Process Planning and Cost Estimation

Sm nadukuru (Talk | contribs) (→Why to perform cost estimation?) |

Sm nadukuru (Talk | contribs) (→Cost estimation and best practices) |

||

| Line 145: | Line 145: | ||

Cost estimation is done throughout the project periodically and there are different cost estimation techniques that are applied which takes various inputs and gives different outputs. You can find detailed information on phases and techniques from the figure below. | Cost estimation is done throughout the project periodically and there are different cost estimation techniques that are applied which takes various inputs and gives different outputs. You can find detailed information on phases and techniques from the figure below. | ||

| − | + | ===Tools and Techniques=== | |

| − | Expert Judgement: Expert judgment uses experience and knowledge of experts in that particular field of the project for cost estimation. It is the cheapest, easiest and fastest technique. No resources are required for the implementation of this technique and it is used in the beginning phase when less or no data is available. | + | '''Expert Judgement:''' Expert judgment uses experience and knowledge of experts in that particular field of the project for cost estimation. It is the cheapest, easiest and fastest technique. No resources are required for the implementation of this technique and it is used in the beginning phase when less or no data is available. |

For eg: Estimating the cost of a small and simple project. | For eg: Estimating the cost of a small and simple project. | ||

| Line 153: | Line 153: | ||

Disadvantages with this technique are that it is very hard to find an expert for the specific project and also that it can be easily biased. | Disadvantages with this technique are that it is very hard to find an expert for the specific project and also that it can be easily biased. | ||

| − | Top-down Estimation: Top-down estimation takes historic data from earlier projects which are similar, as a basis for estimating cost. It is used in the early phase of the project when the availability of data is limited. This is one of the least expensive methods. | + | |

| + | '''Top-down Estimation:''' Top-down estimation takes historic data from earlier projects which are similar, as a basis for estimating cost. It is used in the early phase of the project when the availability of data is limited. This is one of the least expensive methods. | ||

For eg: Cost estimation for making an online platform for a company. For this, the cost estimator can use the data generated while making the online platform for another company. | For eg: Cost estimation for making an online platform for a company. For this, the cost estimator can use the data generated while making the online platform for another company. | ||

| Line 159: | Line 160: | ||

The disadvantage of this technique is that the results obtained are not reliable and accurate compared to others. | The disadvantage of this technique is that the results obtained are not reliable and accurate compared to others. | ||

| − | Parametric Estimation: Parametric estimation utilizes statistical modeling and historical data of the key drivers to develop cost estimation. It is a fast and also cheap method. It is a more accurate technique compared to Top-down and Expert judgement methods. | + | |

| + | '''Parametric Estimation:''' Parametric estimation utilizes statistical modeling and historical data of the key drivers to develop cost estimation. It is a fast and also cheap method. It is a more accurate technique compared to Top-down and Expert judgement methods. | ||

The disadvantage of this technique is that its accuracy lies in the correctness of the data used. | The disadvantage of this technique is that its accuracy lies in the correctness of the data used. | ||

| − | |||

| − | + | '''3-Point Estimation:''' 3-Point estimation is derived from PERT (Program Evaluation and Review Technique). This technique uses 3 estimates to define the final cost; | |

| − | + | ||

| − | + | ||

| − | + | ''Most likely cost (Cm):- the estimated cost if everything is executed as planned. | |

| + | ''Pessimistic cost (Cp):- the estimated cost in the worst case scenario, when nothing goes according to the plan and the cost is very high compared to the budget. | ||

| + | |||

| + | ''Optimistic cost (Co):- the estimated cost in the best case scenario, when everything works much better than the actual plan. In this case, the cost is very less than the budget. | ||

| + | |||

| + | |||

| + | <math>Formulae: Cost_estimation = (Co+4Cm+Cp)/6</math> | ||

| Line 177: | Line 182: | ||

Disadvantages with this method are, instead of one, there are three estimates to be done. It needs more work and more time. And there are chances that everything can go wrong. | Disadvantages with this method are, instead of one, there are three estimates to be done. It needs more work and more time. And there are chances that everything can go wrong. | ||

| − | Bottom-up Estimation: Bottom-up estimation takes the estimates from individual work collections and then combines them to give a final estimate. It is one of the most accurate methods of estimation since it focuses on the cost from a very deep perspective. In this process, the project is fragmented down to smaller activities and more detailed. The more the activities are detailed, the more accurate will be the results. This is the best technique among all other cost estimation methods. | + | |

| + | '''Bottom-up Estimation:''' Bottom-up estimation takes the estimates from individual work collections and then combines them to give a final estimate. It is one of the most accurate methods of estimation since it focuses on the cost from a very deep perspective. In this process, the project is fragmented down to smaller activities and more detailed. The more the activities are detailed, the more accurate will be the results. This is the best technique among all other cost estimation methods. | ||

The only disadvantage which this method is that it takes more time than any others which might result in spending more money. Also, it can be difficult to use this method for complex projects. | The only disadvantage which this method is that it takes more time than any others which might result in spending more money. Also, it can be difficult to use this method for complex projects. | ||

| − | |||

| − | Cost of Quality (CoQ): This includes the amount spent during the project to avoid failure that might happen and also the money spent before and after the project is done, due to the failures. It is a methodology that helps the organization or business to estimate the extent to which their resources are utilized. This also determines the potential savings that can be gained by implementing process improvement steps. | + | '''Reserve Analysis:''' Reserve analysis takes uncertainty into account and determines how much contingency reserves should be assigned to the project. This amount is accounted for uncertainty cost. It can be a fixed value, or a percentage of the cost estimated or can be calculated separately. This is a form of buffer cost. |

| + | |||

| + | |||

| + | '''Cost of Quality (CoQ):''' This includes the amount spent during the project to avoid failure that might happen and also the money spent before and after the project is done, due to the failures. It is a methodology that helps the organization or business to estimate the extent to which their resources are utilized. This also determines the potential savings that can be gained by implementing process improvement steps. | ||

| − | Vendor Bid Analysis: This is the last technique. Vendor bid analysis is used to calculate the cost of the project by comparing the bids quoted by the vendors. This method is used when the product is provided by the vendor or the service is outsourced. | + | '''Vendor Bid Analysis:''' This is the last technique. Vendor bid analysis is used to calculate the cost of the project by comparing the bids quoted by the vendors. This method is used when the product is provided by the vendor or the service is outsourced. |

A disadvantage with this method is that it relies completely on the capability and knowledge of the vendor. | A disadvantage with this method is that it relies completely on the capability and knowledge of the vendor. | ||

Revision as of 22:07, 6 May 2019

Contents |

Abstract

Process Planning and Cost Estimation are two very important and vital parts of any industry or business, either for the public sector or private organization. A process is a set of activities that are carried out in a sequence to reach a goal or target or to obtain the desired product. Any miscalculation or unorganized planning of this process may lead to a loss in terms of money, manpower, time or sometimes even loss of life. Cost estimation is equally important as process planning. It is the initial step in any business or making a budget and also to calculate the profit and loss. Both process planning and cost estimation should go hand in hand for an operation to be executed successfully. And in this article will see the detailed description of both process planning and cost estimation and how they are related to each other.

Process Planning

Introduction

Process planning is also known as manufacturing planning. There are many definitions for process planning based on different standards. According to the American society of Tools and Manufacturing, Process planning is the systematic determination of the methods by which a product is to be manufactured, economically and competitively ". some other basic definitions are:

Process planning is a system that tells which processes are used to convert a piece or part from its initial form to final form.

It is the act of creating detailed work instruction from design data for making a component.

Purpose

- To link design and manufacturing.

- To determine the process and sequence of operations to obtain a useful final product.

- In companies, process planning is used to increase the output of the business.

- To modernize the business methods of the company.

- To identify and eliminate the loopholes and bottlenecks.

Principles of Process Planning

- Define the outputs, and then pin down and make the list of inputs needed for reaching these defined outputs.

- Describing the goals of the processes.

- When plotted out, it should form a logical flow in a unidirectional way.

- Every step which is executed should be jotted down in the process planning, eliminate all the unused steps.

- Needs to be updated regularly with the most recent information.

Scope of process planning

A process is defined as a group of activities specific to achieve an output of an operating system in accordance with the defined measure of effectiveness.

New Product manufacturing/ Service providing: while implementing a new product or new process in making a product, unless there is proper planning, this product or process introduction will be uncertain.

Quality: Change in quality requires a change in the sequence of operations, tools and other features, i.e; change in process planning.

Effective use of facilities: Process planning can find alternative opportunities for the usage of different facilities in order to completely use the available facilities.

Cost reduction: Various opportunities will be available in cost reduction while performing the planning process.

Steps in Process planning

\begin{figure}[H]

\centering

\includegraphics[scale=0.3]{Steps_in_Process_planning.jpg}

\caption{Steps in Process planning}

%\label{fig:demarcation}

\end{figure}

Step-1: Drawing interpretation (Analysis of final product requirements as defined in the engineering design): It is the first step in process planning. The design can either be engineering drawing or CAD design.

In this step, identification of the features, dimensions, geometric tolerances, surface finish specifications, number of parts takes place.

Step-2: Material evaluation and process selection(Evaluating the materials specification and determining the appropriate manufacturing processes):} In this step selection of good and economic manufacturing happen. The parameters that affect this process selection are:

- Functions

- Appearance

- Reliability

- Environment

- Service life

- Compatibility

- Productivity

- Cost

Step-3: Selection of machines and other equipment (Selecting the proper equipment to accomplish the required operations):} After the selection of manufacturing process, the next step is to select the appropriate machines for this process. The factors that affect this process are:

- Economic considerations

- Production rate

- Unit cost of production

- Durability

- Dependability

- Process rejection

- Setup and put away times

- Productive life

- Functional versatility

Also in this step, the organization decides to make or buy the component.

Step-4: Setting process parameters (Establishing specific parameters for each operation and for each machine):} After selecting the machines required, the next step is to calculate the operational setup times and cycle times on each machine and equipment.

This requires the expertise of available machines and tools.

Step-5: Selection of quality assurance methods ( Specifying the inspection guideline for all important processing factors):} The inspection guideline is defined by the process planner.

Overuse of quality assurance methods and inspection would increase the processing time and hence the manufacturing cost will also increase.

Step-6: Cost estimation (Estimating the manufacturing costs of producing a component/product:} In this step, all the costs are calculated. Some features that affect cost estimation are labor, materials, etc.

Step-7: Preparing the process planning documentation: After selecting the best processing plan and the required machines for it, now the next step comes to document all these things clearly and in detail.

- This helps in recording how a part is processed.

- To provide information for future jobs.

- To aid in communication.

Step-8: Communicating the manufacturing knowledge to the other departments: This is the final step in process planning that establishes communication between the different departments who need knowledge on the manufacturing of the product. It helps in ensuring that the selected process is the most economical way possible. This also assists in improving quality.

Limitations of Process planning

Even though there are many advantages of process planning, there are a few limitations to it as well. They are:

- It makes the administration inflexible.

- There is no chance of individual liberty.

- Process planning reduces creativity thoughts of the individual.

- Individuals interest can overcome the interest of the company.

- Process planning consumes a lot of time as it involves gathering the data, analyze and interpretation of this data.

- Sometimes planning can go wrong as it is based on forecasts and future estimations.

- Collection analysis and evaluation of data involve a lot of investment in terms of time, effort and money.

Cost Estimation

Introduction

The basic definition of cost estimation is, it is the process of determining the cost of a program, project, or operation. It is used to forecast the expenses and prepare a budget for the project. Cost estimation helps in decision making and plays a crucial role in developing the scope of a project and determines what all the things are required for completion of a project.

Why to perform cost estimation?

Budgeting and scheduling are the two main areas where there are more chances of problems to arise while managing projects or handling business. It involves a lot of risks as any miscalculation may lead to a huge loss. For eg: Sydney opera house in Sydney, Australia: The Sydney Opera House, which was originally expected to cost just $7 million and open by Australia Day 1963, was eventually completed 10 years late for around $102 million – almost 14 times over budget.

Cost estimation is the first step in deciding whether a project is feasible.

There are many factors that are involved in cost estimation:

- Labor

- Materials

- Machines

- Equipment and facilities

- Services

- Contingency costs

Cost estimation is done while dealing with a project whose outcome is uncertain. Cost estimation is directly linked to the different phases of the project life cycle. They are:

Conceptual: How much the project will cost? How much time it will take for the project to be done?

Planning: Defines the activities involved in the process of completing the project.

Execution: While implementing those activities from the planning phase of the project.

Cost estimation and best practices

Cost estimation is done throughout the project periodically and there are different cost estimation techniques that are applied which takes various inputs and gives different outputs. You can find detailed information on phases and techniques from the figure below.

Tools and Techniques

Expert Judgement: Expert judgment uses experience and knowledge of experts in that particular field of the project for cost estimation. It is the cheapest, easiest and fastest technique. No resources are required for the implementation of this technique and it is used in the beginning phase when less or no data is available.

For eg: Estimating the cost of a small and simple project.

Disadvantages with this technique are that it is very hard to find an expert for the specific project and also that it can be easily biased.

Top-down Estimation: Top-down estimation takes historic data from earlier projects which are similar, as a basis for estimating cost. It is used in the early phase of the project when the availability of data is limited. This is one of the least expensive methods.

For eg: Cost estimation for making an online platform for a company. For this, the cost estimator can use the data generated while making the online platform for another company.

The disadvantage of this technique is that the results obtained are not reliable and accurate compared to others.

Parametric Estimation: Parametric estimation utilizes statistical modeling and historical data of the key drivers to develop cost estimation. It is a fast and also cheap method. It is a more accurate technique compared to Top-down and Expert judgement methods.

The disadvantage of this technique is that its accuracy lies in the correctness of the data used.

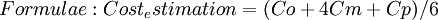

3-Point Estimation: 3-Point estimation is derived from PERT (Program Evaluation and Review Technique). This technique uses 3 estimates to define the final cost;

Most likely cost (Cm):- the estimated cost if everything is executed as planned.

Pessimistic cost (Cp):- the estimated cost in the worst case scenario, when nothing goes according to the plan and the cost is very high compared to the budget.

Optimistic cost (Co):- the estimated cost in the best case scenario, when everything works much better than the actual plan. In this case, the cost is very less than the budget.

This technique is used to reduce the uncertainty and manage the risk.

Disadvantages with this method are, instead of one, there are three estimates to be done. It needs more work and more time. And there are chances that everything can go wrong.

Bottom-up Estimation: Bottom-up estimation takes the estimates from individual work collections and then combines them to give a final estimate. It is one of the most accurate methods of estimation since it focuses on the cost from a very deep perspective. In this process, the project is fragmented down to smaller activities and more detailed. The more the activities are detailed, the more accurate will be the results. This is the best technique among all other cost estimation methods.

The only disadvantage which this method is that it takes more time than any others which might result in spending more money. Also, it can be difficult to use this method for complex projects.

Reserve Analysis: Reserve analysis takes uncertainty into account and determines how much contingency reserves should be assigned to the project. This amount is accounted for uncertainty cost. It can be a fixed value, or a percentage of the cost estimated or can be calculated separately. This is a form of buffer cost.

Cost of Quality (CoQ): This includes the amount spent during the project to avoid failure that might happen and also the money spent before and after the project is done, due to the failures. It is a methodology that helps the organization or business to estimate the extent to which their resources are utilized. This also determines the potential savings that can be gained by implementing process improvement steps.

Vendor Bid Analysis: This is the last technique. Vendor bid analysis is used to calculate the cost of the project by comparing the bids quoted by the vendors. This method is used when the product is provided by the vendor or the service is outsourced.

A disadvantage with this method is that it relies completely on the capability and knowledge of the vendor.

Limitations

Cost estimation has a number of strengths which we have learned in the previous parts. But it also has a few weaknesses and limitations.

- Flexible areas of calculation, efficiency and cost control When there are so many models to estimate cost, with different features and different ways of providing data, it is very difficult to choose the right model for the right estimation.

- Subjective: It is highly subject as in most of the cases the results depend on the knowledge and capabilities of the managers or experts or the vendors.

- Variable factors: Even if the manager has chosen the right method of estimating still there are some external factors that affect the results the of the cost, like change in prices of products, market fluctuation, etc.