides an overall preview of the construction, and its complications. To have an efficient use of BIM within projects, this program must be taught to several people within the disciplines.

Early involvement of contractors and suppliers

Integrated Project Delivery (IPD)

As well as Partnering, Integrated Project Delivery (IPD) is a tool for project cooperation. Members included in to collaboration is the architect, key technical consultants, general contractor and key subcontractors. This way of managing projects creates a common platform that makes it easier to collaborate without the challenges with overcoming key organizational and contractual challenges. As well as allowing information flow and communication, mitigating the risks that arise from a lack of knowledge and understanding. Through this, consensus is being reached among the stakeholders.

According to Pasquire and Court(2013) [15] “The relational an integrated arrangements of Lean Production Delivery and Integrated Project Delivery suggests that no-one person does have “the full picture” but that this picture becomes apparent when the appropriate parties come together."

Integrated contractual agreements is a way of achieving integrated project delivery. This type of contract align different project parties, and has become a popular solution.

Limitations of Lean Construction

A challenge to using Lean in this industry is the current construction management. The practices is similar to the activity center approach seen in mass production. With a focus only on completing the activity, and unpredictable release of work and consumption of resources to finish on time, ignoring the waste created between the subsequent activities. As a result of this the flow and value loses its effect. [16]

References

- ↑ [Lean communication] "Lean communication(Internet)", Available from: www.leancommunications.no/Lean/cid/29165/ , Read: 10.09.15

- ↑ [Lean Thinking: Banish Waste and Create Wealth in Your Corporation, Revised and Updated] Womack, James P. Jones, Daniel T. 2003. Free Press.

- ↑ [The machine that changed the world.] Womack, James P. Jones, Daniel T., Ross, Daniel. 1999/2007. Simon & Schuster, Inc.

- ↑ [The machine that changed the world.] Womack, James P. Jones, Daniel T., Ross, Daniel. 1999/2007., Simon & Schuster, Inc.

- ↑ [Better Thinking, Better Results: Case Analysis of an Enterpris- Wide Lean Transformation.] Emiliani, Bob. 2007. 2. utgave. Micheal J. London & Associates, Inc.

- ↑ [Application of the new production philosophy to construction] Koskela, L ' '(1992), Technical report number 72.' Standford University'

- ↑ [What is Lean Construction.] Howell, G. A. ' ' IGLC - 7 (1999), 1–10

- ↑ [An Enineering Perspective on Lean Construction Theory.] Bjornfot, A. IGLC - 16 (2007), 15-26

- ↑ [An exploration towards a production theory and its application in construction] Koskela. 2007.

- ↑ [Complexity – Construction in a New Perspective] Bertelsen, S. (2003a). Proceedings of the 11th Annual Meeting of the International Group for Lean Construction, Blacksburg, Virginia, USA

- ↑ [“Sju forutsetninger for flyt på byggeplassen"] "Leanforumnorge(Internet)", Available from: www.leanforumnorge.no/no/regionale-forum/generelt-om-lean/foredrag/sju-forutsetninger-for-flyt-paa-byggeplassen, Read: 15.09.15''

- ↑ [“Critical path"] "Businessdictionary(Internet)", Available from: http://www.businessdictionary.com/definition/critical-path.html , Read: 12.09.15

- ↑ [“Last Planner system”] "Leanforumnorge(Internet)", Available from: http://www.leancommunications.no Read: 15.09.15

- ↑ [Lean Thinking: Banish Waste and Create Wealth in Your Corporation, Revised and Updated] Womack, James P. Jones, Daniel T. 2003. Free Press.

- ↑ [An Exploration of Knowledge and Understanding – the Eighth Flow.] Pasquire, C., and Court, P. (2013). IGLC - 21 (2013), 43–52

- ↑ Seed, W.R. Lean construction (2010). Herd 3, 2 (Jan. 2010), 130–1