Quality control

Defects and errors in construction projects have been subject to attention in the medias and debates through the years. There is a general conception of

Edit this abstract ABSTRACT when you are done:

When managing conformance in construction projects an important aspect is quality control (QC), in order to assure high quality of outcome as well as in the project process. Thus the main purpose of performing QC is to determine if the established quality requirements and the project objectives are achieved. Furthermore an important part of QC is to investigate the causes of the arising problems, as well as finding ways to eliminate unsatisfactory performance.

As quality control techniques are needed in order to perform QC, two quality control techniques are introduced in this article. The first technique introduced is “cause and effect diagrams”, which focus on correcting the non-conformance after it has occurred, which is the focus of most quality control techniques. The idea of the technique is to find the roots to the problem and visualizing them by creating a fish bone diagram. The possibilities and limitations to the technique will be clarified. “Statistical process control” is a tool to prevent unsatisfactory performance and is the second technique introduced in the article. This technique deals with statistical analysis of data obtained from similar projects, and control chart can be used to determine if the outcome of the analysis is tolerable. As this technique requires data logging of previous projects, the possibility of implementation of the technique in a construction process is discussed as the complexity and conformance requirements in construction projects can make the technique less effective even though the construction process is a repetitive process overall.

Contents |

Definition of Quality Control

Quality Control (QC) is a part of quality management of construction projects, and to be more exact QC is at the heart of conformance management. The aim of QC in construction projects is to assure high quality of the construction being built and the processes of the project. In this content the definition of “high quality” means fulfilling standards and the established quality requirements in the specific project [1].

Something about corrective and predictive QC.

Product Quality Control vs. Process Quality Control

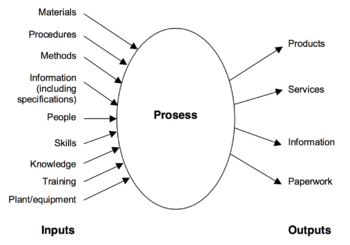

QC deals with the specific products as well as the processes as mentioned. A certain understanding of the process or product is needed in order to perform QC of either part. A process is the transformation of a set of inputs into the desired output. Figure XX shows the inputs can be materials, procedures and knowledge. Each process in a construction project can be analyzed alone and afterwards actions can be determined in order to improve the process, thus the process QC become preventive.

Examples of process QC can for example by:

- Controlling the temperature of the concrete during casting

QC of af product concerns instead the quality of the output/result of the a process in the construction project. It can be a product of a process in the design phase as well as in the construction phase. The output doesn't have be a physical product but can as well be a service, information or conducted paperwork as illustrated on Figure XX. Examples of defects that product QC deal with are:

- Missing information in drawing material

- Moisture damage of a construction element

- Cracking in a welding

Performing quality control

| Primary inputs | Primary outputs |

|---|---|

|

Progress data Deliverables Quality plan |

Quality control measurements Verified deliverables Inspection reports Change requests Corretive actions |

In order to perform QC, tools and inspection procedures are needed. These inspection procedures and QC tools are specified in the part of the quality management called quality assurance [1]. The primary inputs and outputs of performing QC in construction project given by the standard DS/ISO 21500 [2] are shown in Table 1. Here it can be seen that QC has a high dependency of good planning, as the primary inputs is a result of planning the quality in the project. The primary output indicates, that QC is not only a check of requirements are meet, but it also includes documentation, communication and analysis.

The standard DS/ISO 2150 [2] states that QC should be performed during the whole project life cycle and that it includes following aspects:

- Monitoring the quality of the processes and detect defects.

- Analysis of the causes of defects and non-conforming performance.

- Identify ways to eliminate unsatisfactory performance by preventive actions and change requests.

- Communication of the change requests and necessary corrective actions to project organization members.

Karins definition: (Den store report)

John S. Oakland states:

Something about recent practice (digital tools for inspections) and classic quality control techniques... The focus on predictive quality control!!!

Continuous control, Early quality control, Quality control at delivery

Corrective Quality Control

Corrective QC is necessary when non-conformance or a defect is found or a fatal event has occurred, thus corrective QC is defined as a reactive approach. It is necessary because unexpected events and defect always will occur in construction projects, because the ideal project where all problems are prevented is hard to establish, since many people, partners and processes are involved in the project. Questions like “have we met the requirements?” and “what went wrong?” are asked here. Corrective QC deals with critical defects and the less serious defects, which can bring fatal errors later on.

In order to correct non-conformance, knowledge of the causes to the problem has to be obtained. Performing corrective QC can be accomplished with different techniques, and in the following the technique “Cause and effects diagrams” will be clarified.

Cause and effect diagrams

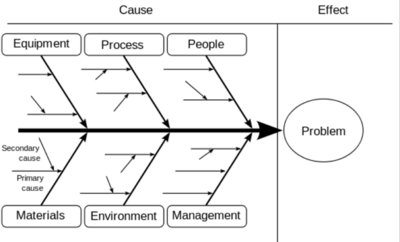

Cause and effect diagrams also go under the names “fishbone diagram” (due to their shape) and “Ishikawa diagram” (after the techniques inventor). The reason for the name “cause and effect diagram” is that the diagram is separates the problem (the effect of the causes) from the causes. The basic idea of the technique is to work back form the problem by asking: “why did it occur”, and in that way finding the different roots to the problem (cite Winch). Each cause is thereby found by using a form of brainstorm technique, and they are grouped under different categories. A cause can either be a primary cause or a secondary cause to the primary cause. When illustrating the causes this way, the diagram takes form as a fish skeleton as shown from Figure XX.

A cause effect diagram shows there often are several roots to non-conformance and defects, and that several corrective actions have to be performed. This allegation becomes clear by grouping the causes under different categories, because it illustrates the difficulties of complex processes. The categories often include people, process/methods, equipment/machines, material, environment and management, as these are some of the basic elements in construction projects (cite hjemmeside).

This technique can also be used as a preventive QC tool. In this way the problem have to be predicted before it occurs and then the problem can be prevented by making qualified decisions for the actions and processes that have to take place. The difficulties will here be to predict all the causes to a specific problem desired to be prevented.

Preventive Quality Control

Preventive techniques

Statistical process control

Implementation of preventive techniques

Monitoring

Digital tools for inspections

Sensor systems

Radio Frequency Identification (RFID)-based quality management system, which functions as a platform for gathering, filtering, managing, monitoring and sharing quality data.

Discussion

What is good quality control

Benefits of good quality control

Consequences of poor quality control

Limitations

The requirements have to be clear (from the client to the designer (architects and engineers), as well as to the entrepreneurs and craftsmen

Operationally orientated and doesn't take factors as customer satisfaction into account

Project specific control

Time – there have to be time to do it.

Knowledge – people have to understand the process in order to control them.

Not enough ressources from the designers