Critical Chain

(→Theory of constraints) |

(→Theory of constraints) |

||

| Line 41: | Line 41: | ||

'''The five step approach of TOC''' | '''The five step approach of TOC''' | ||

| − | # | + | # Identify the system’s constraint(s) |

| − | # | + | # Decide how to exploit the system’s constraint(s) |

| − | # | + | # Subordinate everything else to the above decision |

| − | # | + | # Elevate the system’s constraint(s) |

| − | # | + | # Repeat |

The system’s constraint is the weakest link, e.g. a machine in a production line, only producing half the units of the other machines. If you strengthen the weakest link sufficiently it will not be the weakest link anymore and you will not reap any benefits by continuing to strengthen it. Therefore the five step approach is iterative which can be seen in step 5 forcing you to continuously identify and improve the system’s constraints. | The system’s constraint is the weakest link, e.g. a machine in a production line, only producing half the units of the other machines. If you strengthen the weakest link sufficiently it will not be the weakest link anymore and you will not reap any benefits by continuing to strengthen it. Therefore the five step approach is iterative which can be seen in step 5 forcing you to continuously identify and improve the system’s constraints. | ||

Revision as of 18:01, 19 February 2023

Category:Critical Chain. by Sigrid Thorgaard OBS I have not added all my references yet

Contents |

Abstract

Critical Chain Project Management(CCPM) was firstly introduced by Israeli physicist, Eliyahu M. Goldratt in his book “Critical Chain”. The development of CCPM was a response to poor time management in projects that the critical path method was not able to solve. This article will firstly explain recurring problems with resource-constrained project scheduling. To describe Critical Chain fully it will be compared to its precursor, Critical Path as well as the Theory of Constraints since CCPPM stands on the shoulders of this management philosophy. The elements that Critical Chain consists of and its application will be described and lastly the company criteria for implementation are listed and discussed as well as the method’s limitations.

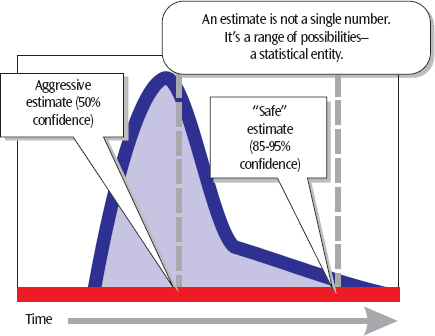

Time management in projects

Often rough estimates are made to produce a seemingly complete project schedule with task due dates and important milestones. Since there is high uncertainty in this planning stage in accordance with the rolling wave principle, a high safety margin is placed between project deliverables to reduce the risk of project delays. Other reasons for a high safety margin can be explained by project managers protecting their estimations from a potential cut by the board or steering group meaning they will state double the safety they actually need. In general time estimates are based on a pessimistic experience and often the larger the number of management involved, the higher the total safety estimation will be. Each level in the organization will simply add their own safety factor on top of the others.

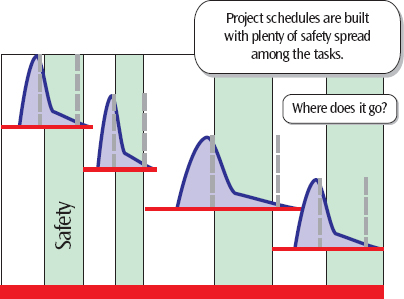

As figure 2 states “Where does it go”, what frustrates many Project Managers (PMs) is seeing these safety buffers become a waste of allocated resources. The reasons for this waste can be explained by two recurring issues in time management:

- People procrastinate and start on a task to finish the task just in time, also called "The student syndrome"

- Even if a worker finishes early they use all the time available, which can be explained by Parkinson's law. If one finishes early they will expand the scope and use more effort on the task than required.

Critical Chain acknowledges the need of safety margins in projects to reduce risks but safety margins will not prevent the project from being late due to the aforementioned problems. Furthermore, these safety margins are shared globally by the whole project meaning that the performance of the project in terms of time management is evaluated globally.

It also needs to be added that some workers will hide that they have finished the task early since reporting an early finish will invite pressure from management in the projects to come.. The early finishes can also make the worker become unpopular among colleagues since they have to deal with the preceding tasks earlier than originally planned.

These structures mean ultimately that early finished tasks are not passed down the project schedule while late finished tasks create a domino effect; either the project will be on time or running late. Another problem in regards to time management is bad multitasking. Bad multitasking means to use resources across multiple projects in a way that ultimately slows down all projects. Multitasking fails to complete tasks fast since the resource is split between multiple tasks and also due to the fact that there is a certain amount of communication time switching from one task to another.

Introducing Critical Chain

The purpose of CCPM is to be efficient in project management meaning delivering the project within the planned deadline. The big idea behind Critical Chain is to eliminate or reduce the aforementioned problems in the resource-constrained project scheduling through a different scheduling technique and management of buffers. It is a methodology that helps build the schedule with task durations that are too short to encourage multitasking, procrastinations or scope expansions of the task. In traditional scheduling, time buffers are an integral part of the task duration estimates. CCPM argues that the only important milestone is the final delivery date and therefore all tasks should not be forced to complete on time since individual tasks will vary in duration from the estimate. Therefore the PM should rather monitor the use-rate of the buffers instead of monitoring the delivery of specific milestones.

Theory of constraints

Critical Chain builds upon The Theory of Constraint (TOC) introduced in Goldratts book “the goal” from 1984. Theory of Constraint is a theory for production management but Goldratt links the same principles to CCPM in Critical Chain.

Theory of Constraints addresses the problems with the application of the Pareto Principle in dependent systems. In systems composed of independent tasks, it will be possible to reap more benefits than problems solved. However, for dependent tasks, a local optimization will not result in a global optimization. Eg. if a machine is optimized it will simply stack inventory leading to more inventory costs if the other machines depending on the optimized machine's output are still running at the same speed as before.

TOC distinguishes between the cost world and the throughput world.

- In the cost world mentality the performance of each step needs to be protected, meaning that all workers will locally optimize their own station.

- In the throughput world, the only thing that counts is the performance as a whole.

It can be stated that for the ‘throughput world’ the pareto principle is not applicable. It is possible to draw parallels from TOC to JIT, where the goal is to reduce lead time globally in the company. TOC will also not allow local optimization where too much inventory is accumulated between two machines or centers (as can be seen in step 3 of the five step approach)

The five step approach of TOC

- Identify the system’s constraint(s)

- Decide how to exploit the system’s constraint(s)

- Subordinate everything else to the above decision

- Elevate the system’s constraint(s)

- Repeat

The system’s constraint is the weakest link, e.g. a machine in a production line, only producing half the units of the other machines. If you strengthen the weakest link sufficiently it will not be the weakest link anymore and you will not reap any benefits by continuing to strengthen it. Therefore the five step approach is iterative which can be seen in step 5 forcing you to continuously identify and improve the system’s constraints.

The link in TOC to CCPM is that like in a production where safety is measured in inventory, safety is measured in projects as buffers. In projects using CCPM the equivalent to the system’s constraint or bottleneck is therefore the critical path.

Critical Path versus Critical Chain

Critical Chain is standing on the shoulders of Critical Path, which is the longest chain of task dependencies made in order to calculate the end-date and monitor the progress of the project. The critical chain is also the longest chain but other than interdependent tasks it takes resources into account.

Example Figure 3 shows an example of a project, where the critical path is EFGHM. If we were told that Activity C and G are to be performed by the same resource, they cannot be performed simultaneously as otherwise planned. Because activity G is on the critical path it should arguably be done before activity C. Even though EFGHM states a finishing time of 52 weeks, the start of activity C will consequently be delayed 18 weeks meaning that ABCDM becomes the longest path resulting in a finishing time of 66 weeks (10+6+10+18+14+8).

Following the Critical Chain which includes resource considerations (Figure 4), the project duration is estimated to 62 weeks (10+6+10+18+10+8) since tasks are arranged according to resource dependencies.

Critical Chain application

In order to apply Critical Chain the following steps need to be followed.

- Determine order of tasks and critical path: Identify the tasks needed to succeed with the project as well as their sequence. Determine critical path.

- Slice the duration of the tasks: Typically the PM will decide on half/half for simplicity but other slices are possible. Put the sliced task duration as a project buffer. The official end-date that is communicated to stakeholders now corresponds to the project buffer’s end date.

- Level resources: Identify resource constraints and arrange tasks according to resource dependencies. Determine critical chain.

- Monitor: During the project monitor the use of the use-rate of the buffer. The use-rate helps anticipate the risk of the project's delay and respond in time.

The different buffers

Buffers are owned by everyone and therefore a shared responsibility meaning that everyone must complete their task as quickly as possible to reduce the consumption of the buffers. The 'crashed' deadlines ensures that all resources will try to complete their task as quickly as possible with the safety of the buffers to ensure quality and a healthy work environment.

Some people divide the buffers in four categories: project buffers, feeding buffers, resource buffers and capacity buffers. The most well-known buffers are the project buffer and the feeding buffer:

- The project buffers: Placed between the last task and the official completion date ensuring the final date is not prolonged

- The feeding buffers: Placed at the end of non-critical chains preventing delays to the critical chain

Limitations

Quality CCPM does not deal with project quality and by implementing tight deadlines there is a risk of poor quality in the deliverables.

Slice of project tasks Often, all project tasks