Quality Management Systems

Contents |

Abstract

When performing project management multiple standards can be used and followed to enhance the projects chance of success and benefits. Standards that all suggest methods to follow and considerations that should be made by the project managers and the stakeholders before, doing and after the execution of a project. [1] [2]

Projects managers should use knowledge from previous projects has input for their project increasing effectiveness and efficiently and thereby the chance of a successful project. In order to do so some output from previous projects needs to be accessible for subsequent project managers consisting of relevant experiences that can be included in the next project. This creates the obligations for the projects managers to use the output produced from previous projects as input for new projects. Furthermore, the project manager must note relevant experiences and included these in the final project report of lessons learned which is to be redistributed.[2] But from all these standards and suggestion what should the project manager be aware of and note doing the project that constitute improvement of prospective projects?

This article will explain how a Quality Management System (QMS) can help to address the problem of how to ensure consistent output from projects that can be used as input for the next project and how project managers can use and benefit from this tool. It will furthermore be discussed if the benefits produced from a project increases when performed within the framework of a QMS. DS/EN ISO 9001 2015 outlays Plan Do Check Act (PDCA) as an essential part of the QMS and by this reason ways of incorporating the PDCA in a project will be suggested.[3] General principles of risk-based thinking will be explained and why it is important to include in a company’s QMS and project management.[2] It will be argued that more organisations should implement a QMS in order to know their current level of performance of projects and knowing their progress from investments and initiatives. By combining methods from standards and literature upon project management and QMS’s, suggestions of how a QMS can help a project manager and organisations to consistently improve from each project to the next.

Quality Management Systems

A Quality Management System(QMS) is a systematic tool that helps an organisation standardise and define processes in order to improve their performance. QMS includes monitoring information internally and externally of an organisation e.g. via collection of information such as performance indicators, training of employees, nonconformities and their root curse, well-argued management decisions based on such information and can ensuring a gradually increase of the performance. It focuses on creating a closed loop in the organisation, known as the Plan Do Check Act (PDCA), which helps structuring processes and gradually improve their performance. It can be adopted in any organisation and must be customised to the specific organisation to enhance its effect. [3]

DS/EN ISO 9001 2015 encounters all aspects of the organisation that must be duly considered when designing the QMS for the specific organisation. Depending on the organisation, some processes of the organisations will be of higher importance than other and must be identified via the risk-based approach.[3] Projects also includes risk and should therefore be included in the QMS where methods of performing these projects is described. Depending on the project the consequence(s) of it not succeeding will vary. To minimise the consequences from an unsuccessful project actions to either decrease the consequence or to lower the probability of unsuccessful projects must be done.[2] This can be accomplished by implementing a QMS fitting the organisation including a described method of performing risk management. [4]

DS/EN ISO 9001:2015 describes the QMS in five main topics: [3]

- Context of the organisation

- Leadership

- Planning

- Support

- Operation

In order for the project manger to use the QMS as a tool it must firstly be defined and implemented by the organisation. This is done by following DS/EN ISO 9001:2015 and applying it in the organisation, creating a customised QMS focusing on processes which is important for the quality of the products and services made by the organisation. In regards to project management a organisations QMS must make a description of how to performe project management, which methods to use and requirements that must be meet. When the QMS has been defined the project manager will have a clear formula of which methods and requirements that must be followed and how to fulfil these when performing project management.

In the following sections these key components of a QMS will be described briefly in order to objectify its relevance as a beneficial tool in relation to project management.

Context of the organisation

An organisation implementing a QMS must consider which factors that needs to be monitored internally and externally. The factors monitored will vary for each organisation since organisations has different values, structures and risks. Therefore, when choosing which factors to measured, the organisation needs to look inwards and estimate which processes is of particular importance to improving customer satisfaction. Also processes for improvements of the organisations QMS must be in place.[3]

Leadership

The management is obligated to follow the QMS and make decisions based on the collected information from it. These decisions must be made using a risk-based approach. Management have the responsibility that the QMS achieves it intended purpose, supports the organisations strategical direction and simultaneously remains focused on the customers satisfaction operation within regulatory requirements. They are responsible for ensuring that the QMS is used throughout the organisation, has an established quality policy and that responsibilities are defined, delegated and understood.[3]

Planning

When designing the QMS the organisations must encounter its own position in the market and how they influence stakeholders. The organisation must determine risk and opportunities which needs to be addressed. Mitigating actions to reduce the identified risks shall be planned in order to lower each risk as much as possible. The organisation must define measurable quality objectives in line with the QMS-policy. These objectives must be known throughout the organisation and planned how to be achieved. The must furthermore describes how these measurable objectives is evaluated.[3]

Support

Resources needed to create, maintain and improve the QMS shall be determined and provided by the organisation including human recourses and their competences, infrastructure and environment required for operation of processes. The competences of employees shall be documented to guarantee tasks is done is compliance with defined requirements. The organisation must measure relevant resources to ensure sufficient supplies. Tracing the flow of the recourses is required in order to determine the status and make improvements where needed. The organisation must determine which processes and information from these that is needed to be documented in order to obtain and improve the effectiveness and efficiency of the QMS. Furthermore, the QMS must describe and document procedures for communication internally and externally. The documentation must be controlled and include necessary metadata to identify the author, date, format, changes that has been made and who approved these.[3]

Operation

Planned action must be followed in order to perform processes in compliance with established criteria and how to obtain. Hereby controlling the processes and ensuring the QMS improve the organisations performance. If changes are made to processes a revision of these changes must be made to ensure compliance with defined criteria. If a nonconformity accrues as an output of any processes a defined Corrective And Preventive Action-process is to handle this.[3][5] Products and services must comply with internal requirements as well as external. These products and services must go through regular provision of defined requirements in order to identify necessary actions to make improvements. This includes check of input and output requirements.

In order to control internal processes, requirements and provision of external provided resources must be established. When choosing an external provided following steps must be follow:[3]

- Define requirements for supplier and the service

- Selection of the best fitting supplier

- Monitoring of the chosen supplier to evaluate their performance

- Re-evaluation of supplier

Performance evaluation

The organisation must determine which data and information to measure, analyse and evaluate upon. This should be processes which is of the highest importance for the organisation. Management must perform reviews of this information which they must use to decided actions to improve the QMS and its processes. As part of the evaluation internal audits shall be performed regularly with the focus of checking compliance with internal procedures, DS/EN ISO 9001:2015 and the efficiency of the QMS.[3]

Plan Do Check Act

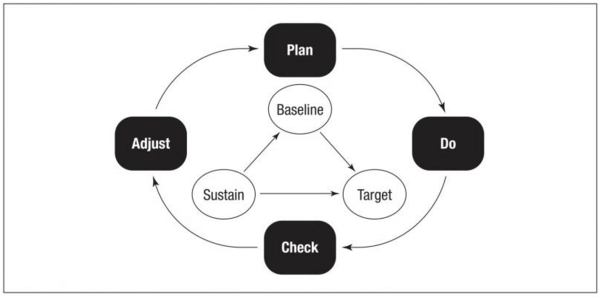

A QMS can be implemented with the method Plan Do Check Act, which is a circular process ensuring continually improvements an organisations processes, products and services via demands from a QMS outlined in DS/EN ISO 9001:2015.

Figure 1 illustrates the PDCA and shows how it incorporates all of the chapters of the DS/EN ISO 9001 2015 as a circular process. Further description of the content of each step is therefore referred to in section “Quality management systems. The PDCA ensures that the QMS is implemented in the organisation as a circular process where plans, processes, actions are frequently evaluated and improved.

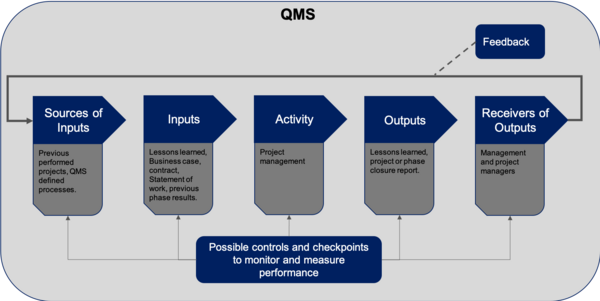

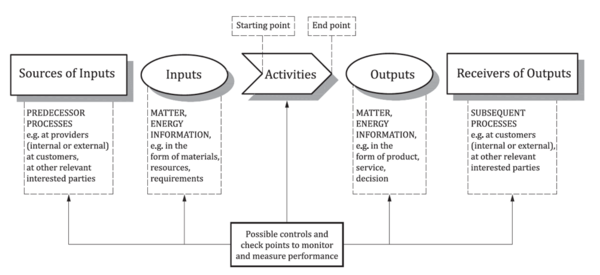

A single processes within a QMS can be illustrated as in figure 2.

This generic way of structuring a single process includes some of the parameters a project manager must encounter in a project. [1][2] The single process can be used as the general structure where a given activity can be put in the box "Activity". Project management can be view they activity, putting project management in context of that some input is needed in order to create the output.

Project Management

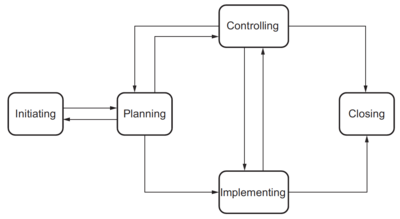

Project management is the way of controlling and guiding a project and its stakeholders towards the project goal by use of methods, tools and expertise within the project’s constraints. Managing a project must be aware of the basic requirements of a project that it is a contemporary constellation with a defined timeframe and the goal of creating or adding benefits compared to the baseline. This is often aligned with the organisation’s strategy.[1] Multiple factor inside and outside the organisation’s boundaries can affect the project and must therefore be encountered by the project manager in order to reduce risks and succeed with the projects goal. Guides and standards upon project management can be used to control and encounter these factors guiding the project manager on what to be aware of. Following standard of DS ISO 21500:2012 the project management is divided into processes, creating a systematic approach for the project manager to follow. These processes describe what to do in each phase of project management, the purpose of the process, its primary inputs and outputs. [1] Project management generally consist of five processes: Initiating, Planning, Controlling, Closing and Implementing. The interaction, input and outputs between the processes can be illustrated via figure 3.

DS/ISO 21500:2012 is one of several standards that can help the project manager to navigate through a project. But with several different standards to follow it can create multiple different ways of performing project management and thereby different outputs. This leads to the needs of a decision of what standard to follow in the organisation to create a consistent output of lessons learned which can be used as part of the input for the next project. These influencing factors be controlled by an effective QMS where Standard Operation Procedures(SOP) describe and standardise general methods and considerations which must be encountered when a project is carried out.

Project Management within a Quality Management System

Performing project management within a QMS will obligate the project manager to follow the SOP described in the QMS. Thereby formally standardising methods, processes and considerations that must be used. SOP's could describe the method for project management specifically customised to an organisation needs or simply refer to a project management standard which has been chosen as the method of choice in the organisation. If the organisation choses to refer to a common standard of project management, they organisation must be aware that processes described in e.g. in DS ISO 21500:2012 is very general and with little or no connection to the organisation where it is to be used, creating a gap between the standard and the real-life project. Combining a project management standard with a QMS where specific processes from the project management standard is described with relation to the organisation will enable project managers to access a tool where methods of project management is ready for use. With the QMS setting the requirements for at project more projects comply with these requirements. [7] The general structuring of a single process as defined in the DS/EN ISO 9001:2015 can be used as a template for all processes. The process of project management can therefore be the activity of the single process. [3] Combining the tool of a general process as described in DS/EN 9001:2015, the QMS/PDCA and standards of project management creates a basis for a controlled circular process for performing a project and as a project management tool that ensures use of previous projects experiences that has followed the same methods defined by the organisations QMS. This can be illustrated with an updated chart of the single process where the activity is project management, the output is lessons learned and closure reports, the receivers of the outputs is management and project managers, which via the implemented QMS and the circular process of the PDCA ensures continues structured input to new projects within the organisation (figure 3).

The whole process lives within the QMS, where each step of the process has been specifically defined disabling uncontrolled processes and variation of what to be included. Hereby producing consistent outputs with best practices easy to use for project managers. As an example of an important SOP to describe in a QMS with relevance to the project management is how a project should be evaluated. A description of which objectives or performance indicators that the project management must be aware of and measure. A concrete template for a project evaluation stating what objectives or performance indicators that must be evaluated by internal and external stakeholders.

Advantages, Limitations and Challenges

There are numerus advantages for the project manager from performing project management within a well-defined QMS, not only does the project manager benefit from this but also the organisation itself. A QMS acts as guide for the project manager, ensuring that the project manager at all times know what to do or at least were to find the information needed to execute the project in compliance with the organisation’s requirements, e.g. descriptions and templates of how to perform risk management. Standardisation of the project management can also ease post projects since the documentation and method used in the last project is well described. Revision and evaluation of the projects will gradually improve the quality of the project management, thereby enhance the chance of an increased number of successful projects. By evaluating projects the QMS captures value from the projects and enables lessons learn to be accessible and reused in the next projects. The experiences noted from these evaluations can be collected and turned into best practices. Suggestions in the project management standards mention that lessons learned during the project should be noted and accumulated in a report when the project is finalised.[2][3] General inputs for this report are suggested in the DS ISO 21500:2012 but only with general terms. These must be specified to comply with DS/EN ISO 9001:2015 in order to obtain consistent performance indicators, best practices and what to avoid in subsequent projects and included as a SOP for project management in a QMS. [1][3][5]

Managing and monitoring of recourses as required in a certified QMS will also benefit the project manager as it creates an overview of the organisations resources and enables the project manager to know if and where more resources for the project can be aquired. Human resources and their competences could be mapped via a competence matrix giving the project manager the benefit of an overview of which employees to pick for the ideal project team(s), easing the processes of creating teams with the necessary knowledge and experience. [9] Furthermore, a QMS demands the organisation to understanding the needs and expectations of interested parties internally and externally of the organisation, creating a foundation for the project managers task of defining stakeholders in a project, saving time and resources as this task is not needed to be done from the ground up at each project.[1][2] By implementing a QMS the organisation will if complying with the standard receive a certification as prove. This certification can be used publicly as branding showing clients that their organisation care and continually wants improve quality of their product or services. As a QMS is a diverse tool that covers all aspects of an organisation it is not limited to improve a single process as project management but can e.g. also benefit program and portfolio management.

Limitations and Challenges:

A QMS can in principle be implemented in all organisations but not all organisations will benefit sufficient from it in relation to its cost. The organisation must for this reason estimate if it will benefit from the tool before closing to use it. If it is estimated to be in favour of the organisation and in this case to serve as a tool in favour of the project manager the organisations must firstly create and implement a QMS customised to the specific organisation. The customisation of the QMS to the specific organisation is important in order to make it efficient and effective, since each organisation has different requirements, risks, businesses models etc. and must for this reason be adjusted to incorporate and focus on the elements of importance in the organisation. Secondly the organisations have to perform projects on a regular basis otherwise the resources needed for implementation of a QMS would not be beneficial in regard to project management.

Other challenges of a QMS is:

- cost of implementation will vary depending on the level of detail of which the QMS describes and organisations size.

- maintenance of the system in order to improve it. This could be flaws in SOP or replacement in methods used.

- too many details and thereby requirement which can make the system rigid.

- employee’s loss the motivation to use it if they are overloaded with requirements of documentation and SOP to follow, blurring or minimising the benefits of the system. This connects to lack of communicating the benefits of the QMS to it users. If the benefits are not clear for is users, the system will not be used.

- the comprehensiveness of the system, which can lead to a decrease in costumer focus.

As a QMS is such a diverse tool including all aspects of an organisation and each organisation will benefit differently from the system, all challenges, limitations, and benefits must be included in the organisation consideration of how to design, implement and maintain their QMS.

Annotated Bibliography

DS ISO 21500 2015

PMBOK

In particular chapter XXX about risk management is important in order to define how and when to performe risk managemt. This should further be in compliance with the requirements of DS/EN ISO 9001:2015 and DS/EN 31010:2010.

DS/EN ISO 9001

The section about a QMS incorporate some of the most inessential part of a QMS. In order to create a QMS in compliance with the standard DS/EN ISO 9001 and it is necessary to systematically go through its requirements.

DS/EN 31010:2010

Risk management is of significant importance through all processes of a QMS. From designing, implementing and maintaining the QMS risk management must be used in order to focus the organisations resources at the right places that reduces risks which has the highest likelihood of probity and consequence. The standard DS/EN 31010 explains how to systamatically performe risk management and risk assessment.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 Dansk Standard. "DS/ISO 21500:2013", Dansk Standard, 31 October 2013.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 Project Management Institute, Inc. "Guide to the Project Management Body of Knowledge (PMBOK® Guide) (6th Edition)", Project Management Institute, Inc. (PMI), 22 September 2017.

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 3.11 3.12 3.13 3.14 3.15 3.16 Dansk Standard. "DS/EN ISO 9001:2015", Dansk Standard, 23 September 2015.

- ↑ Dansk Standard. "DS/EN 31010:2010", Dansk Standard, 28 May 2010.

- ↑ 5.0 5.1 Dansk Standard. "DS/EN ISO 9000:2015", Dansk Standard, 23 September 2015.

- ↑ Holst, Lars Brandt. [Redrawing of DS/EN ISO 9001 2015 PDCA], 2019

- ↑ PWC. "Insights and Trends: Current Portfolio, Programme, and Project Management Practices The third global survey on the current state of project management", PWC, 2012.

- ↑ Holst, Lars Brandt. [Combining DS/EN ISO 9001:2015 of a single process, QMS and DS/ISO 21500:2012], 2019

- ↑ Vulpen, Erik van. "How to Create a Skills Matrix for Success", Accessed 4 March 2019.