Lean Project Management (LPM)

| Line 125: | Line 125: | ||

*[http://apppm.man.dtu.dk/index.php/Agile_Project_Management ''Agile Project Management''] | *[http://apppm.man.dtu.dk/index.php/Agile_Project_Management ''Agile Project Management''] | ||

| − | |||

=References= | =References= | ||

<references /> | <references /> | ||

Revision as of 11:54, 20 March 2022

Developed by Rani Abdul Karim Omar

Lean project management takes into account the lean principles and applies them to project management.

Lean is a philosophy that has the aim to systematically elements waste and add more value. Lean covers a set of tools and techniques that allows companies in almost all areas to streamline their process.

Projects are subject to three main constraints which are scoop, budget, and time.

Lean project management's central objective is to make projects run more efficiently and to deliver better outcomes.[1] Another reason why it is essential is that it provides a lot of other advantages such as the following:

- Increased innovation: Enhance the inventiveness of the project

- Eliminating waste: All non-value-adding process is seen as waste and having a lean approach to the project management aims to minimize all physical waste and non-value-adding times between the steps.

- Improves customer service: With Lean Project management, you always have the customer in focus and deliver what the customer needs.

- Increased quality: By minimizing waste any defects are getting discovered early with the help of quality checks or control.

No matter if the project objectives serve internal or external stakeholders, can Lean project management simplify the different steps in the project and establish a better efficient project group.[1]

Contents |

History

Before the 19th Century: the end-to-end approach

Before the 19th Century, the idea of a production process wasn't introduced to the modern world. By looking from a process point of view all the needed tasks got completed by the end-to-end approach. Business activities like developing, constructing, selling, and distributing the products were completed sequentially for each sale - It can be compared to a small startup business of today. As an example, if a person wanted to buy a shoe, he had to go to the local shoemaker and get a custom-made pair. the shoemaker will thereafter measure the foot, discussing with the customer what material the shoe has to be, and after discussing a price and date to which the shoe has to be picked up. [3].

1900-1927: Henry Ford and the introduction to Flow production.

Following the industrial revolution, and with the development of machines and assembly lines, was Henry Ford the first person to successfully design a complete production process with the philosophy of "flow". Henry Ford was the owner of Ford Motors Company, and with the invention of the Model T car, sold from 1903 to 1927, was it one of the first cars that the average consumer actually could afford.[4]

Henry Ford took the ideas of process standardization, management planning, and mass production and implemented them into the manufacturing of the Model T. By starting with the raw materials in a moving assembly line and ending with a Finished assembled Model T car, the overall cost and production time were reduced drastically. This concept by breaking down the process into sequence steps, using standardized machines, and assembling the components was the building locks that later resulted in lean manufacturing and a break from the early shop practices.[3].

1930-1980: Taiichi Ohno and the Toyota Production System

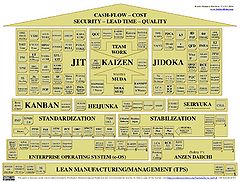

In Japan, following World War II and two atomic bombs were dropped on the cities of Nagasaki and Hiroshima, the country was in an economic crisis with shortages and inflation. [4] The founder of Toyota Motor Corporation, Kiichiro Toyoda, and the Japanese industrial engineer Taiichi Ohno started to implement a Pull strategy in their production lines,[6] where the manufacturing of a car model first started when the customer made the purchase. This idea was in contrast to the Push strategy, where the manufacturer will produce as many products as possible and expect the customer will purchase them later on. This resulted that the cost associated with storage being minimized. Toyoda observed the circumstances of Ford Motor Company in the 1930s, and it appeared to them that with a series of small innovations and creations would it be possible to provide a more efficient and continuity process flow. By reinventing Henry Ford's initial ideas they created the Toyota Production System (TPS). [7]

This system became a philosophy that shifted the focus from particular machines and their utilization to the value-creating flow and eliminating waste.[6] They develop a set of tools that allowed them to minimize the non-value-adding activities, manufacture the actual volume needed, implement self-monitoring devices to provide the right quality, lining the machines up in process sequence. With the help of all these initiatives and more, it resulted in a shorter lead time for the customers, low cost, high variety, and high quality.[7]

1990-Pressent: Lean Manufacturing

In 1990 did Toyota become the best-selling car manufacturer in the United State of America,[6] and had one of the largest market shares in the world. This success has made a huge demand for knowledge about the Toyota way, as it was also called at the time. There is afterward been writing a lot of books and papers investigating the matter, and also in the early 1990’s the word Lean was introduced as another name for TPS.As the Lean Philosophy continues to spread across the world, companies are adapting the tools and principles and developing their own version of Lean. An example could be one of the biggest companies in Denmark Novo Nordisk with their version they call CLEAN (standing for Current LEAN) or the danish Meditech company Radiometer Medical with their version Danaher Business Systems (DBS). Today is Lean concepts also used in other areas than manufacturing, Lean thinking is used in logistics and distribution, services, retail, healthcare, construction, and also in Project Management.[4]

How to use Lean Project management?

When using Lean project management, the focus is on minimizing as much waste as possible and creating a corporate culture that adapts these principles to be more effective. Lean Project management has five main principles.

1. Identify value

The first principle is about identifying the value of the product, or service. This step can be completed by recognizing the project's stakeholders or the with help of stakeholder management. When a project is formed can the key deliverables be for internal stakeholders, or it can be for external stakeholders. An example of an internal stakeholder could be a district director that has a stake in the project's key deliverables and is a shareholder of the project. on the other hand, an external stakeholder could be a customer that purchases the product or service. The external stakeholder is not directly involved with a company but is impacted by the activities, like the quality of the product. When the stakeholder is identified, and the knowledge of who has a stake in the project key deliveries is comprehended, their can better be decide how to make it more valuable.[1]

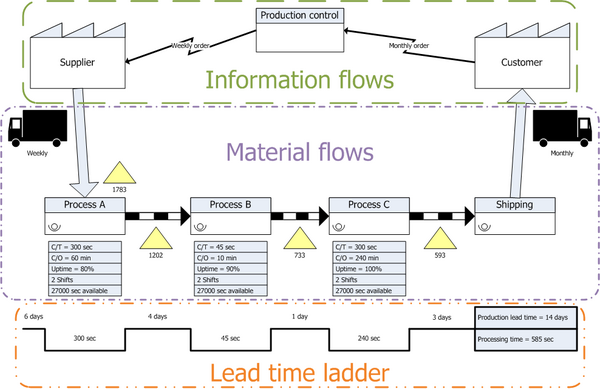

2. Map the value flow

The second principle in Lean project management is about developing a Value stream mapping or VSM. Basically, a VSM is a tool, originally used by Toyota, to create an overview of all the value-adding, and non-value-adding processes. VSM is a visual tool that applies diagrams of the current flow and of the ideal flow from the begging of the project to its fulfillment. The figure below shows how a VSM is made. [8]

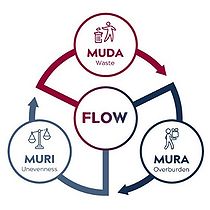

As mentored before, Lean is about eliminating waste in the process flow, and by comparing the two VSM, the one of the current flow and one of the ideal flow, the waste can be recognized for each project management step to increase the efficiency. When Toyota created the VSM, they grouped waste into three types they called Muda, Mura, and Muri. [6]

MUDA - Uselessness

Muda is the Japanese word for uselessness and is often the one with the most focus. For each process step under the manufacturing of a product, we create some value the customer is willing to buy. When talking about Muda, there are two types of Muda, normally called Muda Type 1 and Muda type 2. [8] [10].

Muda Type 1: All activities that do not directly add value to the product but are necessary for the customer. An example of this could be quality control or safety testing of a product.

Muda Type 2: All activities that do not add value to the product and are not necessary for the customer. In general, all Muda Type 2 shall be eliminated.

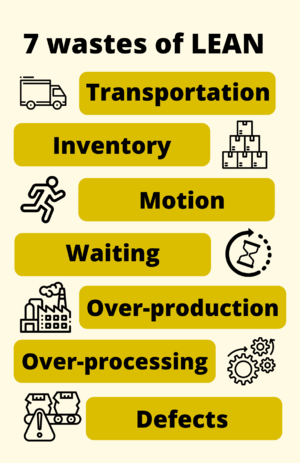

Muda Type 2 is divided into seven categories of waste:

1. Transport: This type of waste involves the cost created with unneeded external movement by individuals or machines of a product or materials.

2. Inventory: This type of waste is really visible with a VSM. This type of waste involves inefficient inventory management, for the raw material, work-in-order, and finished goods, all resulting in unnecessary costs for storing, transportation, etc.

3. Motion: Just like the first type of waste, transportation, motion is about the unneeded cost of internal motion by people or machines. This can take the form of repetitious processes and data flow.

4. Waiting: This type of waste involves the cost of unmet deadlines, or if a machine is not up and running. An example of this can be airplanes, the value an airplane creates comes from flying passengers from one location to another, for each minute the plane is not flying is seen as waiting-waste.

5. Overproduction: This category is the cost involved with additional storage, wasted materials, and worthless inventory coming from overproduction.

6. Over-processing: This type of waste is about unnecessary costs coming from unneeded upgrading for a product or a tool that the customers didn’t ask for.

7. Defects: The last type of waste is about defective products. This can result in expensive repairs and a loss of materials. In general, the early the defective product is identified the lower is the cost. If the defective product is observed under the raw material is better than when a customer complains about the defective product. That is why it can be important to have efficient quality control throughout the production flow.

MURA - Unevenness

Mura is the Japanese word for unevenness and is the reason for the presence of any of the mentored wastes. So Mura drives and result in Muda. An example of this could be, in an assembly line, with multiple workstations a product needs to go through before being finished assembled. If one of the workstations operate faster than the following workstation it will result in inventory, overproduction, waiting, etc. That is why targeting mura is important, the workstations need to be evened out. [8] [10].

MURI - Overburden

The last grouped type of waste is called Muri and it means overburden or beyond one’s power. Muri can, just like Muda, result from Mura, and also in some cases come from an extreme reduction of Muda. Muri exists when the capacity of machines or employe are used for more than 100% to finish a job or in an unsustainable manner. Muri over a timespan can lead to absenteeism of employees, bad conditions, and breakdowns of machines. [8] [10].

This principle is the most essential action in Lean Project Management because it can visualize all the mentioned waste and identify weaknesses in the project life cycle.

3. Create flow

The third principle is about creating flow, and this can be done by rethinking the project management strategy to be more efficient. Also with the help of the first two principles, can the identified waste be eliminated to create more flow. By grouping the different phases in the project and using project milestones as checkpoints or as a "quality control" to make sure no new waste is conceived as the project moves forward.

An example of this could be a mishandled backlog and delayed timeline due to a bottleneck in team associate scheduling. With the help of a VSM, we visualize where the weaknesses are and establish better communication across the team members. Once the waste has been identified and removed, the project team can continue the work to prevent future inefficiencies. [13]

4. Establish pull

The 4th principle in Lean Project Management is about establishing a pull flow. This draws inspiration in Toyota's “just-in-time” concept, where they will first start the manufacturing of a product when the purchase has been made and in that way help factories meet the exact customer demands, as mentioned before.

Establishing pull can assist teams in different initiatives because it upholds work moving effortlessly through the project life cycle. Initiatives that produce customer-facing products will benefit from this system if they use pull signals to work backward. That way, their team only produces inventory when customers need it. [6]

5. Continuous improvement

The 5th and final principle of Lean project management are that it is not a one-time thing. Lean is about always striving for the perfect while acknowledging that the perfect is an impossibility. It is therefore always room for improvement. Toyota made continuous improvement with the help of the tool Kaizen, which is a Japanese word for continuous improvement of working practices, personal efficiency, etc. In practice, a Kaizen event will regularly be held where the use of different Lean tools will be used to help analyze the different workflows for waste. As this is an iterative process, the company culture should slowly adapt to Lean and eliminate waste in all places where one can find it. [13]

Limitations

When talking about Lean project management and Lean in general there are some limitations to the methodology. These limitations can be minimized if taken into account. The main limitations are listed as follows:[14].

Time pressure: Lean project management demands time to the planning aspect of the project. The current workflow needs to be analyzed with the project group's activities, and this can include gathering data over some time, as well as alignment with group members. A part of Lean is about daily management, there will be a lot of time used on meetings to encourage the team and to discuss the assignments that have been finished, what is next up to be completed, and if any challenges are occurring.

Missing Strategy: With the use of Lean tools, a commend challenge is that some organizations lose the overview of the bigger picture. It is important to keep the focus on the actual objective. This can be overcome by creating a charter for each project, as well as a general mission statement.

The implementation of a new culture: By using Lean Project management, the first step is taking in having a more lean-oriented business culture. Lean is generally considered an intense way of operating that requires a lot of dedication from employees. The project team is expected to work independently without much direction, which can be challenging if the team is inexperienced. Lean can be overwhelming and is very results-oriented, which can cause stress for some employees. It is therefore important that communication is effective so that all employees can understand why lean is important and in that way adapt easier to a new way to operate. It can therefore be advantageous to invest in the training and education of employees to get them started properly.

A more vulnerable production: As mentioned before, Lean uses a 'pull' strategy, which means that the work is delivered as required. If using push the products will be manufactured, with an expectation that the customer will buy is. This can make production more worried about not delivering if there is a bottleneck or resources are low. It is therefore practical for a company to maintain a certain type of storage as a safety net. A risk-assessed analysis with an action plan can be beneficial, which can help with precise planning. There are many project management software that can help with these kinds of assignments in real-time.

See also

References

- ↑ 1.0 1.1 1.2 M. Ronald (2003). Building a Project-Driven Enterprise: How to Slash Waste and Boost Profits Through Lean Project Management Technology Perspectives; 1st edition, ISBN 9780966269710

- ↑ Wikipedia. Henry Ford Retrieved 02.03.2022

- ↑ 3.0 3.1 https://www.lean.org/explore-lean/a-brief-history-of-lean/, accessed: 21-02-2022

- ↑ 4.0 4.1 4.2 M. Niklas & Å. Pär (2013). DETTE ER LEAN Rheologica Publishing, ISBN 9789198039320

- ↑ Wikipedia. The house of Toyota Production System. Retrieved 20.03.2022

- ↑ 6.0 6.1 6.2 6.3 6.4 L. Jeffrey (2021). The Toyota Way, Second Edition: 14 Management Principles from the World's Greatest Manufacturer McGraw-Hill Education, ISBN 9781260468519

- ↑ 7.0 7.1 Leach, L. P. (2006). Lean Project Management: Eight Principles for Success. Combining Critical Chain Project Management [CCPM] and Lean tools to accelerate project results, BookSurge Publishing; 1st Edition , Boise, Idaho, ISBN 1419644068

- ↑ 8.0 8.1 8.2 8.3 J. Shook, & M. Rother, (1999). Learning to See. Value Stream Mapping to add value and Eliminate Muda, Charlies Chapters, ISBN 9780966784305

- ↑ Wikipedia. Value Stream Mapping. Retrieved 18.03.2022

- ↑ 10.0 10.1 10.2 https://theleanway.net/muda-mura-muri, accessed: 28-02-2022

- ↑ Wikipedia. 7 wastes of LEAN. Retrieved 17.03.2022

- ↑ Wikipedia. MUDA, MURA and MURI. Retrieved 11.09.2016

- ↑ 13.0 13.1 J. Womack, & D. Jones, (1996). Lean Thinking: Banish Waste and Create Wealth in Your Corporation, Simon & Schuster, ISBN 9780743249270

- ↑ https://backlog.com/blog/lean-management-pros-cons-everything/, accessed: 03-03-2022