Value stream mapping in construction management

| Line 10: | Line 10: | ||

===VSM in the construction industry=== | ===VSM in the construction industry=== | ||

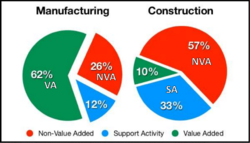

| − | [[File:ManvsCon.PNG| | + | [[File:ManvsCon.PNG|250px|thumb|right|Figure 1: Construction industry vs. Manufacturing industry.<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>]] |

The construction industry in terms of productivity, quality and efficiency, is often characterized as a backward industry, that fails to innovate compared to other industries. The Lean Thinking philosophy was adopted to the construction industry since the 1970's, and several successful implementations has been achieved. The Construction | The construction industry in terms of productivity, quality and efficiency, is often characterized as a backward industry, that fails to innovate compared to other industries. The Lean Thinking philosophy was adopted to the construction industry since the 1970's, and several successful implementations has been achieved. The Construction | ||

Industry Institute states that only 10% are value added inputs and striking 57% are waste. This is compared to the manufacturing industry where 62% is value added and 26% is waste. The lack of performance in the construction industry compared to other industries, has been directly related to the low rate of innovation<ref name="master_thesis">http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y</ref>. These statistics are a major motivation, for studying and identifying the wastage, which is frequently present in the industry. Consequently how to apply Lean tools and techniques to reduce the wastage. Examples of value adding activities are pouring concrete, erecting steel pr installing the roof. Examples of waste are excessive material handling, design errors, conflict between contractors, ineffective supply chain and rework. | Industry Institute states that only 10% are value added inputs and striking 57% are waste. This is compared to the manufacturing industry where 62% is value added and 26% is waste. The lack of performance in the construction industry compared to other industries, has been directly related to the low rate of innovation<ref name="master_thesis">http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y</ref>. These statistics are a major motivation, for studying and identifying the wastage, which is frequently present in the industry. Consequently how to apply Lean tools and techniques to reduce the wastage. Examples of value adding activities are pouring concrete, erecting steel pr installing the roof. Examples of waste are excessive material handling, design errors, conflict between contractors, ineffective supply chain and rework. | ||

====8 types of waste==== | ====8 types of waste==== | ||

| − | [[File:8 wastes.PNG| | + | [[File:8 wastes.PNG|250px|thumb|right|Figure 2: 8 types of waste<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>]] |

| − | + | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! '''Types of Information Waste''' | ||

| + | ! '''Examples''' | ||

| + | ! '''Causes''' | ||

| + | |- | ||

| + | | '''Waiting''' | ||

| + | Idle time due to unavailable information | ||

| + | | - People waiting for information | ||

| + | | | ||

| + | *Lack of access | ||

| + | *Untimely updating of data bases | ||

| + | *Multiple approvals | ||

| + | *Poorly designed or executed process to provide information | ||

| + | |- | ||

| + | | | ||

| + | | - Information waiting for people | ||

| + | | | ||

| + | *Information created too soon may be obsolete by the time it is used | ||

| + | |- | ||

| + | | '''Inventory''' | ||

| + | Information that is unused or is “work in progress” | ||

| + | | - Too much information | ||

| + | | | ||

| + | *Poor understanding of user needs | ||

| + | |- | ||

| + | | | ||

| + | | - Multiple/redundant sources | ||

| + | | | ||

| + | *Tendency for everybody to maintain their own files | ||

| + | |- | ||

| + | | | ||

| + | | - Outdated/obsolete information | ||

| + | | | ||

| + | *Lack of “version control” | ||

| + | *Lack of disciplined system for updating new and purging old information | ||

| + | *Inadequate archiving standards or practices | ||

| + | |- | ||

| + | | | ||

| + | | - “Just-in-case” information | ||

| + | | | ||

| + | *Collection, processing and storage of every element of data that process participants can think of, whether or not a specific end use has been identified | ||

| + | |- | ||

| + | | '''Excessive Processing''' | ||

| + | Information processing beyond requirements | ||

| + | | - Excessive/custom formatting | ||

| + | | | ||

| + | *Lack of standardization | ||

| + | |- | ||

| + | | | ||

| + | | - Numerous, fragmented reports | ||

| + | | | ||

| + | *Poor output design | ||

| + | *Lack of understanding of the needs of the users of process outputs | ||

| + | |- | ||

| + | | | ||

| + | | - Unnecessary serial processing | ||

| + | | | ||

| + | *Poor system design | ||

| + | *Lack of understanding of concurrent processing capabilities | ||

| + | |- | ||

| + | | | ||

| + | | - Excessive approvals for information release | ||

| + | | | ||

| + | *Stove pipe, command and control mentality | ||

| + | *Turf protection | ||

| + | |- | ||

| + | | '''Over Production''' | ||

| + | Producing, distributing more information than needed | ||

| + | | - Unnecessary detail and accuracy | ||

| + | | | ||

| + | *Tendency to “over-design” | ||

| + | *More detail than necessary in early | ||

| + | design | ||

| + | |- | ||

| + | | | ||

| + | | - Pushing, not pulling data, information | ||

| + | | | ||

| + | *Uncontrolled process | ||

| + | |- | ||

| + | | | ||

| + | | - Over-dissemination | ||

| + | | | ||

| + | *Poor understanding of each | ||

| + | participant’s needs | ||

| + | *“Send all information to everyone,” | ||

| + | rather than to meet specific needs | ||

| + | |- | ||

| + | | '''Transportation''' | ||

| + | Unnecessary movement of information between people, organizations, or systems | ||

| + | | - Information handled by multiple people before arriving at user | ||

| + | | | ||

| + | *Lack of direct access due to IT system limits, organizational inefficiencies, knowledge hoarding, security issues | ||

| + | |- | ||

| + | | | ||

| + | | - Information hunting | ||

| + | | | ||

| + | *Lack of clear information flow paths, failure of process to produce information needed | ||

| + | |- | ||

| + | | | ||

| + | | - Data re-formatting or reentry | ||

| + | | | ||

| + | *Incompatible information types (drawings vs. digital descriptions) | ||

| + | *Incompatible software systems or tools | ||

| + | *Lack of availability, knowledge, or training in conversion and linking systems | ||

| + | |- | ||

| + | | | ||

| + | | - Switching computers (e.g., CAD to PC) to access information | ||

| + | | | ||

| + | *Software/hardware incompatibilities | ||

| + | *IS support | ||

| + | |- | ||

| + | | '''Unnecessary Motion''' | ||

| + | Unnecessary human movement (physical or user movement between tools or system) | ||

| + | | - Walking to information, retrieving printed materials | ||

| + | | | ||

| + | *Lack of distributed, direct access | ||

| + | *Lack of on-line access | ||

| + | *Lack of digital versions of heritage information | ||

| + | |- | ||

| + | | | ||

| + | | - Excessive keyboard, mouse operations | ||

| + | | | ||

| + | *Lack of training | ||

| + | *Poorly designed user interfaces | ||

| + | *Incompatible software suites | ||

| + | *Too much information to sort through | ||

| + | |- | ||

| + | | | ||

| + | | - Poor physical arrangement or organization | ||

| + | | | ||

| + | *Team members not co-located | ||

| + | *Organization structure inhibits formation of right teams | ||

| + | |- | ||

| + | | '''Defects''' | ||

| + | Erroneous data, information, reports | ||

| + | | - Errors in data reporting/entries | ||

| + | | | ||

| + | *Human error | ||

| + | *Poorly designed input templates | ||

| + | |- | ||

| + | | | ||

| + | | - Errors in information provided to customers | ||

| + | | | ||

| + | *Lack of disciplined reviews, tests, verification | ||

| + | |- | ||

| + | | | ||

| + | | - Information does not make sense to user | ||

| + | | | ||

| + | *Raw data delivered when user needs derived information, recommendations, or decisions | ||

| + | |} | ||

Revision as of 15:35, 12 June 2017

Value stream mapping (VSM) is a tool used within the field of Project Management to visualize and improve the overall flow process of a product or service from raw material all the way to the customer. It has its origin at TOYOTA, being a part of their lean management tools, where it is known as “material and information flow mapping”. VSM helps document all the activities required to complete a request from a customer. It includes people who normally manage individual functions or processes, and makes the overall flow of material and information across the entire process visible. In addition, it brings alignment to the organization, by involving the people who in fact do the work, and provides a platform for improvement and implementation. VSM is dynamic tool, since its continuously updated as the processes is being improved. VSM differs from the traditional tool; process/flow maps, by having a process focus, rather than a product focus. It provides a holistic view of how thing work, with a costumer perspective. One vital gain from applying VSM, is that it provides a common language when talking about processes, and allowing people to operate solely based on facts.

Contents |

The Big Idea

describe the tool, concept or theory and explain its purpose. The section should reflect the current state of the art on the topic

VSM generic formulation

Value stream mapping (VSM) originated in the manufacturing industry. It was developed by Toyota Motors Corporation, being a part of their Lean management tools. The Lean management philosophy is to identify and eliminate every activity in the design, production and supply chain management related processes that does not create value for a costumers point of view[1]. Generally it is characterized as a process-improving management philosophy, that seeks to minimize the waste without decreasing the productivity.

Value stream mapping (VSM) is used to both analyse and design the flow of material and information, that is required to bring a product or service to the end customer. It is a visual tool that provides a holistic view of the overall process, and thus a platform for strategically improvement and adding value to the costumers[2]. The goal is to design an “ideal state”, also known as the “future state” by analyzing the “current state”. The current state presents how the process is at the time of making the VSM, which is important due to its dynamic nature. The waste present within the work flow system, is identified by reflecting the current state. Having identified the wastes, a future state can be designed where the wastes are eliminated. VSM generates security within the organisations, which is essential to success. Insecurity often result in withhold of important information about the flow and processes, and will consequent lead to delay and loss of value.

VSM in the construction industry

The construction industry in terms of productivity, quality and efficiency, is often characterized as a backward industry, that fails to innovate compared to other industries. The Lean Thinking philosophy was adopted to the construction industry since the 1970's, and several successful implementations has been achieved. The Construction Industry Institute states that only 10% are value added inputs and striking 57% are waste. This is compared to the manufacturing industry where 62% is value added and 26% is waste. The lack of performance in the construction industry compared to other industries, has been directly related to the low rate of innovation[2]. These statistics are a major motivation, for studying and identifying the wastage, which is frequently present in the industry. Consequently how to apply Lean tools and techniques to reduce the wastage. Examples of value adding activities are pouring concrete, erecting steel pr installing the roof. Examples of waste are excessive material handling, design errors, conflict between contractors, ineffective supply chain and rework.

8 types of waste

| Types of Information Waste | Examples | Causes |

|---|---|---|

| Waiting

Idle time due to unavailable information |

- People waiting for information |

|

| - Information waiting for people |

| |

| Inventory

Information that is unused or is “work in progress” |

- Too much information |

|

| - Multiple/redundant sources |

| |

| - Outdated/obsolete information |

| |

| - “Just-in-case” information |

| |

| Excessive Processing

Information processing beyond requirements |

- Excessive/custom formatting |

|

| - Numerous, fragmented reports |

| |

| - Unnecessary serial processing |

| |

| - Excessive approvals for information release |

| |

| Over Production

Producing, distributing more information than needed |

- Unnecessary detail and accuracy |

design |

| - Pushing, not pulling data, information |

| |

| - Over-dissemination |

participant’s needs

rather than to meet specific needs | |

| Transportation

Unnecessary movement of information between people, organizations, or systems |

- Information handled by multiple people before arriving at user |

|

| - Information hunting |

| |

| - Data re-formatting or reentry |

| |

| - Switching computers (e.g., CAD to PC) to access information |

| |

| Unnecessary Motion

Unnecessary human movement (physical or user movement between tools or system) |

- Walking to information, retrieving printed materials |

|

| - Excessive keyboard, mouse operations |

| |

| - Poor physical arrangement or organization |

| |

| Defects

Erroneous data, information, reports |

- Errors in data reporting/entries |

|

| - Errors in information provided to customers |

| |

| - Information does not make sense to user |

|

hello

dwa

Application

provide guidance on how to use the tool, concept or theory and when it is applicable

remember a image/list of all the symbols

pre cast concrete Yard example from the conference paper[1]

Limitations

critically reflect on the tool/concept/theory. When possible, substantiate your claims with literature

Annotated Bibliography

Provide key references (3-10), where a reader can find additional information on the subject. Summarize and outline the relevance of each reference to the topic. (around 100 words per reference). The bibliography is not counted in the suggested 3000 word target length of the article.

- ↑ 1.0 1.1 https://www.researchgate.net/publication/282156168_Implementing_Value_Stream_Mapping_Tool_in_the_Construction_Industry

- ↑ 2.0 2.1 http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y

- ↑ 3.0 3.1 http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf