The Kaizen Method in Project Management

(→PDCA) |

(→PDCA) |

||

| Line 39: | Line 39: | ||

*Provision of student services and support services | *Provision of student services and support services | ||

*Classroom instruction | *Classroom instruction | ||

| + | |||

*Plan | *Plan | ||

Revision as of 19:27, 22 March 2022

Contents |

Introduction

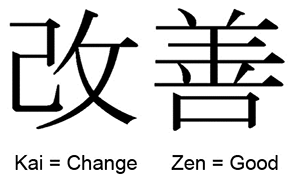

Kaizen (改善, かいぜん), the Sino-Japanese word or Continuous Improvement (CI) is a strategy where employees at all levels of a company work together proactively to achieve regular, incremental improvements to the manufacturing process. In a sense, it combines the collective talents within a company to create a powerful engine for improvement. It has a dual nature, as an action plan, where events are organized focusing on improving specific areas within a company, and as a philosophy, where all employees are actively engaged in suggesting and implementing improvements to the company. [1]

Kaizen is easy to understand, not hard to implement, and because of the broad concept behind the word: “change for the good,” there are many ways you can apply Kaizen in an organization. [2]

History

Kaizen has its origins during World War II. When the United States entered the war, a group of Americans led by W. Edwards Deming, an engineer and statistician, set out to convert car factories into tank factories, quickly and with minimal resources. To achieve their lofty goal, Deming and his colleagues asked the workers to find small ways to improve their processes and quickly found out that small changes led to significant, measurable, and innovative results. After World War II, Deming traveled to Japan to help with manufacturing, as Japan was trying to rebuild. The Japanese took to heart the Deming principles. Businessman and industrial engineer Taiichi Ohno was the first Japanese business figure to translate Deming quality control principles into incredible, world-leading results. He called it the Toyota Production System (TPS). TPS, also known as “just-in-time” manufacturing, a system for reducing waste and maximizing efficiencies through continuous improvement. Kaizen is also identified as a significant example of a Lean business strategy. Taiichi Ohno used Kaizen in the Toyota factory to improve the quality of the vehicles. Initially, in companies like Ford or GM, the cars were assembled and sold without proper quality controls in place. Once the customers drove the cars and found problems, they would come back to the company to fix the issues. Deming principles changed that process so that every part is checked in the assembly line; if any problem is found, the assembly is stopped, and the issue is fixed then and there. Sounds so obvious now, but it was innovative then, and it revolutionized car manufacturing. [3]

Kaizen Process

- Setting goals and providing any necessary background.

- Reviewing the current state and developing a plan for improvements.

- Implementing improvements.

- Reviewing and fixing what doesn’t work.

- Reporting results and determining any follow-up items.[4]

PDCA

The Plan-do-check-act cycle is a four-step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement. The PDCA cycle is considered a project planning tool. The PDCA Cycle should be used when:

- Starting a new improvement project

- Developing a new or improved design of a process, product, or service

- Defining a repetitive work process

- Planning data collection and analysis in order to verify and prioritize problems or root causes

- Implementing any change

- Working toward continuous improvement

As an example, The Pearl River, NY School District, a 2001 recipient of the Malcolm Baldrige National Quality Award, used the PDCA cycle as a model for defining most of their work processes, from the boardroom to the classroom. The PDCA model was the basic structure for the district’s:

- Overall strategic planning

- Needs analysis

- Curriculum design and delivery

- Staff goal-setting and evaluation

- Provision of student services and support services

- Classroom instruction

- Plan

The A+ Approach begins with a "plan" step, which the school district calls "analyze." In this step, students’ needs are analyzed by examining a range of data available in Pearl River’s electronic data "warehouse." The data reviewed includes everything from grades to performance on standardized tests. Data can be analyzed for individual students or stratified by grade, gender, or any other subgroup. Because PDCA does not specify how to analyze data, a separate data analysis process (Figure 3) is used here as well as in other processes throughout the organization.

Advantages

Some of the advantages of implementing Kaizen in an organization are:

- Utilization of Resources – Kaizen focuses on improving products through the utilization of existing resources (your people) to achieve incremental and continuous improvement. Kaizen is centered around making small changes instead of relying on massive changes or investments to gain improvements.

- Increased Efficiency – Central to Kaizen methodology is the importance of providing a well-planned work area, eliminating unnecessary waste such as movement or in operations, and imparting proper training for all employees.

- Employee Satisfaction – Kaizen is about creating an atmosphere of teamwork and change, where new ideas are encouraged. Team members are asked to examine the processes and make suggestions for improvement.[5]

Limitations

Despite the many benefits of kaizen, there are some limitations business managers need to be aware of before deciding to implement it. This is because implementing kaizen is tantamount to altering current management systems. As soon as kaizen is implemented in an organisation, it is very difficult to return to old management systems. Hence, kaizen might be easier to implement in businesses without already established management systems.

- One of the greatest kaizen disadvantages is that people are always reluctant to change. Therefore, when businesses want to implement kaizen, they have to put up with a certain resistance. Employees might not be ready to accept a different system from what they have been used to. On the other hand, management might be reluctant to implement kaizen because they feel it is expensive.

- In addition, when implementing kaizen, could be very difficult for some organisations to change their current approach to work. Hence, if a business is not prepared for change when implementing kaizen, it could lead to friction.

- Another kaizen disadvantage is the method of training. The kaizen methodology requires training staff and management to understand and adopt the kaizen philosophy. This might require altering the usual process of work.

- Employees might be excited at first to implement changes. However, their excitement could wear away when the changes become difficult to adapt to. As such, they may resort to old practices and stick to ‘business as usual’.[6]

References

- ↑ https://www.leanproduction.com/kaizen/#:~:text=Kaizen%20(Continuous%20Improvement)%20is%20a,a%20powerful%20engine%20for%20improvement.

- ↑ https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology

- ↑ https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology

- ↑ https://theleanway.net/what-is-continuous-improvement

- ↑ https://www.kartalegal.com/insight/what-is-kaizen-in-law-methodology

- ↑ https://draminu.com/kaizen-advantages-and-disadvantages/