Cost control with statistic tools

(→Cost Variance) |

(→Indices) |

||

| Line 47: | Line 47: | ||

===Indices=== | ===Indices=== | ||

| − | ====Schedule Variance==== | + | ====Schedule Variance</ref><ref name="PMI_EV"></ref>==== |

The Schedule Variance (SV) determines whether a project is ahead of or behind schedule. It is calculated by subtracting the Planned Value (PV) from the Earned Value (EV). A positive value indicates a favorable condition and a negative value indicates an unfavorable condition. | The Schedule Variance (SV) determines whether a project is ahead of or behind schedule. It is calculated by subtracting the Planned Value (PV) from the Earned Value (EV). A positive value indicates a favorable condition and a negative value indicates an unfavorable condition. | ||

| Line 65: | Line 65: | ||

where PV, known also as the Budgeted Cost of Work Scheduled (BCWS), is planned to be used during the project. | where PV, known also as the Budgeted Cost of Work Scheduled (BCWS), is planned to be used during the project. | ||

| − | ====Cost Variance==== | + | ====Cost Variance</ref><ref name="PMI_EV"></ref>==== |

A project’s Cost Variance (CV) shows whether a project is under or over budget. This | A project’s Cost Variance (CV) shows whether a project is under or over budget. This | ||

| Line 76: | Line 76: | ||

CV%=CV/EV | CV%=CV/EV | ||

| − | |||

====Cost Performance Index (CPI)<ref name="2013a"></ref>==== | ====Cost Performance Index (CPI)<ref name="2013a"></ref>==== | ||

Revision as of 07:31, 18 February 2021

Contents |

Basic Concept

Cost control is one of the major parts in the cost management in Project management. Cost control is the process of monitoring project status to update project costs and managing changes to the cost baseline. The main benefit of this process is that the cost baseline is maintained throughout the project. The appropriateness of this process is that the cost baseline is maintained throughout the project. [1]

Under the conditions of a market economy, the pursuit of profit maximization and improving economic efficiency are the main goals of enterprises. Controlling project costs is an important way for companies to reduce costs and increase profits. Controlling project costs is an important guarantee for enhancing the competitiveness of enterprises. Therefore, it is necessary to strengthen project cost management, continuously reduce costs, improve enterprise competitiveness, and increase economic benefits.

The major component of the Project cost control includes:[1]

- Influencing the factors that create changes to the authorized cost baseline;

- Ensuring that all change requests are acted on in a timely manner;

- Managing the actual changes when and as they occur;

- Ensuring that cost expenditures do not exceed the authorized funding by period, by WBS component, by activity, and in total for the project;

- Monitoring cost performance to isolate and understand variances from the approved cost baseline;

- Monitoring work performance against funds expended;

- Preventing unapproved changes from being included in the reported cost or resource usage;

- Informing appropriate stakeholders of all approved changes and associated cost; and

- Bringing expected cost overruns within acceptable limits.

Cost control is vitally important in all kind of projects, especially significant in construction projects. If construction companies want to gain a competitive advantage in the fierce market competition, they must effectively control the production costs of construction projects. The reason is that during the entire project life cycle, people pay attention to the cost control work of the construction enterprise, which can effectively avoid unnecessary waste on the construction site. Conversely, as an important work content of construction enterprises, project cost management and control of construction enterprises can also reflect the overall management and control capabilities of enterprises to a certain extent. The effect of cost control is ideal, which means that the company's overall control ability is good. Therefore, improving the project cost control of construction enterprises is of great significance to improving the overall management and control level of construction enterprises.

Any construction company hopes to obtain more economic benefits through construction projects to promote the development of the company's business strategy. Company has to strengthen the project cost control of construction companies, make cost planning in the preparatory work of the project, do a good job of cost control during project implementation, analyze and summarize the experience of cost control after the project is completed, and continuously improve the level of project cost control of construction companies. It can guarantee the benefits of the project to the greatest extent, and effectively reduce the construction cost to the minimum through cost control measures, help construction companies accumulate more capital, and achieve the purpose of enhancing the competitiveness of construction companies in the same industry.

Cost Control Input[1]

The input of the cost control includes following parts:

- Project management plan, which includes cost management plan, cost baseline and performance measurement baseline. The cost management plan indicates how the project cost will be managed and controlled. The cost baseline is applied as the comparison with actual results to determine if a change, corrective action, or preventive action is necessary. Similarly, performance measurement baseline is compared to actual results to determine if a change, corrective action, or preventive action is necessary.

- Project documents: Lessons learned earlier in the project can be applied to later phases in the project to improve cost control.

- Project funding requirements: The project funding requirements include projected expenditures and anticipated liabilities.

- Work performance data: Work performance data contains data on project status such as which costs have been authorized, incurred, invoiced, and paid

- Organizational process assets: The organizational process assets that can influence the Control Costs process include: Existing formal and informal cost control-related policies, procedures, and guidelines; Cost control tools; and Monitoring and reporting methods to be used.

Earned Value Method [1] [2]

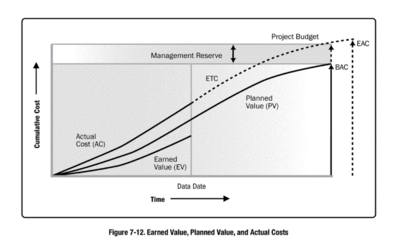

The data analysis is always involved in the cost control and one common method is Earn value analysis. Earned value analysis compares the performance measurement baseline to the actual schedule and cost performance. EVM integrates the scope baseline with the cost baseline and schedule baseline to form the performance measurement baseline. EVM develops and monitors three key dimensions for each work package and control account:[1][2]

- Planned value. Planned value (PV) is the authorized budget assigned to scheduled work. It is the authorized budget planned for the work to be accomplished for an activity or work breakdown structure (WBS) component, not including management reserve. This budget is allocated by phase over the life of the project, but at a given point in time, planned value defines the physical work that should have been accomplished. The total of the fines the physical work that should have been accomplished. The total of the PV is sometimes referred to as the performance measurement baseline (PMB). The total planned value for the project is also known as budget at completion (BAC).[1]

- Earned value. Earned value (EV) is a measure of work performed expressed in terms of the budget authorized for that work. It is the budget associated with the authorized work that has been completed. The EV being measured needs to be related to the PMB, and the EV measured cannot be greater than the authorized PV budget for a component. The EV is often used to calculate the percent complete of a project. Progress measurement criteria should be established for each WBS component to measure work in progress. Project managers monitor EV, both incrementally to determine current status and cumulatively to determine the long-term performance trends.[1]

- Actual cost. Actual cost (AC) is the realized cost incurred for the work performed on an activity during a specific time period. It is the total cost incurred in accomplishing the work that the EV measured. The AC needs to correspond in definition to what was budgeted in the PV and measured in the EV (e.g., direct hours only, direct costs only, or all costs including indirect costs). The AC will have no upper limit; whatever is spent to achieve the EV will be measured.[1]

Application

Indices

Schedule Variance</ref>[2]

The Schedule Variance (SV) determines whether a project is ahead of or behind schedule. It is calculated by subtracting the Planned Value (PV) from the Earned Value (EV). A positive value indicates a favorable condition and a negative value indicates an unfavorable condition.

SV=EV-PV

The Schedule Variance can be expressed as a percentage by dividing the Schedule Variance (SV) by the Planned Value (PV):

SV%=SV/PV

Schedule Performance Index(SPI)[3]

SPI is a conformance measure of actual progress to schedule. SPI is measured as the ratio of EV to Planned Value (PV), that is

SPI=EV/PV

where PV, known also as the Budgeted Cost of Work Scheduled (BCWS), is planned to be used during the project.

Cost Variance</ref>[2]

A project’s Cost Variance (CV) shows whether a project is under or over budget. This measure is determined by subtracting the Actual Cost (AC) from the Earned Value (EV).

CV=EV-AC

This number can be expressed as a percentage by dividing the Cost Variance (CV) by the Earned Value (EV):

CV%=CV/EV

Cost Performance Index (CPI)[3]

CPI is a measure of budgetary conformance of actual cost of work performed, and is the most useful index indicating the cumulative cost efficiency of a project. CPI is the ratio of EV to Actual Cost (AC), that is

CPI=EV/AC

where AC, known also as Actual Cost of Work Performed (ACWP), is an indication of the resources that have been used to achieve the actual work performed.

Statistical Process Control

Statistical Process Control (SPC) is the application of statistical methods to monitor a process for the purpose of ensuring that it produces conforming product or service.[3] SPC is a widely used technique for quality control. The most popular technique in SPC is a control chart that can be used to monitor process stability, to detect any assignable variations, or to forecast process movements. Measuring the process capability has received significant attention in the last two decades, within the framework of the SPC techniques, especially in the univariate domain.[4]

Statistical process control is a preventive method, emphasizing the participation of all staff, emphasizing the entire process, using control charts to analyze the stability of the process, and early warning of abnormal factors in the process.

Traditional earned value management is essentially a static analysis process. Judging the status of the project based on the size of the current observations, ignoring the inherent characteristics of the project itself, and lacking an examination of the stability of the project process. Due to the process factors of the project itself, the mean value of the whole process often shifts. This kind of shift may be caused by random reasons or special reasons. Earned value dynamic analysis is to measure CPI and SPI through SPC using control charts, analyze the stability of the project process, and identify the reasons for the deterioration of the project.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 Project Management: A guide to the Project Management Body of Knowledge (PMBOK guide) 6th Edition (2017)

- ↑ 2.0 2.1 2.2 2.3 Project Management Institute(PMI). (2005) "Practice Standard for Earned Value Management", [URL:https://blog.alevi.ru/wp-content/uploads/2015/08/Earned-Value-Management.pdf] Retrieved on 29 December 2017

- ↑ 3.0 3.1 3.2 Aliverdi, R., Moslemi Naeni, L., & Salehipour, A. (2013). Monitoring project duration and cost in a construction project by applying statistical quality control charts. International Journal of Project Management, 31(3), 411–423. https://doi.org/10.1016/j.ijproman.2012.08.005

- ↑ Hadian, H., & Rahimifard, A. (2019). Multivariate statistical control chart and process capability indices for simultaneous monitoring of project duration and cost. Computers and Industrial Engineering, 130(March), 788–797. https://doi.org/10.1016/j.cie.2019.03.021

Annotated Bibliography

- Project Management: A guide to the Project Management Body of Knowledge (PMBOK guide) 6th Edition (2017)

- Project Management Institute(PMI). (2005) "Practice Standard for Earned Value Management"

- Aliverdi, R., Moslemi Naeni, L., & Salehipour, A. (2013). Monitoring project duration and cost in a construction project by applying statistical quality control charts. International Journal of Project Management, 31(3), 411–423. https://doi.org/10.1016/j.ijproman.2012.08.005

- Hadian, H., & Rahimifard, A. (2019). Multivariate statistical control chart and process capability indices for simultaneous monitoring of project duration and cost. Computers and Industrial Engineering, 130(March), 788–797. https://doi.org/10.1016/j.cie.2019.03.021