The A3 report

| Line 6: | Line 6: | ||

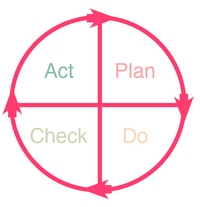

| − | [[File:PDCA3.png|200px|thumb|right|Figure 1: The PDCA cycle]] The name of the "A3 report" refers to the standard size A3-paper on which it fits. The idea behind the tool was developed by Toyota and was used from the 1960’s. It became a part of the Toyota Production System as a standard for problem solving, proposals, plans and status reviews. The A3 report is evolved around a Plan-Do-Check-Act (PDCA) cycle developed by Walter Shewhart. The PDCA system is a way of continuously improving and managing an organization in a systematic way. The A3 documents the findings from the PDCA cycle but is very flexible to the problem for which it is used to analyze.<ref name=(Schwagerman, 2013)> ''Schwagerman III, W. C., & Ulmer, J. M. (2013). The A3 Lean Management and Leadership Thought Process. Journal of Technology, Management & Applied Engineering, 29(4).'' </ref> The A3 describes in principal the chronologically story of the PDCA in one or more A3’s by step wise going through the different stages of the PDCA. For this reason the A3 report has been referred to as “Standardised storytelling”.<ref name=''(Shook, 2009)''> ''Shook, J. (2009). Toyota's secret: the A3 report. MIT Sloan management review, 50(4), 30-33.'' </ref> Even though the tool origins and is widely used in manufacturing, it has been applied successfully in a range of industries such as healthcare, for educational purposes, aircraft maintenance<ref name=(Ko, 2013) /> as well as construction<ref name=Ko, C. H., & Tsai, P. C. (2013). Applying Lean Production A3 to Enhance Construction Work Flow. Life Science Journal, 10(2) | + | [[File:PDCA3.png|200px|thumb|right|Figure 1: The PDCA cycle]] The name of the "A3 report" refers to the standard size A3-paper on which it fits. The idea behind the tool was developed by Toyota and was used from the 1960’s. It became a part of the Toyota Production System as a standard for problem solving, proposals, plans and status reviews. The A3 report is evolved around a Plan-Do-Check-Act (PDCA) cycle developed by Walter Shewhart. The PDCA system is a way of continuously improving and managing an organization in a systematic way. The A3 documents the findings from the PDCA cycle but is very flexible to the problem for which it is used to analyze.<ref name=(Schwagerman, 2013)> ''Schwagerman III, W. C., & Ulmer, J. M. (2013). The A3 Lean Management and Leadership Thought Process. Journal of Technology, Management & Applied Engineering, 29(4).'' </ref> The A3 describes in principal the chronologically story of the PDCA in one or more A3’s by step wise going through the different stages of the PDCA. For this reason the A3 report has been referred to as “Standardised storytelling”.<ref name=''(Shook, 2009)''> ''Shook, J. (2009). Toyota's secret: the A3 report. MIT Sloan management review, 50(4), 30-33.'' </ref> Even though the tool origins and is widely used in manufacturing, it has been applied successfully in a range of industries such as healthcare, for educational purposes, aircraft maintenance<ref name=(Ko, 2013) /> as well as construction<ref name="Ko, C. H., & Tsai, P. C. (2013). Applying Lean Production A3 to Enhance Construction Work Flow. Life Science Journal, 10(2)" </ref>. |

Revision as of 21:26, 23 November 2014

Abstract

The A3 report is a widely used LEAN-tool which derives from Toyota's production system. It is used in various industries and has a range of different applications. Most commonly the A3 report is used as a tool for problem-solving, communication, knowledge-sharing etc. in organisations. This article will describe the origin of the A3 report and the different types of A3 reports. An overview of the different elements in the A3 reports in combination with a stepwise description of the use is provided. Furthermore it will be described how to choose and customize one or more A3 reports for portfolio management as well as implementation advice.

Introduction

The name of the "A3 report" refers to the standard size A3-paper on which it fits. The idea behind the tool was developed by Toyota and was used from the 1960’s. It became a part of the Toyota Production System as a standard for problem solving, proposals, plans and status reviews. The A3 report is evolved around a Plan-Do-Check-Act (PDCA) cycle developed by Walter Shewhart. The PDCA system is a way of continuously improving and managing an organization in a systematic way. The A3 documents the findings from the PDCA cycle but is very flexible to the problem for which it is used to analyze.[1] The A3 describes in principal the chronologically story of the PDCA in one or more A3’s by step wise going through the different stages of the PDCA. For this reason the A3 report has been referred to as “Standardised storytelling”.[2] Even though the tool origins and is widely used in manufacturing, it has been applied successfully in a range of industries such as healthcare, for educational purposes, aircraft maintenance[3] as well as constructionCite error: Closing </ref> missing for <ref> tagRefer to the same reference again by writing: Cite error: Invalid <ref> tag;

refs with no content must have a name

References

Create a reference list like this one, by writing- ↑ Schwagerman III, W. C., & Ulmer, J. M. (2013). The A3 Lean Management and Leadership Thought Process. Journal of Technology, Management & Applied Engineering, 29(4).

- ↑ Shook, J. (2009). Toyota's secret: the A3 report. MIT Sloan management review, 50(4), 30-33.

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs named.28Ko.2C