Root cause analysis (RCA)

Abstract

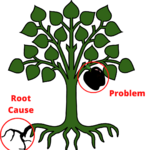

While managing programs or projects we face many challenges which affect the schedule or quality of the project. For the elimination of such similar future challenges, it is important to identify from where the problem has started (Root Cause). Root cause analysis is a method to identify the source of the problem and to know how it has happened and how to prevent such problems in future. Multiple industries like Construction, manufacturing, pharmaceutical, Information technology uses this method for successful identification of causes for the problem. RCA also gives the scope to identify the gaps in the existing process, reduce the cost of production or increase production. In this article, we will learn about What is root cause analysis and its importance, when and how RCA has to be done and methods of doing root cause analysis.

Introduction

Root cause analysis (RCA) is an important aspect of a broad problem-solving process and continuous improvement. A root cause is a part that contributed to a failure and should be removed completely using process improvement.The root cause is the most fundamental problem—the most fundamental reason—that puts in motion the a whole cause-and-effect that leads to the problem. Root cause analysis alone would not give any results, it has to be used as part of a bigger problem-solving effort aimed at improving quality. Organization uses continuous improvement method to remove that problem completely .

Root cause analysis refers to a variety of methodologies, tools, and procedures used to identify the root causes of issues. Some RCA approaches are more focused toward finding actual root causes than others, while others are more broad problem-solving procedures, but others simply provide support for the root cause analysis core activity.[1]

Process of Root cause Analysis

Root cause analysis tools

Five Why analysis

Five Why analysis is widely used root cause analysis tool in the industry as it helps to identify the root cause with few simple “WHY” question and without in need of any statistical tool. This method is one of the fasted methods to know the real root cause of the problem. In 1930s this tool was developed by Sakichi Toyoda, Founder of Toyota Industries, but only in 1970s this tool was used in many industries. [2]

== Steps to perform five why analysis ==

- Take a particular problem

- Question “WHY” it occurred and note down the answer.

- If that is not the exact root cause then you can ask another “WHY” question to that answer .Note down the new answer.

- Follow these steps till you identify the root cause. It can take any number of “WHY” to reach the cause. [3]