The Kaizen – Toyota KATA method

(→Improvement Kata) |

|||

| Line 11: | Line 11: | ||

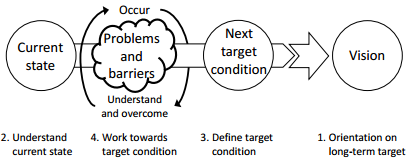

====Improvement Kata==== | ====Improvement Kata==== | ||

| − | + | [[File:ImprKata.png]] | |

=====Vision===== | =====Vision===== | ||

=====Current condition===== | =====Current condition===== | ||

| Line 17: | Line 17: | ||

=====Obstacles===== | =====Obstacles===== | ||

=====PDCA===== | =====PDCA===== | ||

| + | |||

===Coaching Kata=== | ===Coaching Kata=== | ||

Revision as of 10:57, 19 September 2016

Overall there are two paradigms within management – the Command and Control Paradigm (CCP) and the Interaction and Learning Paradigm (ILP) (Rasmussen, 2011). The first one, CCP, would put the manager in the position of an enlightened leader, who has all the answers and operates in a deterministic world. In other words, the manager like the conductor of an orchestra, directs the symphony, giving specific directions to each musician. On the other side, we find the paradigm of interaction and learning, where a manger does not yet have all the answers, but acquires them through interaction. A manager rather than giving detailed action plans, creates a frame for action. It is said that the second approach works better when dealing with complex tasks, varying demands, and unpredictable environments. Within project management these two paradigms are also represented in the form of traditional and agile project management. This article views project management from the ILP paradigm and it assumes that a project or a portfolio manager often needs to deal with problems without having a clear solution. In this situation the right approach always has to do with exploration and innovation.

This article examines a management method, which has proven to be very successful in supporting fast and innovative solutions to complex problems in Toyota, namely Kaizen and the Toyota Kata method. This article states that project and portfolio managers dealing with product or process development and organisational change can benefit from the teachings of Kaizen and Toyota Kata.

The Kaizen method engages manager and employees to think solutions beyond the usual, and ensures continuous improvement, as it breaks the problem at hand into smaller problems, solved one by one using the scientific method (Anon., 2016) of experimentation instead of the usual "implementation" approach. This liberates the solutions as the improvement efforts are allowed to lead to failure and failure is even a welcomed learning. The efforts themselves are encouraged to be small, so that their effect can be controlled and, most importantly, confirmed. An important benefit of the Kaizen management method is the humanisation of the workplace. People working on a Kaizen project feel empowered and full of purpose, as they are not blindly following orders but are part of creating their work environment and procedures. The article starts out by elaborating on the methods origins’ and later describes the processes and tools needed to use it successfully. Benefits and limitations are outlined and finally, the current and future applications of the method within project management are discussed.

Contents |