Quality Control and Safety During Construction

Abstract

Construction sites has through the years been subjected to injuries, accidents and faults. Budgets and deadlines are not kept, because of inadequate planning, errors, and poorly executed work. To satisfy customers requirements and to emphasise the importance of security, construction firms are now dedicating increasingly amounts of resources to prevent this. Political and private initiatives have made quality control a separate field in construction. This article will look at how quality control is used, the benefits and values of it and which supporting activities are used.

http://www.arbeidstilsynet.no/artikkel.html?tid=250636

Contents |

Definition: Quality Control

Quality Control is often associated with Quality Assurance (QA) and Quality Management Systems (QMS). They all correlate and depend on each other all thought there are different definitions. The American Society of Quality have made the following definitions of the terms:[1]

Quality Assurance is: “All the planned and systematic activities implemented within the quality system that can be demonstrated to provide confidence that a product or service will fulfil requirements for quality.”

Quality Control is: “The operational techniques and activities used to fulfil requirements for quality.”

Thus, the difference between them is mainly that the QA is everything involving the QC such as documentation, planning and the supporting activities around QC, while QC is the actual controlling part. Together QA and QC are parts of the QMS. The concept of Total Quality Control (TQC) emphazises the use of the tree to provide the best possible quality in every part of the company. [2]

Background

Until the mid-20th century the conventional way to make sure products were up to standards was with post-production controls, where the defect products would be repaired or thrown away. After the second world war companies started to rethink the idea as factories and production became more efficient and the demand bigger. Toyota introduced the Toyota Production System which later influenced the Lean-philosophy. In the 50’s the Demin-circle was introduced by W. Edwards Deming and is considered the origin of the total quality management (TQM). In the end of the 60’s the term Quality management systems arises. This was the first time where they would look at the entire process of making a product, not just the production in itself. The management and the service provided to the customers would be taken into account just as the quality of the product. [3]

Plan - Do - Chech - Act

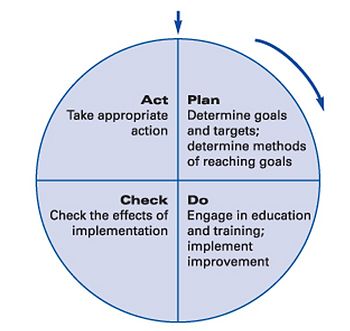

One of the most basic ideas of the QC and especially the TMC is the theory behind Plan - Do - Chech - Act (PDCA). It is based on the Deming Circle introduced by W. Edwards Deming in the 1950's. The concept has influenced the construction industry and many others since. PDCA is based on four parts, each shown in figure 1.

The most crucial aspect of the PDCA which makes it a great method or tool is the continious evaluation of the performed work. Every time a process is done the company will have to chech the quality and document deviations. Necessary steps will be taken to meet required standards. The documentation will be used in future projects to provide a confidence that errors will not reappear.

The practical use of the PDCA is many, but mostly it is the idea that has influence other teqnicues and tools, some of them will be discussed during this article.

ISO 9001:2015

The concept of the QMS was originally based on assembly line productions, where there would be identical products produced repeatedly. Transferrin this into the construction industry, where the nature of each project would be totally different was a bigger challenge. One of the strongest initiatives to help this along was made by the International Organization for Standardization (ISO). They developed standards for implementing QC in the industry. The most commonly used is the ISO 9001:2015, which is also the only one amongst the ISO Standards which can be certified to. It is not required to certify, but there are more then one million companies wolrdwide with certification.[4]

Acquiering an ISO 9001 certification has become a way to prove the company's credibility, and in some industries it is even legally mandated to optain one. The ISO 9001 standard uses several tools and ideas in their standards to provide their users with the following benefits:

- Organize processes

- Improve the efficiency of processes

- Continually improve

Performing the Quality Control

In the initial phase of the project, planning is important to utilize the benefits of QC. Identifying the potential issues and making a strategy is one of the first steps in QC. There are different tools to use for the planning, e.g. Benchmarking, Flowcharting, Cost-to-benefit Analysis or Cause and Effect Diagrams. Using these brings predictability to the project, using preious knowledge overviews of the project and analycis of the project to plan the QC to be as efficient as possible, thus applying the concept of PDCA.[5]

The following parts will end up in a Quality Plan(QP), specifying the use and which goals to achieve with the QC. As well as creating a guidance for the QC it will also create a verification for the customer who have to rely on the contractor to provide the required quality. The QP should integrate the overall goals and strategic plans in the organization to the individual project, to provide an ongoing progress. It concerns aspects from top organizational level to the lower levers where the actual QC on site is executed.[6]

Basic Quality Control

Check Sheets

One of the most common ways to perform QC is by Check Sheets also referred to as Checklists. They give directions about what to control and how to do it. Using the construction of a concrete wall as an example. Typically parameters can be e.g. placement, height, reinforcement, formworks etc. The sheets are created and adapted to each individual project. All controlled areas will be documented and stored for later auditing. The controls are directed towards areas where the companies know faults occur, often a result of the risk assessment prior to the project start. The Check Sheets is a combination of preventive and corrective QC. It is also considered one of the most basic and simple ways of QC, with only small amounts of planning required. On the other hand processing the information acquired from the Check Sheets requires a sufficient amount of work. Using the knowledge gained from the controls are important in future work.

References

- ↑ [1],American Society of Quality

- ↑ Chris Hendrickson, (2000), Project Management for Construction Fundamental Concepts for Owners, Engineers, Architects and Builders, Department of Civil and Environmental Engineering, Carnegie Mellon University, Pittsburgh

- ↑ [2], American Society of Quality

- ↑ [3], International Organization for Standards, uploaded 21.09.17

- ↑ [4], uploaded 26.09.17

- ↑ http://asq.org/learn-about-quality/quality-plans/