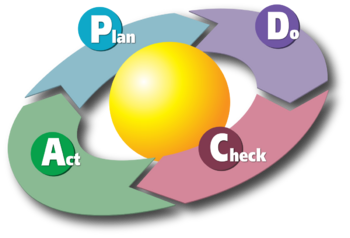

PDCA cycle

"It [The PDCA cycle] is a flow diagram for learning and for improvement of a product or of a process." [1] W. Edwards Deming

The PDCA (Plan-Do-Check-Act) cycle, also known as the Deming cycle or the Shewhart cycle, is a project management method used to continuously improve the quality of a process or a product. This cycle is based on the four following phases: Plan, Do, Check, and Act.[2]

- In the Plan phase, the problem to tackle is identified, and an action plan is set up.

- In the Do phase, the plan is put into action by the project team.

- In the Check phase, the differences between the results and the expectations are evaluated.

- In the Act phase, corrective actions are taken in order to improve the evaluated situation.

By breaking down a complex problem into these four phases, the organization obtains a clear overview of the situation and is forced to systematically identify areas of improvement, take actions about it, compare the results and the expectations, and make the necessary adjustments.

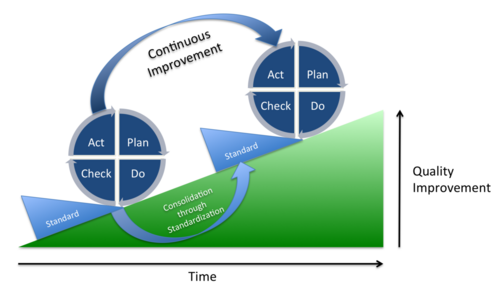

The PDCA cycle is an iterative method, which means that at the end of the fourth phase, it is recommended to implement again the method on the new situation to continue the improvement of the product or the process. This iterative approach results in an increase of efficiency and effectiveness inside the organization.

Developed by Eric Vincent Vong

Contents |

Presentation of the method

The PDCA method has four phases, each leading to the other, and aims to establish a virtuous circle to improve the quality of a product or a process. [3]

Plan

It is the most important phase in project management because objectives must be defined before acting. Usually, this phase is carried out in three stages.

- Identify the problem to solve, using for example the five W’s or brainstorming.

- Understand the causes, using for instance the fishbone diagram.

- Look for solutions and define an action plan.

Do

It is the moment where the action plan is implemented. Examples of action plan can be creating a prototype, carrying out tests, writing a software code, … In this phase, each team inside the project team works on its side, according to the action plan.

One point to mention and to be careful on is that even if each team works on its side, it is essential to have regular meetings with the whole project team to avoid the tunnel effect and to keep a global overview of the progress of the tasks, because some tasks can impact another one.

Check

In this phase, the project team makes sure that the solution that has been developed (in the Do phase) to tackle the problem (identified in the Plan phase) works well. The easiest way to do that is to compare the results with the expectations in terms of key performance indicators.

Of course, this analysis will emphasize differences. But it is understandable, and it is essential to keep these differences in mind for the next phase.

Act

This phase is usually carried out in two stages:

- First, corrective actions are taken in order to minimize the differences between results and expectations identified in the Check phase.

- Then, the project team draws conclusions of the whole four phases and uses it to begin again the PDCA cycle, by capitalizing on the knowledge acquired.

Visual representation

The most important idea to remember about the PDCA cycle is that each iteration must lead towards a better situation, a better quality of the product or the process. To remember this idea, the PDCA method can be represented with a block behind the wheel, which prevents it from going back and which symbolizes the capitalization of the knowledge.

Examples

Toyota

Toyota is a Japanese automobile company, well known for its efficiency and its quality control. The PDCA method has been and is still a key point of their success, especially in its production process. Indeed, this company uses the PDCA method to make sure to always meet the highest quality standards, by optimizing their process and by capitalizing on their knowledge.

The PDCA method used by Toyota to improve their production process can be described as following [4]:

- In the Plan phase, the company defines the production goals and sets up an action plan to achieve them. This action plan emphasizes details about the production processes, by answering the five W’s (What, When, Who, Where, and Why).

- In the Do phase, the company puts into action the plan defined previously to produce vehicles. During that stage, different kind of data is collected, for instance speed or quality of the production, so that it can be analyzed in the next phase.

- In the Check phase, the company compares the initial plan and its expected goals with what really happened during the production in order to evaluate the differences. By analyzing the data previously collected, Toyota is able to highlight areas that can be improved.

- In the Act phase, the company takes action to improve its production processes based on what was found in the Check phase. Toyota, for example, implemented new tools and new processes to improve their production process.

The PDCA method is part of Toyota’s culture, as underlined by Adriaan van Wyk, former production leader of Toyota South Africa Motors, in which he worked from 2003 to 2008:

"PDCA is so deeply ingrained in Toyota’s fabric that it was not taught explicitly. I had to become part of the culture and live it before I could make it my own.” [5] Adriaan van Wyk

Ningbo Women and Children’s Hospital

In 2019, the Department of Obstetrics and Gynecology at the Ningbo Women and Children’s Hospital in China decided to apply the PDCA method to reduce the time between the decision to conduct a cesarean section and the delivery of the newborn during emergency cases. This time is called DDI, which stands for “Decision to Delivery Interval”. By shortening this time, it would improve the chance of survival of the mother and the newborn.

The PDCA method used in this hospital can be described as following [6]:

- In the Plan phase, that took place in 2019, the hospital identified that the average DDI time was equal to 14.40 minutes. By analyzing their process, three main causes impacting an increase of the DDI time have been pointed out:

- A defective process

- A lack of first-aid experience

- A poor cooperation between the departments

- In the Do phase, the hospital tackled each of these causes by implementing improvement measures:

- Establish a specific team to deal with these emergencies and standardize the working processes.

- Implement regular theoretical and practical trainings.

- Involve multiple departments when conducting emergency drills.

- In the Check phase, the hospital evaluated the progress monthly, by creating a summary about the improvements measured over time.

- In the Act phase, the hospital refined their processes, which leads to a successful reduction of their average DDI time, from 14.40 minutes in 2019 to 12.18 minutes in 2020.

Variation of the method

PDSA

During the eighties, Deming introduced an alternative of the PDCA cycle, called PDSA cycle, which stands for Plan-Do-Study-Act. The main change is that the Check phase, in which the project team is supposed to compare and evaluate the differences between the results and the expectations of the plan, is replaced by the Study phase, where the project team is supposed to evaluate the results of the plan and make observations [1].

Consequently, the PDCA cycle is more focused on continuous improvement through a more structured approach whereas the PDSA cycle is more focused on testing and implementing changes quickly, and possibly revise the theory if necessary.

OPDCA

More recently, some scholars decided to add an Observe phase at the beginning of the PDCA cycle, changing it into the OPDCA cycle. This change was made to emphasize the importance of the observation of the current situation before creating any action plan [7].

DMAIC (from the Six Sigma)

The DMAIC cycle is a method widely used in the Six Sigma method and aims to improve a business process. DMAIC stands for Define-Measure-Analyze-Improve-Control and is highly inspired from the PDCA cycle.

The five phases can be described as following [8]:

- Define: Define the problem or the opportunity for improvement

- Measure: Quantify the current perform of the process thanks to data collection

- Analyze: Analyze the data previously collected to identify the roots of the problems, which can negatively impact the performance of the process

- Improve: Take actions to address the roots of the problems

- Control: Implement a control plan to sustain the improvements made during the Improve phase.

Pros and cons

Pros

Cons

References

- ↑ 1.0 1.1 W. Edwards Deming, "The New Economics for Industry, Government, Education", 1993

- ↑ Nancy R. Tague, "The quality toolbox, Second Edition", 2005

- ↑ Rémi Bachelet, "L’essentiel des outils d’organisation de projet", Ecole Centrale de Lille, 2019

- ↑ Jeffrey Liker, "The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer", 2004

- ↑ Adriaan van Wyk, "PDCA - Make a 400 year old principle the foundation of your success", LinkedIn article, 2019

- ↑ Ming-Na Lu, Bai-Lei Zhang, Qiao-Hong Dai, Xian-Hu Fu, "Application of the Plan-Do-Check-Act Cycle in Shortening the Decision to Delivery Interval Time", Risk Management and Healthcare Policy, 2022

- ↑ Foresight University, "Shewhart-Deming’s Learning and Quality Cycle"

- ↑ Michael L. Gorge, "Lean Six Sigma: Combining Six Sigma Quality with Lean Production Speed", 2002