Quality Gates in Project Management

(→Performance standards) |

(→Quality Gate Process) |

||

| Line 78: | Line 78: | ||

=== Quality Gate Process === | === Quality Gate Process === | ||

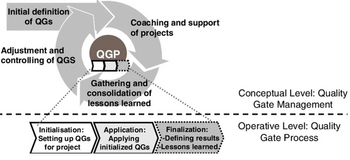

Operating quality gates is an iterative management and an ongoing process. According to Salger et alii <ref name="Salger"> ''Salger, Frank & Bennicke, Marcel & Engels, Gregor & Lewerentz, Claus. (2008). Comprehensive Architecture Evaluation and Management in Large Software-Systems. 5281. 205-219. 10.1007/978-3-540-87879-7_13</ref> it can be grouped into the conceptual and operative level and is described in the Quality Gate Process (QGP). [[File:QGP.png| right|thumb|350px|Figure 2: Quality gate processes <ref name = "Salger"/>]] The figure suggests iterative application of the processes. | Operating quality gates is an iterative management and an ongoing process. According to Salger et alii <ref name="Salger"> ''Salger, Frank & Bennicke, Marcel & Engels, Gregor & Lewerentz, Claus. (2008). Comprehensive Architecture Evaluation and Management in Large Software-Systems. 5281. 205-219. 10.1007/978-3-540-87879-7_13</ref> it can be grouped into the conceptual and operative level and is described in the Quality Gate Process (QGP). [[File:QGP.png| right|thumb|350px|Figure 2: Quality gate processes <ref name = "Salger"/>]] The figure suggests iterative application of the processes. | ||

| − | |||

'''Conceptual level:''' | '''Conceptual level:''' | ||

On the conceptual level quality gate management takes place. First, the initial definition of quality gates and its criteria are required. Further, coaching and support of the project in the three aspects (cost, time and quality) takes place. Afterwards the criteria defined for the quality gates is gathered and consolidated and results in the lessons learned. In this stage a gate is ready for the pass or fail assessment. Last but not least adjustment and controlling of the quality gates takes place when assessing the criteria and deciding to go or not go into the next project phase. | On the conceptual level quality gate management takes place. First, the initial definition of quality gates and its criteria are required. Further, coaching and support of the project in the three aspects (cost, time and quality) takes place. Afterwards the criteria defined for the quality gates is gathered and consolidated and results in the lessons learned. In this stage a gate is ready for the pass or fail assessment. Last but not least adjustment and controlling of the quality gates takes place when assessing the criteria and deciding to go or not go into the next project phase. | ||

| − | |||

'''Operative level:''' | '''Operative level:''' | ||

The operative level describes the operations executed by the project manager along the project’s process. First is the initialisation where quality gates are set up for the project. Next is their active application of the initialized gates. The project manager is responsible for the active execution on the project’s deliverables. Last is the finalization where results are defined and lead to lessons learned. | The operative level describes the operations executed by the project manager along the project’s process. First is the initialisation where quality gates are set up for the project. Next is their active application of the initialized gates. The project manager is responsible for the active execution on the project’s deliverables. Last is the finalization where results are defined and lead to lessons learned. | ||

| − | |||

=== The 4 Tenets – The Setup Advisory for Project Managers === | === The 4 Tenets – The Setup Advisory for Project Managers === | ||

Revision as of 21:16, 21 February 2021

Contents |

Abstract

Projects are temporary and unique endeavors and require active management of their integration, scope, schedule, cost, quality, resources, and communication according to the Project Management Institute. [1]

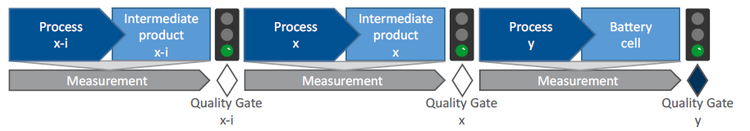

One tool to control project management is the Stage Gate approach that divides projects into stages with gates and tracks their progress and success. In the 1990s a modification to focus on especially schedule, cost, and quality was established known as Quality Gates. A quality gate represents a checkpoint of predefined criteria set by the project manager to evaluate the current progress of a project. Hereby a focus lies on the three aspects of time and cost, both resource-related and quality (2). After assessing the specified benchmarks and standards, an evaluation of passing or failing the gate is made.

This article sets the quality gate model into the picture with other phase gate models and points out its differences, benefits, and limitations. More weight lies on the quality criteria and its control in project management and its lifecycles. Besides, how four main tenets set, assess, and complete gates together with intermediate milestones. [2] The article also explains the required steps a project manager needs to take in order to introduce quality gates for projects. A proposal of applying the quality gates by segmenting projects into the three stages of front-end, middle, and back-end gates for different project stages [3][4] is suggested with a detailed successive explanation. Finally, the concern of resource-intensity in quality gate processes is discussed whereby more focus on scoping and lean management for projects is recommended. Also, the development from sequential towards iterative quality control is elaborated along with expanding the application from product-only towards service-oriented sectors.

Abb. Quality Gate Process: QGP

Big idea

Text

5 Ws + 1H of Quality Gates

Who? Project Manager, Process Manager, Project Owner

What? Designing, embedding and checking quality criteria

When? Whole lifecycle – from initiation to closing

Where? Developments and processes, e.g. in new product development (NPD), manufacturing, IT software, finance, M&A

Why? Gain control over quality development, status and state of the art

How? Define and assess quality criteria, milestones and gates

Example of quality gates from practice:

Quality Gates, Stage Gate and Phase Gate models

Quality gates are a comparable form of the stage-gate model and also other phase gate models. It is suggested to separate projects into the four different categories of:

1. Planning

2. Design

3. Development

4. Deployment

Also in the stage gate model projects are separated into phases because the outcome is often unknown and controlling can therefore take place after each phase. Setting gates after each phase, which must be passed before continuing to the next, allows control. Further, it enables early identification of potential risks and provides increased visibility.

According to PMI a project has the dimensions of integration, scope, schedule, cost, quality, resources, and communication and Cooper’s Stage Gate model intends to include all aspects in its model. Contrary, the Quality Gate model focuses specifically on the factors of time (schedule), cost and quality – all three of them are essential for a project’s quality outcome. In this way, it differs to the Stage Gate model. The gates are set timely independent and flexible, but in a sequential order – whereas its criteria to pass a gate are defined very specifically.

Quality gates as a project management tool have been established because practitioners felt that in our rapidly changing world and disrupting time there is less focus on quality due to a downside in order to increase time-to-market. Scholars therefore point out that “Quality gates […] are supposed to increase the confidence stakeholders have in a release” [5].

Quality Gates and Quality Management & Control

Quality management consists of four basic pillars, its planning, assurance, control and improvement [6]. In project management, quality is of relevance in order to achieve the intended outcome and function of the endeavour. Already Cooper pointed out in his stage gate model in 1990 [7] that many newly launched products lack quality inspection processes. To achieve control over quality management in projects several tools evolved over the years and gained publicity.

Total quality management

"A management approach of an organisation centred on quality, based on the participation of all its members and aiming at long term success through customer satisfaction and benefits to all members of the organisation and society." [8]

European Foundation for Quality Management (EFQM) model

“The EFQM Model is a globally-recognised management framework which allows organisations to achieve success by measuring where they are on the path towards transformation, helping them understand the gaps and possible solutions available, and empowering them to progress and significantly improve their organisation’s performance.” It helps to define purpose, create culture, forge strong leaders, transform organisation, foster agile practices, address unique organisational challenges, forecast the future. [9]

(Lean) six sigma

The combination of the principles from lean and six sigma. Lean management focuses on continuous process improvement based on small, incremental changes with the overall goal to improve efficiency and quality. Together with six sigma it aims for improving processes and performance by narrowing resources and variations down to the minimum required.

Compared to these quality management tools quality gates focus on specific quality aspects at specific times, the gates, compared to non-stop iterative quality management perspectives. It sets and later assesses quality criteria and intervenes when errors occur in the project’s development. Thus, it becomes obvious that quality gates are rather different to prevalent and common quality management and control techniques. Using these argumentations project managers can justify its presence and application for endeavours where quality-heaviness is key.

Application

- Set the project scope - Set quality requirements

Quality Gate Process

Operating quality gates is an iterative management and an ongoing process. According to Salger et alii [10] it can be grouped into the conceptual and operative level and is described in the Quality Gate Process (QGP).

Conceptual level:

On the conceptual level quality gate management takes place. First, the initial definition of quality gates and its criteria are required. Further, coaching and support of the project in the three aspects (cost, time and quality) takes place. Afterwards the criteria defined for the quality gates is gathered and consolidated and results in the lessons learned. In this stage a gate is ready for the pass or fail assessment. Last but not least adjustment and controlling of the quality gates takes place when assessing the criteria and deciding to go or not go into the next project phase.

Operative level:

The operative level describes the operations executed by the project manager along the project’s process. First is the initialisation where quality gates are set up for the project. Next is their active application of the initialized gates. The project manager is responsible for the active execution on the project’s deliverables. Last is the finalization where results are defined and lead to lessons learned.

The 4 Tenets – The Setup Advisory for Project Managers

To successfully implement and assess quality gates four essential tenets are of relevance.

Performance standards

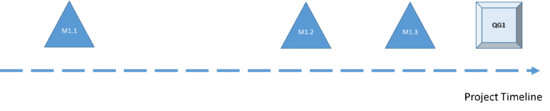

To reach the quality gates, milestones have to be completed successfully otherwise a quality gate will very likely not be passed at the gate deadline. Milestones inhabit single criteria relevant for quality gates.

An assessment of the project’s status is evaluated based on the actual performance of intermediate milestones. Each criteria must be met successfully by each party. When a quality gate is not met, the project cannot proceed to its successive milestones and gates. A project evaluation is required based on the governance decisions:

- Go

Criteria is met and a quality gate is passed

- No-Go

Criteria is not fulfilled and a quality gate is failed

- Defer

Criteria is deferred to another responsible or gate

- Modify

Criteria is changed and can implement quality gate assessment pass or fail

Application of Quality Gates

Front-end Gates

- Invest, Commit, Design

Middle Gates

- Implement, Integrate, Validate

Back-end Gates

- Try, Introduce, Release

Limitations

Resource Requirements

- QGP is time and labour intense, project manager is required - Project needs to be of a certain size, otherwise it is not worthwhile - Maybe mention lean possibilities; adopt the amount of quality gates to the project scope

Sequentiality/Waterfall Model

- Often it is claimed and critized that phase gate models such as the QGP are due to their native sequential developments harming (product and/or service) development - Show that QGP can also be iterative processes

Non-product Realization Projects

- Critics say QGP are mainly used in physical product realization projects because of quality nature - Give examples of software, service, IT applications

Annotated Bibliography

(1) PMI Guide - Project Management

(2) PMI Symposium – Quality Control with Quality Gates

(3) Quality Gates Concept in Battery Production

References

- ↑ Project Management Institute, Inc.. (2017). Guide to the Project Management Body of Knowledge (PMBOK® Guide) (6th Edition). Project Management Institute, Inc. (PMI). Retrieved from https://app.knovel.com/hotlink/toc/id:kpGPMBKP02/guide-project-management/guide-project-management

- ↑ Achieving Total Project Quality Control Using The Quality Gate Method, Presented at the 1993 PMI Annual Symposium;, John M. Aaron, Cesare P. Bratta, D. Paul Smith

- ↑ Achieving Total Project Quality Control Using The Quality Gate Method, Presented at the 1993 PMI Annual Symposium;, John M. Aaron, Cesare P. Bratta, D. Paul Smith

- ↑ 4.0 4.1 Quality Management for Battery Production: A Quality Gate Concept Joscha Schnell, Gunther Reinhart Procedia CIRP 57 ( 2016 ) 568 – 573 49th CIRP Conference on Manufacturing Systems (CIRP-CMS 2016) Institute for Machine Tools and Industrial Management (iwb), Technical University of Munich (TUM)

- ↑ G. Schermann, J. Cito, P. Leitner and H. C. Gall, "Towards quality gates in continuous delivery and deployment," 2016 IEEE 24th International Conference on Program Comprehension (ICPC), Austin, TX, USA, 2016, pp. 1-4, doi: 10.1109/ICPC.2016.7503737

- ↑ Rose, Kenneth H. (July 2005). Project Quality Management: Why, What and How. Fort Lauderdale, Florida: J. Ross Publishing. p. 41. ISBN 978-1-932159-48-6

- ↑ Cooper, Robert G. (1986). Winning at new products. Addison-Wesley. ISBN 0201136651

- ↑ Pfeifer, Tilo (2002), Quality Management: Strategies, Methods, Techniques, Munich, Germany: Carl Hanser Verlag, p. 5, ISBN 9783446220034

- ↑ https://www.efqm.org/index.php/efqm-model/

- ↑ 10.0 10.1 Salger, Frank & Bennicke, Marcel & Engels, Gregor & Lewerentz, Claus. (2008). Comprehensive Architecture Evaluation and Management in Large Software-Systems. 5281. 205-219. 10.1007/978-3-540-87879-7_13

- - ex1