Value Stream Analysis and Mapping for Project Management

(→On a Program Management environment) |

(→On a Program Management environment) |

||

| Line 148: | Line 148: | ||

*IS support | *IS support | ||

|- | |- | ||

| − | | | + | | '''UnnecessaryMotion''' |

| − | | | + | | Walking to information, retrieving printed materials |

| − | | | + | | |

| + | *Lack of distributed, direct access | ||

| + | *Lack of on-line access | ||

| + | *Lack of digital versions of heritage information | ||

|- | |- | ||

| − | | | + | | '''UnnecessaryMotion''' |

| − | | | + | Unnecessary human movement (physical or user movement between tools or system) |

| − | | | + | | Excessive keyboard, mouse operations |

| + | | | ||

| + | *Lack of training | ||

| + | *Poorly designed user interfaces | ||

| + | *Incompatible software suites | ||

| + | *Too much information to sort through | ||

|- | |- | ||

| − | | | + | | '''UnnecessaryMotion''' |

| − | | | + | | Poor physical arrangement or organization |

| − | | | + | | |

| + | *Team members not co-located | ||

| + | *Organization structure inhibits formation of right teams | ||

|- | |- | ||

| − | | | + | | '''Defects''' |

| − | | | + | Erroneous data, information, reports |

| − | | | + | | Errors in data reporting/entries |

| + | | | ||

| + | *Human error | ||

| + | *Poorly designed input templates | ||

|- | |- | ||

| − | | | + | | '''Defects''' |

| − | | | + | | Errors in information provided to customers |

| − | | | + | | |

| + | *Lack of disciplined reviews, tests, verification | ||

|- | |- | ||

| − | | | + | | '''Defects''' |

| − | | | + | | Information does not make sense to user |

| − | | | + | | |

| + | *Raw data delivered when user needs derived information, recommendations, or decisions | ||

|} | |} | ||

Revision as of 19:49, 22 September 2016

Value Stream Analysis and Mapping (VSA/M) is a tool for business process improvement.[1] Value Stream Analysis (VSA) is a method that implements lean principles for the examination of business processes. The tool, focus on the development of tasks which add value to the final product, efficiently linked together to form a continuously flowing stream of value.[1]

Contents |

History

In order to understand its origins we must look back into the early 40s. By then, Toyota was trying to compete with the American automobile market by productivity means. Taiichi Ohno in 1956 traveled to the US in order to visit the automobile plants and see how could he improve its production system back in Japan. Despite what he saw on those production plants, what catches his attention is the self-service supermarkets in which he could choose exactly what he wanted and how much of it. That idea was efficient as well as timely saver for him and where to become later the fundamentals for pursuing manufacturing improvements. Along the next years Ohno will develop this production system on a systematic framework based on Lean and Just-In-Time principles. Toyota defined six elementary rules[2]:

- Never send defective products downstream to the next process

- Each process only orders what it currently needs from the upstream process

- Each process only produces the quantity ordered by the downstream process

- Maintain a level rate of production

- Use Kanban to fine-tune the rate of production

- Work to reach a stable rate of production

These first studies where focused mainly on manufacturing processes in spite of process design. But the principles can still be applied either to shop floor and non-shop floor activities. And as Womack and Jones describe it, the main principles of lean for product development are[3][4]:

- Value: providing the customer with the right product, for the right price, at the right time.

- Value Stream: the set of actions that bring a product from concept to realization, order to delivery, or raw material to finished good

- Flow: seamless movement through value-creating steps.

- Pull: acting only to satisfy customer needs, rather than forcing, or pushing, a product upon the marketplace.

- Perfection: continuously and relentlessly improving the value, value stream, flow, and pull in business operations.

Methodology

The value stream must be analyzed and mapped thoroughly to reduce waste along processes and enable flow. Also to move the processes towards a more rapid response for customer pull. On a product development context, this means rapid response towards customer needs when it comes either to new products or permutations of the existing ones.[1]

On a manufacturing environment

Fundamentally, the method consists on mapping the current state of the process and apply lean techniques. This enables an improved future state of the process. In order to do so, non-value-added tasks are identified. Then, the tasks considered to support the true value-added tasks such as, set-ups, reviews, etc..., are Type I waste. While completely unnecessary tasks such as waiting in the inventory are Type II waste.[4] A number of techniques are then applied once cathegorised these types of waste. Which in the lean manufacturing pcontext include manufacturing cells, Just-In-Time deliveries, aparts supermarkets, etc... Once established the future state map, it is implementet thorough a plan. Which leads to a an improved state that ideally is used to generate further future states. As seen, the process is being continuously improved.

On a Program Management environment

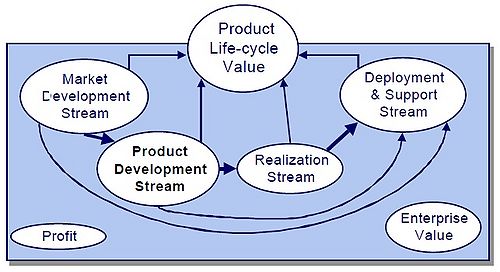

According to the product development team at MIT's Lean Aerospace Initiative[1], the value of the Product Development (PD) process is "a capability delivered at the right time, for the right price, as defined by the end user." Now this value stream is effectively emboided on a notional product designed package. Therefore, as the outcome of a value stream it can be evaluated as a PD value stream, like the manufacturing value stream is done. This way fitting with other activities around the business cycle to define an overall value as we can see on the Figure 1.

In order to extrapolate the VSM under manufacturing principles to a Program Management environment, how does the flow thorough the PD process translates into? In this case it is information. Information flows thorough the PD process like on the manufacturing environment material does.[1] The quality of the information flow is characterized by its Form, Fit, Function and Timelines (FFFT). However, PD value not only comes as a function of the FFFT within the design package, it also comes as the degree the design package allows the end product to match the desires of the customer.

As information flows through the PD process, tasks add value to the information. Since the flows in PD are made of information instead of physical materials. Using the next seven info-wastes should enable to identify wastes associates with the information flows[5]:

| Types of Information Waste | Examples | Causes |

|---|---|---|

| Waiting

Idle time due to unavailable information |

People waiting for information |

|

| Waiting | Information waiting for people |

|

| Inventory | Too much information |

|

| Inventory | Multiple/redundant sources |

|

| Inventory

Information that is unused or is “work in progress” |

Outdated/obsolete information |

|

| Inventory | “Just-in-case” information |

|

| Excessive Processing | Excessive/custom formatting |

|

| Excessive Processing

Information processing beyond requirements |

Numerous, fragmented reports |

|

| Excessive Processing | Unnecessary serial processing |

|

| Excessive Processing | Excessive approvals for information release |

|

| Over Production

Producing, distributing more information than needed |

Unnecessary detail and accuracy |

design |

| Over Production | Pushing, not pulling data, information |

|

| Over Production | Over-dissemination |

participant’s needs

rather than to meet specific needs |

| Transportation | Information handled by multiple people before arriving at user |

|

| Transportation | Information hunting |

|

| Transportation

Unnecessary movement of information between people, organizations, or systems |

Data re-formatting or reentry |

|

| Transportation | Switching computers (e.g., CAD to PC) to access information |

|

| UnnecessaryMotion | Walking to information, retrieving printed materials |

|

| UnnecessaryMotion

Unnecessary human movement (physical or user movement between tools or system) |

Excessive keyboard, mouse operations |

|

| UnnecessaryMotion | Poor physical arrangement or organization |

|

| Defects

Erroneous data, information, reports |

Errors in data reporting/entries |

|

| Defects | Errors in information provided to customers |

|

| Defects | Information does not make sense to user |

|

Application

Discussion

Value Stream Mapping can be thought as a tool which facilitates the transformation from a traditional manufacturing company to a Lean Enterprise. It is a planning tool to target ideal processes and roadmaps to desired improvements.[6]

Advantages

Limitations

Related Articles

The lessons from Toyota for product development had been captured by Fujimoto and Clark[7] and Ward and Sobek.[8][1] Follow the references for further study.

Most of the VSM work that has been acomplished is around the manufacturing context. For practical implementation of VSA/M on manufacturing operations please refer to .[9]

Understanding how to break the PD process down into stages:[10]

Key references

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 http://dspace.mit.edu/bitstream/handle/1721.1/7333/Value%20Stream%20Analysis%20and%20Mapping.pdf?sequence=1

- ↑ http://world-class-manufacturing.com/Kanban/kanban.html

- ↑ http://www.lean.org/Bookstore/ProductDetails.cfm?SelectedProductId=160

- ↑ 4.0 4.1 http://web.mit.edu/esd.83/www/notebook/WomackJones.PDF

- ↑ http://dspace.mit.edu/bitstream/handle/1721.1/81908/PDVSM_V.1_2005.pdf?sequence=1

- ↑ http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.201.6852&rep=rep1&type=pdf

- ↑ https://books.google.fr/books?id=7cCAASTW6IQC&hl=es

- ↑ https://books.google.dk/books/about/Principles_that_Shape_Product_Developmen.html?id=ZbYGtwAACAAJ&redir_esc=y

- ↑ https://www.amazon.es/Learning-See-Eliminate-Enterprise-Institute/dp/0966784308

- ↑ https://www.amazon.com/Product-Design-Development-Karl-Ulrich/dp/0070658110