Work Breakdown Structure in Construction Management

Kasperloewe (Talk | contribs) |

Kasperloewe (Talk | contribs) (→Limitations) |

||

| Line 50: | Line 50: | ||

== Limitations == | == Limitations == | ||

| + | Any model used in project management comes with limitations, where a work breakdown structure is no excuse. A number of things can go wrong during a project to destroy the work breakdown structure, or there could simple be a lack of input, so a project manager cannot create one. The input required to construct a work breakdown structure is shown in Figure 1. | ||

| + | |||

| + | Another one of the worst things that can happen to a work breakdown structure, is [[scope creep]]. Scope creep is when the scope of a project changes, resulting in a change of activities/deliverables. As an example, this could be the new metro line decides once the project plans and budgets are complete, that they want to add an extra station, perhaps make 4 tunnels instead of 2 or maybe even make half the metro run above ground. This makes the original work breakdown more or less useless as it will now require numerous of new activities to achieve the final goal. | ||

| + | |||

| + | It is also important to realize that the model cannot be used as a schedule on its own. The work breakdown structure does not give any information regarding the interdependency of each tasks of a project. This meaning that many of the tasks for each activity may involve other tasks, and some must be done in a specific order. This being said, the model is a very useful tool when making the project schedule as all the tasks are already outlined. | ||

| + | As tried in the section [[Estimating cost and identify risks]] putting a cost to a risk might prove useful when doing a budget with a work breakdown structure but this does not include the unknown unknowns. With this meaning the risks no one expected or even knew could happen during a project. | ||

== Annotations == | == Annotations == | ||

Revision as of 17:26, 26 February 2018

Ever since the Work Breakdown Structure (WBS) was first introduced to Project Management by NASA [1], it has been used in in many different fields of engineering. The Work Breakdown is found to be a very useful tool as projects grow more and more advanced and with increased complexity. Projects with huge budgets such as with the Apollo space program, having multiple tasks needed to be complete in order to send humans to the moon, requires a lot of management through the whole life-cycle of a project. Time has shown many times that having a poorly planned project, the effects can be very heavy and end up as a direct impact of the success of a project. For this exact problem a model that provides the project manager the tool to handle and plan a project is needed, and this is where the work breakdown structure come in handy. Not many projects in the field of civil engineering comes close to the innovative and complexity of the Apollo space program. However, they grow more and more complex and are therefore very useful in construction management. The work breakdown structure takes the scope of the project and make it into smaller manageable chunks which frames the project and all its tasks. Doing this, an overview of cost, time and risks is a lot easier to establish.

This article aims to explain the use of work breakdown structure in Construction Management through practical examples from the major Metro Cityring project in Copenhagen city. This is done by first describing the basic theory behind and how a work breakdown works. Afterwards, how the project manager can use the model to break down a goal into manageable tasks and lastly how this can be used to estimate time, resources and cost of a construction project.

Contents |

The basics behind and the reason to do a work breakdown structure

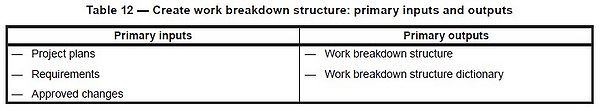

The work breakdown structure is a commonly used tools by project managers all over the world. This is due to the increased complexity of projects with increasing number of stakeholders. According to [2] the breakdown structure is an important part of planning, as it clearly identifies the plan’s products and reducing risk of important aspects being missed. It improves the communication as the products dependencies become clear and highlighting where and which stakeholders should work together. Also a very important point is that it can help prepare “work packages” for suppliers. This makes it easier for stakeholders tendering the project to prepare a bid for the various jobs. Especially in construction management is the last point useful as construction involves many different groups of workforce, e.g. carpenters, bricklayers, plumbers, electricians and so on. The creation of a work breakdown structure follows a well defined scope Scoping. This means having determined the overall goal where after the final goal can be divided into smaller activities. These activities can then be divided into even more smaller tasks and so on. A practical explanation will come in the following chapters. The input needed in order to construct a work breakdown structure is defined in the ISO21500 standards [3] as in the following tables:

This gives a so called product-orientated grouping of project work elements which defines the scope [4] .Having this hierarchy of activities gives the project manager a clear picture of each jobs that needs to be completed in order to reach the final goal. This is a very useful tool as starting a project can be very difficult in terms of knowing what is needed to complete a goal. This especially in construction management as the projects are often large and complex and with many different stakeholders and parties involved. Therefore, a project manager will not know all the smaller processes, and not knowing what workforce is needed for each activity before breaking down the project. When doing the work breakdown structure, PRINCE2 suggests the following:

- Involve a team of people representing a wide range of interests and with different skills involved in the plans output. In construction management this could be involving a bricklayer when constructing a wall, as getting his input on what is needed for that task can prove very useful.

- Identify products by running a structured brainstorm session.

- Reach a final commonly agreed structure among the team, such that there are no disputes afterwards of the breakdowns form.

- Describe the expected state of each delivered product as it helps to pass the product on to the next activity. This meaning when delivering a wall, is the wall just supposed to be delivered in raw bricks, or is it the final wall to be delivered with plaster, wallpaper, paint etc.

- Different shapes and colors can be used to for deliverables, activities and tasks. Also colors can be applied to tasks to show which group is responsible for each. An example could be that every product delivered by a carpenter gets a red box, bricklayer a green box and so forth.

- If the project is broken into several stages the stages can be extracted to its own breakdown structure, where a more detailed plan can be made. This is done in order to keep the work breakdown structure somewhat neat and still give the needed overview.

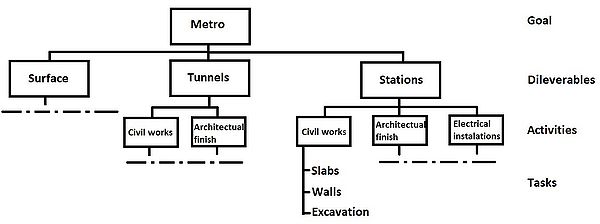

The hierarchy of a work breakdown structure start as mentioned with a predefined goal, followed by a number of deliverables, activities and tasks. The goal is self-explanatory as this is the final product you want to end up with. The deliverables what is needed to be handed over to the client in order to call the project finished. Activities which processes is needed to achieve the deliverables. And finally which tasks/jobs are needed to complete each activities. Once the activities needed to achieve the main goal are identified the project manager can use the WBS to:

- Determine the important milestones of a project.

- Assign project managers for each activity/task.

- Useful support tool to control the project.

- Put an estimation of cost to each activity, making it easier to lay down a budget.

- Risks can be identified when understanding the work that needs to be done.

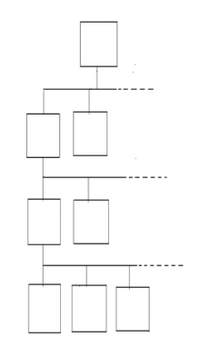

The work breakdown structure usually follows a hierarchy block structures as seen on Figure 2.

Breaking a project into chunks

To begin with the project manager defines the main deliverables of the project. Taking the Metro Cityring into an example, the main goal and first level of the work breakdown structure would be to complete a fully operational metro line. The next level would be to define the deliverables needed to achieve this goal. In this case a completed tunnel with functional trains, completed stations with all architectural finishes and also a re-instated surface level after the excavations. On the third level each of these three deliverables are then broken into activities needed to achieve the deliverables, where after those activities are broken further down into tasks. At this level hierarchy order of the work breakdown structure stops, as at this point time, resources, cost and risks can be identified. This way of breaking down the work into level is taken as an inspiration from NASA page 4.

A good question to this approach and procedure would then be, when the “breaking down” stops. As mentioned in The basics behind and the reason to do a WBS at some point the tasks has to be extracted out of the work breakdown model and used as a goal itself in a new model. WBS suggests that this is a common practice to do when a task exceeds a duration of one day. This obviously makes a lot of new breakdowns, but again this is to keep the original model neat.

Estimating cost and identify risks

Having the project broken into manageable chunks, each task is then associated with time, resources, cost and risks/opportunities. Each is very important to evaluate and estimate as a part of a work breakdown structure, as they can determine the success of a project. The definition of a projects success is a whole field of itself in project management and will not be covered further in this article. However, having made a wrong estimation of time causes delays, which means higher cost. PRINCE2 suggests a great number of techniques useful when doing estimations of projects. As an example of one of these techniques, PRINCE2 suggests using the so-called bottom-up estimation. This method does as the name hence, sum all the cost/time from the bottom and up. Each tasks can also have a risk or opportunity added as a number of cost for each. For the sake of simplicity, a cost of a risk could be labeled with red and an opportunity green. These are obviously difficult to take into the calculation of cost/time estimates, because taking all risks in to account will most likely blow the entire budget, as that would be very expensive.

Risks and opportunities are always a big part of project execution and planning and are associated with a high potential of impacts on a project. Risks are defined as negative impacts which could be both an increase in cost or time of a project. Opportunities on the other hand are defined as positive impacts which could mean a task taking shorter than expected or lower cost of one. Both are obviously dangerous to calculate for and put into a project. Risks as they may come totally unexpected and threatening the entire project, where an opportunity can prove dangerous if you calculate as you are expecting it.

As a practical example of risk/opportunity management, one could look at the excavation for the Metro Cityring. Prior to any excavation a number of tests are conducted on site, to determine the soil conditions. This means having an idea of how much the soil can carry and also how much time it will take to remove. Having hard rock takes a lot longer time removing than digging through sand. When estimating the risks one could chose to include that the soil conditions are not exactly as the tests has proven, meaning the excavation will take longer than estimated. On the other hand it could also be that the excavation takes shorter time than expected, causing the task to cost less. Both these situations could be added to the work breakdown structure when estimating the cost and time. However, one can obviously not take both into account for each tasks.

Limitations

Any model used in project management comes with limitations, where a work breakdown structure is no excuse. A number of things can go wrong during a project to destroy the work breakdown structure, or there could simple be a lack of input, so a project manager cannot create one. The input required to construct a work breakdown structure is shown in Figure 1.

Another one of the worst things that can happen to a work breakdown structure, is scope creep. Scope creep is when the scope of a project changes, resulting in a change of activities/deliverables. As an example, this could be the new metro line decides once the project plans and budgets are complete, that they want to add an extra station, perhaps make 4 tunnels instead of 2 or maybe even make half the metro run above ground. This makes the original work breakdown more or less useless as it will now require numerous of new activities to achieve the final goal.

It is also important to realize that the model cannot be used as a schedule on its own. The work breakdown structure does not give any information regarding the interdependency of each tasks of a project. This meaning that many of the tasks for each activity may involve other tasks, and some must be done in a specific order. This being said, the model is a very useful tool when making the project schedule as all the tasks are already outlined. As tried in the section Estimating cost and identify risks putting a cost to a risk might prove useful when doing a budget with a work breakdown structure but this does not include the unknown unknowns. With this meaning the risks no one expected or even knew could happen during a project.

Annotations

NASA Work Breakdown Structure (WBS), Handbook (2010)

As NASA were the first to develop the concept of a work breakdown structure, their have a great deal of experience is working out one. Therefor a very useful article regarding WBS.

Managing successful projects with PRINCE2, 2009.

The British standards of project management provides a solid ground basics and describes many common tools used within project management.

DS/ISO 21500, 2013. Guidance on project management

The Danish and international standards of project management. Like the PRINCE2 it provides many tools used. However, this from a more wider international point of view.

Rajani Devi, T., & Shobha Reddy, V. (2014). Work Breakdown Structure of the Project.

A very easy to read article describing the concept of work breakdown structure.

References

- ↑ Fleming, Jon F., and Kenneth W. Poole. “NASA Work Breakdown Structure (WBS) Handbook.” (2016)

- ↑ Managing successful projects with PRINCE2, 2009 edition manual. (2009). Managing Successful Projects With Prince2, 2009 Edition Manual. TSO (The Stationary Office).

- ↑ DS/ISO 21500, 2013. Guidance on project management, 2nd edition.

- ↑ Rajani Devi, T., & Shobha Reddy, V. (2014). Work Breakdown Structure of the Project.