Kanban: a project management framework

Guilleroigp (Talk | contribs) (→Definition) |

Guilleroigp (Talk | contribs) |

||

| Line 1: | Line 1: | ||

| + | |||

| + | Kanban: a project management framework | ||

| + | |||

Over the last decades important new approaches have appeared in operations planning and control of production systems.<ref name="Uno">R.J. Boucherie, X. Chao and M. Miyazawa, "Arrival first queueing networks with applications in kanban production systems", 2001</ref> Kanban (看板, meaning ‘cards’ in Japanese) is a visual system whose first purpose was to gain control in processes and make their workflow more manageable. The efficiency of daily activities within industrial processes represent a challenge for every production company. In fact, this tool is not only applicable to production processes, but also to every project taking place in almost every business function (operations, marketing, recruitment, business expansion...). | Over the last decades important new approaches have appeared in operations planning and control of production systems.<ref name="Uno">R.J. Boucherie, X. Chao and M. Miyazawa, "Arrival first queueing networks with applications in kanban production systems", 2001</ref> Kanban (看板, meaning ‘cards’ in Japanese) is a visual system whose first purpose was to gain control in processes and make their workflow more manageable. The efficiency of daily activities within industrial processes represent a challenge for every production company. In fact, this tool is not only applicable to production processes, but also to every project taking place in almost every business function (operations, marketing, recruitment, business expansion...). | ||

The target of Kanban is achieved by the implementation of certain activities or practices that, if well implemented, will gradually help improving the workflow. Its improvement implies not only a reduction of lead time and a better organization of the activities, but also a reduction of waste, a more value-added approach for the customer and a better predictability for future scenarios. These benefits are crucial in today's market, characterized for experimenting changes and competitiveness in a fast-paced environment. | The target of Kanban is achieved by the implementation of certain activities or practices that, if well implemented, will gradually help improving the workflow. Its improvement implies not only a reduction of lead time and a better organization of the activities, but also a reduction of waste, a more value-added approach for the customer and a better predictability for future scenarios. These benefits are crucial in today's market, characterized for experimenting changes and competitiveness in a fast-paced environment. | ||

| − | + | =Big idea= | |

| − | ==The | + | ==== Origin of Kanban ==== |

| + | Kanban agile methodology has its origin in the Toyota’s Production System. It was first implemented in the fifties by Taichii Ohno, an industrial engineer working for the company <ref name="Dos"> Ohno, T.: Toyota Production System. Beyond Large-Scale Production. Productivity Press, Portland (1988) </ref>. After the second world war, the Japanese automotive industry was stucked in the context of a strong United States within this industry. Due to this situation, Kiichiro Toyoda, the CEO of Toyota set out to put an end to this situation focusing on the efficiency of Japanese market. The target was to match the efficiency of the American market and represented a great challenge, as the US market was ten times more efficient than the Japanese. The company centered its efforts towards innovation and the efficiency of its industrial processes. During this change of direction, [[Wikipedia:Taiichi Ohno| Taiichi Ohno''']], an industrial engineer working for the company, developed a new work methodology inspired by the ´´grocery store model´´ that he observed in the American supermarkets chain [[Wikipedia:Piggly Wiggly| Piggly Wiggly''']]. The concept of this model is that the stores stock need to be maintained in a sufficient level so that the customer’s demand is met looking for keeping the lowest stock level possible. Thus, Taiichi Ohno decided to introduce a visual demand tracking system in the factory consisting of cards that were attached to finished goods, and once a good was sold, the card returned to the production line <ref name="Tres"> Kanban tool, History of Kanban, last visited 27th of February 2020, https://kanbantool.com/es/guia-kanban/historia-de-kanban </ref>. This way, the production lines worked once a stablished number of cards returned the production line, and the idea of it was to: | ||

| + | *Minimize inventory levels and production cycle time. | ||

| + | *Increase the speed of information exchange. | ||

| + | *Improve productivity. | ||

| + | |||

| + | In the beginning, this methodology was originated with the creation of the just-in-time production system. However, this methodology has evolved during the years so that nowadays Kanban has been modified and adapted project management and software development processes. | ||

| + | |||

| + | ==== The Kanban method==== | ||

| + | |||

| + | In the last decades, Kanban has been applied to other industries, as its principles have been proved to bring positive outcomes out of the automotive sector, specially, in the software development projects in the IT industry. | ||

| + | |||

| + | The main target of the Kanban methodology is to make workflow more visual. Through the design of a Kanban board, processes can be more clear and a more efficient scenario could be achieved by the reduction of the work in progress (WIP). Thanks to a better and more transparent visualization of the processes, problems could be better identified, highlighting which points of the process are not working efficiently. | ||

| + | |||

| + | The Kanban basic elements to run the methodology are a board divided into columns and cards. Every column of the board represents a stage in the timeline of the project. On the other hand, cards represent a work item. | ||

| + | |||

| + | The representation of the methodology could be either physical or digital. The physical representation is done by drawing the board on paper or in a blackboard and using stickers as cards. The more advanced options are digital, such as software systems that include a Kanban virtual solution. | ||

| + | |||

| + | ==== Kanban Principles==== | ||

| + | |||

| + | The Kanban methodology could be summarized into different principles which represent the basic practices to go through in the development of the Kanban tool to make its implementation successful: | ||

| + | |||

| + | #'''Visualize the current workflow:''' it is crucial to make the processes visual and accessible so that everyone involved in the project development understands how the work is performed. | ||

| + | #'''Measurement of current situation:''' not only is it important to understand the workflow, but also to understand how successful the performance is currently being. | ||

| + | #'''Service level agreement (SLA) and policies:''' to guarantee a good service level resultant from a project, minimum standards are stablished. | ||

| + | #'''Limit Work in progress (WIP):''' by reducing the workers’ workload, they can better focus in the work to be done without feeling overloaded. This way, lead times could be reduced, and the workflow can result in a more continuous one. | ||

| + | #'''New performance measurement:''' in order to measure how well the Kanban system works, an update in the team’s progress is done through a diagram to show if the lead time is being met, the WIP …. EXPLICAR MEJOR. This is done using Cumulative Flow Diagrams (CFD). | ||

| + | #'''Optimize:''' maintaining a continuous improvement mindset is important to keep a team’s common effort towards this practice. Data has a key role in this process. | ||

| + | |||

| + | <ref name="Cuatro"> Andrew T. Pham and David K. Pham., “Business-Driven IT-Wide Agile (Scrum) and Kanban (Lean) Implementation”, 2013</ref>. | ||

| + | |||

| + | ==== Kanban Board==== | ||

| + | |||

| + | A Kanban board allows displaying the entire process in one unique system, offering a more manageable workflow. This board is usually divided into three columns which represent the stage of every task: “To do”, “In progress” and “Complete”. However, depending on the project that is being done, the name of the columns can be adapted. An example of how a Kanban board looks like is represented in the Figure X. | ||

| + | |||

| + | When there are new work tasks to do in the project, cards representing these new tasks are added in the “To do” column, in the left hand side of the board. During the progress of the tasks, cards start moving from the left to the right hand side of the board until the “Done” stage, which determines the completion of a task. There are usually some rules settled by the project manager to determine when a task is completed, and every team member participating in the project is aware of them, so the system can be updated regularly. | ||

| + | |||

| + | ==== Kanban Cards==== | ||

| + | |||

| + | |||

| + | =Kanban: an Agile methodology= | ||

| + | |||

| + | == Agile in project management == | ||

| − | = | + | AÑADIR FOTO BIEN |

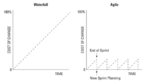

| + | [[File:Pm_agile.png|thumb|right|150px|'''Figure 1: Waterfall vs. Agile''' <ref name=seven>Mark C. Layton, Steven J. Ostermiller, Dean J. Kynaston, “Agile project management for dummies”, 2020 <ref/>]] | ||

[[File:scrumframework1.jpg|thumb|right|400px|Scrum framework overview.<ref name=seven>Straughan, G. (2017) [https://www.developmentthatpays.com/scrumban "Development That Pays: Scrumban"], Software Project Management </ref>]] | [[File:scrumframework1.jpg|thumb|right|400px|Scrum framework overview.<ref name=seven>Straughan, G. (2017) [https://www.developmentthatpays.com/scrumban "Development That Pays: Scrumban"], Software Project Management </ref>]] | ||

| − | + | Over the last decades, project management has been changing from a more linear approach to an environment in which agile is dominating. This linear approach was followed through the waterfall methodology, where deadlines and objectives of every project are based on fixed estimations or assumptions, so companies drive their projects missing the changing environment that surrounds it. This waterfall methodology that companies use are proven to be inefficient in changing environments, as projects are supposed to follow clear steps which are not designed to be re-thinked or re-designed, so it can be very costly and time. <ref name="Dos">Andrew Stellman, Jennifer Greene, "Learn Agile: Understanding Scrum, XP, Lean and Kanban", 2015</ref> | |

| − | + | Agile, on the other hand, consists of an approach that help teams to achieve more efficient and effective practices in the which require flexibility in uncertain environments and where changes are fast. This could be done by the application of a set of different agile methodologies. These methodologies have an iterative approach, which means that they involve an evolutionary development, so that during its application steps are repeated in a cyclic way. <ref name="Dos">Andrew Stellman, Jennifer Greene, "Learn Agile: Understanding Scrum, XP, Lean and Kanban", 2015</ref> The main differences regarding the opportunity to make a change and its costs between both the traditional approach and the disruptive agile one are represented in Figure 1. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Regarding project management, the application of agile can be addressed to different areas, such as software development, processes improvement or project management in general. It was first used in the IT industry, where companies found in agile a great solution to solve the traditional problems found in software development processes. There is a mindset around the concept of agile consisting of a good flow of information between the stakeholders involved in order to bring more value to the customer while making progressive and meaningful steps. <ref name="Tres">https://www.atlassian.com/agile </ref> | |

| − | ==== | + | ====What is scrum?==== |

| − | + | ||

| − | + | ====Scrum vs. Kanban==== | |

| − | + | ||

| − | ==== | + | =Application= |

| − | + | https://books.google.dk/books?id=dXDLlAgETvMC&pg=PA22&dq=kanban+agile&hl=es&sa=X&ved=2ahUKEwjbw_uGl832AhWXS_EDHekVDQgQ6AF6BAgDEAI#v=onepage&q=kanban%20agile&f=false | |

| − | # | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | |||

(To do) Brief introduction of the general idea of how the methodology is applied/developed. | (To do) Brief introduction of the general idea of how the methodology is applied/developed. | ||

| − | |||

| − | |||

====Kanban cards==== | ====Kanban cards==== | ||

(To do) Define different kinds of Kanban cards, the information that has to be contained and why is it important. Introduce a picture of how a card looks like). | (To do) Define different kinds of Kanban cards, the information that has to be contained and why is it important. Introduce a picture of how a card looks like). | ||

| Line 49: | Line 81: | ||

*Project speed | *Project speed | ||

*Other metrics | *Other metrics | ||

| − | |||

| − | |||

| − | |||

== Advantages== | == Advantages== | ||

Revision as of 01:00, 18 March 2022

Kanban: a project management framework

Over the last decades important new approaches have appeared in operations planning and control of production systems.[1] Kanban (看板, meaning ‘cards’ in Japanese) is a visual system whose first purpose was to gain control in processes and make their workflow more manageable. The efficiency of daily activities within industrial processes represent a challenge for every production company. In fact, this tool is not only applicable to production processes, but also to every project taking place in almost every business function (operations, marketing, recruitment, business expansion...).

The target of Kanban is achieved by the implementation of certain activities or practices that, if well implemented, will gradually help improving the workflow. Its improvement implies not only a reduction of lead time and a better organization of the activities, but also a reduction of waste, a more value-added approach for the customer and a better predictability for future scenarios. These benefits are crucial in today's market, characterized for experimenting changes and competitiveness in a fast-paced environment.

Contents |

Big idea

Origin of Kanban

Kanban agile methodology has its origin in the Toyota’s Production System. It was first implemented in the fifties by Taichii Ohno, an industrial engineer working for the company [2]. After the second world war, the Japanese automotive industry was stucked in the context of a strong United States within this industry. Due to this situation, Kiichiro Toyoda, the CEO of Toyota set out to put an end to this situation focusing on the efficiency of Japanese market. The target was to match the efficiency of the American market and represented a great challenge, as the US market was ten times more efficient than the Japanese. The company centered its efforts towards innovation and the efficiency of its industrial processes. During this change of direction, Taiichi Ohno, an industrial engineer working for the company, developed a new work methodology inspired by the ´´grocery store model´´ that he observed in the American supermarkets chain Piggly Wiggly. The concept of this model is that the stores stock need to be maintained in a sufficient level so that the customer’s demand is met looking for keeping the lowest stock level possible. Thus, Taiichi Ohno decided to introduce a visual demand tracking system in the factory consisting of cards that were attached to finished goods, and once a good was sold, the card returned to the production line [3]. This way, the production lines worked once a stablished number of cards returned the production line, and the idea of it was to:

- Minimize inventory levels and production cycle time.

- Increase the speed of information exchange.

- Improve productivity.

In the beginning, this methodology was originated with the creation of the just-in-time production system. However, this methodology has evolved during the years so that nowadays Kanban has been modified and adapted project management and software development processes.

The Kanban method

In the last decades, Kanban has been applied to other industries, as its principles have been proved to bring positive outcomes out of the automotive sector, specially, in the software development projects in the IT industry.

The main target of the Kanban methodology is to make workflow more visual. Through the design of a Kanban board, processes can be more clear and a more efficient scenario could be achieved by the reduction of the work in progress (WIP). Thanks to a better and more transparent visualization of the processes, problems could be better identified, highlighting which points of the process are not working efficiently.

The Kanban basic elements to run the methodology are a board divided into columns and cards. Every column of the board represents a stage in the timeline of the project. On the other hand, cards represent a work item.

The representation of the methodology could be either physical or digital. The physical representation is done by drawing the board on paper or in a blackboard and using stickers as cards. The more advanced options are digital, such as software systems that include a Kanban virtual solution.

Kanban Principles

The Kanban methodology could be summarized into different principles which represent the basic practices to go through in the development of the Kanban tool to make its implementation successful:

- Visualize the current workflow: it is crucial to make the processes visual and accessible so that everyone involved in the project development understands how the work is performed.

- Measurement of current situation: not only is it important to understand the workflow, but also to understand how successful the performance is currently being.

- Service level agreement (SLA) and policies: to guarantee a good service level resultant from a project, minimum standards are stablished.

- Limit Work in progress (WIP): by reducing the workers’ workload, they can better focus in the work to be done without feeling overloaded. This way, lead times could be reduced, and the workflow can result in a more continuous one.

- New performance measurement: in order to measure how well the Kanban system works, an update in the team’s progress is done through a diagram to show if the lead time is being met, the WIP …. EXPLICAR MEJOR. This is done using Cumulative Flow Diagrams (CFD).

- Optimize: maintaining a continuous improvement mindset is important to keep a team’s common effort towards this practice. Data has a key role in this process.

[4].

Kanban Board

A Kanban board allows displaying the entire process in one unique system, offering a more manageable workflow. This board is usually divided into three columns which represent the stage of every task: “To do”, “In progress” and “Complete”. However, depending on the project that is being done, the name of the columns can be adapted. An example of how a Kanban board looks like is represented in the Figure X.

When there are new work tasks to do in the project, cards representing these new tasks are added in the “To do” column, in the left hand side of the board. During the progress of the tasks, cards start moving from the left to the right hand side of the board until the “Done” stage, which determines the completion of a task. There are usually some rules settled by the project manager to determine when a task is completed, and every team member participating in the project is aware of them, so the system can be updated regularly.

Kanban Cards

Kanban: an Agile methodology

Agile in project management

AÑADIR FOTO BIEN

Over the last decades, project management has been changing from a more linear approach to an environment in which agile is dominating. This linear approach was followed through the waterfall methodology, where deadlines and objectives of every project are based on fixed estimations or assumptions, so companies drive their projects missing the changing environment that surrounds it. This waterfall methodology that companies use are proven to be inefficient in changing environments, as projects are supposed to follow clear steps which are not designed to be re-thinked or re-designed, so it can be very costly and time. [2]

Agile, on the other hand, consists of an approach that help teams to achieve more efficient and effective practices in the which require flexibility in uncertain environments and where changes are fast. This could be done by the application of a set of different agile methodologies. These methodologies have an iterative approach, which means that they involve an evolutionary development, so that during its application steps are repeated in a cyclic way. [2] The main differences regarding the opportunity to make a change and its costs between both the traditional approach and the disruptive agile one are represented in Figure 1.

Regarding project management, the application of agile can be addressed to different areas, such as software development, processes improvement or project management in general. It was first used in the IT industry, where companies found in agile a great solution to solve the traditional problems found in software development processes. There is a mindset around the concept of agile consisting of a good flow of information between the stakeholders involved in order to bring more value to the customer while making progressive and meaningful steps. [3]

What is scrum?

Scrum vs. Kanban

Application

(To do) Brief introduction of the general idea of how the methodology is applied/developed.

Kanban cards

(To do) Define different kinds of Kanban cards, the information that has to be contained and why is it important. Introduce a picture of how a card looks like).

Kanban and Project Management

(To further develop) There are some metrics that could be monitored in order to measure the performance of a project:

- Lead and cycle time

- Project speed

- Other metrics

Advantages

(To do) Description of the main advantages of applying this tool, based on the theory and from a project management point of view.

Shortcomings

(To do) Description of the main limitations of applying this tool, based on the theory and from a project management point of view.

References

- ↑ R.J. Boucherie, X. Chao and M. Miyazawa, "Arrival first queueing networks with applications in kanban production systems", 2001

- ↑ 2.0 2.1 2.2 Ohno, T.: Toyota Production System. Beyond Large-Scale Production. Productivity Press, Portland (1988)

- ↑ 3.0 3.1 Kanban tool, History of Kanban, last visited 27th of February 2020, https://kanbantool.com/es/guia-kanban/historia-de-kanban

- ↑ Andrew T. Pham and David K. Pham., “Business-Driven IT-Wide Agile (Scrum) and Kanban (Lean) Implementation”, 2013