Integrated Cost and Schedule Control

(→Cost Control) |

(→Cost Control) |

||

| Line 36: | Line 36: | ||

===Cost Control=== | ===Cost Control=== | ||

| − | [[File:Cost control (Baseline). | + | [[File:Cost control (Baseline).png|300px | thumb| |'''Figure 1:''' Cost Control comparison.]] |

A cost control system should follow the next steps<ref name="multiple"> Barron. (1994). “Integrated cost and schedule control”, 3/1–3/3.</ref>: | A cost control system should follow the next steps<ref name="multiple"> Barron. (1994). “Integrated cost and schedule control”, 3/1–3/3.</ref>: | ||

Revision as of 16:36, 17 September 2015

It is generally known that without a good planning it is rather difficult to implement a project successfully. However, appropriate planning does not guarantee a successful execution of the project because the future is highly unpredictable and uncertain. Therefore, it is really important to control how the different tasks are progressing. In order to get an overview of the current situation of the project, we should compare the actual state with the planned program in terms of Scope, Schedule and Costs.

When it comes to measuring project performance, the planned schedule can be compared to the accomplished one (Schedule Control). But at the same time, the budgeted cost and the actual cost can also be balanced (Cost Control). Nevertheless, if this aspects are analyzed separately, one can initially think that if a project meets the objectives of cost, it is on plan, but the truth could be that it is in reality delayed. In cases like the previous example, how do we actually know the overall situation of the project? How can delays be compared with monetary data? A very useful method to achieve all this goals without subjective interpretations of the reality is the Earned Value Management (EVM) technique, which will be one of the main topics developed in the present article. Moreover, with this method you can not only evaluate the performance of the project at any time, but also analyze future trends to estimate the cost and time of completion of the project.

Contents |

Background

Completing a project on schedule is important not only in terms of time but also economically. Reducing the duration of a project can impact the overall costs in terms of less salary payments, interests on loans or preventing loss of profit (for example, if a project consists on developing a new toy before Christmas and it finishes in February).

The main rewards that can be obtained by controlling the cost and schedule of the different tasks of a project are [1]:

- Achieving better management visibility.

- Developing disciplined planning.

- Realistic schedules.

- Achievable objectives.

- And, finally, the project ending on schedule and within budget.

Over the years, the control of cost and schedule has been usually done separately. However, the best option concerning the objective of obtaining an overall impression about how the project is progressing, is to integrate the control of both aspects. Therefore, even when the two first methods are also interesting and will be shortly described, the main method developed in this article is the EVM.

((describe the tool, concept or theory and explain its purpose. The section should reflect the current state of the art on the topic))

Application

((provide guidance on how to use the tool, concept or theory and when it is applicable))

Schedule Control

In order to perform a schedule control, the next steps should be followed [1]:

- Development of schedule having using management tools such as the WBS (Work breakdown structure) and the Work Packages, which give information of the tasks that need to be completed in terms of resources needed, time to complete it, budget, required inputs from other tasks, etc.

- Communication of the schedule using, for example, a Gant Chart.

- Evaluation and information of how the project is being accomplished.

- Identification of problems comparing the planned schedule to the executed one.

- Development of procedures for correcting such errors and schedule redirection.

Cost Control

A cost control system should follow the next steps[1]:

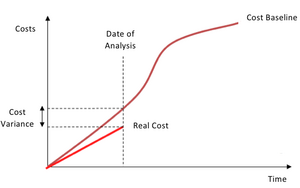

- Distribution of the budget through the different tasks of the project and creation of a cost baseline, which will be the planned budget accumulated over time. The data can be based on historical results or theoretical cost performance.

- Measurement and comparison of the planned and actual performance.

- Calculation of the variances and investigation of the reasons of those which are unfavorable.

- Analysis and implementation of corrective measures.

Integrated Cost and Schedule Control (EVM technique)

Drawbacks and Limitations

It is very important that the data concerning how cost and schedule are developing are as precise and consistent with reality as possible. On the one hand, regarding the control of the progress of a project, it is very important that the capture of the state of a task is part of the work that has to be developed in each of the Work Packages. In other words, the workers should understand that the process control is one of their obligations and that they should provide feedback of the deviations that they detect as quick as possible. On the other hand, the control should be done over how the work is going on and not over how the employees are working. With this two indications concerning the human resources, the results of the control would be more objective and reliable. If the previous is not happening, the whole control process will be based on inaccurate data.

((critically reflect on the tool/concept/theory. When possible, substantiate your claims with literature))

References

((Provide key references (3-10), where a reader can find additional information on the subject. Summarize and outline the relevance of each reference to the topic. (around 100 words per reference). The bibliography is not counted in the suggested 3000 word target length of the article.))