Cost control with statistic tools

(→Earned Value Measurement Techniques) |

(→Earned Value Measurement Techniques) |

||

| Line 67: | Line 67: | ||

===Earned Value Measurement Techniques=== | ===Earned Value Measurement Techniques=== | ||

According to the Project Management Institute(PMI). (2005) Practice Standard for Earned Value Management, these are the significant techniques in the Earned Value Measurement<ref name="PMI_EV"></ref>: | According to the Project Management Institute(PMI). (2005) Practice Standard for Earned Value Management, these are the significant techniques in the Earned Value Measurement<ref name="PMI_EV"></ref>: | ||

| + | |||

| + | *Fixed Formula | ||

| + | A typical example of fixed formula is the 50/50 technique. With this method, 50 percent of the work is credited as complete for the measurement period in which the work begins, regardless of how much work has actually been accomplished. The | ||

| + | remaining 50 percent is credited when the work is completed. Other variations of the | ||

| + | fixed formula method include 25/75 and 0/100. Fixed formula techniques are most | ||

| + | effectively used on small, short-duration tasks. | ||

| + | |||

| + | *Weighted Milestone | ||

| + | The weighted milestone technique divides the work to be completed into segments, | ||

| + | each ending with an observable milestone; it then assigns a value to the achievement | ||

| + | of each milestone. The weighted milestone technique is more suitable for longer | ||

| + | duration tasks having intermediate, tangible outcomes. | ||

| + | |||

| + | *Percent Complete | ||

| + | The percent complete technique is among the simplest and easiest, but can be the | ||

| + | most subjective of the Earned Value measurement techniques if there are no objective | ||

| + | indicators to back it up. This is the case when, at each measurement period, the | ||

| + | responsible worker or manager makes an estimate of the percentage of the work | ||

| + | complete. These estimates are usually for the cumulative progress made against the | ||

| + | plan for each task. However, if there are objective indicators that can be used to arrive | ||

| + | at the percent complete (for example, number of units of product completed divided | ||

| + | by the total number of units to be completed), then this can be a more useful technique. | ||

| + | |||

| + | *Apportioned Effort | ||

| + | If a task has a direct, supportive relationship to another task that has its own Earned | ||

| + | Value, the value for the support task may be determined based on (or apportioned | ||

| + | to) the Earned Value of the reference base activity. Examples of proportional tasks | ||

| + | include quality assurance and inspection activities. | ||

| + | |||

| + | *Level of Effort | ||

| + | Some project activities do not produce tangible outcomes that can be measured | ||

| + | objectively. Examples include project management and operating a project technical | ||

| + | library. These activities consume project resources and should be included in EVM | ||

| + | planning and measurement. In these cases, the level of effort (LOE) technique is used for determining Earned Value. A Planned Value is assigned to each LOE task for each | ||

| + | measurement period. This Planned Value is automatically credited as the Earned Value | ||

| + | at the end of the measurement period. | ||

==Application== | ==Application== | ||

Revision as of 04:36, 23 February 2021

Contents |

Abstract

Cost is an important factor that affects business forecasting, decision-making and analysis. Under the conditions of a market economy, market competition is extremely fierce. To win in the fierce competition, an enterprise must face the market and adopt modern management and scientific methods to make business predictions for the arrangement of production plans, the selection of process plans, and the development of new products, so as to make correct decisions. At the same time, in order to better analyze the production and operation of the enterprise, effective measures must be taken to promote the enterprise to complete various plans and tasks. Only by providing accurate cost information in a timely manner can the forecasting, decision-making and analysis activities be established on a reliable basis. Therefore, cost indicators have become important data for business forecasting, decision-making and analysis.

With the increasingly competition among enterprises in the market, people pay more and more attention to the importance of project cost control. Cost control has become the main symbol and indispensable content of project management's in-depth development. Cost control has become the foundation of the economic accounting system of construction enterprises, and its position in project management is particularly important.

Cost control can effectively achieve the overall goal of maximizing corporate profits and enhancing its own market competitiveness. Only by correctly understanding the importance of cost control and clarifying the content of cost control can we actively take action to find effective ways to improve project management, reduce costs, achieve the goal of cost management, and ultimately realize the requirements of maximum profit for enterprises.

The Wiki focuses on the cost control using statistical tools in the Project management. Firstly, the basic concept of the cost control is introduced. One of the major cost control method Earn Value method is introduction with concept and characteristics. After that the application of the method with different indicators and statistical tools are presented. The limitation and annotated bibliography are discussed in the end.

Basic Concept

Cost control is one of the major parts in the cost management in Project management. Cost control is the process of monitoring project status to update project costs and managing changes to the cost baseline. The main benefit of this process is that the cost baseline is maintained throughout the project. The appropriateness of this process is that the cost baseline is maintained throughout the project. [1]

Under the conditions of a market economy, the pursuit of profit maximization and improving economic efficiency are the main goals of enterprises. Controlling project costs is an important way for companies to reduce costs and increase profits. Controlling project costs is an important guarantee for enhancing the competitiveness of enterprises. Therefore, it is necessary to strengthen project cost management, continuously reduce costs, improve enterprise competitiveness, and increase economic benefits.

The major component of the Project cost control includes:[1]

- Influencing the factors that create changes to the authorized cost baseline;

- Ensuring that all change requests are acted on in a timely manner;

- Managing the actual changes when and as they occur;

- Ensuring that cost expenditures do not exceed the authorized funding by period, by WBS component, by activity, and in total for the project;

- Monitoring cost performance to isolate and understand variances from the approved cost baseline;

- Monitoring work performance against funds expended;

- Preventing unapproved changes from being included in the reported cost or resource usage;

- Informing appropriate stakeholders of all approved changes and associated cost; and

- Bringing expected cost overruns within acceptable limits.

Cost control is vitally important in all kind of projects, especially significant in construction projects. If construction companies want to gain a competitive advantage in the fierce market competition, they must effectively control the production costs of construction projects. The reason is that during the entire project life cycle, people pay attention to the cost control work of the construction enterprise, which can effectively avoid unnecessary waste on the construction site. Conversely, as an important work content of construction enterprises, project cost management and control of construction enterprises can also reflect the overall management and control capabilities of enterprises to a certain extent. The effect of cost control is ideal, which means that the company's overall control ability is good. Therefore, improving the project cost control of construction enterprises is of great significance to improving the overall management and control level of construction enterprises.

Any construction company hopes to obtain more economic benefits through construction projects to promote the development of the company's business strategy. Company has to strengthen the project cost control of construction companies, make cost planning in the preparatory work of the project, do a good job of cost control during project implementation, analyze and summarize the experience of cost control after the project is completed, and continuously improve the level of project cost control of construction companies. It can guarantee the benefits of the project to the greatest extent, and effectively reduce the construction cost to the minimum through cost control measures, help construction companies accumulate more capital, and achieve the purpose of enhancing the competitiveness of construction companies in the same industry.

Cost Control Input[1]

The input of the cost control includes following parts:

- Project management plan, which includes cost management plan, cost baseline and performance measurement baseline. The cost management plan indicates how the project cost will be managed and controlled. The cost baseline is applied as the comparison with actual results to determine if a change, corrective action, or preventive action is necessary. Similarly, performance measurement baseline is compared to actual results to determine if a change, corrective action, or preventive action is necessary.

- Project documents: Lessons learned earlier in the project can be applied to later phases in the project to improve cost control.

- Project funding requirements: The project funding requirements include projected expenditures and anticipated liabilities.

- Work performance data: Work performance data contains data on project status such as which costs have been authorized, incurred, invoiced, and paid

- Organizational process assets: The organizational process assets that can influence the Control Costs process include: Existing formal and informal cost control-related policies, procedures, and guidelines; Cost control tools; and Monitoring and reporting methods to be used.

Cost Control Analysis: Earned Value Method

Concept

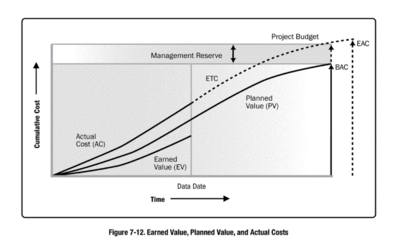

The data analysis is always involved in the cost control and one common method is Earn value analysis. Earned value analysis compares the performance measurement baseline to the actual schedule and cost performance. EVM integrates the scope baseline with the cost baseline and schedule baseline to form the performance measurement baseline. EVM develops and monitors three key dimensions for each work package and control account:[1] [2]

The following definitions are quoted from the Project Management: A guide to the Project Management Body of Knowledge (PMBOK guide) 6th Edition (2017) Chapter 7.4[1]

- Planned value. Planned value (PV) is the authorized budget assigned to scheduled work. It is the authorized budget planned for the work to be accomplished for an activity or work breakdown structure (WBS) component, not including management reserve. This budget is allocated by phase over the life of the project, but at a given point in time, planned value defines the physical work that should have been accomplished. The total of the fines the physical work that should have been accomplished. The total of the PV is sometimes referred to as the performance measurement baseline (PMB). The total planned value for the project is also known as budget at completion (BAC).[1]

- Earned value. Earned value (EV) is a measure of work performed expressed in terms of the budget authorized for that work. It is the budget associated with the authorized work that has been completed. [1]

- Actual cost. Actual cost (AC) is the realized cost incurred for the work performed on an activity during a specific time period. It is the total cost incurred in accomplishing the work that the EV measured. The AC needs to correspond in definition to what was budgeted in the PV and measured in the EV (e.g., direct hours only, direct costs only, or all costs including indirect costs). The AC will have no upper limit; whatever is spent to achieve the EV will be measured.[1]

Characteristic

Earned Value Management has proven itself to be one of the most effective performance measurement and feedback tools for managing projects. It enables managers to close the loop in the plan-do-check-act management cycle.[2]

When projects are ahead of schedule, some are because they have improved the quality of work to avoid rework, and some are just because they have reduced the scope of the project; When some projects have delays, the main tasks have been completed in the early stage. The workload is not large and the risk is relatively small. However, some projects are loose in the front and tight in the back. The remaining work pressure is very high and the risk is high. The two situations have different impacts on the later stage of the project. When the actual cost of some projects is lower than the budget at the end of the project, some projects are achieved by improving work efficiency, and some projects are achieved because the project scope is reduced (the actual efficiency is not high).

It can be seen that if the planned value of the time schedule is compared with the actual value, or the budget value of the project cost is compared with the actual value, it cannot be guaranteed to fully reflect the performance of project management itself. It depends on the effect of the actual work done. Only on the premise of completing the same task, the difference in time and cost can be comparable. In the usual project management, the planned time and budget cost of each task in the plan can be obtained through the project plan, and the actual time and actual cost of each task in the project plan can be obtained by tracking the project process. However, when the two sets of data are directly compared, the problems mentioned above will appear, which may be unfair to evaluate project performance.

In order to be able to use the earned value method to manage the performance of the project, certain prerequisites are required, including a project plan and tracking the actual progress of the project. In the planning and actual tracking, there must be clear and specific project tasks, the budgeted cost can be calculated for each task, and the actual cost when each task is completed.

For the earned value method, the project manager should not only understand the concept and calculation method of the project's earned value, but more importantly, the idea of its project management: the performance of the project needs to be compared with the actual plan, and the most essential thing is to pay attention to the project task itself. The completion situation requires comprehensive use of the content, time, and cost of the project task to measure project performance.

Earned Value Measurement Techniques

According to the Project Management Institute(PMI). (2005) Practice Standard for Earned Value Management, these are the significant techniques in the Earned Value Measurement[2]:

- Fixed Formula

A typical example of fixed formula is the 50/50 technique. With this method, 50 percent of the work is credited as complete for the measurement period in which the work begins, regardless of how much work has actually been accomplished. The remaining 50 percent is credited when the work is completed. Other variations of the fixed formula method include 25/75 and 0/100. Fixed formula techniques are most effectively used on small, short-duration tasks.

- Weighted Milestone

The weighted milestone technique divides the work to be completed into segments, each ending with an observable milestone; it then assigns a value to the achievement of each milestone. The weighted milestone technique is more suitable for longer duration tasks having intermediate, tangible outcomes.

- Percent Complete

The percent complete technique is among the simplest and easiest, but can be the most subjective of the Earned Value measurement techniques if there are no objective indicators to back it up. This is the case when, at each measurement period, the responsible worker or manager makes an estimate of the percentage of the work complete. These estimates are usually for the cumulative progress made against the plan for each task. However, if there are objective indicators that can be used to arrive at the percent complete (for example, number of units of product completed divided by the total number of units to be completed), then this can be a more useful technique.

- Apportioned Effort

If a task has a direct, supportive relationship to another task that has its own Earned Value, the value for the support task may be determined based on (or apportioned to) the Earned Value of the reference base activity. Examples of proportional tasks include quality assurance and inspection activities.

- Level of Effort

Some project activities do not produce tangible outcomes that can be measured objectively. Examples include project management and operating a project technical library. These activities consume project resources and should be included in EVM planning and measurement. In these cases, the level of effort (LOE) technique is used for determining Earned Value. A Planned Value is assigned to each LOE task for each measurement period. This Planned Value is automatically credited as the Earned Value at the end of the measurement period.

Application

Indices of Earned Value Method

Schedule Variance[2]

The Schedule Variance (SV) determines whether a project is ahead of or behind schedule. It is calculated by subtracting the Planned Value (PV) from the Earned Value (EV). A positive value indicates a favourable condition and a negative value indicates an unfavourable condition.

SV=EV-PV

The Schedule Variance can be expressed as a percentage by dividing the Schedule Variance (SV) by the Planned Value (PV):

SV%=SV/PV

Schedule Performance Index(SPI)[3]

SPI is a conformance measure of actual progress to schedule. SPI is measured as the ratio of EV to Planned Value (PV), that is

SPI=EV/PV

where PV, known also as the Budgeted Cost of Work Scheduled (BCWS), is planned to be used during the project.

Cost Variance[2]

A project's Cost Variance (CV) shows whether a project is under or over budget. This the measure is determined by subtracting the Actual Cost (AC) from the Earned Value (EV).

CV=EV-AC

This number can be expressed as a percentage by dividing the Cost Variance (CV) by the Earned Value (EV):

CV%=CV/EV

Cost Performance Index (CPI)[3]

CPI is a measure of budgetary conformance of the actual cost of work performed and is the most useful index indicating the cumulative cost efficiency of a project. CPI is the ratio of EV to Actual Cost (AC), that is

CPI=EV/AC

where AC, known also as Actual Cost of Work Performed (ACWP), is an indication of the resources that have been used to achieve the actual work performed.

Guideline for application of the key EVM practice [2]

Earned value management (EVM) strategically enhances good project management through key practices that promote the planning and control of cost and schedule performance. [2]

The following outline, which is quoted from Project Management Institute(PMI). (2005) Practice Standard for Earned Value Management, illustrate the fundamental practices of EVM and project management:[2]

- Establish a performance measurement baseline (PMB)

- Decompose work scope to a manageable level

- Assign unambiguous management responsibility

- Develop a time-phased budget for each work task

- Select EV measurement techniques for all tasks

- Maintain integrity of PMB throughout the project.

- Measure and analyze performance against the baseline

- Record resource usage during project execution

- Objectively measure the physical work progress

- Credit earned value according to EV techniques

- Analyze and forecast cost/schedule performance

- Report performance problems and/or take action.

Statistical Process Control

Concept

Statistical Process Control (SPC) is the application of statistical methods to monitor a process for the purpose of ensuring that it produces conforming product or service.[3] SPC is a widely used technique for quality control. The most popular technique in SPC is a control chart that can be used to monitor process stability, to detect any assignable variations, or to forecast process movements. Measuring the process capability has received significant attention in the last two decades, within the framework of the SPC techniques, especially in the univariate domain.[4]

Statistical process control is a preventive method, emphasizing the participation of all staff, emphasizing the entire process, using control charts to analyze the stability of the process, and early warning of abnormal factors in the process.

Traditional earned value management is essentially a static analysis process. Judging the status of the project based on the size of the current observations, ignoring the inherent characteristics of the project itself, and lacking an examination of the stability of the project process. Due to the process factors of the project itself, the mean value of the whole process often shifts. This kind of shift may be caused by random reasons or special reasons. Earned value dynamic analysis is to measure CPI and SPI through SPC using control charts, analyze the stability of the project process, and identify the reasons for the deterioration of the project.

Characteristic

SPC emphasizes the whole process monitoring, whole system participation, and emphasizes the use of scientific methods (mainly statistical techniques) to ensure the prevention of the whole process. SPC is not only suitable for quality control, but also for all management processes (such as product design, market analysis, etc.). It is precisely its idea that all employees participate in quality management, the implementation of SPC can help enterprises to truly prevent and control in advance in project management.

Modern enterprise quality management requires more factors inside and outside the enterprise to be included in the scope of inspection and monitoring, and the management functions of different departments within the enterprise simultaneously show the characteristics of more and more detailed division of labor and closer cooperation, which require rapid processing of different sources Data and maximize resource sharing. To meet this need, SPC and computer technology, especially network technology, are more and more closely integrated.

Limitation

When applying the earned value method, there is the possibility of using the earned value obtained on the non-critical path of the project to conceal the possibility of lagging behind on the critical path, which affects the accuracy of project performance judgment. The indicators used in the earned value method are correlated. When multiple variables are involved and correlated, relying on a single variable control chart may lead to unsatisfactory results, such as increasing the incidence of false alarms.[4] Also, There is no accurate way to distinguish between differences that have no impact on the success of the project and differences that may put project goals in danger.[4] For univariate and multivariate situations, most SPC control charts and PCI are highly dependent on the assumption that the data follow a normal distribution or at least can be approximated by a normal distribution.[4]

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 Project Management: A guide to the Project Management Body of Knowledge (PMBOK guide) 6th Edition (2017)

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 Project Management Institute(PMI). (2005) "Practice Standard for Earned Value Management", [URL:https://blog.alevi.ru/wp-content/uploads/2015/08/Earned-Value-Management.pdf] Retrieved on 29 December 2017

- ↑ 3.0 3.1 3.2 Aliverdi, R., Moslemi Naeni, L., & Salehipour, A. (2013). Monitoring project duration and cost in a construction project by applying statistical quality control charts. International Journal of Project Management, 31(3), 411–423. https://doi.org/10.1016/j.ijproman.2012.08.005

- ↑ 4.0 4.1 4.2 4.3 Hadian, H., & Rahimifard, A. (2019). Multivariate statistical control chart and process capability indices for simultaneous monitoring of project duration and cost. Computers and Industrial Engineering, 130(March), 788–797. https://doi.org/10.1016/j.cie.2019.03.021

Annotated Bibliography

1. Project Management: A guide to the Project Management Body of Knowledge (PMBOK guide) 6th Edition (2017)

- The book provides a holistic view of project management covering all the aspects including cost management. The chapter regarding cost management presents the overall standard including basic element, cost control input, involved data analysis method, cost control output. The book provides various detailed description of different methods used in the data analysis in cost control. There are also applications of different methods in various scenarios in project management.

2. Project Management Institute(PMI). (2005) "Practice Standard for Earned Value Management"

- This book is a detailed guideline regarding the earned value method. The book illustrates the earned value method in all aspects including the meaning and scope, the key component and significant indices and their quantification method. The book also presents the way to successfully apply the method to maximize the profit and minimize the cost to achieve better project management performance.

3.Aliverdi, R., Moslemi Naeni, L., & Salehipour, A. (2013). Monitoring project duration and cost in a construction project by applying statistical quality control charts. International Journal of Project Management, 31(3), 411–423. https://doi.org/10.1016/j.ijproman.2012.08.005

- The article presents a brand new method within the application field of the earned value method by introducing the statistic tools in the cost control process. The involving of the statistic tools and charts can compete well against traditional earned value method and can contribute to improving the efficiency of the project management team. The introduction of the statistical tools greatly enhances the controlling by the project manager to cope with the scheme of the whole project.

4. Hadian, H., & Rahimifard, A. (2019). Multivariate statistical control chart and process capability indices for simultaneous monitoring of project duration and cost. Computers and Industrial Engineering, 130(March), 788–797. https://doi.org/10.1016/j.cie.2019.03.021

- The article emphasized the application of statistical process control in the earned value method. The article proposed a new method using multivariable control chart to consider the possible correlation between different key indices in the earned value method. The article also presents some process capability indices (PCIs) for the project manager to better quantify and understand how well a project can meet its requirements. This method provides managers with more reliable information about the deviation between planned and actual performance in terms of time and cost.