Muda, Mura and Muri

| Line 58: | Line 58: | ||

[1]Dansk Lean Forum, 2015. ''Muda, Mura and Muri, Hvem er de?'' https://leanforum.wordpress.com/2015/08/20/lean-muda-mura-muri/ | [1]Dansk Lean Forum, 2015. ''Muda, Mura and Muri, Hvem er de?'' https://leanforum.wordpress.com/2015/08/20/lean-muda-mura-muri/ | ||

| − | |||

| − | |||

Jiwat (2016). 3MUs (Muda, Mura, Muri): A lean Management tool with potentially ‘Big benefits’ for Project Management - IPMA Blog - Learn more about project management. [online] IPMA Blog - Learn more about project management. Available at: http://blog.ipma.world/3mus-muda-mura-muri-lean-management-tool-potentially-big-benefits-project-management/ [Accessed 19 Sep. 2017]. | Jiwat (2016). 3MUs (Muda, Mura, Muri): A lean Management tool with potentially ‘Big benefits’ for Project Management - IPMA Blog - Learn more about project management. [online] IPMA Blog - Learn more about project management. Available at: http://blog.ipma.world/3mus-muda-mura-muri-lean-management-tool-potentially-big-benefits-project-management/ [Accessed 19 Sep. 2017]. | ||

| − | |||

| − | |||

==References== | ==References== | ||

<references /> | <references /> | ||

Revision as of 07:35, 27 September 2017

Contents |

Idea

Muda, Mura and Muri is a concept originally developed by the car manufacturing company Toyota, and is often referred to as the 3 M's of waste in lean manufacturing. The three M's collectively describe the practices companies can eliminate to reduce the non-value adding utilisation of resources. These three waste types can typically be found in both manufacturing and office processes and may be used in lean project management. It is therefore also very applicable to projects and project management. As various projects are often challenged with multiple and diverse obstacles, reducing the 3 M's may be a helpful aid when trying to reduce project failure. The concept can be utilised and applied in the planning and execution stages to improve the performance of the project.

Lean project management is the adoption of lean concepts put into a project management circumstance, with a primary aim for a project to deliver more value with less waste. This is essentially done with removal of bottlenecks during the production process which can then expedite growth and boost productivity. The lean management principles mostly stems from the Toyota Production System (TPS) and their idea of lean from 1990, and automaker company Toyota has been renowned for the way it grew from a small company to a global brand with a lean perspective [1] The main goal of the elimination of Muda, Mura and Muri is to integrate light-weight processes and frameworks that can be applied and utilised with limited need for documentation and added efforts.

Muda

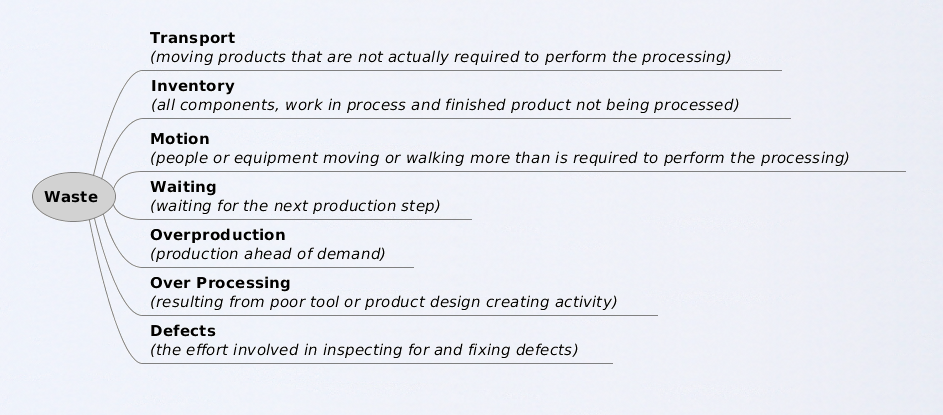

Muda is the Japanese word for "waste" and relates to any activity or practice that does not in any way produce value for the customer and generate loss of resources, time and money [2]. There are, as explained by the so-called "father of the Toyota production system", Taiichi Ohno, 7 categories of waste. A common mistake for companies is to focus only on reducing or eliminating the Muda waste, thinking that it represents and covers all types of excess waste, but simply eliminating Muda will not be of help to the company without finding the reason for the waste, which will usually correlate with the two other wasteful practices; Mura and Muri.

The eight categories of waste:

- Transportation (relates to the movement of products between locations and operations)

- Inventory (depicts the stock of finished goods, raw material and the Work in Progress (WIP) that a business obtain)

- Motion (details the physical activity of a machine or individual whilst comporting an action)

- Waiting (the operation of waiting for a worker or machine to finish, a delivery to arrive etc.)

- Over-processing (operations produced beyond what the customer call for)

- Over-production (producing higher number of products than what is needed from customers)

- Defects and Rework (product rejection and altering needs within the business operations)

An eight category is sometimes also added, disclosing the loss of human potential to create value whilst simultaneously producing waste. [3]

Mura

Mura presents the wastes of unevenness or irregularity and often occurs in linkage with inconsistency in customer demand, cycle times variation and an uneven work pace. It is most often used in relation to material flow, but can also be seen throughout a company's operations and day-to-day activities. The waste of unevenness is usually what creates many forms of the 7 categories of Muda. The Mura waste can often be eliminated by creating and encouraging openness in the supply chain, and is referred to as "levelling" and is often perceived as a counter measure to Mura.

The Mura waste would for example appear in a long-winded implementation project of a new IT system. In the initiation process, work is usually slow and planning, documentation and preparation tasks take longer than expected. After a while, time pressure is increased and work pace escalates, however, the anticipated date of completion is drawing near and the team works overtime to try to finish their tasks in time for the due. Suddenly, defects are discovered. Now the team needs to work even harder to attempt to correct the issues, but there is not enough time. This waterfall example illustrates how the waste of unevenness results in additional Muda wastes and affects the company. Resources and finances are needed to complete the project in time, the client is displeased and worried for the new finish date, the team is overworked and unmotivated.

Muri

Links to the waste of overburden by causing unnecessary stress and strain to employees or equipment. Muri can transpire as a result of lack of training, poorly developed workplaces, lack of maintenance, limited focus on safety and non-successful measures of performance. Muri is usually a result of the unevenness waste, Mura, but it also often commences from various organisational matters, for example procedural and structural bottlenecks.

Application

The three M's in lean manufacturing, Muda, Mura and Muri are often analogous and to eliminate one often means that the others is eliminated simultaneously. By applying various tools such as Kanban, Just in time (JIT) etc. it can strengthen production stream, assisting to reduce Mura, the waste of unevenness. The Trusted Platform Value (TPV) and the 5S methodology are frameworks that can be applied to eliminate the waste of overburden, Muri.

There is no ultimate approach or order on how to reduce the 3 M's, however The Danish Lean Forum has published a recommended elimination process:

1. Reduce Muda To be able to overcome the three wastes, Mura should be reduced to create more surplus for the Lean practices. By trying to identify the Muda wastes it is also likely that the two other M's will more easily appear.

2. Reduce Mura To reduce the unevenness waste, companies and organisations should aim for a healthy and strong alignment of activities and processes, as this will decrease delay and day-to-day waste time. this could for instance be done through Just-in-time systems, which are based on limited inventory, aiming to maximise productivity by reducing storage overhead.

3. Reduce Muri This should be done through competence management and weekly planning meetings. By ensuring follow-up meetings on the planning the process could also be more heavily linked to Kaizen, referring to the continuous improvement approach. Making use of self-organizing teams is also a useful way to ensure reduced burden to employees on project level, as the employees knows best how to coordinate and regulate their work in order to amend and improve it.

Aiming for standardised work is also a possible method, setting pre-decided task time, repeatable process steps and work flows. By making use of the standardised work method organisations have previously proven, not only to reduce Muri but also increase employee morale, quality and productivity and reduce the overall costs [4]

Limitations

“If you are going to do Toyota Production System, you must do it all the way. You also need to change the way you think. You need to change how you look at things.”—Taiichi Ohno. As stated by the creator of the Toyota Production System, eliminating the 3M's requires a thorough transformation. This is therefore incredibly demanding and especially for a medium or large-scale organisation, as you will need to innovate and change the entire mindset of the business. Teams are usually able to change direction and mentality in a much more rapid order, and is therefore more capable of implementing the Toyota Production System approach more immediately, eliminating the Muda, Mura and Muri waste much quicker. A possible method for larger organisations to achieve less waste and elimination of the 3M's is therefore to begin with focusing on reducing the 3M's within the teams and their respective projects. Doing this may also lead to shape the practices of the whole of the organisation.

Annotated bibliography

[1]Dansk Lean Forum, 2015. Muda, Mura and Muri, Hvem er de? https://leanforum.wordpress.com/2015/08/20/lean-muda-mura-muri/

Jiwat (2016). 3MUs (Muda, Mura, Muri): A lean Management tool with potentially ‘Big benefits’ for Project Management - IPMA Blog - Learn more about project management. [online] IPMA Blog - Learn more about project management. Available at: http://blog.ipma.world/3mus-muda-mura-muri-lean-management-tool-potentially-big-benefits-project-management/ [Accessed 19 Sep. 2017].

References

- ↑ [https://leanforum.wordpress.com/2015/08/20/lean-muda-mura-muri/] Liker, J (2004)

- ↑ ["Womack, J.(2006). From Lean Tools to Lean Management

- ↑ [http://agileknowhow.com/2016/07/14/getting-rid-3-ms-agile-tackles-problem-muda-mura-muri/] Mysliwiec, P (2016)

- ↑ [https://bobsleanlearning.wordpress.com/2010/01/14/muda/] Hobbard, B (2010)