Partnering

(→References) |

(→References) |

||

| Line 97: | Line 97: | ||

==References== | ==References== | ||

#Erhvervs- og Byggestyrelsen (2006), "Vejledning i partnering", https://www.bygst.dk/media/13744/Vejledning-i-partnering.pdf, seen 07-06-2017. | #Erhvervs- og Byggestyrelsen (2006), "Vejledning i partnering", https://www.bygst.dk/media/13744/Vejledning-i-partnering.pdf, seen 07-06-2017. | ||

| − | #MT Højgaard (2005), "Partnering ABC", mth.dk/~/media/Files/Partnering/Partnering_ABC.ashx, seen 06-06-2017. | + | #MT Højgaard (2005), "Partnering ABC", https://www.mth.dk/~/media/Files/Partnering/Partnering_ABC.ashx, seen 06-06-2017. |

#XX | #XX | ||

Revision as of 08:28, 15 June 2017

Partnering is a form of collaboration management concept within the construction industry, in which the client, engineer, architecture and entrepreneur enter into a partnership based on dialogue, trust and shared responsibility. Partnering was established in the early 1980s in USA where a full partnership relation between the oil company Shell and the engineering firms Parson & SIP was established and has recently gained ground in the construction industry, as a well-known collaboration between key project stakeholders.

Partnering is part of the development in the construction industry, which is trying to catch up with the manufacturing industry by changing the low productivity development. In partnering, a main focus is for the participants to share the same values and thereby obtain a better starting point for the construction processes and thus a better result, which will be a success for all partners.

Contents |

History

The basic principle of partnering was already present in the 1920s in Britain, a partnering relationship between Bevis-Marks & Spencer, but the term partnering is considered established in the beginning of the 1980s in the United States of America.

The litigation in the construction industry exploded in the early 1980s in USA, so the industry started to work with some basic management principles to deal with the organizational conflicts and the first full partnering relationship was established between the oil company Shell and the engineering firms Parson & SIP. However, the partnering model as it is known today was first developed and introduced by the US Corps of Army Engineers in the late 1980s, as a concept of the Japanese management tool Total Quality Management (TQM). The purpose of the new founded concept was to improve productivity and efficiency in the construction industry. The first projects showed a clear improvement of the efficiency throughout the entire construction process and even reduced the costs.

In the 1990s, the English government started to do some new initiatives in the construction sector to reduce the rising cost development, including conflict management. The results of partnering has been recognized all over the world the recent years and the experience shows that the construction projects often can be built faster and cheaper with a better final result.

The Danish government has because of the results of partnering ordered the governmental clients to carry out a systematic assessment prior of any construction project, to evaluate whether partnering it beneficial in the specific case or not.

Partnering

In partnering, a collaborative partnership is established in which counteraction and distrust is replaced with fellowship and trust through an early involvement of all partners. All expectations are attuned before the project starts, allowing an opportunity of the right decision making from the beginning.

Partnering consists as a minimum of a client, an engineer/architect and an entrepreneur, but can also include investors, the government etc. The partners work together to find their common goals and how to achieve them. By exploiting partnering and incorporation of each one’s competencies and experiences, the productivity development can be increased, the poor quality of the projects can be changed to the better and the many disputes and accidents in the construction industry can be avoided.

Partnering is a philosophy of teamwork and understanding the other partners needs and the construction management concept has shown to lower the costs and achieve a better end-result by sharing the risks.

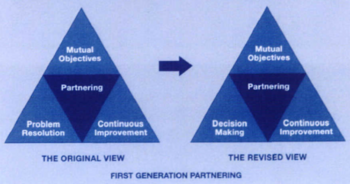

First Generation Partnering

First generation partnering is also known as project partnering, where this form of collaboration is used to address a given project, after which the collaboration ends.

The basic approach produces a range of benefits and experiences, which can be achieved on individual projects and afterwards used in other projects. It is achieved through sharing common project goals, open decision processes and agreeing on dispute resolution principles. First generation partnering helps the companies and employees try one’s skill on it and explore the opportunities for a more effective collaboration with other companies. First generation partnering has shown to have a cost reduction of 5-30% and a time reduction of up to 40%.

First generation partnering is thus an essential step and experience base for all companies who want a solid basis for collaboration towards second- and third generation partnering, but is also considered to limit potential results if the collaboration is not continued. The limited repetition efficacy will reduce the effect of the results, since it takes time and experience to build a good and strong collaboration with great trust among the partners.

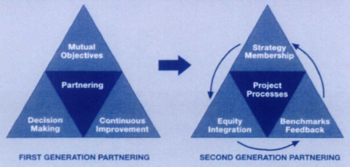

Second Generation Partnering

Second generation partnering is known as strategic partnering, where this form of collaboration is adding a long-term strategy to a series of projects undertaken for one customer. Second generation partnering complies with the problems of the first generation partnering, where collaboration is not repeated and therefore prevent a more fully optimization of the construction industry.

Second generation partnering begins with a strategic decision to a collaboration between partners in an ongoing series of projects. The strategic collaboration focuses on common values and mutual respect, through which continuous improvement of the efficiency of all the construction processes can be seen. Second generation partnering can be described by The Seven Pillars of Partnering, where each is a set of management actions that put this strategic partnering into effect. The Seven Pillars of Partnering are:

- Strategy – developing the client’s objectives and how consultants, contractors and specialists can meet them on the basis of feedback.

- Membership – identifying the firms that need to be involved to ensure all necessary skills are developed and available.

- Equity – ensuring everyone is rewarded for their work on the basis of fair prices and fair profits.

- Integration – improving the way the firms who are involved work together by using collaboration and building trust.

- Benchmarks – setting measured targets that lead to continuous improvements in performance from project to project.

- Project Processes – establishing standards and procedures that embody best practice based on process engineering.

- Feedback – capturing lessons from projects and task forces to guide the development of strategy.

Second generation partnering are resulting in better projects and helps the companies adapt new technologies and changes, through continuous collaboration and experience sharing. Second generation partnering has shown to have a cost reduction of up to 40% and a time reduction of up to 50%.

Third Generation Partnering

Third generation partnering is also known as strategic partnering, where this form of collaboration is a systematic repetition of the collaboration between the involved partners. The main difference between second- and third generations partnering is seen in the role of the client. The client has a dominant position in second generation partnering, whereas the client is considered to be a ‘costumer’.

The key features of third generation partnering are seen trough the overall aim of a long-term continuous improvement in performance that both justify and deliver high levels of profits. Third generation partnering consist of two different main forms – permanent supply teams and supply teams as ‘resource stocks’.

The permanent supply teams are typically specialized in a particular type of construction part/process or a particular market segment, where the continuous collaboration of the same type of product makes it standardized and creates opportunities of a much more efficiency increase in the construction industry. Unlike the permanent supply teams, the supply teams as resource stocks has a much better product selection, which also requires that more companies with the needed competences are involved for the chosen market area.

Third generation partnering are achieving even better results by a systematic repetition, that makes the product more standardized and thereby more efficient. Third generation partnering has shown to have a cost reduction of up to 50% and a time reduction of up to 80%.

Core Values

In partnering, it is essential to have the same values in order to achieve fully functioning collaboration, in order to achieve the desired results. Poor communication, distrust and a defective collaboration can lead to the previously known problems where disputes, unexpected cots and less productivity occur.

Typical core values for collaboration in partnering projects in Denmark:

- Open and honest communication

- Confident and trust-based collaboration

- Shared responsibility

- Respect and equality

- Adherence to agreements

- Free sharing of knowledge

- Pleasant working atmosphere

Benefits of Partnering

Partnering may not solve all the problems encountered in the construction industry, but produces a lot of benefits to the industry and the companies themselves. Partnering creates framework for conflict resolution, improved communication, trust, better project performance and reduced litigation. It lowers the risk of cost overruns and delays as a result of a better time and cost control over the project. Partnering secures a more stable workload, a higher client satisfaction and thus better project results.

Partnering also increases the opportunity for innovation, especially in the development of value engineering changes and constructability improvement due to open communications and existence of trust among project parties. Partnering is a management technique and its success is dependent on the people who want to work for it. Partnering has the potential to change the construction industry to work in a more cooperative environment.

Problems of Partnering

Partnering does not always work without risk; to develop trust between two different companies can be a risk in itself, although trust is one of the key elements of successful partnering. Some companies might have some bad experience with earlier relationships, which will make it difficult to establish a trustful partnering. Instead of trying to develop a win-win environment among the parties, some of the parties try to procure benefits out of the collaboration and earn at the expense of others. Another relationship problem can be found in the sharing of risk. The failure of sharing risk can also put a stop to a complete partnering, as some of the parties may find it difficult to be accountable for others mistakes.

Partnering is costly, as the formation of a partnering arrangement requires extra staff, time and resources, which causes some companies to go away from the partnering concept, because it requires to much efforts. Partnering is culturally opposed to the traditional implementation of construction projects and may break with the former organisation and how things were done earlier.

Partnering may also lead to laziness within the collaboration, if the companies have a long-term relationship and have worked on a series of projects together. The collaboration is well functional, but can also be the easy choice and less innovative, if the relationship is not worked on constantly.

It is important to understand the concept of partnering and requires a lot of training, to be able to produce the many benefits.

Relational contracting

Relational contracting is in some ways similar to partnering, as it is a management concept, which is build on a relationship between parties instead of discrete transactions.

Relational contracting is a contracting concept that seeks to give an explicit recognition to the relationship between parties to a given contract. The relations are established through common internal values and sustained by the value of future relationships. The focus is on the relationship and not the deal itself and the responsibilities and benefits of the contract are apportioned fairly and transparently between the parties.

A relational contracting approach implies a commitment of moving towards common goals in the recognition of each parties expertise. The parties seek a long-term relationship instead of one-time partnerships, which increases the outcomes. The ‘norm-based’ approach ensures a trust-based and strategic beneficial partnership that has just like partnering shown to lower the costs of doing business, increase the efficiency and minimize the possibility of disputes.

Despite the possible outcomes, relational contracting shares some similar challenges as partnering regarding the parties involved in the contract. The concept involves a relinquishment of independence, as each party is more interdependent on others, an acknowledgement of shared costs and to make an effort in seeking a common value-based company.

References

- Erhvervs- og Byggestyrelsen (2006), "Vejledning i partnering", https://www.bygst.dk/media/13744/Vejledning-i-partnering.pdf, seen 07-06-2017.

- MT Højgaard (2005), "Partnering ABC", https://www.mth.dk/~/media/Files/Partnering/Partnering_ABC.ashx, seen 06-06-2017.

- XX