Lean in construction industry

(→References) |

(→Abstract) |

||

| Line 10: | Line 10: | ||

The core idea of LEAN is to maximize value and eliminate or minimize waste, regardless of which area it is applied to, even if it is a single process. This makes the LEAN thinking one of the best in creating value for the customers and their needs. With other words LEAN is an efficient management technique which strives to meet the customer in eye level and offer them an instant customized product or service | The core idea of LEAN is to maximize value and eliminate or minimize waste, regardless of which area it is applied to, even if it is a single process. This makes the LEAN thinking one of the best in creating value for the customers and their needs. With other words LEAN is an efficient management technique which strives to meet the customer in eye level and offer them an instant customized product or service | ||

| − | LEAN thinking operates overall with 5 key principles that aims to optimize and develop projects: (1) Value, (2) Value stream, (3) flow, (4) pull, (5) perfection | + | LEAN thinking operates overall with 5 key principles that aims to optimize and develop projects: (1) Value, (2) Value stream, (3) flow, (4) pull, (5) perfection <ref name="3a" /> |

==History== | ==History== | ||

Revision as of 21:53, 21 February 2021

Contents |

Abstract

The construction industry is one of the largest and most markable industries worldwide. As most of the professions, the construction industry has some chronic problems such as low productivity, poor safety, inferior working conditions, and insufficient quality [1]

These problems are serious diseases which should be managed. They cannot be eliminated completely but can be reduced and handled by specific tools and engagements. Due to the large extend of this industry, there are many aspects which can be optimized and developed. One of the most important challenges in this industry is the wastage. To maintain a sustainable and justified project, it is necessary to apply some approaches seeking towards a decreased amount of wastage. One of the approaches and groundbreaking tools is LEAN.

LEAN construction is a phenomenon inspired by LEAN Management. The arise of LEAN in the construction industry emerged first time in the 1990’s in the West, since there were seen huge success and optimization in the manufacturing industry[2]

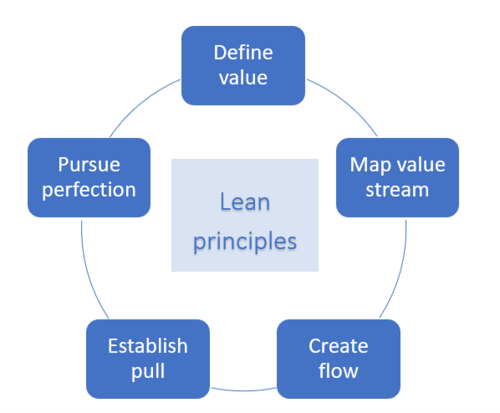

The core idea of LEAN is to maximize value and eliminate or minimize waste, regardless of which area it is applied to, even if it is a single process. This makes the LEAN thinking one of the best in creating value for the customers and their needs. With other words LEAN is an efficient management technique which strives to meet the customer in eye level and offer them an instant customized product or service LEAN thinking operates overall with 5 key principles that aims to optimize and develop projects: (1) Value, (2) Value stream, (3) flow, (4) pull, (5) perfection [3]

History

The arise and development of Lean found place in the Japanese car company Toyota. This new phenomenon revolutionized the manufacturing industry, particularly the production of automobiles. The trend was first introduced by John Krafick in the 1988, while the definition of Lean was first time given in the 1996 by James Womack and Daniel Jones.

Toyota production system had a completely different process than the mass production system of Henry Ford automobiles. Toyota production line was based on two concepts; “Jidoka” and “Just-in-time” . The first mentioned is translated to “automation with a human touch” which means, that each time a problem emerge, the whole production line will stop, to prevent defect objects. The second is based on a production system, that only produce what is needed. The arise of Lean left an imprint on the manufacturing industry, since Lean had a potential of reducing wastes and optimize processes. Lean construction was developed in the 1990’s by Glenn Ballard and Greg Howell. The development of Lean was created to improve the management of construction projects. This was done because there was seen common and similar challenges in the manufacturing sector as construction industry.

Big Idea

Utilization

Utilization is an act which is very worshipped within LEAN thinking. Every property whether it is resources, products or knowledge should be utilized to decrease waste and maximize the profit of the project or company. Even employee’s skills, talents and capabilities should be utilized and distributed where it is most beneficial. Experiences shows that low utilization often leads to undesirable events. The most common of them is delays.

One of the major activities to utilize resources is planning and coordinating . Especially the activities that are done by multiple groups of people need to be scheduled, to create synergy in the project environment. Coordinating is then necessary to ensure utilization of the resources yet maintain a realistic and feasible approach.

Utilization is as on-going process which is meant to start already in the early stages of the design phase, until the project is constructed and delivered. Every phase of the project needs to apply specific tools and methods to optimize it. Each project is unique and therefore there is not a list of things to do and do not. Depending on the project, the client and the circumstances different tools can be applied. However, Lean is based on a terminology which strives toward an increased efficiency of any area.

Lean principles

The lean principles are the core idea and foundation of Lean thinking. It is these 5 principles which can change a work environment and improve the efficiency of it according to Womack and Jones. These principles are with other words the recipe of a healthy and functioning process. Each of the principle covers a specific area of optimization.

1. Define value

Value is a wide concept. In order to understand customer’s needs it is important to have a clear understanding of what value is. A wide range of customers are unconscious of what they actually need or have difficulties in expressing themselves. Value is not only the product or service they are interested in, but also the procedure of it. This can for instance be preferences in relation to properties, commerce agreements, deliveries etc. By using some suitable techniques, one is able to identify and understand the customer’s needs.

2. Map the value stream

As the header indicate, this principle encourages the operator to map the customer’s value stream. This require a in depth analysis of the activities that may contribute to the value stream. Conversely there are activities that is considered as waste, since they do not add value to the customers desired product or service. Not all waste activities can be eliminated, since there is activities that are necessary for the main product. Identifying the unwanted activities are beneficial for both parties. By eliminating those activities you are ensuring the customer a product that meets their demand, and at the same time making sure you are not spending time and money on unnecessary processes.

3. Create flow

Flow means the synergy associated with the production/compiling of the desired product. This step is crucial for the end product. The purpose of this principle is to ensure a smooth flow between the remaining processes and steps in the system. This step is especially needed after eliminating some of the unrewarded activities, mentioned earlier. According to Womack and Jones some of the useable strategies in this step is to reconfigure the production, delegating the workload to more than one unit, invest in the employees, by training them in being multi-skilled and adaptive.

4. Establish pull

Pull is an effect which aims for attracting the customer. This principle is mostly related to inventory and satisfying the customer. The idea of this principle is to reduce space for inventory and materials used during the process. Establishing pull is achieved by producing the required products in the wanted quantity and delivered when needed. This principle is closely related to Just-in-time and has overall the same purpose.

5. Pursue perfection

The fifth and last principle strives toward a continuously process of improvement in all the performed actions. This principle is supplementing the first 4 principles, by extending Lean thinking to become a habit and incorporated part of the organization or work environment. By always pursuing perfection, you will pay more attention for waste elements and processes, and thus eliminate those unwanted activities.

7 wastes

The seven wastes was originally covering the occurrence of wastage in the manufacturing industry. However, parallels are easily drawn regarding waste in the construction industry. These 7 wastes have either a directly or indirectly impact on the environment. The more waste the less sustainable the project is.

The seven wastes are also called TIMWOOD, where each letter represent a recognized aspect of waste. Each waste is described shortly below:

1. Transportation

Transportation is a costly service. The cost is not only related to fuel supply and the drivers fee, but also for the management and environmental expenses. A construction site needs to be supplied with materials and machinery, which make transportation indispensable. However, transportation does not add value to the product itself, therefore it is essential to reduce the costs of it and seek towards a more effective approach.

2. Inventory

Exceed inventory become a waste when it is unprocessed. This applies also for the objects and processes spent on exceed inventory, such as storage, capital, transportation etc. Therefore, Lean cultivates a production that corresponds to the customers need and down grades mass production.

3. Motion

Motion is like transportation an unavoidable process within construction industry. However, motions become a wastage when the site is not utilized, and there is a constantly need for moving items back and forwards. This is unfortunately a common problem, where construction workers and craftsmen spent markable amount of time on grabbing items from one place to another on the site.

4. Waiting

Waiting time can occur due to multiple reasons. Often in the construction site it occurs when one work step finish before another, which then interferes the whole workflow. This is also a very recognized problem, which in many cases leads to a postponement of the time schedule.

5. Over-Processing

Over-processing is a direct waste of time and energy. It is a very unliked actions, since it doesn’t add value to the processed nor being relevant for the final product. Furthermore, it means that the processor will end up not utilizing his/her time.

6. Overproduction

Depending on the product, overproduction can be a directly waste. When producing more than wanted, there will end up being capital tied up in unwanted products. The capital covers among other things raw materials, energy, workload, and time. Besides, being a waste for the producer and customer, it can have a high negative impact on the environment.

7. Defects

Defects are products that deviates from the standard agreed on. They should be replaced with a product consisting of the right properties and qualities. However, it shouldn’t be forgotten that defects also were processed, and resources were used on producing them. Defects have a impact on the environment since they often get thrown away without being used.

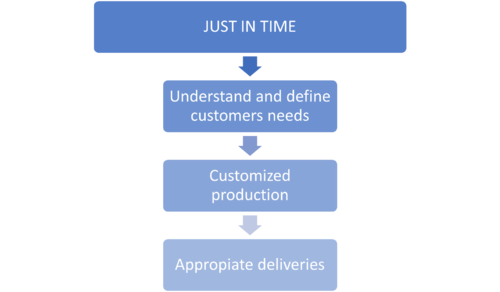

Just in time

Lean worship the customer. This means that the customer is “pulled” toward the operator through some specific tools and behaviors. One of the tools is called Just-in-time. This tool is especially used within traders or suppliers of specific products. By using just-in-time application the operator will optimize a couple of aspects. The most important of it, is to meet customer’s needs and secondary to prepare and customize the delivery in the appropriate time.

Furthermore, there are some additional advantages of using just-in-time in the construction site. Many sites struggles with limited spaces due to the narrow work areas. This problem can be solved by agreeing with the subcontractors on using just-in-time deliveries. The materials are meant to be used as soon as they get delivered on site, and not stored for a longer period. This means the need of storage facilities for materials will be reduced significantly.

However, there may be some external factors that can affect the deliveries. These may be considered when ordering the materials. If the deliveries arrive later than needed, it will cause a loss in the value stream. Here occurs a reverse effect of Lean, since some of the waste sources such as waiting increase and flow decrease.

Application

Implementing Lean

The formula of how to implement Lean in the construction industry is different whether it is consulting companies or executive construction companies. Although these two parties are dependent on each other’s within the industry and working closely on projects, the activities and processes are very different The experience and literature shows there are a larger susceptibility within on-site activities and processes compared to consulting companies.

There is some strategies to be used when applying Lean to the organization. First, the vision of the organization must be defined if it is not already done. Next, it is important to find out what the goals and milestones are for the organization. Especially the milestones with short-term results should be made and focused on.

Since it is the people who performs the activities it is important to grant employee empowerment . The fostering of Lean thinking within the organization is ideal, to plant the principles and utilization ideology in the minds of the employees. Additionally, is planning a key activity, and has a beneficial effect for any process, whether it is regarding project or human resources. Here it is important to be committed and engaged in the transition phase of the organization where Lean are implemented.

Although some advices and strategies are given, one must not forget that each organization, project, and process is unique and therefor needs a customized and particular Lean approaches and tools.

As Howell and Ballard emphasized the importance of self-evaluating which methods, tools, and activities to be applied for the current project. “Implementing lean thinking will lead to change in almost every aspect of project and company management. No one step-by-step guide can be offered because change at the mental model level is a developmental process. Each principle driven action will reveal new opportunities hidden because people simply could not think in ways that made the change possible. Thinking causes action, action causes deep learning, and learning causes new thinking.”

An American study tested the usage of Lean in relation to the overall project process, where the result showed a markable reduction of the time, up to 30 %. The implementation that was done in the case study was the following; developments of facilitation of innovation in design and assembly, improvement in site work flow by proper definition of production units, and visualization of process Another successful implementation of Lean in the design phase revealed that the further stages of the project was significantly optimized in terms of project duration and utilization of the available resources.

Limitations

Since there is no actual procedure to follow when implementing Lean, it can be considered as a limitation. Some of the wastes described earlier may not be recognized in the consultancy companies. They are more applicable by the executer and subcontractors in connection with on-site activities. The consultant companies needs some other tools and concepts that target how to reduce wastes in the consulting activities and processes.

The same goes for Just-in-time. This is also a tool that wont give any rewarding effect in the consulting companies. In contrast it will give a negative effect if talking about delivering information and tender material. The earlier the information are given to the responsible parties the better and more optimized process.

References

- ↑ Luis Alarcón "Lean Construction" Published january 01, 1997. Accessed February 16, 2021.[1]

- ↑ Ong, Joy and Sui Pheng, Low "Waste Reduction in Precast Construction" chapter 4 Lean Construction Implementation Published 2020. Accessed February 18, 2021.[2]

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs named3a