COWI2020

| Line 49: | Line 49: | ||

'''6) Monitoring and review process''' | '''6) Monitoring and review process''' | ||

| + | |||

| + | == Value Stream Mapping == | ||

| + | |||

| + | Value Stream Mapping is a tool from Lean Construction that has a significant impact in revealing the waste of production. | ||

| + | The basic idea behind Value stream mapping is to provide a visual overview of the value stream in the production or organization that can help the organization improve the value stream by eliminating waste. The value stream analysis provides a clear view of the production from raw materials to finished product. The survey provides a better understanding of how the flow of materials and information flow through the value stream. | ||

| + | |||

| + | VSM tool has shown to improve communication between the subjects through involvement and collaboration, enabling a structured method to work on continuous improvement and to solve communication problems in projects. | ||

== Benefits Realisation Management == | == Benefits Realisation Management == | ||

Revision as of 11:37, 28 February 2020

Contents |

SWOT Analysis

The SWOT analysis is a tool that provides a basic framework for situation analysis. It generates lists or inventories of strengths, weaknesses, opportunities and threats which can be used when generating strategies.In project and program management the SWOT analysis can be carried out in all phases of the life cycle in order to monitor and manage internal and external environments. In portfolio management the SWOT analysis can be used to identify new projects, although, there is no single guide or manual on how to perform a SWOT analysis. The conventional SWOT analysis is usually presented in a 2X2 matrix which generates four boxes of inventories - one for strengths, one for weaknesses, one for opportunities and one for threats. See figure to the right.

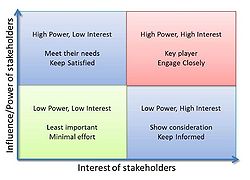

Stakeholder Management

Stakeholders are organisations and persons who are actively involved in a project or affected by a project at some stage during its execution or completion. The ISO 21500 standard defines a stakeholder as "a person, group or organisation that has interests in, or can affect, be affected by, or perceive itself to be affected by, any aspect of the project". The purpose of identifying and classifying stakeholders is to simplify the process of identifying stakeholder concerns and thereby obtaining an easier tool for solving issues.The growing focus on stakeholder analysis is a clear reflection of the general tendency to recognise how stakeholders can influence decision-making processes.Based on the analysis of the stakeholders these can be mapped into overall categories, which allows the managers in an organisation to take action. The most commonly used stakeholder map is the power/interest matrix, seen in the figure to the right, which gives an easy and simple overview of what the different categories require with regards to what their needs are and how much they are able to influence the project.

Benefits Map

Benefits Map helps mapping possible benefits related to different projects and/or programs. This is to make it easier to pick the solutions giving the most or best benefits for the relevant stakeholders. Examples on benefits could be economical aspects or user friendliness. It is important to include key stakeholders and get their input in the benefit mapping process.The Benefit Mapping Process is usually divided into three important stages; identification of benefits, execution of benefits and the sustain of benefits. This means that the process is not only something that needs to be implemented from the start, but carried out throughout the project and even after project implementation.

Earned Value Analysis

An Earned Value Analysis (EVA) used quantative analysis techniques and object performance indicators to measure both work progress and related cost to determine the overall efficiency of a respective activity, work package or project. To be able to do this, the analysis takes into account the scope of the project, the schedule of work and the work undertaken. This is to map the current situation, how much resources that has already been used and how much recourses that is necessary to finalize the project.

To successfully execute an EVA the following steps needs to be done:

1) Time-based schedule

2) Work Breakdown Structure

3) Cost Assessment

4) Progress measurement

5) Responsibility/ authority matrix

6) Monitoring and review process

Value Stream Mapping

Value Stream Mapping is a tool from Lean Construction that has a significant impact in revealing the waste of production. The basic idea behind Value stream mapping is to provide a visual overview of the value stream in the production or organization that can help the organization improve the value stream by eliminating waste. The value stream analysis provides a clear view of the production from raw materials to finished product. The survey provides a better understanding of how the flow of materials and information flow through the value stream.

VSM tool has shown to improve communication between the subjects through involvement and collaboration, enabling a structured method to work on continuous improvement and to solve communication problems in projects.