Lean construction, takt time planning

| Line 11: | Line 11: | ||

Lean is a production philosophy that can be used for everything from goods to services. Lean aims to get rid of wastage and is focuses on a smooth process. With continues improvements it will be possible to optimize working processes in projects, with a goal of giving the costumer more value for money. An expert in the field who has done significant research on the subject Niklas Modig <ref>Modig, N., Åhlstrøm, P. (2012) ''Dette er Lean''. Stockholm: Rheologica. [19.09.2017]</ref> defines Lean as: | Lean is a production philosophy that can be used for everything from goods to services. Lean aims to get rid of wastage and is focuses on a smooth process. With continues improvements it will be possible to optimize working processes in projects, with a goal of giving the costumer more value for money. An expert in the field who has done significant research on the subject Niklas Modig <ref>Modig, N., Åhlstrøm, P. (2012) ''Dette er Lean''. Stockholm: Rheologica. [19.09.2017]</ref> defines Lean as: | ||

| − | ''“A strategy for flow efficiency, with key principles just-in-time and visual management”'' | + | ''“A strategy for flow efficiency, with key principles just-in-time and visual management”'' |

Just-in-time is about materials and workforce getting to the right place in the right time in the production process, while visual management is method that secures clean, tidy and well-organized workplace. | Just-in-time is about materials and workforce getting to the right place in the right time in the production process, while visual management is method that secures clean, tidy and well-organized workplace. | ||

| Line 18: | Line 18: | ||

By the end of the 1940s the car manufacturer Toyota was on the verge of bankruptcy. At the same time in USA Ford had about eight times more efficient within the same industry <ref>Santos, J., Torres, J., Wysk, R. (2006) ''Improving Production with Lean Thinking''. Wiley, 2006. [20.09.2017]</ref>. The leader group in Toyota got a real challenge. They had to achieve the same production rate as Ford within the next three years. If that didn’t happen Toyota would have to declare bankruptcy. The Vice president in Toyota at the time Taiichi Ohno had one clear demand: | By the end of the 1940s the car manufacturer Toyota was on the verge of bankruptcy. At the same time in USA Ford had about eight times more efficient within the same industry <ref>Santos, J., Torres, J., Wysk, R. (2006) ''Improving Production with Lean Thinking''. Wiley, 2006. [20.09.2017]</ref>. The leader group in Toyota got a real challenge. They had to achieve the same production rate as Ford within the next three years. If that didn’t happen Toyota would have to declare bankruptcy. The Vice president in Toyota at the time Taiichi Ohno had one clear demand: | ||

| − | ''“Deliver the right material, in the exact quantity, with perfect quality, in the right place just before its needed”'' <ref>Santos, J., Torres, J., Wysk, R. (2006) ''Improving Production with Lean Thinking''. Wiley, 2006. [20.09.2017]</ref> | + | ''“Deliver the right material, in the exact quantity, with perfect quality, in the right place just before its needed”'' <ref>Santos, J., Torres, J., Wysk, R. (2006) ''Improving Production with Lean Thinking''. Wiley, 2006. [20.09.2017]</ref> |

Toyotas production system was very inefficient and had to be changed quick. The actions that was made resulted in Toyota Production System (TPS), a system consisting of ideas and thoughts that are relevant also today <ref>Womack, J., Jones, D., Roos, D. (2007) ''The machine that changed the world''. New York: First free press. [19.09.2017]</ref>. The Just-in-time principal for example is based on Ohno’s words. When waiting with producing until the need in the marked is actually there, companies will save a lot in storage and the problem with old and no longer usable parts because they simply didn’t order them before it was necessary. | Toyotas production system was very inefficient and had to be changed quick. The actions that was made resulted in Toyota Production System (TPS), a system consisting of ideas and thoughts that are relevant also today <ref>Womack, J., Jones, D., Roos, D. (2007) ''The machine that changed the world''. New York: First free press. [19.09.2017]</ref>. The Just-in-time principal for example is based on Ohno’s words. When waiting with producing until the need in the marked is actually there, companies will save a lot in storage and the problem with old and no longer usable parts because they simply didn’t order them before it was necessary. | ||

| + | |||

| + | [[File:Diagram.png|thumb|650px|'''Figure 2''': To the right is the share price for GM, Ford and Toyota compared. To the left is sales volume for the same manufacturers compared <ref>Cachon, G (2008) ''Matching supply with demand''. New York: McGraw-Hill Irwin. [20.09.2017]</ref>]] | ||

Toyotas production system was largely recognized and the Americans soon adopted the system. It has been written several books about TPS and Lean Production. In the book “Lean Thinking” (2003) the writers Womack and Jones summarizes the five ground principles of Lean Production <ref>Womack, J., Jones, D. (2003) ''Lean Thinking''. New York: First Free Press. [20.09.2017]</ref>. | Toyotas production system was largely recognized and the Americans soon adopted the system. It has been written several books about TPS and Lean Production. In the book “Lean Thinking” (2003) the writers Womack and Jones summarizes the five ground principles of Lean Production <ref>Womack, J., Jones, D. (2003) ''Lean Thinking''. New York: First Free Press. [20.09.2017]</ref>. | ||

| Line 61: | Line 63: | ||

From the more traditional planning methods, it is usual to plan the different tasks long before they are actually going to happen and is often done by people high up in the hierarchy. Traditionally it is believed that early planning is the way to go, but this doesn’t necessarily account for unforeseen events and how much time these tasks are actually going to take. As the name tells, “Last Planner” describes that the people doing the physical job are the ones to plan the tasks. They are the ones with the most practical experience and will have a better understanding on how much time things will take. In table 1, the major differences between Last Planner and traditional planning is shown. Last Planner is therefore based on the different fields doing their part of the planning and the different fields are involved earlier. | From the more traditional planning methods, it is usual to plan the different tasks long before they are actually going to happen and is often done by people high up in the hierarchy. Traditionally it is believed that early planning is the way to go, but this doesn’t necessarily account for unforeseen events and how much time these tasks are actually going to take. As the name tells, “Last Planner” describes that the people doing the physical job are the ones to plan the tasks. They are the ones with the most practical experience and will have a better understanding on how much time things will take. In table 1, the major differences between Last Planner and traditional planning is shown. Last Planner is therefore based on the different fields doing their part of the planning and the different fields are involved earlier. | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Traditional | ||

| + | ! Last Planner | ||

| + | |- | ||

| + | | Changes come up in the process and might lead to major changes. | ||

| + | | Looking to see the full picture of the work needed before it is too late. | ||

| + | |- | ||

| + | | The project has one milestone – completion. | ||

| + | | Every milestone is treated equally. | ||

| + | |- | ||

| + | | Main work schedule is the base for all detail planning. | ||

| + | | Progress is divided into defined faces. | ||

| + | |- | ||

| + | | Project manager or responsible planner is responsible for scheduling. | ||

| + | | Making commitment through involving workers from the “floor” in planning. | ||

| + | |- | ||

| + | | Summary of progress | ||

| + | | Meeting structure to make every production line better. | ||

| + | |- | ||

| + | | “It will probably be better next time”-attitude. | ||

| + | | Follow-up on every deviation and disclosure of reason for mistakes. | ||

| + | |} | ||

Last Planner adds a production control system to the traditional way of planning, where what “should” be done is changed to what “can” be done. It gives a good overview on what is left, and will be the basis for the weekly schedules. With Last Planner the commitment to the work plans will be stronger than what is the case for traditional planning. | Last Planner adds a production control system to the traditional way of planning, where what “should” be done is changed to what “can” be done. It gives a good overview on what is left, and will be the basis for the weekly schedules. With Last Planner the commitment to the work plans will be stronger than what is the case for traditional planning. | ||

Revision as of 20:31, 28 September 2017

Lean construction is a project based production process which focuses on good, reliable and predictable scheduling. The focus and the whole idea with lean construction is maximizing value and minimizing waste, especially in terms of working hours. It is a new way of thinking and will take time and effort to implement into the daily routine of a construction worker and an engineer, but will in the long run be cutting cost, increase productivity, make the whole construction process faster and managing projects more efficiently if done the right way.

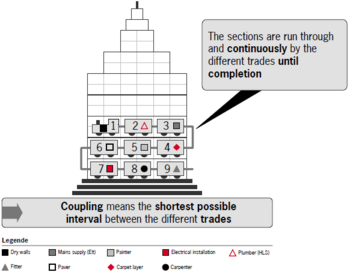

When using takt-time planning the construction industry looks at a concept very similar to the assembly line principal. The difference is that the workers and different sectors of the team moves around. To visualize this, it will be like a train with different fields in every train car driving in a decided order through the building. I order to prevent stoppages in the production and workers waiting, every car needs to have the same pace. Results from various studies show that workers working in a takt time system has more control and a tidier workplace. Takt time planning can also show for less conflicts, better workforce and higher utilization of labor, than in more traditional planning concepts.

Contents |

Background

The concept of Lean was first introduced and used in 1988. With the book “the machine that changed the world” [2] Lean got its breakthrough. The book was based on a research program (International Motor Vehicle Program) from MIT in Cambridge, Massachusetts, USA. The Research was based on finding out why and how Toyota was more competitive than American car manufacturers. The result of the research program was Lean Production.

What is Lean?

Lean is a production philosophy that can be used for everything from goods to services. Lean aims to get rid of wastage and is focuses on a smooth process. With continues improvements it will be possible to optimize working processes in projects, with a goal of giving the costumer more value for money. An expert in the field who has done significant research on the subject Niklas Modig [3] defines Lean as:

“A strategy for flow efficiency, with key principles just-in-time and visual management”

Just-in-time is about materials and workforce getting to the right place in the right time in the production process, while visual management is method that secures clean, tidy and well-organized workplace.

Lean Production

By the end of the 1940s the car manufacturer Toyota was on the verge of bankruptcy. At the same time in USA Ford had about eight times more efficient within the same industry [4]. The leader group in Toyota got a real challenge. They had to achieve the same production rate as Ford within the next three years. If that didn’t happen Toyota would have to declare bankruptcy. The Vice president in Toyota at the time Taiichi Ohno had one clear demand:

“Deliver the right material, in the exact quantity, with perfect quality, in the right place just before its needed” [5]

Toyotas production system was very inefficient and had to be changed quick. The actions that was made resulted in Toyota Production System (TPS), a system consisting of ideas and thoughts that are relevant also today [6]. The Just-in-time principal for example is based on Ohno’s words. When waiting with producing until the need in the marked is actually there, companies will save a lot in storage and the problem with old and no longer usable parts because they simply didn’t order them before it was necessary.

Toyotas production system was largely recognized and the Americans soon adopted the system. It has been written several books about TPS and Lean Production. In the book “Lean Thinking” (2003) the writers Womack and Jones summarizes the five ground principles of Lean Production [8].

• Value: The value of a product is defined by the costumer.

• Cashflow: Identifying of necessary activities to achieve the costumers wanted value and quality. Increase value and minimize wastage.

• Flow: The product should go through the production process, which should only consist of value, no stoppage, mistakes and delays.

• Pull-principle: Resources will be used when needed. When the costumer has the need for it, the production should start.

• Improvements: Perfection is a process happening through continues improvements.

Lean Construction

The name Lean construction was used for the first time in 1993, as a result of a report written by Lauri Koskela. The building industry is suffering of projects being delayed, budget cracks and mistakes. Lean construction was therefore introduced as a continuation of Lean Production, with the goal of better flow in the industry. The Americans were early out with using the philosophy and established organizations, International Group of Lean Construction (IGLC) in 1993 and Lean Construction Institute (LCI) in 1997 being the most prominent.

Even though Lean Construction is based on principles from the industry, there is a difference between industry and construction, Koskela is referring to some of the differences [9].

• Varying premises: Deliveries in construction is done on the same area as the physical work is done.

• Time: The different operations in a construction project is done in a relatively short time.

• Perspective: Production in a fabric goes over a much longer period of time, while the construction industry has a lot more time pressure and shorter projects.

• Sense of responsibility: Different parties takes part of a project at different times with a varying sense of responsibility.

• Repetition: Construction is in large part not directly repeating and most projects are unique.

• Engaged costumer: The owner of the project is in a much bigger way involved in the process compared to the industry where the costumer usually just buys the end product.

Howell [10] is despite these differences stating that there are in fact a lot of superior similarities which makes a lot of these principles possible to use directly into Lean Construction. A lot of the bigger parties in construction has seen the value in implementing tools from Lean Construction and is looking at the industry in their way of working.

When using Lean Construction, a full change in the process of execution is needed. Both engineering and production will have to change. This thinking is called Lean Project Delivery System (LPDS) and is described in detail by Ballard (2008) [11]. This way of thinking is divided into five separate phases. Between every phase is an overlap to make a good flow between each phase.

In figure 3 every colored triangle represents a phase, and the overlapping. In the phase of project definition should the purpose be explained, what is the costumers demands, values and needs. Once the costumer has made his statement the design phase begins. Here will the design concept be decided as well as the design process. In the next phase call Lean Supply, product design should be finalized, and will be as detailed as possible. The process of what is needed in terms of equipment and materials will start and soon go over to the Lean Assembly phase. This is where the building is actually built, installed and handed over to the costumer before the last phase takes place. The building will be used, maintained and be operative in the Using phase [12].

The Last Planner System

The Last Planner System (Last Planner) is a planning tool developed by Glenn Ballard and described in his PhD thesis. Last Planner is today one of the most common tools from Lean Construction with a goal of making better flow and increased efficiency in production.

From the more traditional planning methods, it is usual to plan the different tasks long before they are actually going to happen and is often done by people high up in the hierarchy. Traditionally it is believed that early planning is the way to go, but this doesn’t necessarily account for unforeseen events and how much time these tasks are actually going to take. As the name tells, “Last Planner” describes that the people doing the physical job are the ones to plan the tasks. They are the ones with the most practical experience and will have a better understanding on how much time things will take. In table 1, the major differences between Last Planner and traditional planning is shown. Last Planner is therefore based on the different fields doing their part of the planning and the different fields are involved earlier.

| Traditional | Last Planner |

|---|---|

| Changes come up in the process and might lead to major changes. | Looking to see the full picture of the work needed before it is too late. |

| The project has one milestone – completion. | Every milestone is treated equally. |

| Main work schedule is the base for all detail planning. | Progress is divided into defined faces. |

| Project manager or responsible planner is responsible for scheduling. | Making commitment through involving workers from the “floor” in planning. |

| Summary of progress | Meeting structure to make every production line better. |

| “It will probably be better next time”-attitude. | Follow-up on every deviation and disclosure of reason for mistakes. |

Last Planner adds a production control system to the traditional way of planning, where what “should” be done is changed to what “can” be done. It gives a good overview on what is left, and will be the basis for the weekly schedules. With Last Planner the commitment to the work plans will be stronger than what is the case for traditional planning.

Takt-Time Planning

Takt-time planning is a method with the potential to make a more efficient construction process [13]. The purpose with the method is to get better workflow, with an even and reliable pace for every team going through the building.

In the progress planning, there will be set up a “train” of field carts which go after each other through the construction process. The building will then be divided into zones based on workload, location and function. To get the easiest and most measurable progress each cart will go through a zone in five days, Monday through Friday. Frandson [14] shows for a takt-time planning process through six steps. The order might vary, but will for the most part be the same.

• Collecting data: Planning through Last Planner says how, who and in which order the work shall be done.

• Dividing into zones: The size of the zone and content is defined for the “train” to go through all the zones in the same pace.

• Identifying production line (order of fields): The order is decided and dependencies revealed by the people doing the work.

• Timetable for each field: The execution can be simulated, for the fields to understands the different dependencies towards each other.

• Workflow: If some tasks is non-typical or the experience on the field is low it has to be revealed. Potential changes in the workflow will have to be done.

• Determination of work plan: The production needs close follow-up after it has started. Deviations need to be revealed, changes need to be done early to prevent mistakes through the production line.

Frandson [15] presents a summary of the process, but after the planning process is done, more things and problems can come up. It is therefore important with a good structure in the planning process to get a good result, but also adjustable. There are many different ways in doing this with no right or wrong.

Dividing into zones

To plan for takt-time planning the zone sizes have to be decided first. The zones are often defined in a very natural way through phase or floor plans, geometric zones, fire cell or sections. It is important that zones are approximately the same size, considering workload, location and function. The zones also shouldn’t be bigger than 1000 m2 [16].

The workload for the different fields might vary a lot. It is therefore important to find the field with the most likely biggest workload and divide the zones there after. It is said that not all projects can be optimized with takt-time planning, but it is important to look at it as a whole, find similarities and don’t think too complicated when working with Lean. The idea of dividing into zones is the no matter if the project is an industry building, school, hotel or apartment building.

It can be a few zones that sticks out from the rest and might be harder to plan. These can be taken out of the takt-time plan and is in takt-time planning called a buffer zone. Especially for the more technical fields, the buffer zone will be important. This is because the workload might vary a lot. To prevent big differences in the number off workers between the zones, the buffer zone can be used to prevent big changes in manpower. In zones with a smaller workload, some of the workers will be moved over to the buffer zone to even out the staffing. Typical buffer zones can be technical rooms, larger wardrobes or sports halls, parking cellars etc.

Production line

For TTP to get the wanted result – that the fields get to work undistracted – all the production lines must be planned in an expedient way. All dependencies must be considered, like the walls must be put up by the carpenter before the painter start painting it. A good method in determining the order will be to plan backwards. Start with the work that is going to finish last, work your way backwards till you have a finished order which is called the production line.

Where exactly all the fields are divided is up each different project. The carpenter cart will often have easier defined tasks than the rest, and might therefore be smart to divide into different carts and different fields. It is also here important to get the right information from all the different production teams or fields, in order to suggest an order for the fields[17].

Duration for the fields

Takt-time

A good takt-time plan is known for short, realistic activities [18]. At the same time, it will be so efficient that there will not be room for unforeseen events. An uncertainty analysis should be taken before every single zone, so the takt-time won’t be delayed. It is essential that the takt-time is upheld when it is decided, which that a good plan and a good planner is crucial for TTP [19].

The superior timetable with short-term goals will be set by the management and leaders for the project. This is done with collecting information from the different fields with their wishes and suggestions for the takt-time, together with field order and zoning.

Critical line

The critical line represents the activity that takes the most time and is defined for other activities and the end date of the project. Delays on the critical line may lead to delays on the delivery date.

Backwards planning

Backwards planning is a method that uses Last Planner as a base. The method is a tool which involves every worker on a construction site and will give a sense of ownership and the timetable. When a worker is taking part in the making of a timetable it will be harder for them not to comply with the plan. The Method can strengthen the team-feeling for the workers, make them think more as a team and be less selfish.

Before the planning can even begin the building must be divided in reasonable big zones and the cart order must be decided. All parts of the team, like entrepreneurs, fields and workers doing the job on the site should take part in the planning meeting. If a field is excluded there will be a bigger risk of the timetable not being upheld. It is also important that all parts understand the principles and the plan that’s made.

https://www.researchgate.net/figure/306237179_fig2_Figure-2-Takt-plan-of-Project-3

Workflow

To get a good flow in the work zones and between the zone changes, different buffers and tools are used. When talking about buffers in construction it is usually four different types [20]:

• Time buffers.

• Capacity buffers.

• Inventory buffers.

• Financial buffers.

Out of these the time buffer is the most commonly talked about, which is about putting in extra time between the activities. Capacity buffer is about giving one team less work than what they theoretically could have done and in that way, takes in account for for example illness or other absence. Workers can also be put to the buffer activity which isn’t put into the production line. Inventory buffer could be to have extra of something in storage or order something extra just in case. Financial buffer is putting away more money than necessary to be able to buy something extra when needed [21].

To put in a lot of buffers for a project could be costly, but it will be more challenging to finish a project without them. It is therefore as important with good routines for planning and evaluation to minimize the use of buffers [22].

Finishing production plan

For the production plan can be accepted by all parts there is one thing that must be decided. The order of the production “train”. In other words, where is the first activity after solid construction going to start up? It is different from project to project, but the rule of thumb is to start at the top and work down to the bottom [23].

Figure text: Production order with the different start dates for each zone. The red “train” represents the “normal” zones. The Green the lab-zones. The division is favorable because lab-zones are very different from “normal” zones.

The most important thing is to start the train in a simple zone. It is crucial so the train gets started and the carts don’t get delayed already in the first zone. This can cause the project to be behind schedule already from the beginning. As seen in the figure there is a train going through the building. One green and one red one. It can be favorable to set up more trains if the building consists of many different types of rooms and zones. This example is from a new technological building for NTNU in Trondheim, Norway and will therefore have a lot of lab-zones. Because of this, there were decided to divide into to two trains [24].

References

- ↑ http://docplayer.me/14839468-Filosofien-i-toyota-production-system-har-videre-blitt-utviklet-og-tilpasset-byggebransjen-av-porsche-consulting-for-a-bygge-i-takt.html

- ↑ Womack, J., Jones, D., Roos, D. (2007) The machine that changed the world. New York: First free press. [19.09.2017]

- ↑ Modig, N., Åhlstrøm, P. (2012) Dette er Lean. Stockholm: Rheologica. [19.09.2017]

- ↑ Santos, J., Torres, J., Wysk, R. (2006) Improving Production with Lean Thinking. Wiley, 2006. [20.09.2017]

- ↑ Santos, J., Torres, J., Wysk, R. (2006) Improving Production with Lean Thinking. Wiley, 2006. [20.09.2017]

- ↑ Womack, J., Jones, D., Roos, D. (2007) The machine that changed the world. New York: First free press. [19.09.2017]

- ↑ Cachon, G (2008) Matching supply with demand. New York: McGraw-Hill Irwin. [20.09.2017]

- ↑ Womack, J., Jones, D. (2003) Lean Thinking. New York: First Free Press. [20.09.2017]

- ↑ Koskela, L. (1992) Application of the New Production Philosophy of Construction. Stanford University [20.09.2017]

- ↑ Howell, G. (1999) What is Lean Construction. International Group of Lean Construction. [20.09.2017]

- ↑ Ballard, G. (2008) The Lean Project Delivery System: An Update. Lean Construction Journal [20.09.2017]

- ↑ Ballard, G. (2008) The Lean Project Delivery System: An Update. Lean Construction Journal [20.09.2017]

- ↑ Frandson, A., Berghede, K., Tommelein, I. (2014) Takt-time planning and the last planner. Preceedings IGLC-22. [21.09.2017]

- ↑ Frandson, A., Berghede, K., Tommelein, I. (2014) Takt-time planning and the last planner. Preceedings IGLC-22. [21.09.2017]

- ↑ Frandson, A., Berghede, K., Tommelein, I. (2014) Takt-time planning and the last planner. Preceedings IGLC-22. [21.09.2017]

- ↑ Frandson, A., Berghede, K., Tommelein, I. (2014) Takt-time planning and the last planner. Preceedings IGLC-22. [21.09.2017]

- ↑ Frandson, A. Berghede, K., Tommelien, I. (2013) Takt-time planning for Constuction of Exterior Cladding. Proceedings IGLC-21 [27.09.2017]

- ↑ Grimsmo, E. (2010) Resultatrapport prosjekt 14318 Organisasjonsutvikling og læring knyttet til trimmet bygging. Byggekostnadsprogrammet. [online] Available at: http://byggekostnader.no/article.php?articleID=478&categoryID=279 [28.09.2017]

- ↑ Frandson, A. Berghede, K., Tommelien, I. (2013) Takt-time planning for Constuction of Exterior Cladding. Proceedings IGLC-21 [27.09.2017]

- ↑ Østby-Deglum, E., Svalestuen, F., Drevland, F. (2013) Prosjekteringsledelse. Trondheim: NTNU [28.09.2017]

- ↑ Østby-Deglum, E., Svalestuen, F., Drevland, F. (2013) Prosjekteringsledelse. Trondheim: NTNU [28.09.2017]

- ↑ Østby-Deglum, E., Svalestuen, F., Drevland, F. (2013) Prosjekteringsledelse. Trondheim: NTNU [28.09.2017]

- ↑ Frandson, A., Berghede, K., Tommelein, I. (2014) Takt-time planning and the last planner. Preceedings IGLC-22. [21.09.2017]

- ↑ NTNU Teknologibygget (2014-17) by project manager Odd Einar Landsen.

1. [1] 2. [2] 3. [3] 4. [4] 5. [5] 6. [6] 7. [7] 8. [8] 9. [9] 10. [10] 11. [11] 12. [12]

13. [13]

Cite error:

<ref> tags exist, but no <references/> tag was found