Heathrow Terminal 5

| Line 14: | Line 14: | ||

In 1990 Sir John Egan became the CEO of BAA and would continue to work through 1999. He had previously worked for Jaguar, a company that seemed to be very close to shutting down, but he turned the trend and is largely credited for the success. Egan used his knowledge about Lean production from the automobile industry and attempted to apply it the construction of T5. Furthermore he recognized that projects are often unique and therefore approached as a ''"blank slate"''<ref name="Davies, Gann, Douglas"> Andrew Davies, David Gann,Tony Douglas"> ''Innovations in Megaprojects: Systems Integration At London Heathrow Terminal'', California Management Review, 2009</ref>, as BAA did prior to his arrival. In an effort to ameliorate this he wanted to create standardized parts of projects in an effort to apply Lean principles, that emphasized simplification and standardized tasks. | In 1990 Sir John Egan became the CEO of BAA and would continue to work through 1999. He had previously worked for Jaguar, a company that seemed to be very close to shutting down, but he turned the trend and is largely credited for the success. Egan used his knowledge about Lean production from the automobile industry and attempted to apply it the construction of T5. Furthermore he recognized that projects are often unique and therefore approached as a ''"blank slate"''<ref name="Davies, Gann, Douglas"> Andrew Davies, David Gann,Tony Douglas"> ''Innovations in Megaprojects: Systems Integration At London Heathrow Terminal'', California Management Review, 2009</ref>, as BAA did prior to his arrival. In an effort to ameliorate this he wanted to create standardized parts of projects in an effort to apply Lean principles, that emphasized simplification and standardized tasks. | ||

| − | Egan gathered a team to explore practices, principles, and technologies from different industries in an effort to see what would work in the T5 project. Later on he would establish an organization that worked independently from BAA in an effort to provide the freedom of choice needed to promote experimentation and innovation. Later on BAA would establish a Continuous Improvement Project Process (CIPP) in an effort to provide a set of standardized and repeatable time-sequenced tasks, milestones, and stage-gates to deliver cost-effective and profitable projects. The projects in question would have a budget between $4M-$8M. CIPP also looked into the design process by working with modular design, so that the construction processes would have similar construction processes, despite being vastly similar. This was not done with the sole intent to apply these processes to T5, but for capital projects. Furthermore it gave BAA knowledge about suppliers’ capabilities, which was used in T5 | + | Egan gathered a team to explore practices, principles, and technologies from different industries in an effort to see what would work in the T5 project. Later on he would establish an organization that worked independently from BAA in an effort to ''"provide the freedom of choice needed to promote experimentation and innovation."'''<ref name="Davies, Gann, Douglas"> Andrew Davies, David Gann,Tony Douglas"> ''Innovations in Megaprojects: Systems Integration At London Heathrow Terminal'', California Management Review, 2009</ref> Later on BAA would establish a Continuous Improvement Project Process (CIPP) in an effort to ''"provide a set of standardized and repeatable time-sequenced tasks, milestones, and stage-gates to deliver cost-effective and profitable projects."'''<ref name="Davies, Gann, Douglas"> Andrew Davies, David Gann,Tony Douglas"> ''Innovations in Megaprojects: Systems Integration At London Heathrow Terminal'', California Management Review, 2009</ref> The projects in question would have a budget between $4M-$8M. CIPP also looked into the design process by working with modular design, so that the construction processes would have similar construction processes, despite being vastly similar. This was not done with the sole intent to apply these processes to T5, but for capital projects. Furthermore it gave BAA knowledge about suppliers’ capabilities, which was used in T5 |

==Inquiry process== | ==Inquiry process== | ||

Revision as of 14:36, 16 September 2016

Contents |

Abstract

The Heathrow terminal 5 (T5) project was created with the intent of easing the congestion of the airport, centralizing all British Airways flights, and increasing the revenue from other airlines. Due to the size of the project both in size and budget it was complex to manage, this was not ameliorated by the fact that it took eight years to get government approval. The project consisted of a control tower, two satellite buildings, and supporting infrastructure. The latter included river diversions, connections between terminals, and a train station. This resulted in 16 major projects, and 147 sub-projects, all separate from each other and involving over 60 contractors in total. [1] Due to the fact that construction projects by nature are prone to delays it’s quite remarkable that Terminal 5 was completed on time, within budget, and with less fatalities than expected. The reason for this was the fact that the contracts between British Airways and the contractors were quite unique for at time. The contracts were unique because all contractors pooled together risk payments and were promised a share in the event that their work was finished on time. This proved to be an effective incentive not only to be on time and on budget, but also to nudge the contractors towards better teamwork as the prospects of getting the bonuses was higher than way. The result was a construction project finished on time and on budget with fewer fatalities than there would normally be on a project of that size. Unfortunately there were issues on the operation level that led to bad reviews on the opening week that overshadowed the success of the construction project. [2]

Overview

T5 project is considered a mega project; due to the fact that these are "projects of a significant cost that attract a high level of public attention or political interest because of substantial direct and indirect impacts on the community, environment, and budgets". [3] The client and owner of Heathrow Airport, and by extension T5, in this case is BAA. In this article only one of the contractors will be singled out; Lain O’Rouke. This is due to the fact that LOR grew with the project in such a way that it has completely changed the shape of the organization today.

Phases of T5 project

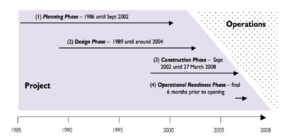

The T5 project in question can be divided into 4 phases shown in figure 1. It should be noted that the planning phase contains a 4-year long period of inquiry (1995-1999) and subsequent "consent to proceed with construction"[4]. in 2001. The T5 project is one of the longest in British history and cost around £80, cementing its label as a mega project.

Planning phase

In 1990 Sir John Egan became the CEO of BAA and would continue to work through 1999. He had previously worked for Jaguar, a company that seemed to be very close to shutting down, but he turned the trend and is largely credited for the success. Egan used his knowledge about Lean production from the automobile industry and attempted to apply it the construction of T5. Furthermore he recognized that projects are often unique and therefore approached as a "blank slate"[4], as BAA did prior to his arrival. In an effort to ameliorate this he wanted to create standardized parts of projects in an effort to apply Lean principles, that emphasized simplification and standardized tasks.

Egan gathered a team to explore practices, principles, and technologies from different industries in an effort to see what would work in the T5 project. Later on he would establish an organization that worked independently from BAA in an effort to "provide the freedom of choice needed to promote experimentation and innovation."[4] Later on BAA would establish a Continuous Improvement Project Process (CIPP) in an effort to "provide a set of standardized and repeatable time-sequenced tasks, milestones, and stage-gates to deliver cost-effective and profitable projects."[4] The projects in question would have a budget between $4M-$8M. CIPP also looked into the design process by working with modular design, so that the construction processes would have similar construction processes, despite being vastly similar. This was not done with the sole intent to apply these processes to T5, but for capital projects. Furthermore it gave BAA knowledge about suppliers’ capabilities, which was used in T5

Inquiry process

Stakeholders

Construction and Performance Management

Opening and Operational Management

References

- ↑ [http://www.airport-technology.com/projects/heathrow5/] London Heathrow Airport Expansions (LHA/EGLL), United Kingdom

- ↑ [http://www.the-chiefexecutive.com/features/feature68469/] 'Why stakeholders matter

- ↑ [http://flyvbjerg.plan.aau.dk/whatisamegaproject.php] What is a Megaproject?

- ↑ 4.0 4.1 4.2 4.3 Andrew Davies, David Gann,Tony Douglas"> Innovations in Megaprojects: Systems Integration At London Heathrow Terminal, California Management Review, 2009