Kanban framework

Kanban can be referred to as either a method within process improvement or a visual method in Just-in-Time and Lean manufacturing, following article will be focusing on its uses in process improvement.

The Kanban methodology originates from Japan and is therefore a Japanese word that can be translated to “signboard”. Kanban is a framework that is used in teams that is following the agile methodology, which has gained popularity throughout the software development industry, since the adaption by David Anderson back in 2010. To practice Kanban, it is essential to acquire a lean thinking mindset, which focuses on the improvement of processes and elimination of waste, called Muda in Japanese [2]. To understand more about Lean visit following link Lean in Project Management.

When teams want to implement lean and a lean mindset, Kanban can work as a beneficial method to bring exactly this to the team, which is explained by David Anderson in following quote.

“The Kanban Method introduces a complex adaptive system that is intended to catalyze a Lean outcome within an organization. Complex adaptive systems have initial conditions and simple rules that are required in order to seed complex, adaptive, emergent behavior.” – David Anderson [3]

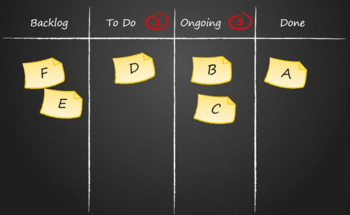

In general Kanban helps project managers to keep an overview of their projects and the tasks involved in them, it also increases collaboration between the team members that is involved within the projects, mainly because visualization with the use of Kanban boards, creates project transparency. How exactly Kanban works will be the focus of this article with an overview of the historical development of this specific method, an elaboration on its uses in project management will also be enlightened, where the final point of the article will define some of the limitations that is linked to the use of Kanban.

Contents |

Historical State of the Art

Description of how Kanban first originated and in which context is was developed. Furthermore how the Kanban method has been adopted into system development.

Kanban in Project Management

Not a methodology for project management, but has an important relationship to it.

- Start with what you do know

- Agree to pursue incremental, evolutionary change

- Initially, respect current roles, responsibilities and job titles

Use ref: Managing Successful Projects with PRINCE2 2017 Edition

Features of the Kanban framework

Visualize Workflow

- Describe kanban cards and boards

Limit Work-in-Progress

- Stay to the script

Measure and manage flow

- Use of CDFs and WIP area charts

Make process policies explicit

- Securing a common understanding

Use models to recognize improvement opportunities

Limitations of the Kanban framework

- Describe what limitations there has been found when working with the Kanban framework

- Use of Scrumban can cover some of the limitations

Annotated Biography

References

- ↑ The kanban method. (2022). How to implement kanban. [1]

- ↑ Stellman, A., & Greene, J. (2015). Learning Agile: 1st edition. O'Reilly Media

- ↑ Anderson, D. (2010). Kanban Successful Evolutionary Change for Your Technology Business. Blue Hole Press

Other notable references not yet used: Books:

- Learning Agile: Understanding Scrum, XP, Lean and Kanban. By Andrew Stellman & Jennifer Greene

- Kanban: Successful evolutionary change for your technology business. By David J. Anderson

- The Lean Toolbox: A handbook for lean transformation. By John Bicheno & Matthias Holweg

Websites:

Articles:

- Identification of criteria affecting software project monitoring task of Agile Kanban method. By Hamzah Alaidaros, Mazni Omar and Rohaida Romli

- https://aip-scitation-org.proxy.findit.cvt.dk/doi/pdf/10.1063/1.5055423

- Collaborative Work Management with a Highly-Available Kanban Board. By Annette Bieniusa, Peter Zeller, and Shraddha Barke

- file:///Users/JakobWeber/Downloads/5bd0583fd9001d01d4104a4f.pdf